warning light OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 19 of 625

CC-10 1973 OPEL SERVICE MANUAL

wiper blades. Check amount and direction of fluid

sprayed by washers during use.,

E. Defrosters - Check performance by moving con-

trols to “DEF” and noting

am$nmt of air directed

against the windshield.

I

F. Wheel Alignment and

Balabce - In addition to

abnormal tire wear, the need fbr wheel alignment

service may be indicated by a pull to the right or

!eftwhen driving on a straight and level road. The need

for wheel balancing is usually

iddicated by a vibra-

tion of the steering wheel or

se;+ tihile driving at

normal highway speeds.I

IG. Brakes

- Be alert to illumiriation of the brake

warning light or changes in braking action,

SUCK as

repeated pulling to one side, unusual sounds when

braking or increased brake pedal travel. Any of thesecould indicate the need for

brakk system inspection

and/or service.

H. Parking Brake and Transmission “PARK”

Mechanism

- Check parking brake holding ability by

parking on a fairly steep hill and restraining the vehi-

cle with the parking brake only.

eon cars with auto-

matic transmissions, check the holding ability of the

“PARK” mechanism by releasing all brakes after

the transmission selector lever hak been placed in the“P” position.

I. Glass

- Check for broken, scrritched, dirty or da-

maged glass on vehicle that

coulld obscure vision’or

become an injury hazard.

J. Lights and Buzzers

- Check all instrument panel

illuminating and warning lights,’ seat belt reminder

light and buzzer, ignition key

b&er, interior lights,

license plate lights, side marker! lights, headlamps,

parking lamps, tail lamps, brake lights, turn signals,

backup lamps, and hazard warding flashers. Have

someone observe operation of

&ach exterior light

while you activate the controls: The operation of

instrument panel warning lights is covered in the

“Starting and Operating“ section of your

Own&%

Manual.K. Transmission Shift Indicator

‘- Check to be sure

automatic transmission shift

indiCator accurately i”-

dicates the shift position selected.

I

CAUTION: Before making thk check below,I

be sure to have a clear dist&e ahead and:

behind the car, set the parking brake and

firmly apply the foot brake.

Do not depress

accelerator pedal. Be prepared to

turn off ’

ignition switch

immediat+y if engine

should start.L. Starter Safety Switch (Automatic Transmissibn

Cars)

- Check starter safety switch by placing the

transmission in each of the driving gears while

at-tempting to start the engine. The starter should oper-ate only in the Park (“P”) or Neutral (“N”)

positions.

M. Horn

- Blow the horn occasionally to be sure thatit works. (Ignition switch must be in the “ON” posi-

tion.)

N. Seat Back Latches

- Check to see that seat back

latches are holding by pulling forward on the top of

each folding seat back.

0. Rearview Mirrors and Sun Visors

- Check that

friction joints are properly adjusted so mirrors and

sun visors stay in the selected position.

P. Door Latches

- Check for positive closing, latch-

ing and locking.

Q. Hood Latches - Check to make sure hood closesfirmly by pressing on the hood at the latching point

after each closing. Check also for broken, damaged

or missing parts which might prevent secure latch-

ing.R. Fluid Leaks

- Check for fuel, water, oil or other

fluid leaks by observing the ground beneath the vehi-cle after it has been parked for a while. If gasoline

fumes or fluid are noticed at any time, the cause

should be determined and corrected without delay

because of the possibility of fire.

S. Exhaust System

- Be alert to any change in the

sound of the exhaust system or a smell of fumes

which may indicate a leak.

Head Restraints

- Check that no head restraint

components are missing, damaged or loose. (Does

not apply to GT Models).

Disc BrakesCheck brake pads and condition of rotors while

wheels are removed during tire rotation. (Note belowregarding more frequent checks also applies to disc

brakes.)

Parking and Drum BrakesCheck drum

brake linings and other internal brake

components at each wheel (drums, wheel cylinders,

etc.). Parking brake adjustment also should be

checked whenever drum brake linings are checked.

NOTE: More frequent checks should be

made if driving conditions a.nd habits result

in frequent brake application. When brakes

require relining, it is recommended thatyou use those genuine General Motors

parts specified for your car,and Delco fluid

as required.

Page 26 of 625

BATTERY AND CABLES - ALL MODELSlA- 5

and terminal connections should not exceed 2/10

volt.

