transmission OPEL GT-R 1973 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 394 of 625

MANUAL TRANSMISSION70-33

Installing Gearshift Interlock Ball and Gearshift

Thrust Spring1. Install gearshift interlock ball into top transmis-

sion bore and then install gearshift thrust spring.

Installing Transmission Case Cover1. Install case cover gasket, cover, and tighten

screws.

Installing Gearshift Linkages1. Install selector ring and lock nut onto selector

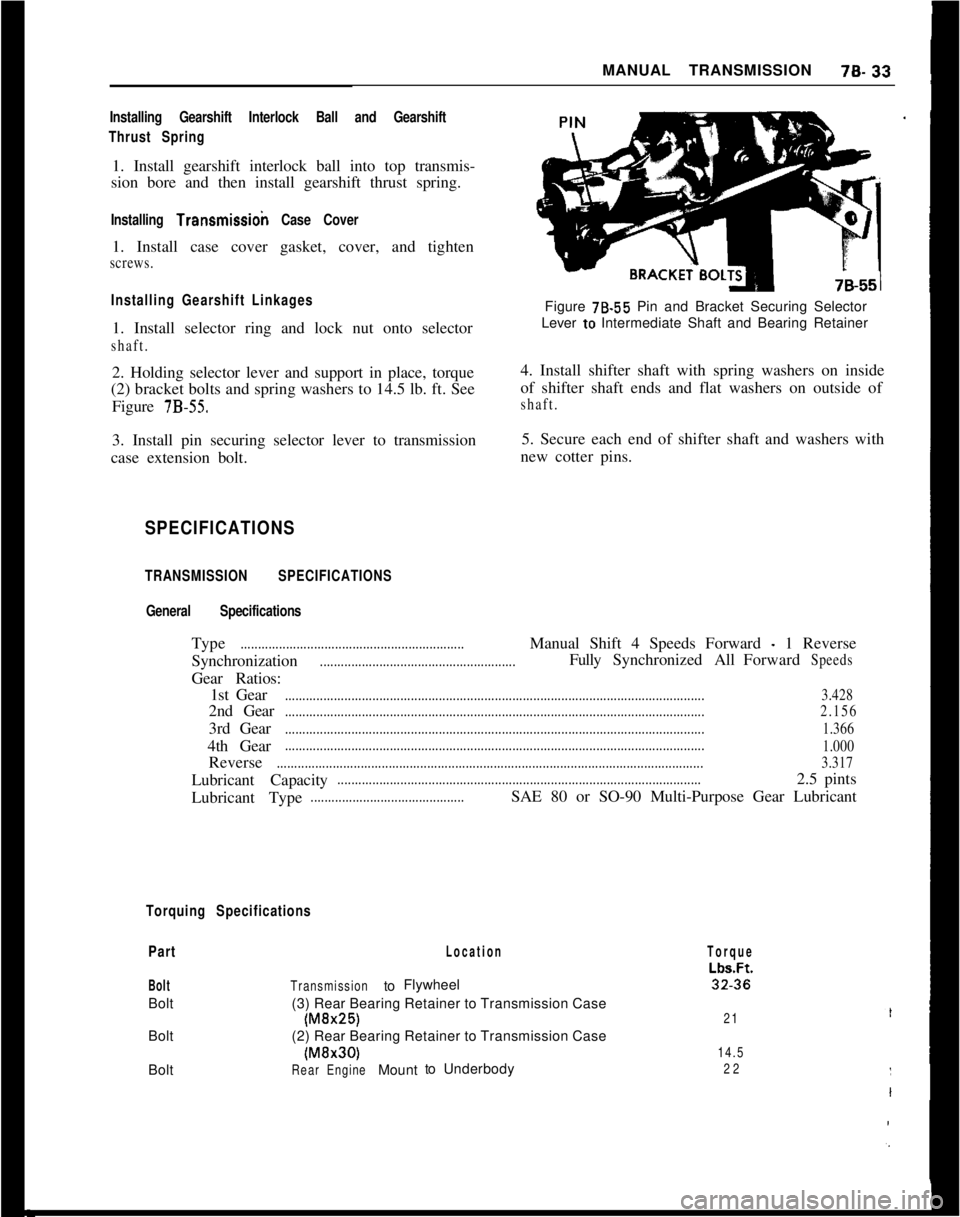

shaft.2. Holding selector lever and support in place, torque

(2) bracket bolts and spring washers to 14.5 lb. ft. See

Figure

7B-55.3. Install pin securing selector lever to transmission

case extension bolt.Figure 78.55 Pin and Bracket Securing Selector

Lever to Intermediate Shaft and Bearing Retainer

4. Install shifter shaft with spring washers on inside

of shifter shaft ends and flat washers on outside ofshaft.5. Secure each end of shifter shaft and washers with

new cotter pins.

SPECIFICATIONS

TRANSMISSION SPECIFICATIONS

General SpecificationsType

................................................................Manual Shift 4 Speeds Forward - 1 Reverse

Synchronization

........................................................FullySynchronizedAllForwardSpeedsGear Ratios:

1st Gear

........................................................................................................................3.4282nd Gear

........................................................................................................................2.1563rd Gear

........................................................................................................................1.3664th Gear

........................................................................................................................

