bulb OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 29 of 625

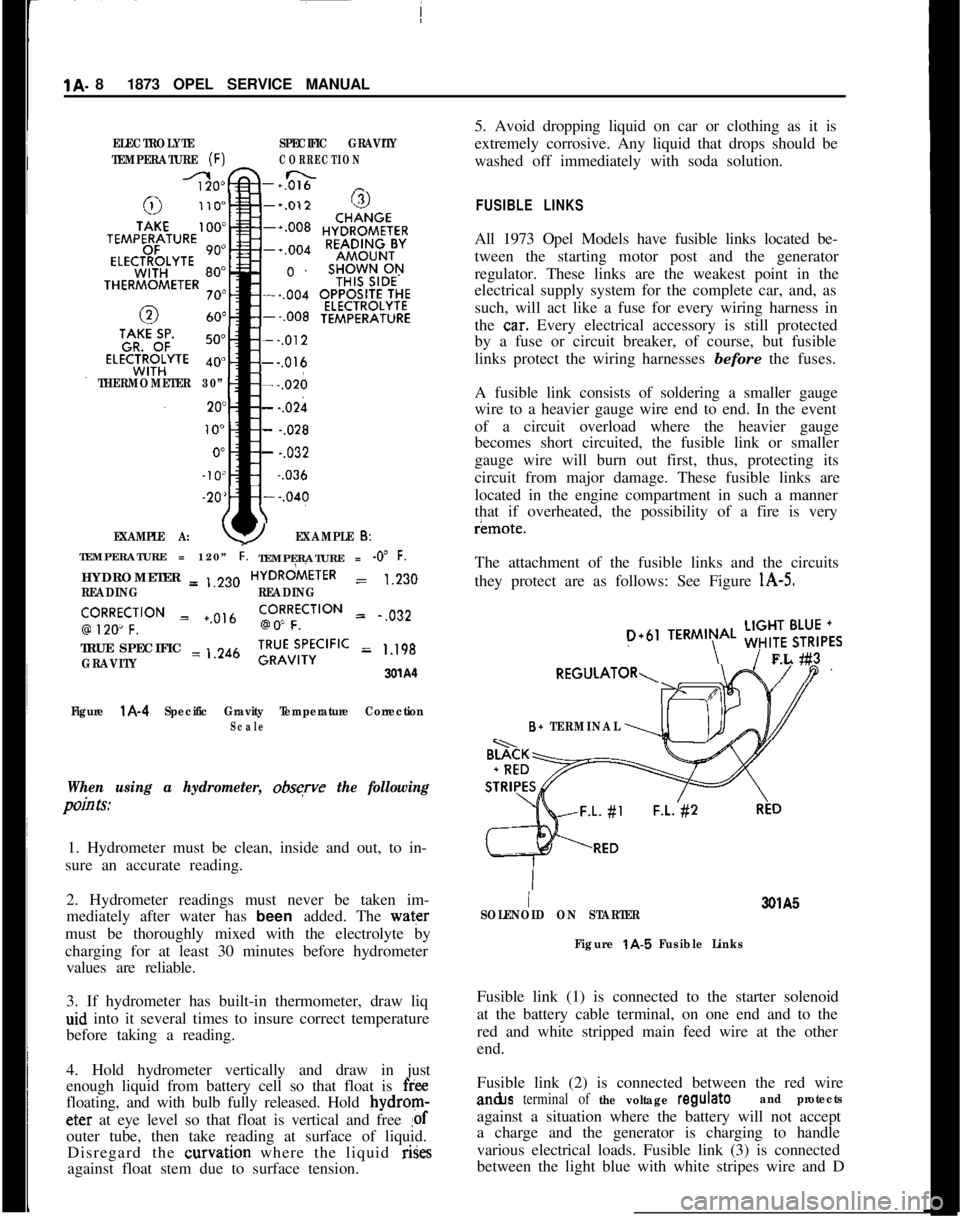

1A. 81873 OPEL SERVICE MANUALELECTROLYTESPECIFIC GRAVITY

TEMPERATURE

(F)CORRECTION

-+0&&n _

THERMOMETER 30”

EXAMPLE A:

--,012---,016---,026

- -.02h

- -.028

- -.032~

-.036

YEXAMPLE 6:TEMPERATURE = 120”

i.TEMPERATURE = -0” F.HYDROMETER = ,,230HYDRdiETER

= 1.230

READINGREADING

‘,9R2Ro~CF;‘“” = +.0,6go!RFfCilON = .,032

TRUE SPECIFIC = ,.246

GRAVITY;RU”v;,‘;CIFIC = 1.198

3xA‘l

Figure

l A-4 Specific Gravity Temperature CorrectionScale

When using a hydrometer, obsqve the following

pain Is:1. Hydrometer must be clean, inside and out, to in-

sure an accurate reading.

2. Hydrometer readings must never be taken im-

mediately after water has been added. The water

must be thoroughly mixed with the electrolyte by

charging for at least 30 minutes before hydrometer

values are reliable.

3. If hydrometer has built-in thermometer, draw liq

aid into it several times to insure correct temperature

before taking a reading.

4. Hold hydrometer vertically and draw in just

enough liquid from battery cell so that float is

freefloating, and with bulb fully released. Hold bydrom-eter at eye level so that float is vertical and free

!ofouter tube, then take reading at surface of liquid.

Disregard the curvation where the liquid rises

against float stem due to surface tension.5. Avoid dropping liquid on car or clothing as it is

extremely corrosive. Any liquid that drops should be

washed off immediately with soda solution.

FUSIBLE LINKSAll 1973 Opel Models have fusible links located be-

tween the starting motor post and the generator

regulator. These links are the weakest point in the

electrical supply system for the complete car, and, as

such, will act like a fuse for every wiring harness in

the

ca.r. Every electrical accessory is still protected

by a fuse or circuit breaker, of course, but fusible

links protect the wiring harnesses before the fuses.

A fusible link consists of soldering a smaller gauge

wire to a heavier gauge wire end to end. In the event

of a circuit overload where the heavier gauge

becomes short circuited, the fusible link or smaller

gauge wire will burn out first, thus, protecting its

circuit from major damage. These fusible links are

located in the engine compartment in such a manner

that if overheated, the possibility of a fire is veryr¬e.

The attachment of the fusible links and the circuits

they protect are as follows: See Figure

l A-5.