5. Connedt voltmeter positive lead to ground on en-

gine.

At&h prod to voltmeter negative lead and

apply prod to center of battery negative post. Volt-

age drop across the battery ground cable and termi-

nal conne$tions should not exceed 2/10 volt at

200amps.

6. A reading in excess of 2/10 volt when testing

either battery cable indicates excessive resistance in

cable or cpnnections. Clean and tighten cable or con-

nections. Clean and tighten cable terminals

(sub-para. c, below) and recheck for voltage drop. If volt-

age drop Still exceeds 2/10 volt, replace cable with a

genuine Buick-Opel cable to insure ample capacity.

Undercharge Failure of BatteryThe most frequent trouble experienced with storage

batteries is failure to maintain a state of charge suffi-

cient to crank the engine and also furnish current to

the ignitibn system, lights and accessories. Failure to

maintain a proper state of charge may be due to one

or more of the following conditions:

1.

Opertiting Conditions. When determining cause

of premature failure of a battery, consideration must

be given /to the conditions under which the car is

operated.,

In very low temperatures the capacity of a storage

battery

ii considerably reduced and the energy re-

quired f& cranking the. engine is considerably in-

creased. :

Frequent starting, particularly in cold weather,

ac-compani

place in the limited running time. This condition is

aggravated by night driving when lights are turned

on, or by operation of an air conditioner in heavy

traffic.

When thk car is operated under these conditions,adjusting,the voltage regulator to the high limit may

allow enough increase to keep the battery at a safe

state of charge. If the high limit setting does not

maintain a safe state of charge, an occasional booster

charge should be given to the battery.

2. Low charging Rate. In case of premature battery

failure, tbe charging rate of alternator should always

be checked and adjusted if below specifications.

3.

Zntemd Condition The internal condition of the

battery niay be such that it cannot hold a chargesatisfactoiily. Check electrolyte level and test the

battery using the 421 Battery Test.

Overcharge Failure of BatteryA common cause of battery failure is overcharging,

that is, continued input of excessive charging current

after the battery has reached a fully charged condi-

tion.

One evidence that battery is being overcharged is the

need for frequent addition of water to the battery in

order to maintain the electrolyte level above the tops

of the battery separators, since overcharging causes

rapid water loss. When this becomes evident, the

charging rate of alternator should be immediately

checked, as well as the voltage regulator, and ad-

justed to avoid internal damage to battery.

ADJUSTMENTS AND MINOR SERVICEPERIODIC BATTERY INSPECTION AND SERVICE

The battery requires very little attention, but peri-

odic inspection is essential to secure the maximum

efficiency and life. The following services are essen-

tial to maintain the battery at maximum efficiency.

WARNING: Never expose battery to open flame or

electric spark

- battery action generates hydrogen gas

which is flammable and explosive. Do not allow bat-

tery fluid to contact skin, eyes, fabrics or painted

surfaces

- fluidis a sulfuric acid solution which could

cause serious personal injury or property damage.

Wear eye protection when working with battery.