1.000Reverse

..........................................................................................................................3.317Lubricant Capacity

........................................................................................................2.5 pints

Lubricant Type

............................................SAE 80 or SO-90 Multi-Purpose Gear Lubricant

Torquing Specifications

Part

BoltBolt

Bolt

Bolt

Location

TransmissiontoFlywheel

(3) Rear Bearing Retainer to Transmission Case

(M&25)(2) Rear Bearing Retainer to Transmission Case(MBr30)

RearEngineMounttoUnderbody

Torque

Lbs.Ft.32.36

21

14.5

22

Page 395 of 625

79.341973 OPEL SERVICE MANUAL

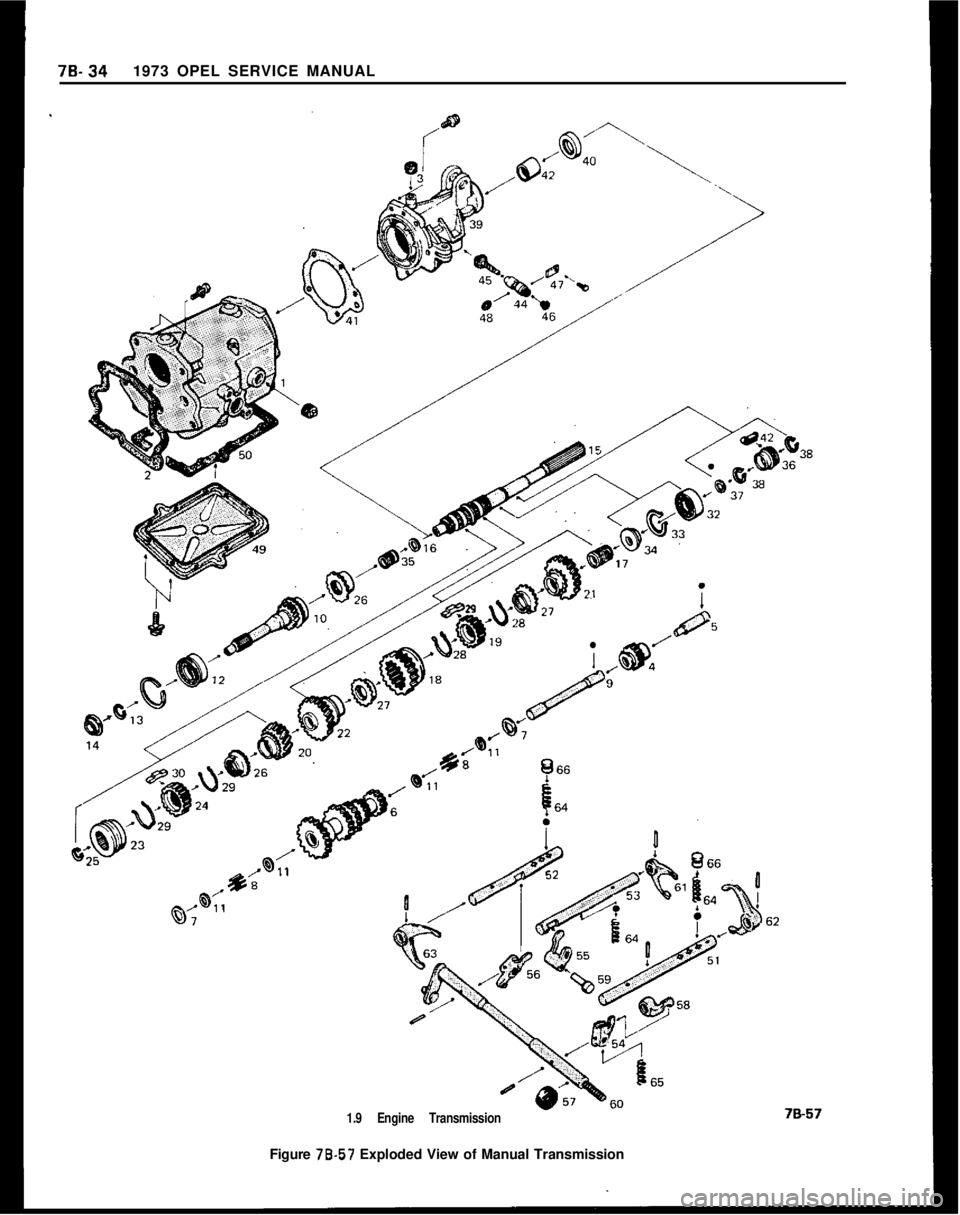

1.9 Engine TransmissionFigure 78-57 Exploded View of Manual Transmission

Page 396 of 625

tiANUAL TRANSMISSION78.35

1’ Case, Transmission

2Gasket, Trans. Case to Clutch Housing

3 Cap, Ventilator

4 Gear, W/Bushings,

ReverSe Idler

5 Shaft, Reverse Idler Gear

6 Cluster Gear, Countershaft

7Washer, Trans. Counter Gear Thrust

8Roller. Trans. Counter Gear Bearing

9 Countershaft. Cluster Gear

10 Gear, Main Drive

11Spacer Ring, Trans. Counter Gear Bearing Roller

12 Bearing, Trans. Main Shaft Pilot

13 Ring, Trans. Main Drive Gear Ball Bearing Lock

14 Seal Ring, Main Drive Gear to Clutch

15 Shaft, Main

16 Ring, Trans. Main Shaft Snap Front

17 Needle Bearing, 1st Speed Gear on Main Shaft

18 Sliding Gear, 1st and 2nd Speed

19 Guide Unit, 1st and 2nd Speeding Sliding Gear

20 Gear. 3rd Speed

2

1Gear, 1 st Speed

22 Gear, 2nd Speed

23 Sleeve, Trans. Gear Shifter

24 Carrier, Trans. Gear Shifter Sleeve

25 Snap Ring, Trans. Gear Shifter Sleeve

26 Cone, Trans. 3rd and 4th Speed Syncronizer

27 Cone, Trans. 1st and 2nd Speed Syncronizer

28 Spring, Syncronizer (1st and 2nd Speed)

29 Spring, Syncronizer

30 Shoe, 1st and 2nd Speed Shifter

31 Shoe, 3rd and 4th Speed Shifter

32 Bearing, Trans. Main Shaft R.R.

33 Snap Ring, Trans. Main Shaft Ball Bearings

34 Washer, Main Shaft Between Inner Ball Bearing

and 1st Speed Gear

3j36

37

ii40

41

42

43

44

45

46

47

48

49

50

51

52

53

54Bearing, Trans. Main Shaft Needle

- Right

Gear, Speedometer Drive

Washer, Speedo Drive Gear

Ring, Speedo Drive Gear Snap

Retainer,

R.R. Bearing

Oil Seal, Trans. R.R.