D+61TERMIN\AL ;;!$6,,FL #3

B+ TERMINAL

I3QlA5

SOLENOID ON STARTER

Figure

t A-5 Fusible LinksFusible link (1) is connected to the starter solenoid

at the battery cable terminal, on one end and to the

red and white stripped main feed wire at the other

end.

Fusible link (2) is connected between the red wirean&s

terminal of the voltage regulateand protectsagainst a situation where the battery will not accept

a charge and the generator is charging to handle

various electrical loads. Fusible link (3) is connected

between the light blue with white stripes wire and D

Page 70 of 625

LIGHTING SYSTEMSlF-492. Take

Le:s off housing. See Figure lF-7.

3. Remove housing.1

Installation;I

1. Install

le$ in housing.

2. Replace

+.Model 54

;,

1, Remove Ilamp lens from outside.

/

2. Remove kear quarter trim pad.

/

3. Remove

ifour screws from inside car. See FigurelF- 8.

Figure 1 F-8

I- Removing Tail Light Housing - Model 54

I

4. Disconnkct wiring connector.

I

1. Connect iwiring to lamp

2. Install hbusing using four (4)

scre%s.3. Replace

p quarter trim pad

4. Replace

Lens,Models

57-$RI

Removal1. Unscrew!lens from housing.2.

III luggage compartment, unscrew three (3) hous-

ing attaching nuts. See Figure lF-9.

Figure lF-9 Tail Light Housing Attaching Nuts

-Models 57.57R

3. Disconnect wire connector.

Installation1. Plug in wiring harness.

2. Replace housing with three (3) attaching nuts.

3. Replace lens.

Rear License Plate Lamp Assembly Removal1. Remove two screws holding housing to bumper.

2. Pull lamp assembly down.

3. To replace bulb, take out two

screws holding lens

in place.

Installation1. Replace bulb and lens to housing.

2. Replace lamp assembly to bumper with two (2)

screws.

SIDE MARKER LIGHTS

Front Removal1. Remove outer lens.

2. Remove two sheet metal screws for housing at-

tachment.

3. Disconnect wire connectors.

Page 76 of 625

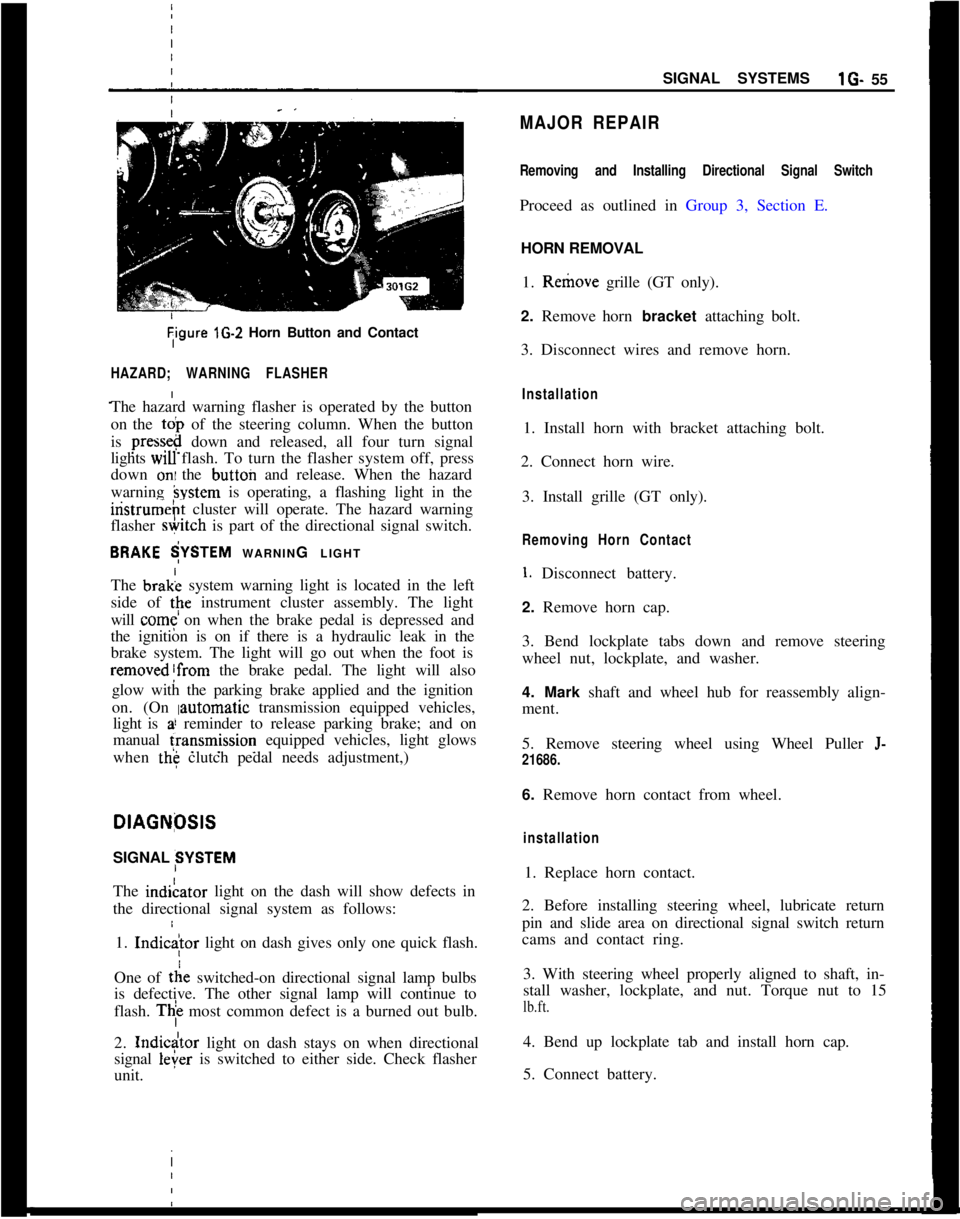

Tigure lG-2 Horn Button and Contact

HAZARD; WARNING FLASHER

The hazard warning flasher is operated by the button

on the

toi, of the steering column. When the button

is

press&@ down and released, all four turn signal

lights

WIU flash. To turn the flasher system off, press

down

oni the button and release. When the hazard

warning

hystem is operating, a flashing light in the

iristrumeht cluster will operate. The hazard warning

flasher

&itch is part of the directional signal switch.