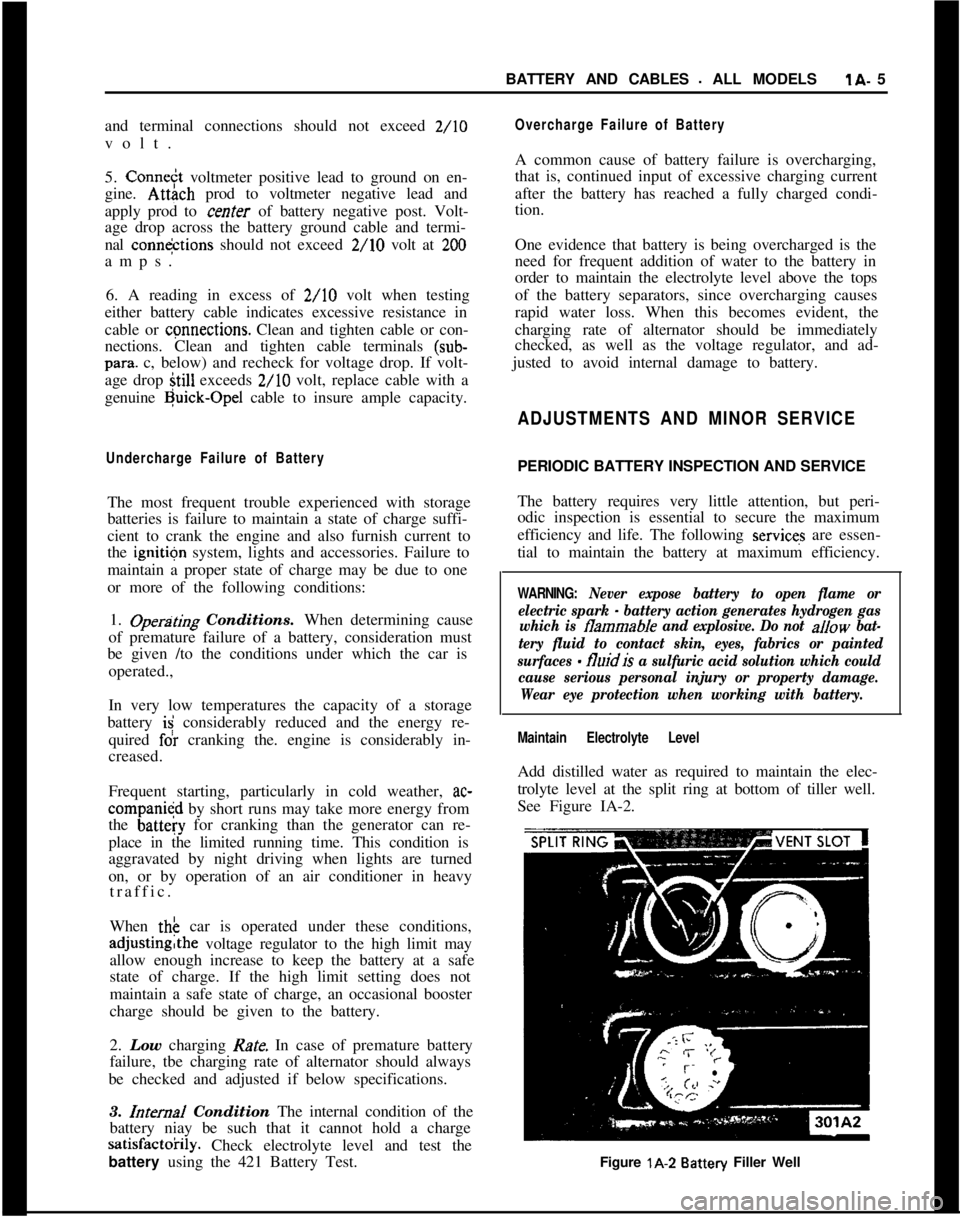

Maintain Electrolyte LevelAdd distilled water as required to maintain the elec-

trolyte level at the split ring at bottom of tiller well.

See Figure IA-2.

Figure lA-2

Battery Filler Well

Page 75 of 625

lG- 54 1973 OPEL SERVICE’ MANtiAL/SIGNAL SYSTEMSCdNTENTS

9Subject

DESCRIPTION AND OPERAT!ON:

Directional Signal Lever

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HazardWarning

Flasher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BrakeSystemWarningLight

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

SignalSystem,.......................

i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUS,TMENTS:

MAJOR REPAIR:

Directional Signal Switch

:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HornRemoval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removing Horn Contact

. . . . :.............................................

SPECIFICATIONS:

FuseChart. . . . . . I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

1 G-54

1 G-54

1 G-55

lG-55 _1 G-55

1 G-55

16-551 G-55

1 G-56

DESCRIPTION AND OPERATION

DIRECTIONAL SIGNAL LEVERThe direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal,

and high and low beams. See Figure

lG-1.301Gl

Figure lG-1 Directional Signal Position for Headlamp

OperationThe direction signal lever is provided with a

two-step mechanism for operation of headlight high and

low beams, and passing signal (not in New Jersey).

With headlights off, moving the lever repeatedly to-

wards steering wheel flashes headlights as a passing

signal. With headlights on, moving the lever repeat-

edly towards steering wheel up to first stop also

flashes passing signal regardless whether or not the

direcl:ion signals are switched on. When the lever is

moved up to the second stop, the headlights are

changed from high to low beam

dr vice versa. On all

Rallye cars, when switching from low to high beam

position, with the fog lamp instrument panel switch

“ON” and ignition switch in “RUN” position, the

fog lights are automatically

switChed off. Direction

signals work in the normal manner; pushing the lever

up for right turn signal and pulling the lever down

for left turn signal.

