open gas tank OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 87 of 625

ll- 66 1973 OPEL SERVICE MANUALi

ConditionPossible CauseCorrection

Gas gauge does not read

full when tank tilled1. Tank unit misadjusted1. Install 40 ohm resistor

between connector and ground

I

(disconnect from unit). If

dash unit reads full within

one pointer width. Remove

/

Igas tank unit from tank, install

connector, ground unit and

adjust tab to obtairi full reading on

dash. Reinstall tank unit.

2. Defective’ voltage

stabilizer1. See corrective action above.

Gas gauge not operating1. Corroded tank unit

terminal I1. Check tank unit terminal, if

corroded clean, pack connector

with grease and reinstall

connector..

2. Loose dash gauge

!

1. Install 40 ohm resistor between

sending unit connector. and

ground (disconnect from tank

terminal). If dashgauge does

not read rull, check dash gauge

attaching nuts for secureness

and tighten if required.

(Requires removal of dash panel)

Momentarily touch dash gauge

attaching studs to 12 volt

source. If indicator moves,

reinstall panel; if not, replace

gauge. (Caution do not keep

studs connected to 12 volt

source for more than a few

seconds

- damage to gauge can

result)

3. Open

w&g1. Remove connector from sending

unit and ground (40 ohm

resistor may be used if

ohmmeter available. Remove

multiple connector from rear

of dash. Connect test light

to ground and touch other end

to connector socket with blue

and black wire, if it does not

light (40 ohm reading of ohm

meter used) repair open circuit.

4. Defective gas tank

sending unit1. Install 40 ohm resistor between

temperature sending unit and

ground (disconnect from unit)

if dash unit reads full scale.

Replace tank unit (check for

terminal corrosion before

replacing).

Page 88 of 625

I

GAUGES1 I- 67I

I Condition

Car

&s out of gas with

gauge indicating fuel in

tank. 1

I

I

I

I

IPossible Cause

1. Tank unit misadjusted

2. Defective voltage

stabilizer.Correction

1. Follow corrective action as

stated above (obtain empty

reading on dash)

1. See corrective action above.

Temperature gauge not1. Loose dash gauge1. See corrective action above.

Iattaching nut.

I

I

I2. Defective temperature1. Install 40 ohm resistor

Isending unitbetween temperature sneding

Iunit and ground (disconnect

I

from unit). If dash unit reads

I

full scale, replace temperature

Isending unit.

I

I

I3. Open wiring.1. Follow corrective action as

Istated above (connector socket

Iwith blue wire).Tempkrature gauge indicates

hot when engine temperature1. Incorrect temperature1. Check for correct sending unit

sending unit

normal.(white porcelain) replace if

incorrect.

2. i>efective temperaturesending unit.1. See corrective action above.

3. Dkfective voltage

stabilizer.

1. See Corrective action above.

GAS

GdUGE TROUBLE DIAGNOSIS - GT4. Disconnect the tank unit lead wire (light blue with

black tracer) from the tank unit.

An inoperative gas gauge reading can normally be

found to result from a poor grounding condition

within the circuit. Using the procedure as outlined

below may lead to the correction of the inoperative

reading without replacement of either the tank unit

or the

dph unit.5. Connect ihe stock tank unit; ground unit, and

operate manually.

6. If the dash unit shows a correct reading, then

replacement of the tank unit is required as the cor-

rection.

1. Makelcertain the gas tank (ground) strap is prop-

erly secured.A correct reading will be one which resembles the

movement of the manually-operated tank unit.

2. Make’certain the ground wire (brown in color) for

gasoline/ and temperature gauges is properly con-

nected tb the windshield wiper motor and is secured.

(This

gl?ound wire is also common for the heater

blower

etor.)7. If the dash unit does not show a correct reading,

then its replacement is necessary.

If the adove procedure does not produce a satisfac-

tory gaube reading, an attempt to isolate the defec-

tive

par<, i.e. tank or dash unit should be made.

3. Rem&e a tank unit from parts stock.MAJOR

AEPAIR

OPEL 1900. MANTA

Removing Voltage Stabilizer1. Remove instrument cluster housing assembly.