BRAKE $YSTEM WARNING LIGHT

The brak; system warning light is located in the left

side of

tpe instrument cluster assembly. The light

will

come on when the brake pedal is depressed and

the ignition is on if there is a hydraulic leak in the

brake system. The light will go out when the foot is

removed!from the brake pedal. The light will also

glow with the parking brake applied and the ignition

on. (On

Iautomatic transmission equipped vehicles,

light is

a! reminder to release parking brake; and on

manual

fransmission equipped vehicles, light glows

when

the clutch pedal needs adjustment,)

I

DlAGNfXlS

SIGNAL SYSTEM

The indiLator light on the dash will show defects in

the directional signal system as follows:

1.

Indic

tie switched-on directional signal lamp bulbs

is defective. The other signal lamp will continue to

flash.

Thi most common defect is a burned out bulb.

2.

Indicdtor light on dash stays on when directional

signal

leier is switched to either side. Check flasher

unit. I

SIGNAL SYSTEMSlG- 55

MAJOR REPAIR

Removing and Installing Directional Signal Switch

Proceed as outlined in Group 3, Section E.

HORN REMOVAL

1. Remove grille (GT only).

2. Remove horn bracket attaching bolt.

3. Disconnect wires and remove horn.

Installation

1. Install horn with bracket attaching bolt.

2. Connect horn wire.

3. Install grille (GT only).

Removing Horn Contact

1. Disconnect battery.

2. Remove horn cap.

3. Bend lockplate tabs down and remove steering

wheel nut, lockplate, and washer.

4. Mark shaft and wheel hub for reassembly align-

ment.

5. Remove steering wheel using Wheel Puller

J-

21686.

6. Remove horn contact from wheel.

installation

1. Replace horn contact.

2. Before installing steering wheel, lubricate return

pin and slide area on directional signal switch return

cams and contact ring.

3. With steering wheel properly aligned to shaft, in-

stall washer, lockplate, and nut. Torque nut to 15

lb.ft.

4. Bend up lockplate tab and install horn cap.

5. Connect battery.

Page 78 of 625

,I

IINSTRUMENT PANEL

lH- 57

/

/SubjectPage No. INSTRUMENT PANEL

CONTENTS

DESCRIPTION AND OPERATION:

Instrument Panel

- Opel 1900 - Manta. . . . . . . . . . . . . . . . . . . . . .Instrument

Panel-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

MAINTENANCE AND ADJUSTMENTS:

MAJOR REPAIR:

Instrument Cluster Housing

- Opel 1900 - Manta . .

Windshield Wiper Switch

. , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .InstrumentCluster

Bulbs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .InstrumentCluster

Housing-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Combined Switch Assemblies

. . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CigarLighter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)

I H-57

1H-58

1H-59

1H-61

lH-61

1H-61

1H-63

1H-64

DESCF(lPTlON AND OPERATION2. The fog light toggle switch lower half is pushed in.INSTRUFENT PANEL (OPEL 1900. MANTA)

Headligl$ Switch

3. The parking lights and/or low beam headlights are

on.The thr& position light switch controls the head-

lights, @lights, parking lights, side marker lights,

license

plate light and instrument panel lights and is

located

4t the lower left on the instrument panel.

With thk switch knob pulled outward to the first

stop,

thi parking lights, side marker lights, license

plate

ligiit and instrument panel lights will light. Theinstrumdnt panel lights can be turned off by turning

the

lightSwitch knob counterclockwise past the first

detent. IThe fog lights are automatically turned off if the

ignition switch is on and the headlights are on high

beam.

Windshield Wiper Switch

The windshield wiper switch is located on the instru-ment panel to the right of the headlight switch.

By pull&g the lightswitch knob out all the way, the

headlights will also be turned on.

IBy pushing the lower half of this switch in to the first

stop, the wipers will operate at slow speed. By push-ing in to the second stop, the wipers will operate at

fast speed.

Fog

Ligh) Switch (Rallye)The fog

iight toggle switch is located in the instru-

ment cluster to the left of the temperature and fuel

gauge

cl+ster. The fog lights can be turned off at any

time by

t,he toggle switch, but can only be turned on

when: ,

Electrically Heated Rear Window Switch (If

Equipped)The heated rear

wind&v switch is located in the

instrument panel to the right of the clock opening.

1. The ignition switch is on or the engine running.

ITo operate (only possible with the engine running),

push in on the lower half of the switch. When the

rear window is being heated, the switch will

belighted.

Page 82 of 625

I

I

IINSTRUMENT PANELlH- 61Figwe 1 H-7

- Disconnecting Cluster Wires

4. Install instrument cluster trim plate and replace

two screw and plugs.

5. Con&t speed0 cable by turning coupling clock-

wise. 1

6. Install light

.switch button and heater control

knobs. I

I

7. Con+ct battery cable.

Removidg Windshield Wiper Switch - Opel 1900Manta I

1.

Rem* instrument cluster trim plate.

2. Corndress retaining clips and remove switch. See

Figure iH-8.

I

Figure lH-8 . Removing Windshield Wiper Switch3. Disconnect wiring connector.

Installation1. Connect wiring to switch.

2. Snap switch back into panel.

3. Replace instrument cluster trim plate.

Removing Instrument Cluster Bulbs - Opel 1900.

Manta1. Remove instrument cluster assembly.

2. Replace bulbs from back ofcluster. See Figure

lH-

9.Figure lH-9 Removing Instrument

Clu’ster Bulbs

Installation1. Replace bulbs in cluster.

2. Replace instrument cluster assembly.

Removing and Installing Ignition SwitchRefer to Group 3, Section F.

Removal of Instrument Cluster Housing Assembly.

GTDisconnect battery before making any electrical re-

pairs.

1. Disconnect battery cable.

2. Remove right access cover and remove screw. See

Figure lH-10.

Page 534 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 2596.15

Figure 95.17 Float Type Flow Valve

enough to close the valve and stop the flow of refrig-

erant liquid.

For the sake of simplicity, we have described the

float and valve action as being in a sort of definite

wide open or tight shut condition. Actually, though,

the liquid level falls rather slowly as the refrigerant

boils away. Likewise, the float goes down gradually

and gradually opens the valve just a crack. New

refrigerant liquid barely seeps in through the

“cracked” valve. At such a slow rate of flow, it raises

the liquid level in the evaporator very slowly.