Gasket, R.R. Bearing Retainer

Bushing. Trans. Main Shaft

- R.R.

Clip, Speedo Gear

Guide, Speedo Drive

Gear, Speedo Driven

Seal, Speedo

- Shaft Sleeve

Bracket, Speedo and Guide on Trans.

Seal Ring, Speedo Drive Guide

Cover, Trans. Case

Gasket, Trans. Case Cover

Shifter Shaft, 1st and 2nd Speed

Shifter Shaft, 3rd and 4th Speed

Shaft, Reverse Speed Shifter

Intermediate Lever, 1st and 2nd Speed

Shifter

55

Lever, Reverse Shifter Intermediate

56Lever, Intermediate 3rd. 4th and Reverse

57Seal, Shifter Shaft Oil in Trans.

58Cam. on Shifter Shaft

59Shifter Shaft, Intermediate Lever Reverse

60

Shaft, W/Lever and Bolt, in Trans.

61

Fork (Yoke), Reverse Speed Shifter

62Yoke, Trans. Shifter (1st and Reverse)

63Fork (Yoke), Trans. 2nd and 3rd Speed

64

Spring, Trans. Gearshift Interlock Thrust

65

Detent Spring, Reverse Speed Gearshift

66Interlock

Plug, Gearshift Interlock Detent

Page 397 of 625

7C- 361973 OPEL SERVICE MANUAL

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description of the Opel Three-Speed Automatic,Transmission....................................................................

Principles of Operation....................................................

ComponentOperation

andLocation............................

Mechanical Operation......................................................

Hydraulic Control Units and Valves............................H,y&aulic Operation..........................................................

DIAGNOSIS:

Sequence for Trouble Diagnosis..................................

Checking

Procedures........................................................

ExternalOil

Leaks..............................................................

Trouble

DiagnosisChart..................................................

Hydraulic Pressure

Checks............................................

MAINTENANCE AND ADJUSTMENTS:

Detent Cable Adjustment..............................................

ServicingSelector

Lever..................................................

MAJOR REPAIR:

Transmission Removal and Installation

AllModels........................................................................

Removalof

OilPan............................................................

RemovalofValveBody....................................................

Removalof

ServoPiston................................................

Removalof

Selector

LeverandShaft........................

RemovalofModulatorAssembly..................................

RemovalofDetentValveAssembly............................

RemovalofExtensionHousing......................................

Removal of Speedometer Drive Gear, Governor

Body and Governor Hub..............................................

Removal of Converter Housing, Oil Pump, Reverse

and Second Clutch Assembly..................................

Removal of Third Clutch Assembly, Planetary

Carrier Assembly, Reaction Sun Gear and Drum

Assembly and Low Bank............................................

Disassembly, Inspection and Reassembly of

Converter Housing, Oil Pump and Reverse Clutch

Disassembly, Inspection and Reassembly of

SecondClutch

................................................................

Disassembly, Inspection and Reassembly of

ThirdClutch....................................................................

Disassembly, Inspection and Reassembly of

Planetary Carrier

............................................................Page No.7c- 377c- 387c- 447c- 487c- 487c- 64

7C- 81

7C- 81IC- 817c- 827c- 877c- 917c- 937c- 947c- 99.7c- 99

7c-1007c-loo

7&l 01

7c-102

7c-102

7c-103

7c-103

7c-104

7c-105

7c-111

7c-114

7c-118

Page 398 of 625

AUTOMATIC TRANSMISSION7c- 37

Disassembly, Inspection and Reassembly of

ReactionSunGearandDrum....................................

Disassembly, Inspection and Reassembly of

Governor Body................................................................

Disassembly, Inspection and Reassembly of

GovernorHub..................................................................

Disassembly, Inspection and Reassembly of

ExtensionHousing........................................................

Disassembly, Inspection and Reassembly of

Servo Piston....................................................................

Disassembly, Inspection and Reassembly of

ValveBody........................................................................

Disassembly, Inspection and Reassembly of

Case....................................................................................

InspectingandTestingConverter................................

InstallationofSelectorLeverandShaft....................

InstallationofLowBand................................................

Installation of Reaction Sun Gear and Drum..........

Installation of Output Shaft and Planetary

Carrier................................................................................

Installation of Second and Third Clutch Assemblies

IntoCase..........................................................................

InstallationofReverseClutch......................................

DeterminingSelectiveWasherSize............................

Installation of Converter Housing, Oil Pump and

Clutch Assembly............................................................

Installation of Governor Assembly..............................

InstallationofExtensionHousing................................

InstallationofSpeedometerDrivenGear..................

Installation of Detent Valve, Modulator Valve

and Modulator Assembly............................................

Installation and Adjustment of Servo........................

InstallationofValveBody..............................................

InstallationofOilPanandGasket..............................

Torque Converter..............................................................

SPECIFICATIONS:

GeneralSpecifications......................................................

7c.

7c-

,l

‘118

197c-1207c-1207c-1207C-121

7C-124

7C-125

7C-125

7C-125

7C-127

7C-127

7C-127

7C-128

7C-129

7C-129

7C-129

7c-130

7c-131

7c-131

7c-131

7C-132

7c-133

7c-134

7c-134DESCRIPTION AND OPERATION

DESCRIPTIONThe Opel Three-Speed Automatic is a fully auto-matic unit utilizing a torque converter and a Ravig-neaux planetary gear set, with three multiple disc

clutches and a single band to provide three forward

speeds and reverse. See Figure 7C-71. Automatic

upshifts and downshifts are controlled by road speed,

engine vacuum and an accelerator pedal connection

to the transmission.