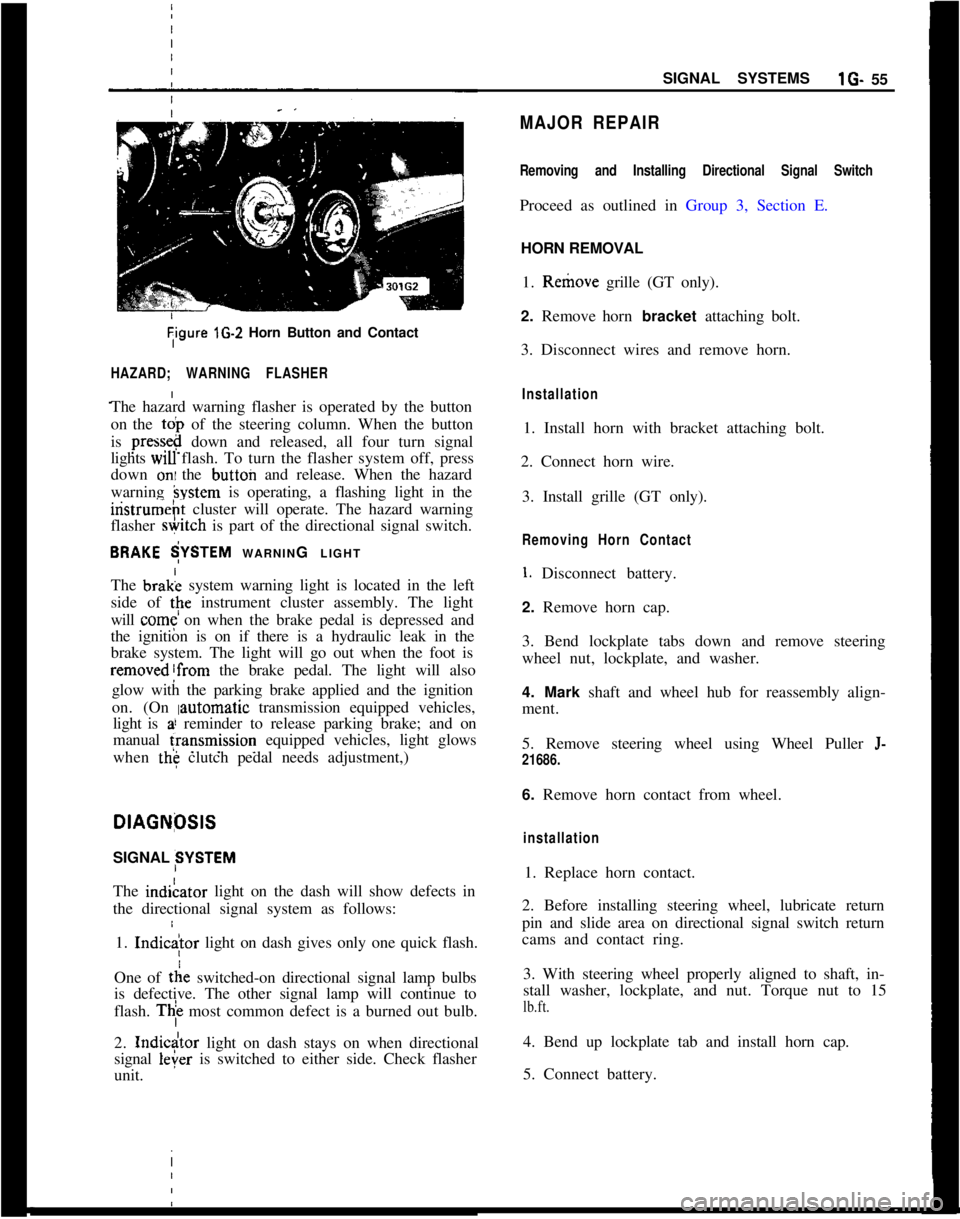

The horn button is located in the center part of the

steering wheel. The horn is actuated by pushing

down on the ends of both spokes on Opel 1900 andManta’s or on the center horn button on the Rallye.