With that in mind, it is easy to see how it would be

possible for a stabilized condition to exist. By that,

we mean a condition wherein the valve would be/

DIAPHRAGMACTUATINGBACK.UP PLATE

PINS \

t

>IAPHRAGM \

/

BoDyEQUALIZER\4]

PASSAGE

‘!!!ISEATSCkEEN:ARRIAGEORIFICE

AGE SPRINGIER ELEMENT:MOB”LBSPRING SEAT

OUTLET

W-16opened barely enough to allow just exactly the right

amount of refrigerant liquid to enter the freezer to

take the place of that leaving as a vapor.

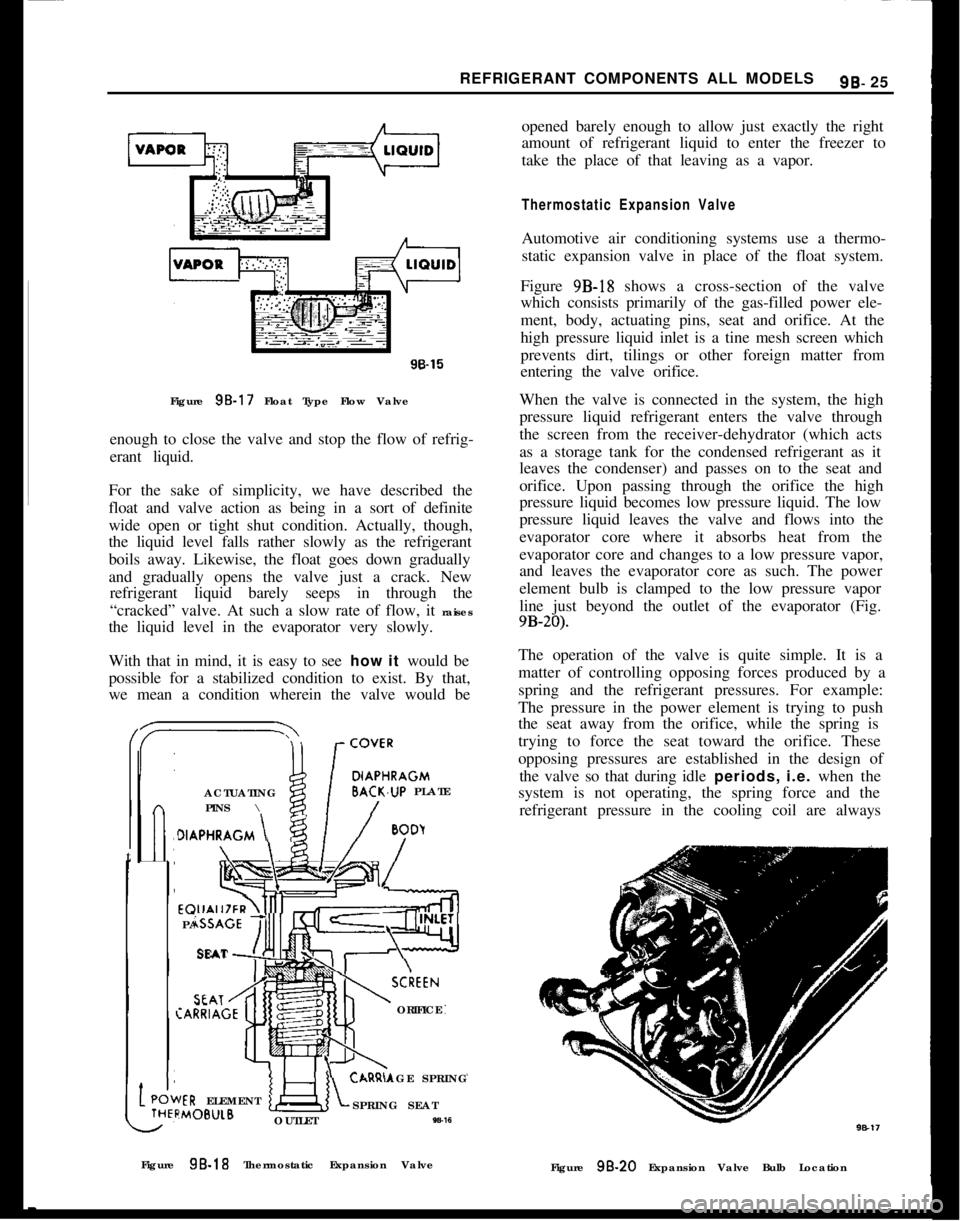

Thermostatic Expansion ValveAutomotive air conditioning systems use a thermo-

static expansion valve in place of the float system.

Figure 9B-18 shows a cross-section of the valve

which consists primarily of the gas-filled power ele-

ment, body, actuating pins, seat and orifice. At the

high pressure liquid inlet is a tine mesh screen which

prevents dirt, tilings or other foreign matter from

entering the valve orifice.

When the valve is connected in the system, the high

pressure liquid refrigerant enters the valve through

the screen from the receiver-dehydrator (which acts

as a storage tank for the condensed refrigerant as it

leaves the condenser) and passes on to the seat and

orifice. Upon passing through the orifice the high

pressure liquid becomes low pressure liquid. The low

pressure liquid leaves the valve and flows into the

evaporator core where it absorbs heat from the

evaporator core and changes to a low pressure vapor,

and leaves the evaporator core as such. The power

element bulb is clamped to the low pressure vapor

line just beyond the outlet of the evaporator (Fig.

9B-20).The operation of the valve is quite simple. It is a

matter of controlling opposing forces produced by a

spring and the refrigerant pressures. For example:

The pressure in the power element is trying to push

the seat away from the orifice, while the spring is

trying to force the seat toward the orifice. These

opposing pressures are established in the design of

the valve so that during idle periods, i.e. when the

system is not operating, the spring force and the

refrigerant pressure in the cooling coil are always

Figure 9B-18 Thermostatic Expansion Valve

Figure

98.20 Expansion Valve Bulb Location

Page 535 of 625

98-26 1973 OPEL SERVICE MANUAL

greater than the opposing pressure in the power ele-

ment. Therefore, the valve remains closed. When the

compressor is started, it will reduce the pressure and

temperature of the refrigerant in the cooling coil to

a point where the vapor pressure in the power ele-

ment becomes the stronger. The seat then moves off

the orifice and liquid starts to flow through the valve

orifice into the cooling coil.

The purpose of the power element is to help deter-

mine the quantity of liquid that is being metered into

the cooling coil. As the temperature of the low pres-

sure line changes at the bulb, the pressure of

the

vapor in the power element changes, resulting in a

change of the position of the seat. For example, if the

cooling coil gets more liquid than is required, the

temperature of the low pressure line is reduced and

the resultant lowering of the bulb temperature

reduces the pressure of the vapor in the power ele-

ment, allowing the seat to move closer to the orifice.