Page 399 of 625

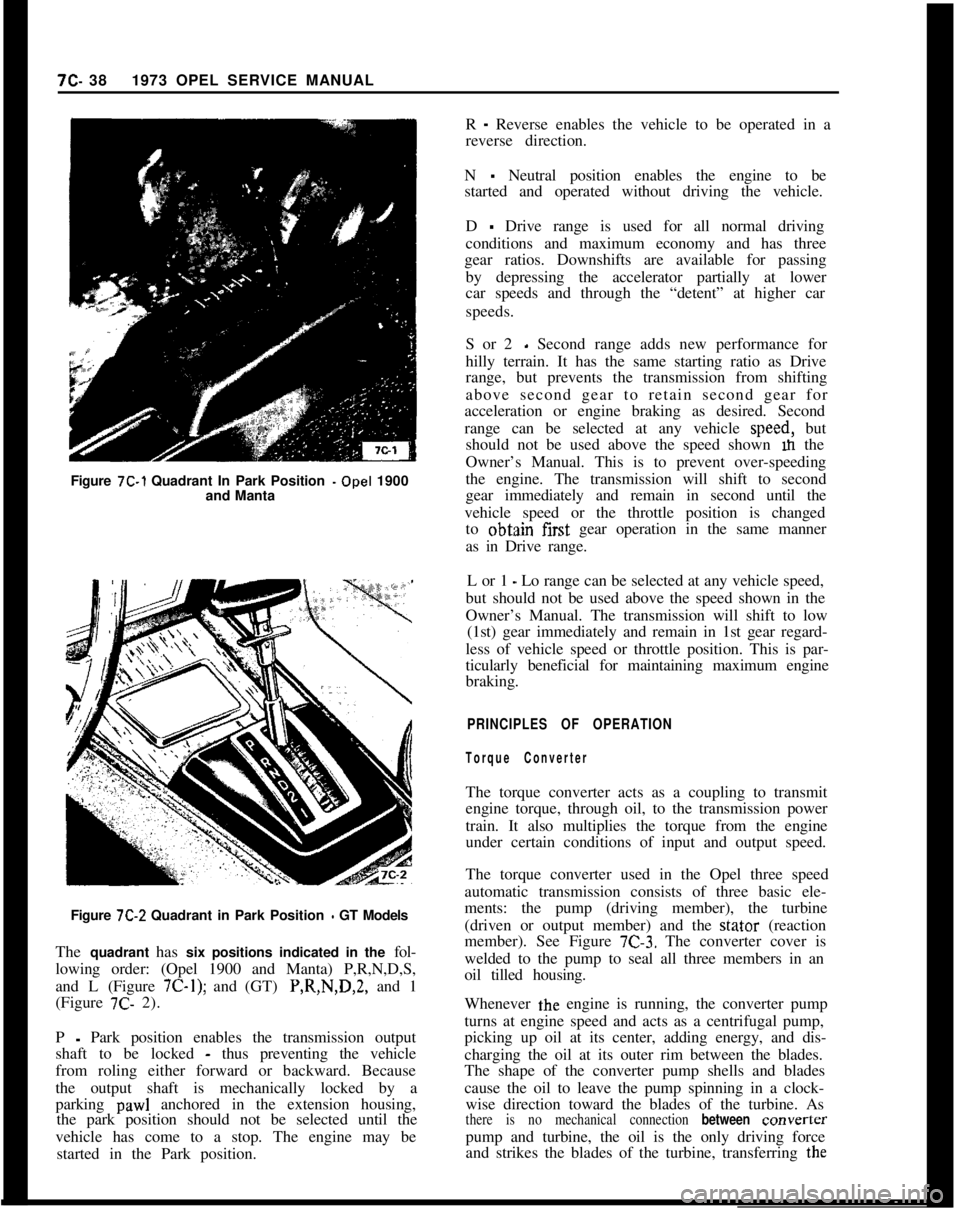

Figure 7C-1 Quadrant In Park Position -Opel 1900

and Manta7C- 381973 OPEL SERVICE MANUAL

R

- Reverse enables the vehicle to be operated in a

reverse direction.

N

- Neutral position enables the engine to be

started and operated without driving the vehicle.

D

- Drive range is used for all normal driving

conditions and maximum economy and has three

gear ratios. Downshifts are available for passing

by depressing the accelerator partially at lower

car speeds and through the “detent” at higher car

speeds.

S or 2

- Second range adds new performance for

hilly terrain. It has the same starting ratio as Drive

range, but prevents the transmission from shifting

above second gear to retain second gear for

acceleration or engine braking as desired. Second

range can be selected at any vehicle speed, but

should not be used above the speed shown m the

Owner’s Manual. This is to prevent over-speeding

the engine. The transmission will shift to second

gear immediately and remain in second until the

vehicle speed or the throttle position is changed

to obtajn first gear operation in the same manner

as in Drive range.

L or 1

- Lo range can be selected at any vehicle speed,

but should not be used above the speed shown in the

Owner’s Manual. The transmission will shift to low

(1st) gear immediately and remain in 1st gear regard-

less of vehicle speed or throttle position. This is par-

ticularly beneficial for maintaining maximum engine

braking.

PRINCIPLES OF OPERATION

Torque ConverterThe torque converter acts as a coupling to transmit

engine torque, through oil, to the transmission power

train. It also multiplies the torque from the engine

under certain conditions of input and output speed.