The button is provided with a spring-loaded plunger.See Figure

lG-2.

Page 76 of 625

Tigure lG-2 Horn Button and Contact

HAZARD; WARNING FLASHER

The hazard warning flasher is operated by the button

on the

toi, of the steering column. When the button

is

press&@ down and released, all four turn signal

lights

WIU flash. To turn the flasher system off, press

down

oni the button and release. When the hazard

warning

hystem is operating, a flashing light in the

iristrumeht cluster will operate. The hazard warning

flasher

&itch is part of the directional signal switch.

BRAKE $YSTEM WARNING LIGHT

The brak; system warning light is located in the left

side of

tpe instrument cluster assembly. The light

will

come on when the brake pedal is depressed and

the ignition is on if there is a hydraulic leak in the

brake system. The light will go out when the foot is

removed!from the brake pedal. The light will also

glow with the parking brake applied and the ignition

on. (On

Iautomatic transmission equipped vehicles,

light is

a! reminder to release parking brake; and on

manual

fransmission equipped vehicles, light glows

when

the clutch pedal needs adjustment,)

I

DlAGNfXlS

SIGNAL SYSTEM

The indiLator light on the dash will show defects in

the directional signal system as follows:

1.

Indic

tie switched-on directional signal lamp bulbs

is defective. The other signal lamp will continue to

flash.

Thi most common defect is a burned out bulb.

2.

Indicdtor light on dash stays on when directional

signal

leier is switched to either side. Check flasher

unit. I

SIGNAL SYSTEMSlG- 55

MAJOR REPAIR

Removing and Installing Directional Signal Switch

Proceed as outlined in Group 3, Section E.

HORN REMOVAL

1. Remove grille (GT only).

2. Remove horn bracket attaching bolt.

3. Disconnect wires and remove horn.

Installation

1. Install horn with bracket attaching bolt.

2. Connect horn wire.

3. Install grille (GT only).

Removing Horn Contact

1. Disconnect battery.

2. Remove horn cap.

3. Bend lockplate tabs down and remove steering

wheel nut, lockplate, and washer.

4. Mark shaft and wheel hub for reassembly align-

ment.

5. Remove steering wheel using Wheel Puller

J-

21686.

6. Remove horn contact from wheel.

installation

1. Replace horn contact.

2. Before installing steering wheel, lubricate return

pin and slide area on directional signal switch return

cams and contact ring.

3. With steering wheel properly aligned to shaft, in-

stall washer, lockplate, and nut. Torque nut to 15

lb.ft.