This immediately reduces the amount of liquid leav-

ing the valve. Under normal operation, the power

element provides accurate control of the quantity of

refrigerant to the cooling coil.

To employ our tire pump analogy once more for

clarity, it is the same situation that would exist if you were inflating a tire with a very slow leak. Providing

you pumped the air into the tire as fast as it leaked

out, you would be able to maintain pressure even

though the air would merely be circulating through the tire and leaking out through the puncture.

To Sum Up

So far, we’ve discussed only what each unit in an air

conditioning system does. We’ve learned that the

evaporator is the unit in which liquid refrigerant

soaks up heat from the air, the compressor is a pump

for squeezing this heat out of the vapor, the con-

denser is a radiator for getting rid of the heat, and the

thermostatic expansion valve is a device for regulat-

ing the pressure on the refrigerant. Now, let’s

find

out how the temperature of the cooled air is con-

trolled.

METHOD OF TEMPERATURE CONTROL

To achieve temperature control, the compressor is

run intermittently, automatically turning on and off

as necessary to maintain proper temperature.

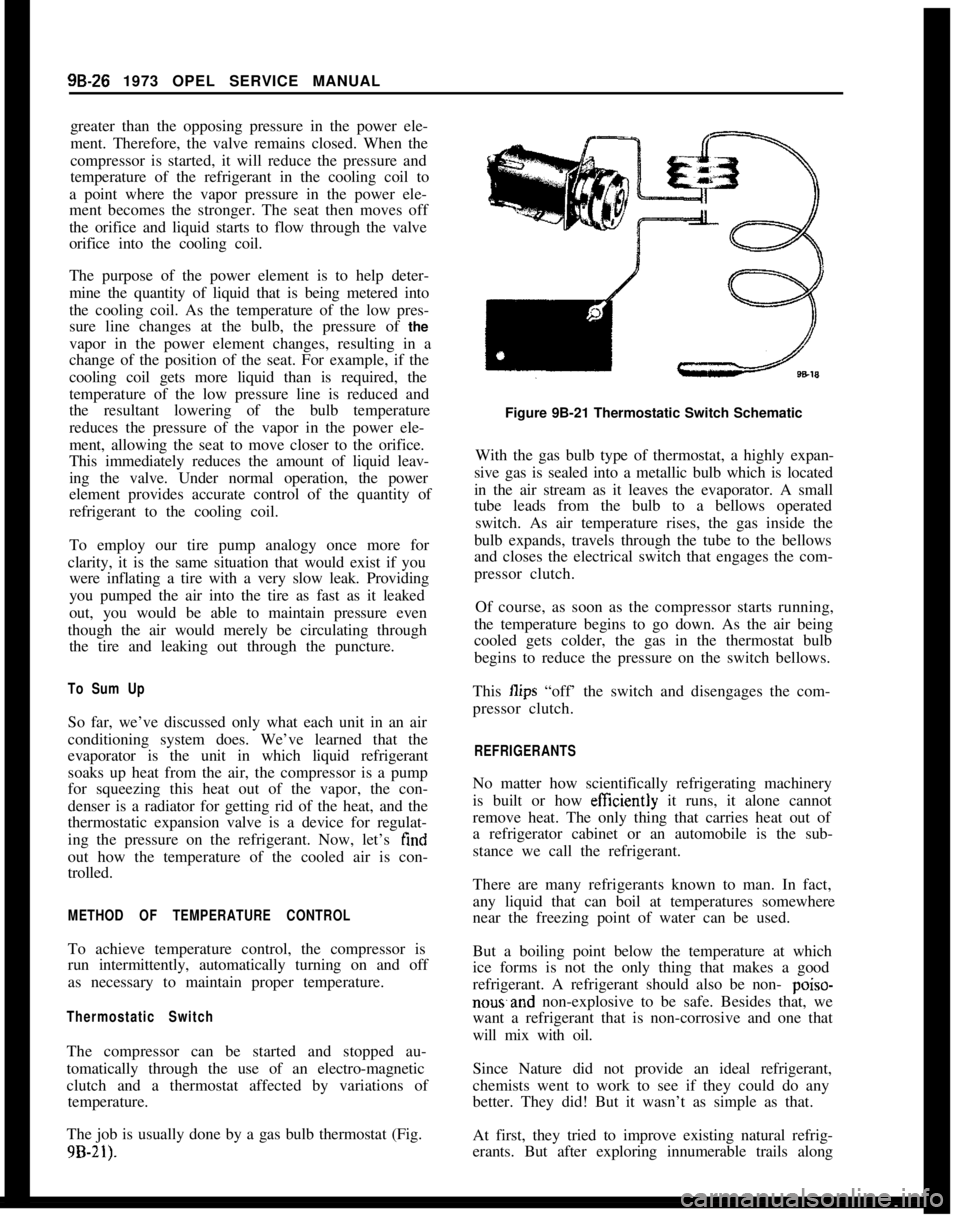

Thermostatic Switch

The compressor can be started and stopped au-

tomatically through the use of an electro-magnetic

clutch and a thermostat affected by variations of temperature.

The job is usually done by a gas bulb thermostat (Fig.

9B-21).

Figure 9B-21 Thermostatic Switch Schematic

With the gas bulb type of thermostat, a highly expan-

sive gas is sealed into a metallic bulb which is located

in the air stream as it leaves the evaporator. A small

tube leads from the bulb to a bellows operated switch. As air temperature rises, the gas inside the

bulb expands, travels through the tube to the bellows

and closes the electrical switch that engages the com-

pressor clutch.

Of course, as soon as the compressor starts running,

the temperature begins to go down. As the air being

cooled gets colder, the gas in the thermostat bulb

begins to reduce the pressure on the switch bellows.

This

Ilips “off’ the switch and disengages the com-

pressor clutch.

REFRIGERANTS

No matter how scientifically refrigerating machinery

is built or how

efftciently it runs, it alone cannot

remove heat. The only thing that carries heat out of

a refrigerator cabinet or an automobile is the sub-

stance we call the refrigerant.

There are many refrigerants known to man. In fact,

any liquid that can boil at temperatures somewhere

near the freezing point of water can be used.