Figure

7C-2 Quadrant in Park Position - GT Models

The quadrant has six positions indicated in the fol-

lowing order: (Opel 1900 and Manta) P,R,N,D,S,

and L (Figure

7C-1); and (GT) P,R,N,D,2, and 1

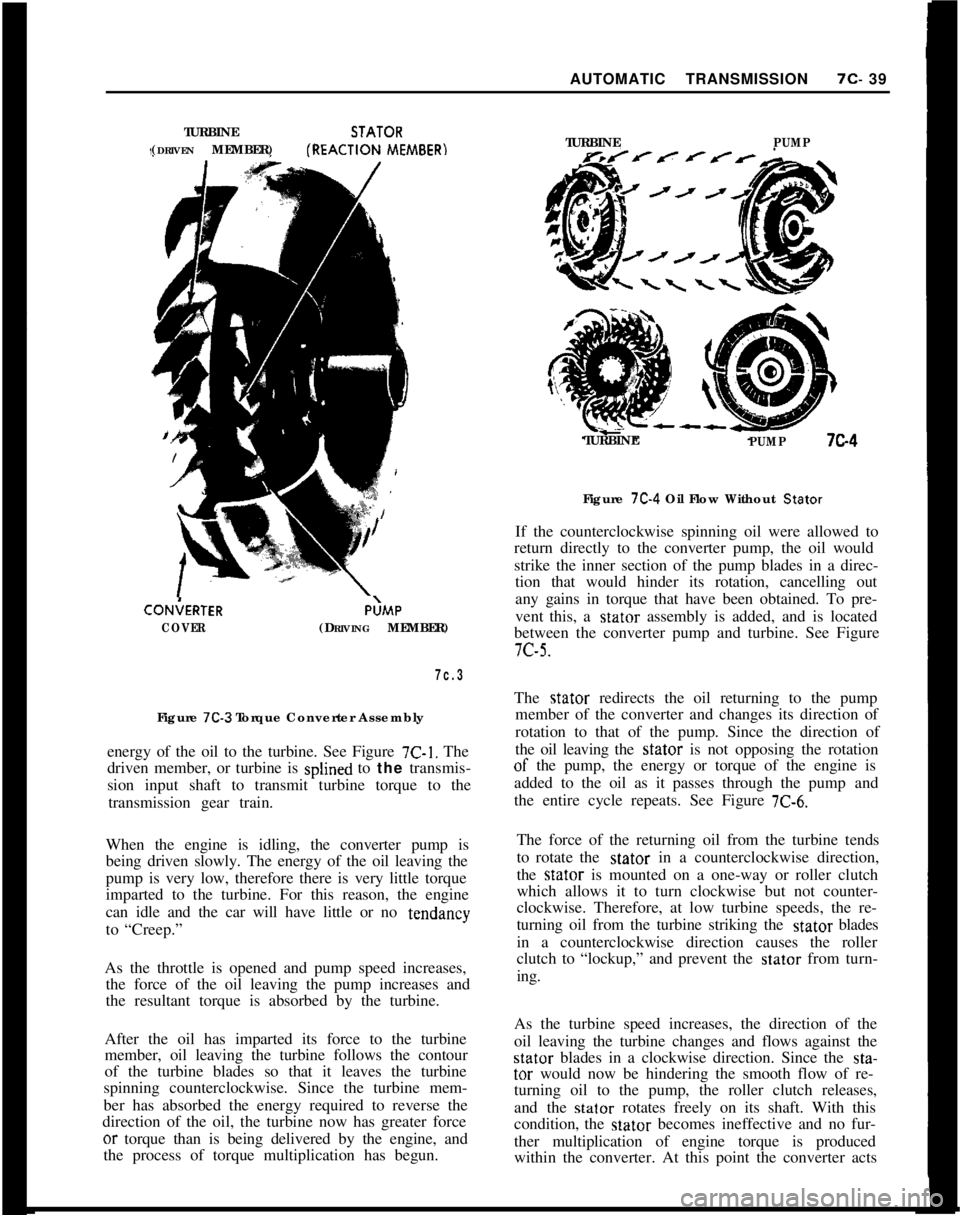

(Figure 7C- 2).The torque converter used in the Opel three speed

automatic transmission consists of three basic ele-

ments: the pump (driving member), the turbine

(driven or output member) and the stator (reaction

member). See Figure

7C-3. The converter cover is

welded to the pump to seal all three members in an

oil tilled housing.

P

- Park position enables the transmission output

shaft to be locked

- thus preventing the vehicle

from roling either forward or backward. Because

the output shaft is mechanically locked by a

parking

paw1 anchored in the extension housing,

the park position should not be selected until the

vehicle has come to a stop. The engine may be

started in the Park position.Whenever the engine is running, the converter pump

turns at engine speed and acts as a centrifugal pump,

picking up oil at its center, adding energy, and dis-

charging the oil at its outer rim between the blades.

The shape of the converter pump shells and blades

cause the oil to leave the pump spinning in a clock-

wise direction toward the blades of the turbine. Asthere is no mechanical connection between converterpump and turbine, the oil is the only driving force

and strikes the blades of the turbine, transferring the

Page 400 of 625

AUTOMATIC TRANSMISSION7c- 39

TURBINESTATOR

(DRIVEN MEMBER)fREACTION

MEMBER)CON;ERTER

COVERP;MP

(DRIVING MEMBER)

7c.3Figure

7C-3 Torque Converter Assembly

energy of the oil to the turbine. See Figure

7C-1. The

driven member, or turbine is splined to the transmis-

sion input shaft to transmit turbine torque to the

transmission gear train.

When the engine is idling, the converter pump is

being driven slowly. The energy of the oil leaving the

pump is very low, therefore there is very little torque

imparted to the turbine. For this reason, the engine

can idle and the car will have little or no tendancy

to “Creep.”

As the throttle is opened and pump speed increases,

the force of the oil leaving the pump increases and

the resultant torque is absorbed by the turbine.