Page 165 of 625

FLVTRlJNK PLAT

DRAW BAR16x1-1/2 -DRAW‘ BAR EXTENSION-%GSAFETY CHAIN PLATE6INSTALLATION INSTRUCTIONS

1971

- 72 - 73 OPEL 1900 SERIES S/W

GROUP NO. 7.068

REMOVE LICENSE PLATE

STEP 1. ASSEMBLE HITCH AS ILLUSTRATED. HOLD

HITCH IS POSITION WITH FLOOR PLATE RESTING

AGAINST THE CROSS FRAME IN FRONT OF GAS TANK.

CENTER DRAW BAR SUPPORT ON THE REAR BODY

PANEL, RAISE UNTIL LEVEL.

STEP 2.MARK AND DRILL TWO

7116” HOLES IN REAR

BODY PANEL AND ATTACH AS SHOWN.

STEP 3.DRILL TWO

112” HOLES IN CROSS FRAME IN

FRONT OF THE GAS TANK AND CONTINUE DRILLING UP

THROUGH THE INNER FLOOR. NOTE: HOLD DRILL

VERTICAL WHILE DRILLING THROUGH THE INNER FLOOR.

ENLARGE BOTTOM HOLE SLIGHTLY TO ACCEPT SPACER.

STEP 4. ATTACH TRUNK PLATE AS ILLUSTRATED. PLACE

THE FLOOR PLATES ON THE 2

l/2” CARRIAGE BOLTS

AND INSERTS THROUGH THE OPENINGS

iN THE BACK OF

THE TRUNK WELL.INSERT SPACERS AS SHOWN AND

COMPLETE INSTALLATION.

REPLACE LICENSE PLATE.

TIGHTEN ALL

112” NUTS TO A MAXIMUM TORQUE OF

60 FOOT LBS. AND 7/16” NUTS TO A MAXIMUM OF

45 FOOT LBS.

INSTALL BALL USING A MAXIMUM TORQUE OF 150

FOOT LBS.

MAXIMUM GROSS WEIGHT 100 LBS

MAXIMUM TONGUE WEIGHT 100 LBS.

MOST STATES PROHIBIT OBSTRUCTION OF LICENSE

PLATES, BALL SHOULD BE REMOVED WHEN NOT IN

USE IF IT OBSTRUCTS A CLEAR VIEW.

ZH-9Figure

ZH-9 Opel 1900 Wagon Trailer Hitch Installation

Page 325 of 625

6B- 341973 OPEL SERVICE MANUAL

test by partially draining the cooling system and dis-

connecting the water outlet housing from the ther-

mostat housing which is mounted on the right front

side of cylinder head.

The standard thermostat valve should start to open

at 189 degrees F and fully open at approximately 212

degrees F. If thermostat does not operate at specified

temperatures, it should be replaced as it cannot be

repaired.MAJOR REPAIR

WATER PUMP REPAIRSThe water pump bearing outer race is shrunk fit into

the water pump cover. For this reason the cover,

shaft bearing, and hub are not repairable.

Water Pump RemovalOpel radiators do not have a drain plug. Drain radia-

tor by first, loosening radiator cap, then remove

lower hose from lower radiator tank.

1. Drain coolant into a clean container. Remove

radiator and shroud.

2. Remove fan belt.

3. Remove fan blade and pulley on water pump shaft.

4. Disconnect inlet hose and heater hose from water

pump. Remove bolts, pump assembly and gasket

from timing chain cover.

5. Check pump shaft bearing for end play or rough-

ness in operation. If bearings are not in serviceable

condition, the assembly must be replaced.

Water Pump Installation1. Make sure the gasket surfaces on pump and timing

chain covers are clean. Install pump assembly with

new gasket. Bolts must be tightened uniformly.

Torque to 11 lb. ft.

2. Install radiator and shroud. Connect radiator hose

to pump inlet and heater hose to nipple.

3. Install fan pulley and fan blade, tighten attaching

bolts securely. Install belts and adjust for proper

tension.4. Fill cooling system and check

,for leaks at pump

and hose joints.

RADIATOR REMOVAL AND INSTALLATION

RemovalI. Loosen radiator cap, then remove lower radiator

hose and drain radiator coolant into suitable con-

tainer.

2. On vehicles with automatic transmission, unscrew

oil lines from connectors on lower radiator tank and

plug lines. On GT models with automatic transmis-

sion the lines have to be disconnected at the coupling

before removing from the tank. It is essential that no

dirt enters the oil lines. When unscrewing oil lines,

hold connectors on lower radiator tank with pliers to

avoid leakages. Ensure that no dirt enters oil cooler.