4. Bend up lockplate tab and install horn cap.

5. Connect battery.

Page 77 of 625

:lG- 56 1973 OPEL SERVICE MANUAL

I

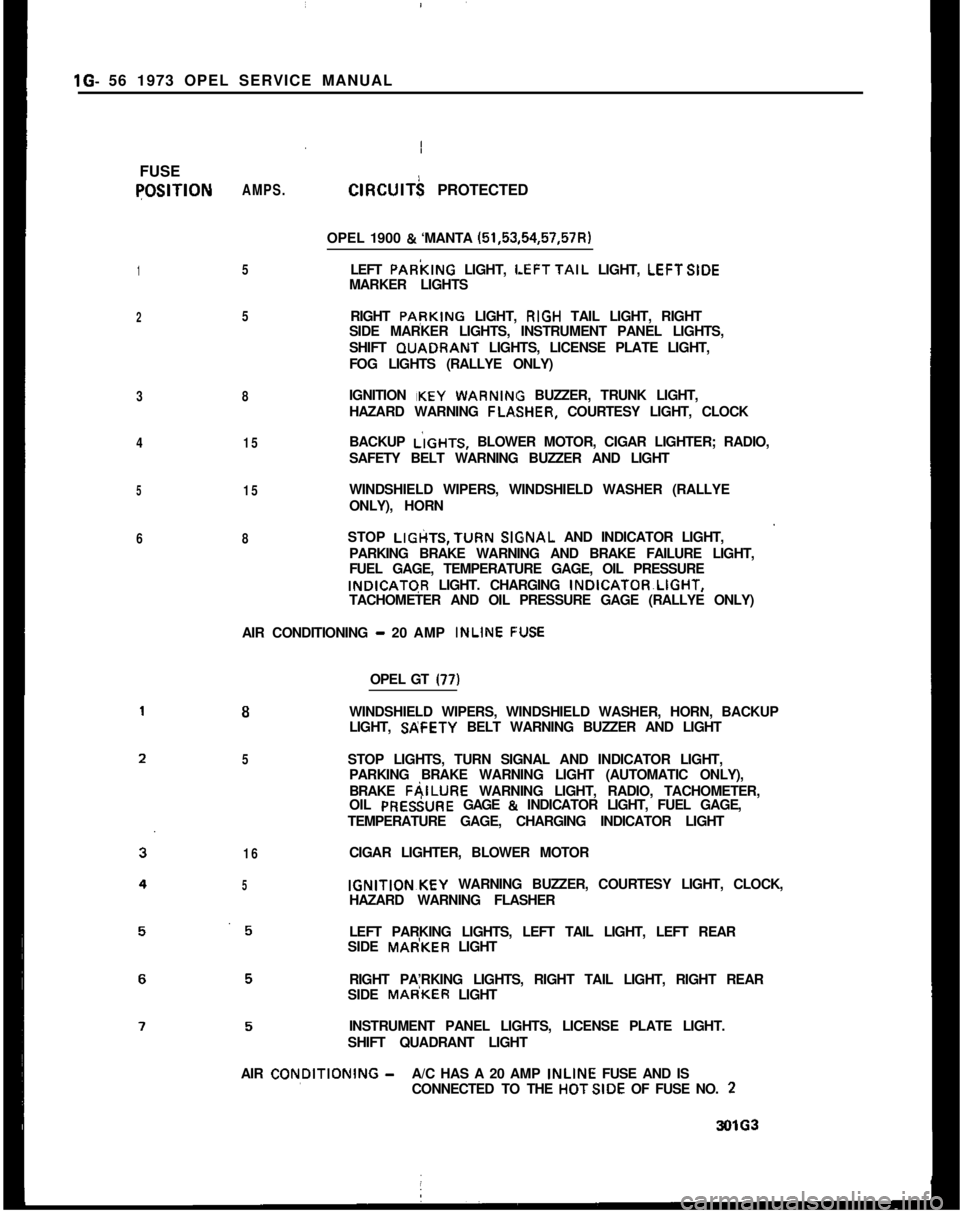

FUSEqOSlTlON

1

2

3

4

5

6AMPS.

5

5

8

15

15

8ClRClJlT$ PROTECTED

OPEL 1900

& ‘MANTA (51,53,54,57,57R)

LEFT PARkING LIGHT,

LEFTTAIL LIGHT, LEFTSIDE

MARKER LIGHTS

RIGHT PApKING LIGHT, RIGH TAIL LIGHT, RIGHT

SIDE MARKER LIGHTS, INSTRUMENT PANEL LIGHTS,

SHIFT GUADRANT LIGHTS, LICENSE PLATE LIGHT,

FOG LIGHTS (RALLYE ONLY)

IGNITION IKEY

WARNIN BUZZER, TRUNK LIGHT,

HAZARD WARNING FLA,SHER, COURTESY LIGHT, CLOCK

BACKUP L’IGHTS, BLOWER MOTOR, CIGAR LIGHTER; RADIO,

SAFETY BELT WARNING BUZZER AND LIGHT

WINDSHIELD WIPERS, WINDSHIELD WASHER (RALLYE

ONLY), HORN

STOP LIGtiTS,TURN

SlGsNAL AND INDICATOR LIGHT,

PARKING BRAKE WARNING AND BRAKE FAILURE LIGHT,

FUEL GAGE, TEMPERATURE GAGE, OIL PRESSUREINDICATGR LIGHT. CHARGING INDICATOR~LIGHT,

TACHOMETER AND OIL PRESSURE GAGE (RALLYE ONLY)