After the oil has imparted its force to the turbine

member, oil leaving the turbine follows the contour

of the turbine blades so that it leaves the turbine

spinning counterclockwise. Since the turbine mem-

ber has absorbed the energy required to reverse the

direction of the oil, the turbine now has greater forceor torque than is being delivered by the engine, and

the process of torque multiplication has begun.TURBINE

PUMPTURBINE

PUMP7c4Figure

7C-4 Oil Flow Without Stator

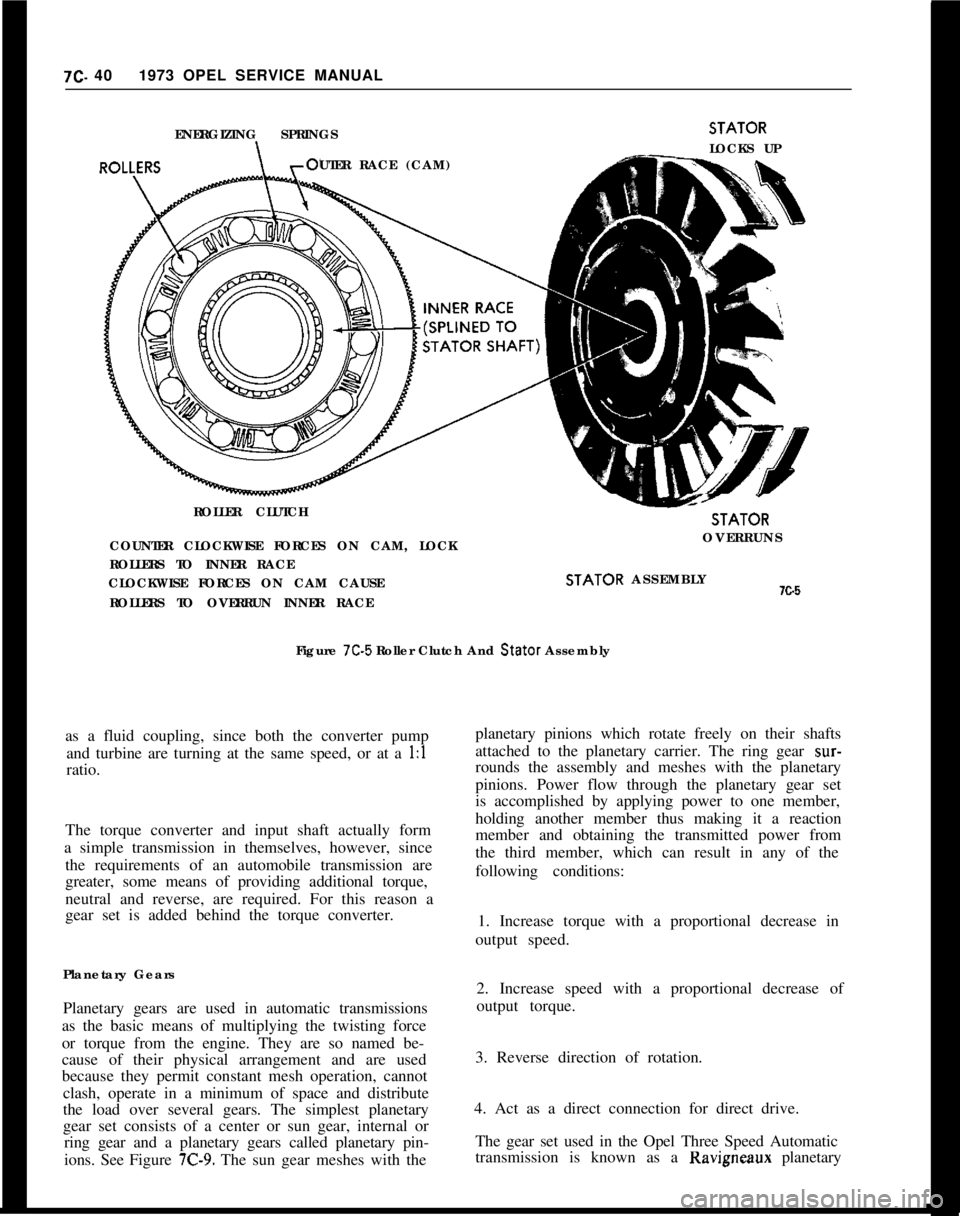

If the counterclockwise spinning oil were allowed to

return directly to the converter pump, the oil would

strike the inner section of the pump blades in a direc-

tion that would hinder its rotation, cancelling out

any gains in torque that have been obtained. To pre-

vent this, a stator assembly is added, and is located

between the converter pump and turbine. See Figure7c-5.