3. Remove lower attaching nut and slide radiator

upward and out of engine compartment.

Installation1. Install radiat,or into engine compartment and se-

cure lower attaching nut.

2. On vehicles with automatic transmissions, fasten

oil cooler lines to lower radiator tank. It is essential

that no dirt enters the oil lines. When tightening oil

lines, hold connectors on lower radiator tank with

pliers to avoid leakages. Ensure that no dirt enters oil

cooler. Torque to 1 I-15

lbs.ft.3. Install lower radiator hose and add collected coo-

lant.

All Opels are provided with a radiator initial fill of

an antifreeze solution containing corrosion inhibitor.

The antifreeze has either a glycol or glycerin base

and protects the engine against freezing, down to

minus 22 degrees F. (minus 30 degrees C.). Before

the start of the cold season, coolant must be checked

with a hydrometer and if necessary, brought to the

necessary specific gravity by adding anti-freeze with

a glycol or glycerin base. As the specific gravities of

all anti- freeze solutions having a glycol or glycerin

base are practically the same, the hydrometer can be

used for all these types. Because of the tolerances of

the hydrometer, or slight differences in specific

gravity, variations of plus or minus 5 degrees can be

expected. Coolant must be checked at a temperature

of plus 68 degrees F. (plus 20 degrees C.)