But a boiling point below the temperature at which

ice forms is not the only thing that makes a good

refrigerant. A refrigerant should also be non-

poiso-

nowand non-explosive to be safe. Besides that, we

want a refrigerant that is non-corrosive and one that

will mix with oil.

Since Nature did not provide an ideal refrigerant,

chemists went to work to see if they could do any

better. They did! But it wasn’t as simple as that.

At first, they tried to improve existing natural refrig-

erants. But after exploring innumerable trails along

Page 546 of 625

REFRIGERANT COMPONENTS ALL MODELS

99.37

in front of the radiator so that it receives a high

volume of air flow. Air passing over the condenser

absorbs the heat from the high pressure gas and

causes the refrigerant to condense into a high pres-

sure liquid.Receiver. DehydratorThe receiver-dehydrator is located in the engine

compartment. The purpose of the receiver dehydra-

tor is two fold: the unit insures a solid column of

liquid refrigerant to the expansion valve at all times,

and also absorbs any moisture in the system that

might be present. A bag of desiccant (moisture ab-

sorbing material) is provided to absorb moisture. A

sight glass (see Figure 9B-33) permits visual check-

ing of the refrigerant flow for bubbles or foam. The

continuous appearance of bubbles or foam above an

ambient temperature of 70 degrees F. usually indi-

cates an inadequate refrigerant charge. Bubbles or

foam appearing at ambient temperatures below 70

degrees F. do not necessarily indicate an inadequate

charge and may appear even when the system is

operating properly. A filter screen in the unit pre-

vents foreign material from entering the remainder

of the system.

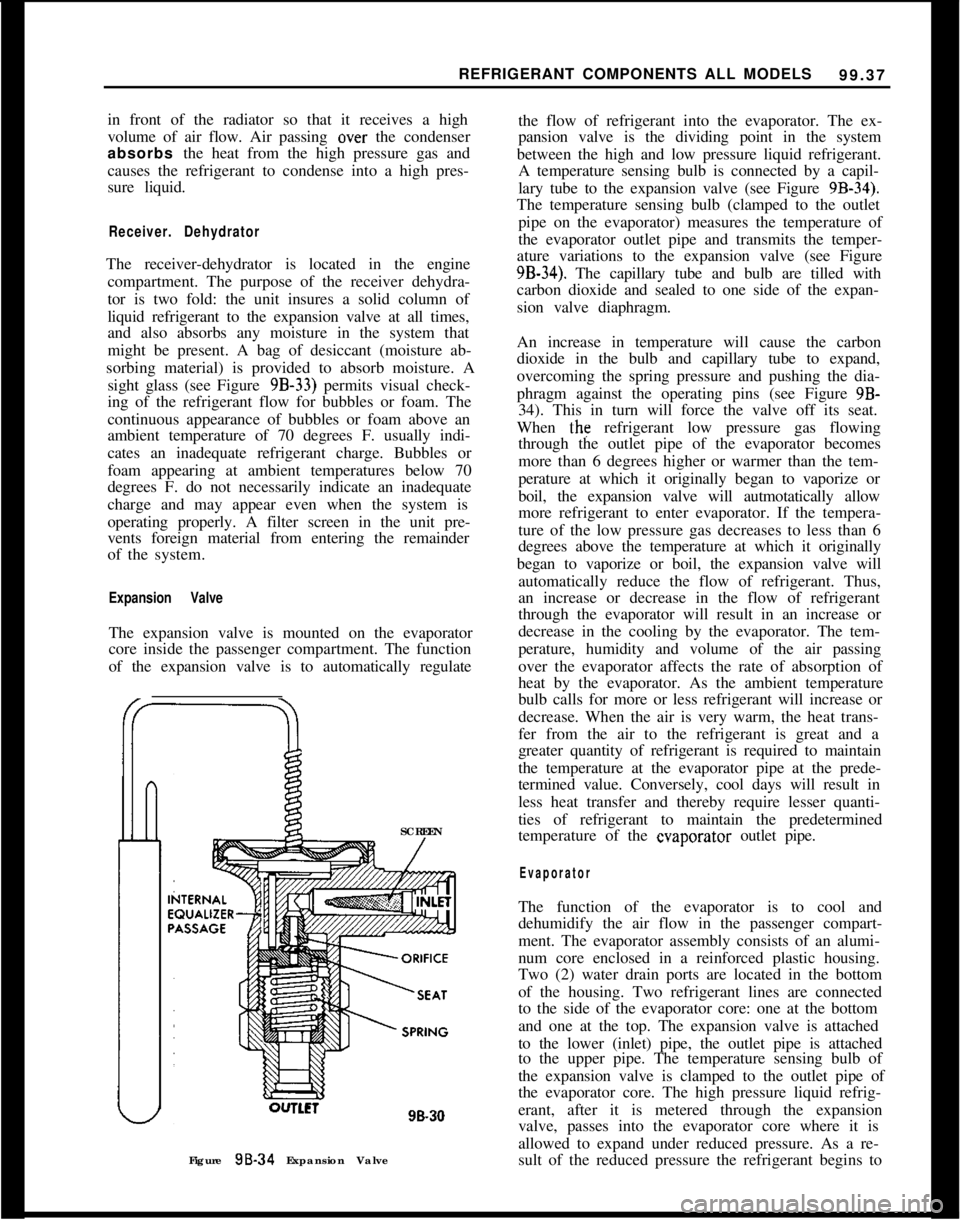

Expansion ValveThe expansion valve is mounted on the evaporator

core inside the passenger compartment. The function

of the expansion valve is to automatically regulate

SCREEN

lLCl98.30

Figure 98-34 Expansion Valvethe flow of refrigerant into the evaporator. The ex-

pansion valve is the dividing point in the system

between the high and low pressure liquid refrigerant.

A temperature sensing bulb is connected by a capil-

lary tube to the expansion valve (see Figure

9B-34).The temperature sensing bulb (clamped to the outlet

pipe on the evaporator) measures the temperature of

the evaporator outlet pipe and transmits the temper-

ature variations to the expansion valve (see Figure

9B-34). The capillary tube and bulb are tilled with

carbon dioxide and sealed to one side of the expan-

sion valve diaphragm.

An increase in temperature will cause the carbon

dioxide in the bulb and capillary tube to expand,

overcoming the spring pressure and pushing the dia-

phragm against the operating pins (see Figure 9B-

34). This in turn will force the valve off its seat.