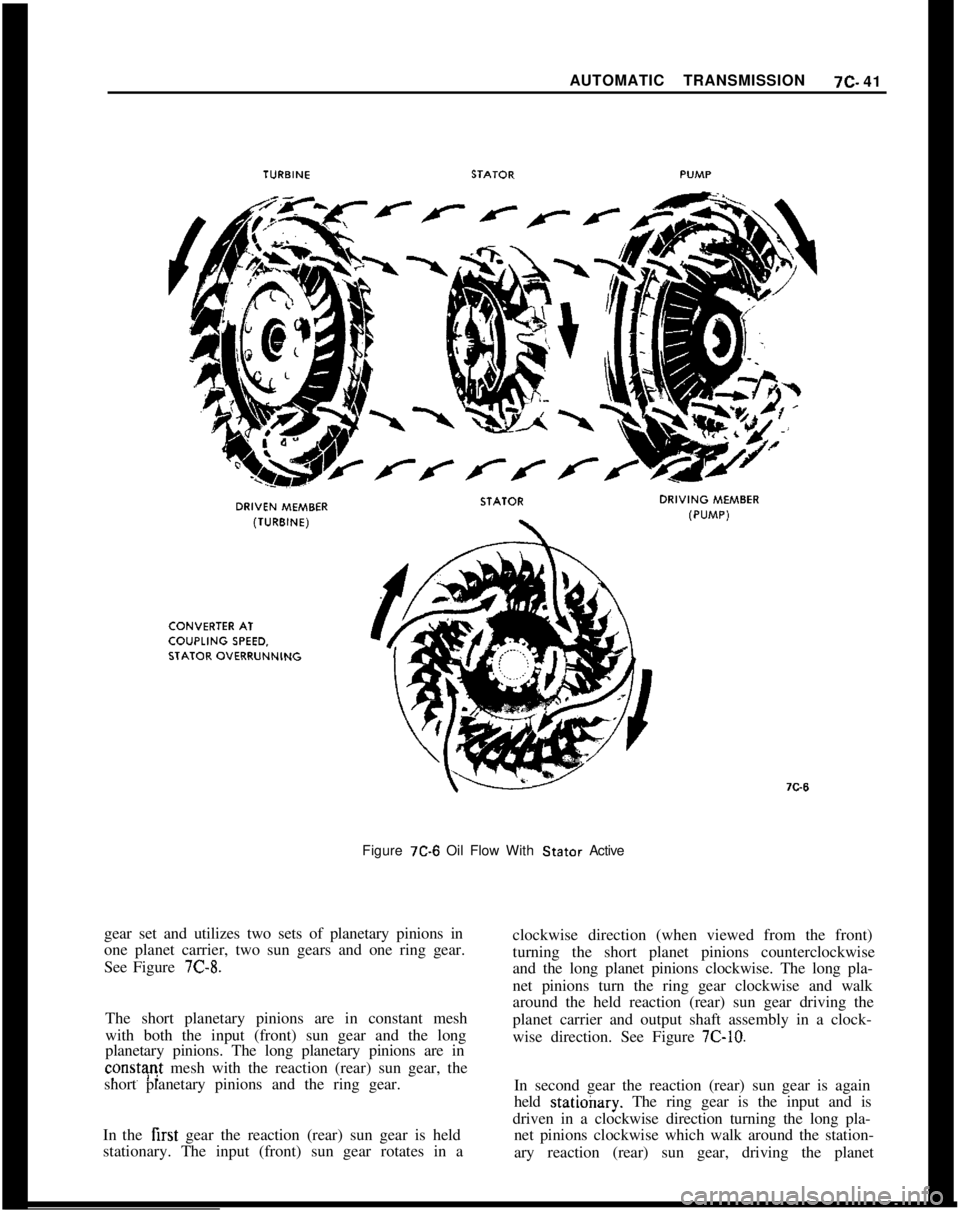

The stator redirects the oil returning to the pump

member of the converter and changes its direction of

rotation to that of the pump. Since the direction of

the oil leaving the stator is not opposing the rotationof the pump, the energy or torque of the engine is

added to the oil as it passes through the

the entire cycle repeats. See Figure

7C-6.pump and

The force of the returning oil from the turbine tends

to rotate the stator in a counterclockwise direction,

the stator is mounted on a one-way or roller clutch

which allows it to turn clockwise but not counter-

clockwise. Therefore, at low turbine speeds, the re-

turning oil from the turbine striking the stator blades

in a counterclockwise direction causes the roller

clutch to “lockup,” and prevent the stator from turn-

ing.

As the turbine speed increases, the direction of the

oil leaving the turbine changes and flows against thestator blades in a clockwise direction. Since the sta-tar would now be hindering the smooth flow of re-

turning oil to the pump, the roller clutch releases,

and the stator rotates freely on its shaft. With this

condition, the stator becomes ineffective and no fur-

ther multiplication of engine torque is produced

within the converter. At this point the converter acts

Page 401 of 625

7C- 401973 OPEL SERVICE MANUAL

ENERGIZING SPRINGS

UTER RACE (CAM)

ROLLER CLUTCHSTATOR

LOCKS UPSTATOR

COUNTER CLOCKWISE FORCES ON CAM, LOCKOVERRUNS

ROLLERS TO INNER RACE

CLOCKWISE FORCES ON CAM CAUSESTATOR ASSEMBLYx.5

ROLLERS TO OVERRUN INNER RACE

Figure 7C-5 Roller Clutch And Stator Assembly

as a fluid coupling, since both the converter pump

and turbine are turning at the same speed, or at a 1:l

ratio.

The torque converter and input shaft actually form

a simple transmission in themselves, however, since

the requirements of an automobile transmission are

greater, some means of providing additional torque,

neutral and reverse, are required. For this reason a

gear set is added behind the torque converter.

Planetary Gears

Planetary gears are used in automatic transmissions

as the basic means of multiplying the twisting force

or torque from the engine. They are so named be-

cause of their physical arrangement and are used

because they permit constant mesh operation, cannot

clash, operate in a minimum of space and distribute

the load over several gears. The simplest planetary

gear set consists of a center or sun gear, internal or

ring gear and a planetary gears called planetary pin-

ions. See Figure

7C-9. The sun gear meshes with theplanetary pinions which rotate freely on their shafts

attached to the planetary carrier. The ring gear

sur-rounds the assembly and meshes with the planetary

pinions. Power flow through the planetary gear set

is accomplished by applying power to one member,

holding another member thus making it a reaction

member and obtaining the transmitted power from

the third member, which can result in any of the

following conditions:

1. Increase torque with a proportional decrease in

output speed.

2. Increase speed with a proportional decrease of

output torque.