Page 329 of 625

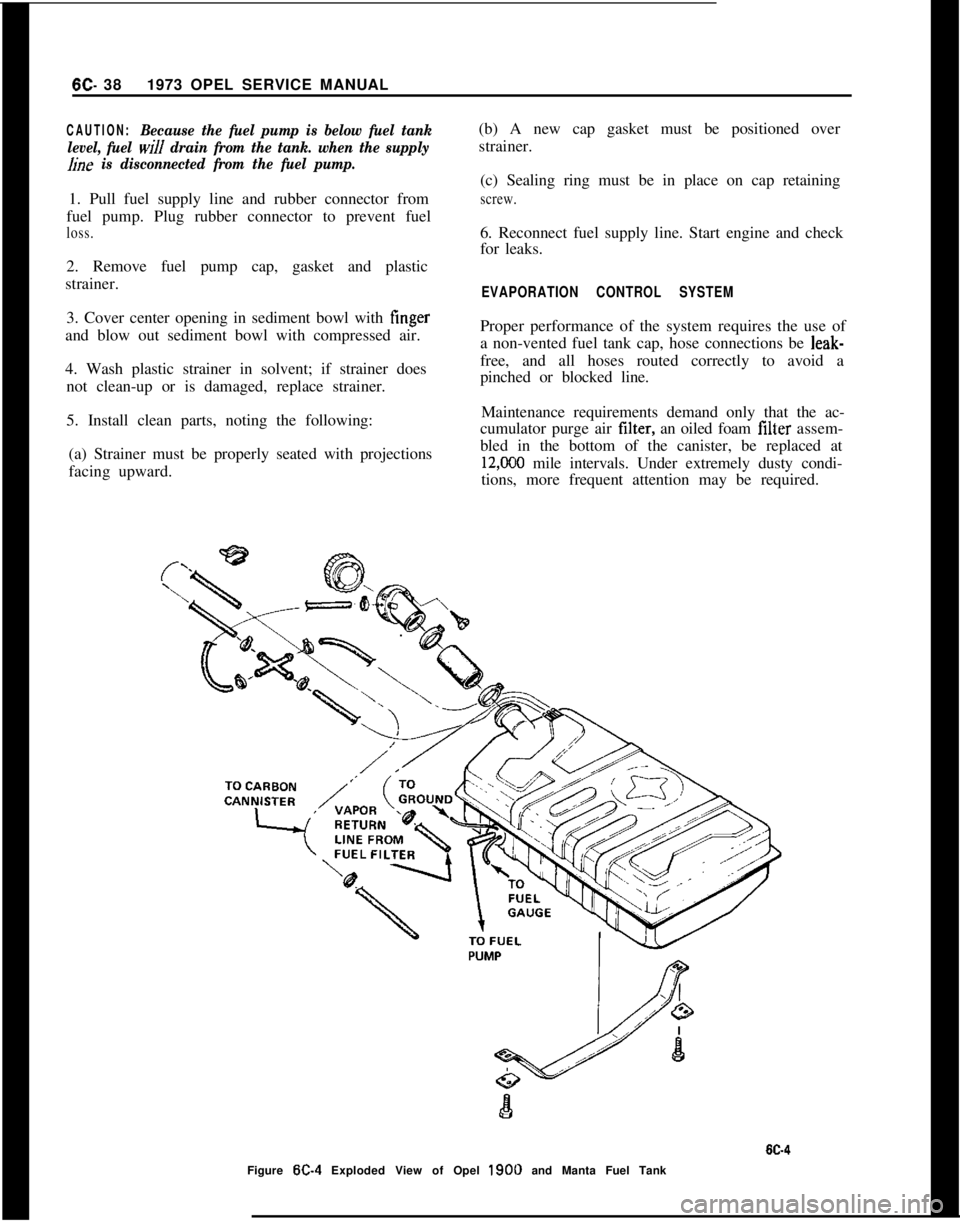

6C- 381973 OPEL SERVICE MANUALCAUTION:Because the fuel pump is below fuel tank

level, fuel

will drain from the tank. when the supply

hne is disconnected from the fuel pump.1. Pull fuel supply line and rubber connector from

fuel pump. Plug rubber connector to prevent fuel

loss.2. Remove fuel pump cap, gasket and plastic

strainer.

3. Cover center opening in sediment bowl with finger

and blow out sediment bowl with compressed air.

4. Wash plastic strainer in solvent; if strainer does

not clean-up or is damaged, replace strainer.

5. Install clean parts, noting the following:

(a) Strainer must be properly seated with projections

facing upward.(b) A new cap gasket must be positioned over

strainer.

(c) Sealing ring must be in place on cap retaining

screw.6. Reconnect fuel supply line. Start engine and check

for leaks.

EVAPORATION CONTROL SYSTEMProper performance of the system requires the use of

a non-vented fuel tank cap, hose connections be leak-

free, and all hoses routed correctly to avoid a

pinched or blocked line.

Maintenance requirements demand only that the ac-

cumulator purge air tilter, an oiled foam filter assem-

bled in the bottom of the canister, be replaced at

12,CKO mile intervals. Under extremely dusty condi-

tions, more frequent attention may be required.