AIR CONDITIONING

- 20 AMP INLINE F:USE

8

5

16

5OPEL GT

(77)WINDSHIELD WIPERS, WINDSHIELD WASHER, HORN, BACKUP

LIGHT, SP;FETY BELT WARNING BUZZER AND LIGHT

STOP LIGHTS, TURN SIGNAL AND INDICATOR LIGHT,

PARKING BRAKE WARNING LIGHT (AUTOMATIC ONLY),

BRAKE FAILURE WARNING LIGHT, RADIO, TACHOMETER,

OIL PRESiURE GAGE

& INDICATOR LIGHT, FUEL GAGE,

TEMPERATURE GAGE, CHARGING INDICATOR LIGHT

CIGAR LIGHTER, BLOWER MOTORIGNITION~KEY WARNING BUZZER, COURTESY LIGHT, CLOCK,

HAZARD WARNING FLASHER

LEFT PARKING LIGHTS, LEFT TAIL LIGHT, LEFT REAR

SIDE MAdKER LIGHT

RIGHT PA’RKING LIGHTS, RIGHT TAIL LIGHT, RIGHT REAR

SIDE MAdKER LIGHT

INSTRUMENT PANEL LIGHTS, LICENSE PLATE LIGHT.

SHIFT QUADRANT LIGHT

AIR CON,DlTlONlNG

-A/C HAS A 20 AMP INLINE FUSE AND IS

CONNECTED TO THE HOTSIDE OF FUSE NO. 23OlG3

Page 79 of 625

1 H- 581973 OPEL SERVICE MANUAL

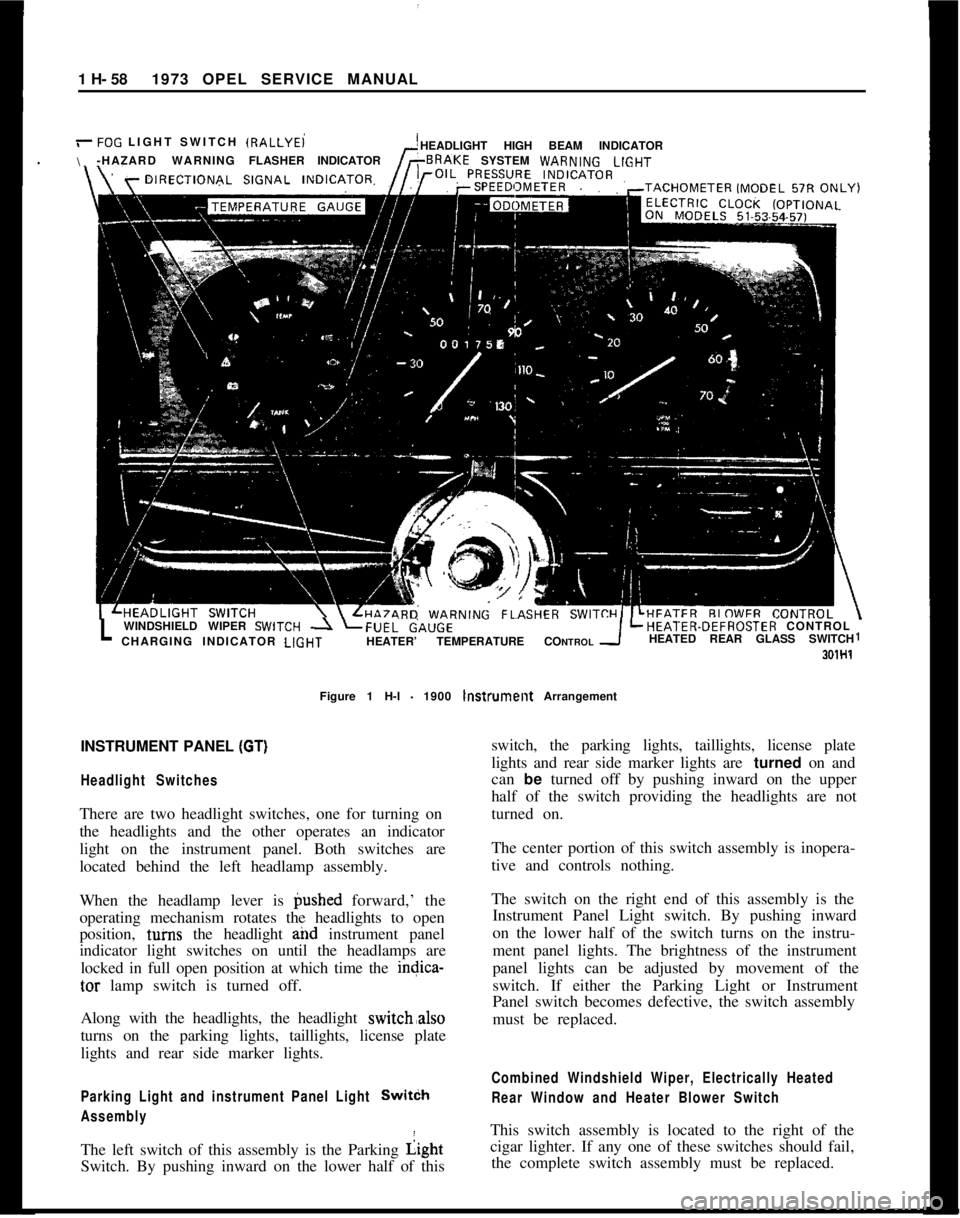

/-FOG LIGHT SWITCH IRALLYEi

\HEADLIGHT HIGH BEAM INDICATOR

-HAZARD WARNINGFLASHERINDICATORSYSTEM WARN,NGLlGHT

LWINDSHIELD WIPER SWlTCH -1 LFUEL&,UGELHEATER-DEFROSTER CONTROL

CHARGING INDICATOR LlGHTHEATER’ TEMPERATURE CONTROLHEATED REAR GLASS SWITCH1

301H1Figure 1 H-l

- 1900 lnstrumellt Arrangement

INSTRUMENT PANEL

(GT)I

Headlight SwitchesThere are two headlight switches, one for turning on

the headlights and the other operates an indicator

light on the instrument panel. Both switches are

located behind the left headlamp assembly.

When the headlamp lever is @shed forward,’ the

operating mechanism rotates the headlights to open

position, tuins the headlight and instrument panel

indicator light switches on until the headlamps are

locked in full open position at which time the indica-

tar lamp switch is turned off.

Along with the headlights, the headlight switch,also

turns on the parking lights, taillights, license plate

lights and rear side marker lights.

Parking Light and instrument Panel Light SwitCh

AssemblyThe left switch of this assembly is the Parking Light

Switch. By pushing inward on the lower half of thisswitch, the parking lights, taillights, license plate

lights and rear side marker lights are turned on and

can be turned off by pushing inward on the upper

half of the switch providing the headlights are not

turned on.

The center portion of this switch assembly is inopera-

tive and controls nothing.

The switch on the right end of this assembly is the