3. Reverse direction of rotation.

4. Act as a direct connection for direct drive.

The gear set used in the Opel Three Speed Automatic

transmission is known as a Ravigneaux planetary

Page 402 of 625

AUTOMATIC TRANSMISSION7c- 41

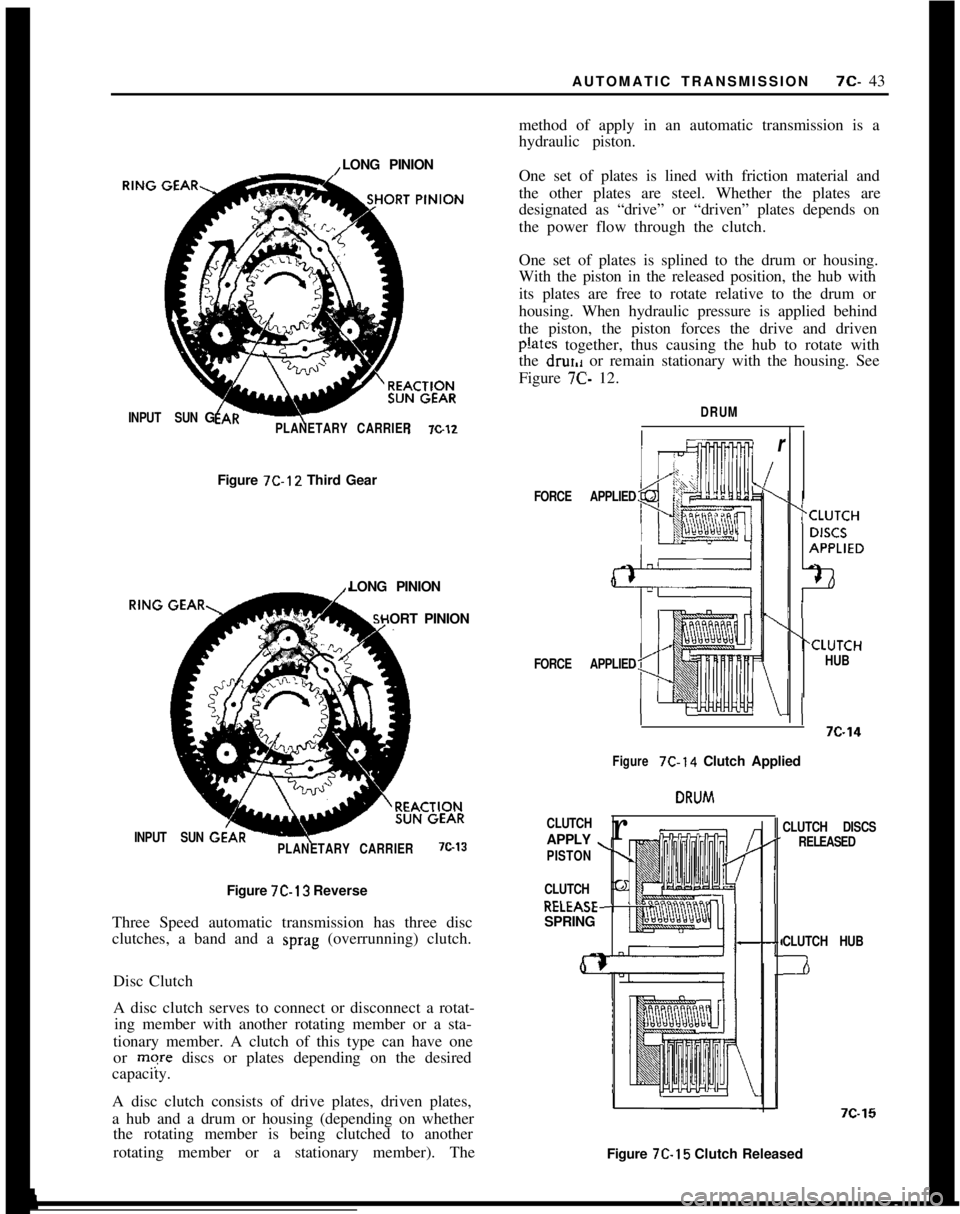

Figure

7C-6 Oil Flow With Stator Active

gear set and utilizes two sets of planetary pinions in

one planet carrier, two sun gears and one ring gear.

See Figure

7C-8.The short planetary pinions are in constant mesh

with both the input (front) sun gear and the long

planetary pinions. The long planetary pinions are inconstr$ mesh with the reaction (rear) sun gear, the

short planetary pinions and the ring gear.

In the first gear the reaction (rear) sun gear is held

stationary. The input (front) sun gear rotates in aclockwise direction (when viewed from the front)

turning the short planet pinions counterclockwise

and the long planet pinions clockwise. The long pla-

net pinions turn the ring gear clockwise and walk

around the held reaction (rear) sun gear driving the

planet carrier and output shaft assembly in a clock-

wise direction. See Figure

7C-10.In second gear the reaction (rear) sun gear is again

held statioinry. The ring gear is the input and is

driven in a clockwise direction turning the long pla-

net pinions clockwise which walk around the station-

ary reaction (rear) sun gear, driving the planet

Page 404 of 625

AUTOMATIC TRANSMISSION7c- 43

LONG PINIONINPUT SUNGPLANETARY CARRIERFigure 7C-12 Third Gear

LONG PINION

ORT PINION

INPUT SUN

PLANETARY CARRIER7c.13Figure 7C-13 Reverse

Three Speed automatic transmission has three disc

clutches, a band and a sprag (overrunning) clutch.

Disc Clutch

A disc clutch serves to connect or disconnect a rotat-

ing member with another rotating member or a sta-

tionary member. A clutch of this type can have one

or mgre discs or plates depending on the desired

capacity.

A disc clutch consists of drive plates, driven plates,

a hub and a drum or housing (depending on whether

the rotating member is being clutched to another

rotating member or a stationary member). Themethod of apply in an automatic transmission is a

hydraulic piston.

One set of plates is lined with friction material and

the other plates are steel. Whether the plates are

designated as “drive” or “driven” plates depends on

the power flow through the clutch.

One set of plates is splined to the drum or housing.

With the piston in the released position, the hub with

its plates are free to rotate relative to the drum or

housing. When hydraulic pressure is applied behind

the piston, the piston forces the drive and drivenp!ates together, thus causing the hub to rotate with

the

drur.1 or remain stationary with the housing. See

Figure 7C- 12.

DRUM

FORCE APPLIED

FORCE APPLIEDr

7c-14

Figure

7C-14 Clutch Applied

CLUTCHAPPLY

\

PISTON

CLUTCH

RELEASE-SPRING

r

HUB

CLUTCH DISCS

RELEASED

CLUTCH HUBFigure

7C-15 Clutch Released