Figure

W-4 Exploded View of Opel 1900 and Manta Fuel Tank

Page 534 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 2596.15

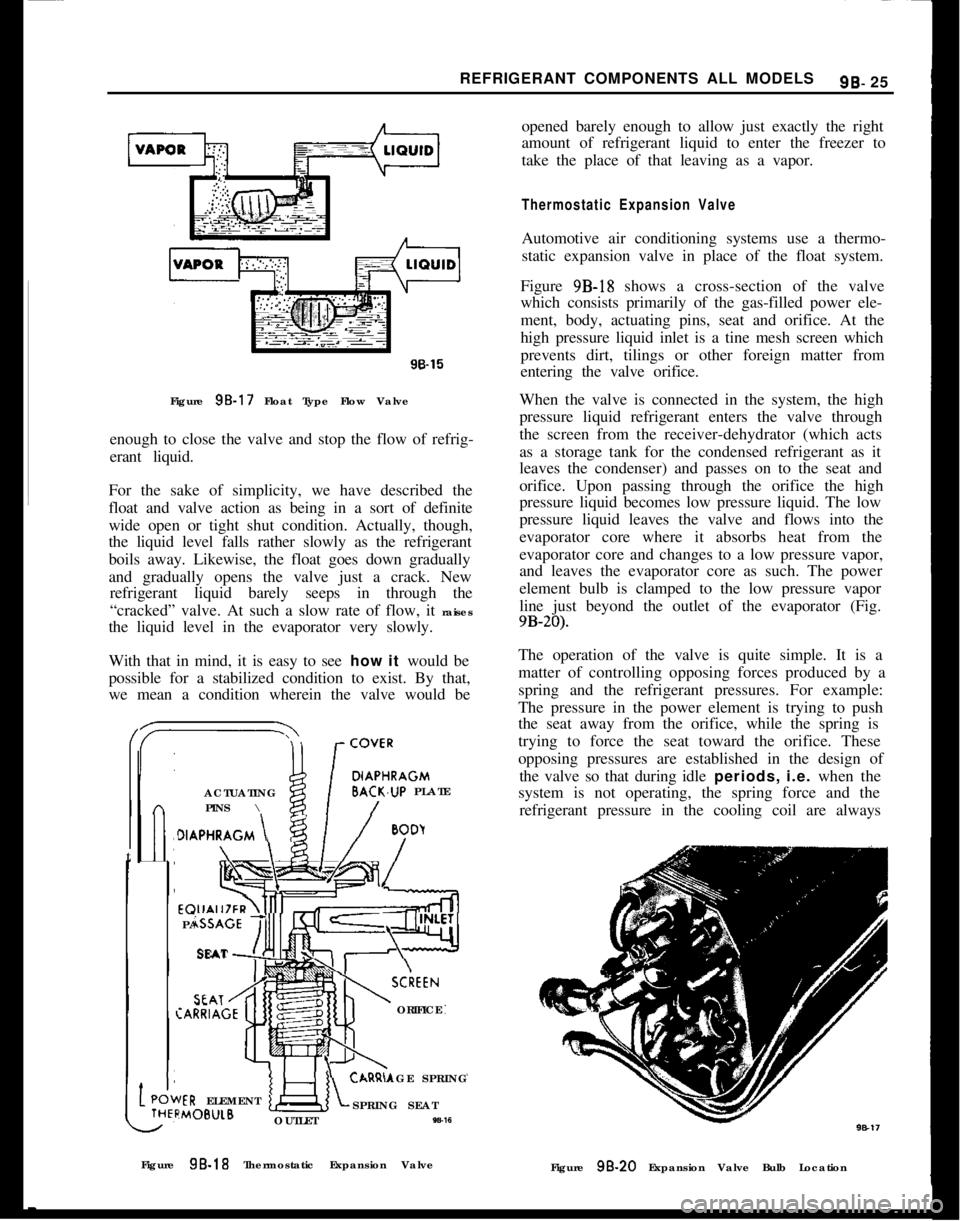

Figure 95.17 Float Type Flow Valve

enough to close the valve and stop the flow of refrig-

erant liquid.

For the sake of simplicity, we have described the

float and valve action as being in a sort of definite

wide open or tight shut condition. Actually, though,

the liquid level falls rather slowly as the refrigerant

boils away. Likewise, the float goes down gradually

and gradually opens the valve just a crack. New

refrigerant liquid barely seeps in through the

“cracked” valve. At such a slow rate of flow, it raises

the liquid level in the evaporator very slowly.

With that in mind, it is easy to see how it would be

possible for a stabilized condition to exist. By that,

we mean a condition wherein the valve would be/

DIAPHRAGMACTUATINGBACK.UP PLATE

PINS \

t

>IAPHRAGM \

/

BoDyEQUALIZER\4]

PASSAGE

‘!!!ISEATSCkEEN:ARRIAGEORIFICE

AGE SPRINGIER ELEMENT:MOB”LBSPRING SEAT

OUTLET

W-16opened barely enough to allow just exactly the right

amount of refrigerant liquid to enter the freezer to

take the place of that leaving as a vapor.

Thermostatic Expansion ValveAutomotive air conditioning systems use a thermo-

static expansion valve in place of the float system.

Figure 9B-18 shows a cross-section of the valve

which consists primarily of the gas-filled power ele-

ment, body, actuating pins, seat and orifice. At the

high pressure liquid inlet is a tine mesh screen which

prevents dirt, tilings or other foreign matter from

entering the valve orifice.

When the valve is connected in the system, the high

pressure liquid refrigerant enters the valve through

the screen from the receiver-dehydrator (which acts

as a storage tank for the condensed refrigerant as it

leaves the condenser) and passes on to the seat and

orifice. Upon passing through the orifice the high

pressure liquid becomes low pressure liquid. The low

pressure liquid leaves the valve and flows into the

evaporator core where it absorbs heat from the

evaporator core and changes to a low pressure vapor,

and leaves the evaporator core as such. The power

element bulb is clamped to the low pressure vapor

line just beyond the outlet of the evaporator (Fig.