When the refrigerant low pressure gas flowing

through the outlet pipe of the evaporator becomes

more than 6 degrees higher or warmer than the tem-

perature at which it originally began to vaporize or

boil, the expansion valve will autmotatically allow

more refrigerant to enter evaporator. If the tempera-

ture of the low pressure gas decreases to less than 6

degrees above the temperature at which it originally

began to vaporize or boil, the expansion valve will

automatically reduce the flow of refrigerant. Thus,

an increase or decrease in the flow of refrigerant

through the evaporator will result in an increase or

decrease in the cooling by the evaporator. The tem-

perature, humidity and volume of the air passing

over the evaporator affects the rate of absorption of

heat by the evaporator. As the ambient temperature

bulb calls for more or less refrigerant will increase or

decrease. When the air is very warm, the heat trans-

fer from the air to the refrigerant is great and a

greater quantity of refrigerant is required to maintain

the temperature at the evaporator pipe at the prede-

termined value. Conversely, cool days will result in

less heat transfer and thereby require lesser quanti-

ties of refrigerant to maintain the predetermined

temperature of the evaporator outlet pipe.

EvaporatorThe function of the evaporator is to cool and

dehumidify the air flow in the passenger compart-

ment. The evaporator assembly consists of an alumi-

num core enclosed in a reinforced plastic housing.

Two (2) water drain ports are located in the bottom

of the housing. Two refrigerant lines are connected

to the side of the evaporator core: one at the bottom

and one at the top. The expansion valve is attached

to the lower (inlet) pipe, the outlet pipe is attached

to the upper pipe. The temperature sensing bulb of

the expansion valve is clamped to the outlet pipe of

the evaporator core. The high pressure liquid refrig-

erant, after it is metered through the expansion

valve, passes into the evaporator core where it is

allowed to expand under reduced pressure. As a re-

sult of the reduced pressure the refrigerant begins to

Page 549 of 625

98.40 1973 OPEL SERVICE MANUAL

2. Interconnect manifold and gage set (J-5725-01),

gage charging lines (J-5418) and gage adapters

(J-5420) to air conditioning system as shown in Figure

9B-40.3. Place transmission in “Park” for automatics and

in neutral for manuals. Apply hand brake.

4. Turn blower switch to the “Hi” position.

5. Turn temperature switch to “Max” position.

6. Run engine at 2000 RPM for ten (10) minutes with

car doors and windows closed and the hood up. Place

a high volume industrial type fan in front of radiator

if head pressure should exceed 250 psi and also at

high ambients to bring the pressures to within the

limits specified in the Functional Charts in Division

V.In the case of the Opel 1900 and the Manta, a ther-

mometer should be placed in a position to read the

temperature of the air discharging from the right-

hand A/C outlet. In case of the GT, a thermometer

should be placed in a position to read the tempera-

ture of the air discharging from the left-rear A/C

outlet.

HEATER-AIR CONDITIONER REFRIGERANT

CIRCUIT TROUBLE DIAGNOSIS GUIDE

Insufficient Cooling (Check Air Flow)

Normal Air Flow (Inspect system for visual defects.

Run functional tests.)

Discharge Air

- Normal Temp Check for air leaks

through dash, car body, windows, or from heater or

ventilators.

Discharge Air

- High Temp Check sight glass for

foaming and compressor clutch for engagement.

No Compressor Clutch Engagement Check connec-

tions at clutch switch, harness connectors, and check

clutch switch.

No Foaming Compare evaporator pressure to that

on functional test table.

Foaming System is probably low on refrigerant.

Check for leaks, repair, evacuate, and charge. If

foaming still occurs, check for restriction in refriger-

ant lines between condenser and receiver dehydrator.

Evaporator Pressure Normal Compare head pres-

sure to pressure on functional test table.

Evaporator Pressure Low Ice may be forming on

evaporator. Low volume of air discharging at A/C

outlet after system has been running above idle con-dition

,for approximately 15-30 min.utes. Discharging

air gradually elevating in temperature. Check expan-

sion valve. If valve isn’t permitting flow of liquid,

this will be indicated by a warm pipe out of the

evaporator. This may be caused by: 1) Clogged or

Plugged inlet screen in the expansion valve; 2)

Broken capillary line; or 3) Discharged temperature

bulb. If the valve is okay, the pipe out of the evapora-

tor will be cold.

Evaporator Pressure High Check the expansion

valve to determine if themobulb is making good con-

tact and is properly insulated. Operate engine at 2000

RPM with maximum air conditioning setting. If

evaporator pressure remains high, feel suction line.

If line feels frosty or extremely

(cold with relative

high ambient conditions, then partially cover the

condenser to obtain head pressures from 265 psi to

280 psi maximum. If evaporator pressure rises above

30 psi, change the expansion valve.

Also, check if compressor may be the cause due to

some internal or external mechanical trouble which

prevents reduction of pressure. Check for external

troubles, slipping belt, bad clutch and/or pulley, or

improper clutch engagement, before investigating

the compressor internally.

Head Pressure High Check for the following: Con-

denser air flow low, air in system, excessive refriger-

ant in system, restriction in condenser.Head.PressureLowRestriction in flow of refrigerant

to evaporator, or expansion valve plugged or defec-

tive.

Low Air Flow (Check blower operation and

evaporator. Check operation of controls.)

Ice BIocking Evaporator Run functional test. If

evaporator pressure is low, ice may form on evapora-

tor and reduce air flow.

Evaporator Pressure Low Ice may be forming on

evaporator. Low volume of air discharging at A/C

outlet after system has been running above idle con-

dition for approximately 15-30 minutes. Discharging

air gradually elevating in temperature. Check expan-

sion valve. If valve isn’t permitting flow of liquid,

this will be indicated by a warm pipe out of the

evaporator. This may be caused by: 1) Clogged or

plugged inlet screen in the expansion valve; 2)

Broken capillary line, or 3) Discharged temperature

bulb. If the valve is okay, the pipe out of the evapora-

tor will be cold.BlowerNot OperatingCheck for the following: Fuse

blown, blower switch defective, wire broken or loose

connection, poor ground connection, or blower mo-

tor defective.