9B-20).The operation of the valve is quite simple. It is a

matter of controlling opposing forces produced by a

spring and the refrigerant pressures. For example:

The pressure in the power element is trying to push

the seat away from the orifice, while the spring is

trying to force the seat toward the orifice. These

opposing pressures are established in the design of

the valve so that during idle periods, i.e. when the

system is not operating, the spring force and the

refrigerant pressure in the cooling coil are always

Figure 9B-18 Thermostatic Expansion Valve

Figure

98.20 Expansion Valve Bulb Location

Page 540 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 31

When adding oil, the container should be exception-

ally clean and dry due to the fact that the refrigera-

tion oil in the container is as moisture-free as it is

possible to make it. Therefore, it will quickly absorb

any moisture with which it comes in contact. For this

same reason the oil container should not be opened

until ready for use and it should be capped immedi-

ately afte;r use.

When it is necessary to open a system, have every-

thing you will need ready and handy so that as little

time as possible will be required to perform the oper-

ation. Don’t leave the system open any longer than

is necessary.

Finally, after the operation has been completed and

the system sealed again, air and moisture should be

evacuated from the system before recharging.

THE PRIMARY CAUSES OF SYSTEM FAILURES

LeaksA shortage of refrigerant causes oil to be trapped in

the evaporator. Oil may be lost with the refrigerant

at point of leakage. Both of these can cause compres-

sor seizure.

Oil circulates in the system with the refrigerant; in

solution with the liquid and in globules with the

vapor. It leaves the compressor by the action of the

pistons and mixes with the refrigerant liquid in the

condenser. The oil then enters the evaporator with

the liquid and, with the evaporator properly flooded,

is returned to the compressor through the low pres-

sure line. Some of the oil returns as globules in the

vapor, but more important, it is swept as a liquid

along the walls of the tubing by the velocity of the

vapor. If the evaporator is starved, the oil cannot

return in sut?icient quantities to keep the compressor

properly lubricated.

High Temperature and PressureAn increase in temperature causes an increase in

pressure. This accelerates chemical instability due to

existing contaminants in the system, and initiates

chemical instability in clean systems. Other results

are brittle hoses,

“0” ring gaskets, and valve dia-

phragms with possible decomposition, broken com-

pressor discharge reeds, and seized compressor

bearings.

A fundamental law of nature accounts for the fact

that when a substance, such as a refrigerant, is in-

creased in temperature, its pressure is also increased.

Any chemical reactions caused by contaminants al-

ready in the system are greatly accelerated as the

temperature increases. A 15 degree rise in tempera-

ture doubles the chemical action. Even in a goodclean system, heat alone can start a chain of harmful

chemical reactions.

While temperature alone can cause the synthetic rub-

ber parts to become brittle and possibly to decom-

pose, the increased pressure can cause them to

rupture or blow.

As the temperature and pressure increases the stress

and strain on the compressor discharge reeds also

increases. This can result in broken reeds. Due to the

effect of the contaminants caused by high tempera-

ture and pressure, compressor bearings can be

caused to seize.

High temperature and pressure are also caused by air

in the system.

Air in the SYstemAir results from a discharged system or careless ser-

vicing procedures. This reduces system capacity and

efficiency and causes oxidation of oil into gum and

varnish.

When a leak causes the system to become dis-

charged, the resulting vacuum within the system will

cause air to be drawn in. Air in the system is a

non-condensable gas and will build up in the con-

denser as it would in an air compressor tank. The

resultant heat produced will contribute to the condi-

tions discussed previously.

Many systems are contaminated and also reduced in

capacity and efficiency by servicemen who either do

not know or are careless regarding proper servicing

procedures.

Too frequently, systems which have been open to the

atmosphere during service operations have not been

properly purged or evacuated. Air is also introduced

into the system by unpurged gauge and charging

lines. Remember that any air in the system is too

much air.

Poor ConnectionsHose clamp type fittings must be properly made.

Hoses should be installed over the sealing flanges and

with the end of the hose at the stop flange. The hose

should never extend beyond the stop flange. Locate

the clamp properly and torque as recommended. Be

especially careful that the sealing flanges are not

nicked or scored or a future leak will result.

When compression fittings are used, over tightening

can cause physical damage to the “0” ring gasket

and will result in leaks. The use of torque and back-

ing wrenches is highly recommended. When making

a connection with compression fittings, the gaskets

should always be first placed over the tube before