Page 557 of 625

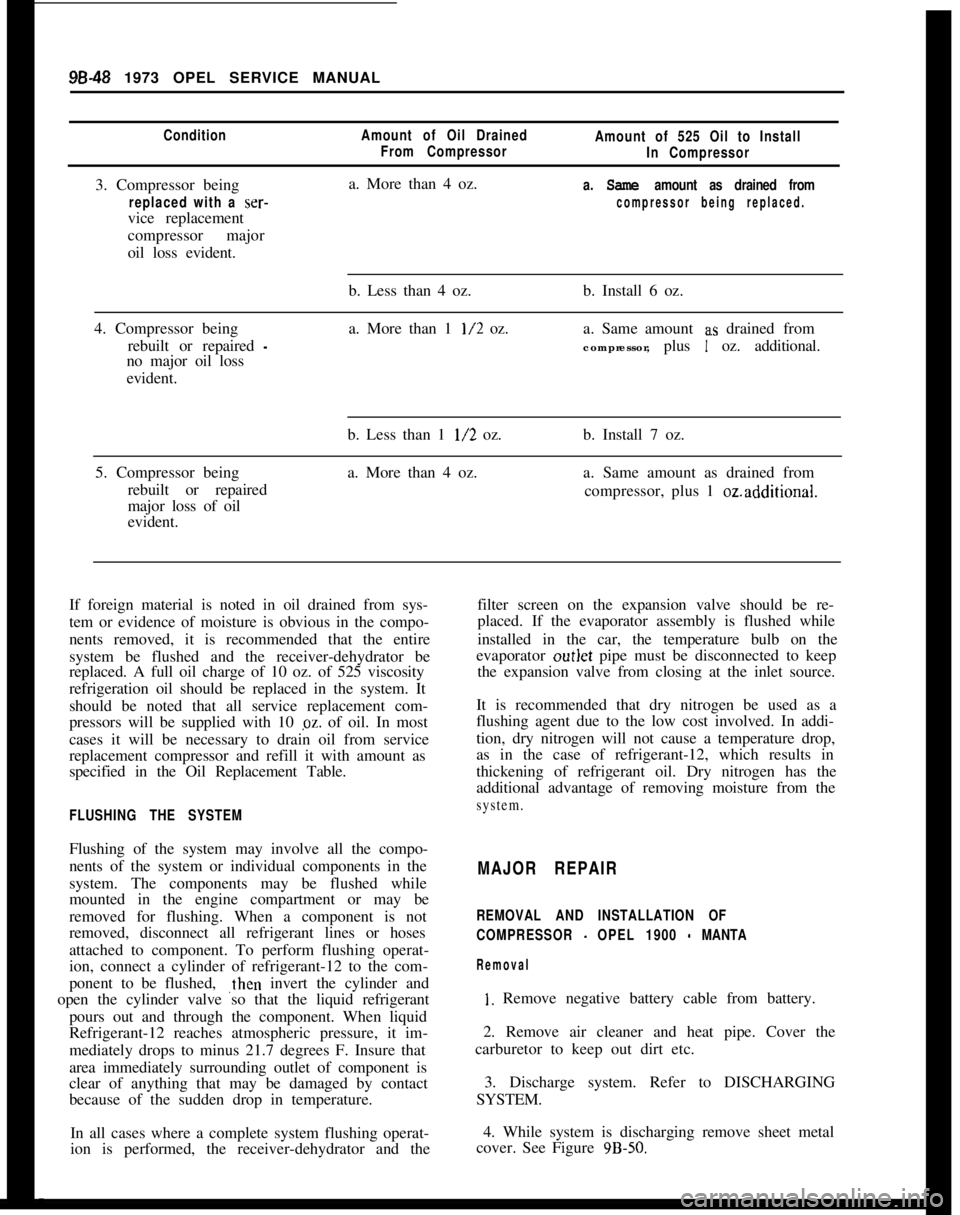

98-48 1973 OPEL SERVICE MANUALCondition3. Compressor being

replaced with a ser-vice replacement

compressor major

oil loss evident.

Amount of Oil Drained

From Compressora. More than 4 oz.Amount of 525 Oil to Install

In Compressor

a.

Same amount as drained from

compressor being replaced.4. Compressor being

rebuilt or repaired

-no major oil loss

evident.b. Less than 4 oz.

a. More than 1

l/2 oz.b. Install 6 oz.

a. Same amount a.s drained from

compressor, plus

1 oz. additional.

5. Compressor being

rebuilt or repaired

major loss of oil

evident.b. Less than 1

l/2 oz.

a. More than 4 oz.b. Install 7 oz.

a. Same amount as drained from

compressor, plus 1

ozadditional.If foreign material is noted in oil drained from sys-

tem or evidence of moisture is obvious in the compo-

nents removed, it is recommended that the entire

system be flushed and the receiver-dehydrator be

replaced. A full oil charge of 10 oz. of 525 viscosity

refrigeration oil should be replaced in the system. It

should be noted that all service replacement com-

pressors will be supplied with 10 pz. of oil. In most

cases it will be necessary to drain oil from service

replacement compressor and refill it with amount as

specified in the Oil Replacement Table.filter screen on the expansion valve should be re-

placed. If the evaporator assembly is flushed while

installed in the car, the temperature bulb on the

evaporator outlet pipe must be disconnected to keep

the expansion valve from closing at the inlet source.

FLUSHING THE SYSTEMIt is recommended that dry nitrogen be used as a

flushing agent due to the low cost involved. In addi-

tion, dry nitrogen will not cause a temperature drop,

as in the case of refrigerant-12, which results in

thickening of refrigerant oil. Dry nitrogen has the

additional advantage of removing moisture from thesystem.Flushing of the system may involve all the compo-

nents of the system or individual components in the

system. The components may be flushed while

mounted in the engine compartment or may be

removed for flushing. When a component is not

removed, disconnect all refrigerant lines or hoses

attached to component. To perform flushing operat-

ion, connect a cylinder of refrigerant-12 to the com-

ponent to be flushed, ,then invert the cylinder and

open the cylinder valve so that the liquid refrigerant

pours out and through the component. When liquid

Refrigerant-12 reaches atmospheric pressure, it im-

mediately drops to minus 21.7 degrees F. Insure that

area immediately surrounding outlet of component is

clear of anything that may be damaged by contact

because of the sudden drop in temperature.MAJOR REPAIR

REMOVAL AND INSTALLATION OF

COMPRESSOR

- OPEL 1900 - MANTA

Removal

I. Remove negative battery cable from battery.

2. Remove air cleaner and heat pipe. Cover the

carburetor to keep out dirt etc.

3. Discharge system. Refer to DISCHARGING

SYSTEM.

In all cases where a complete system flushing operat-4. While system is discharging remove sheet metal

ion is performed, the receiver-dehydrator and thecover. See Figure

9B-50.