Instrument Panel Light switch. By pushing inward

on the lower half of the switch turns on the instru-

ment panel lights. The brightness of the instrument

panel lights can be adjusted by movement of the

switch. If either the Parking Light or Instrument

Panel switch becomes defective, the switch assembly

must be replaced.

Combined Windshield Wiper, Electrically Heated

Rear Window and Heater Blower SwitchThis switch assembly is located to the right of the

cigar lighter. If any one of these switches should fail,

the complete switch assembly must be replaced.

Page 80 of 625

/

I

IINSTRUMENT PANELlH- 59

Figure 1 H-2

- GT Instrument and Switch Arrangement

The Wihdshield Wipers have two-speed operation.

By pushing the lower half of the switch inward to the

first stop, the wipers will operate at half speed and

by deprbssing to the second stop will provide full

speed oieration. When the switch is returned to the

off posit/on, the wiper blades automatically return to

their park position.

I

The El

this optlpn. The engine must be running before

suffi-cient current can be generated to energize this circuit

even th6ugh the switch is depressed to the “ON”

position! When the window is being heated, a warm-

ing light’on the instrument panel will glow. This light

is locate? below the left ventilation inlet.

The

Heiter Blower Switch is a three position switch.

By depressing the lower half of the switch to the first

stop,

th& blower will operate at low speed. Whendepressdd to the second stop, the blower will operate

at high ipeed.

Four Way Hezrerd Warning Flasher SwitchThe

hazard warning flasher switch is located below

the heater controls in the center console. By

depress-ing the lower half of the switch, all four turn- signal

lamps flash at the same time. Although this system

makes use of the regulat turn signal system, it has a

separate feed wire to the switch which allows for its

operation even with the ignition switch and doors

locked. No vehicle should be driven with this system

in operation because of its universal meaning “This

Vehicle Is Not Moving”. To turn the system off,

simply depress the upper half of the switch.

MAJOR REPAIR

Removal of Instrument Cluster Housing Assembly.Opel 1900 Manta

Before starting any instrument panel repair, always

disconnect battery ground cable first.

I

Page 93 of 625

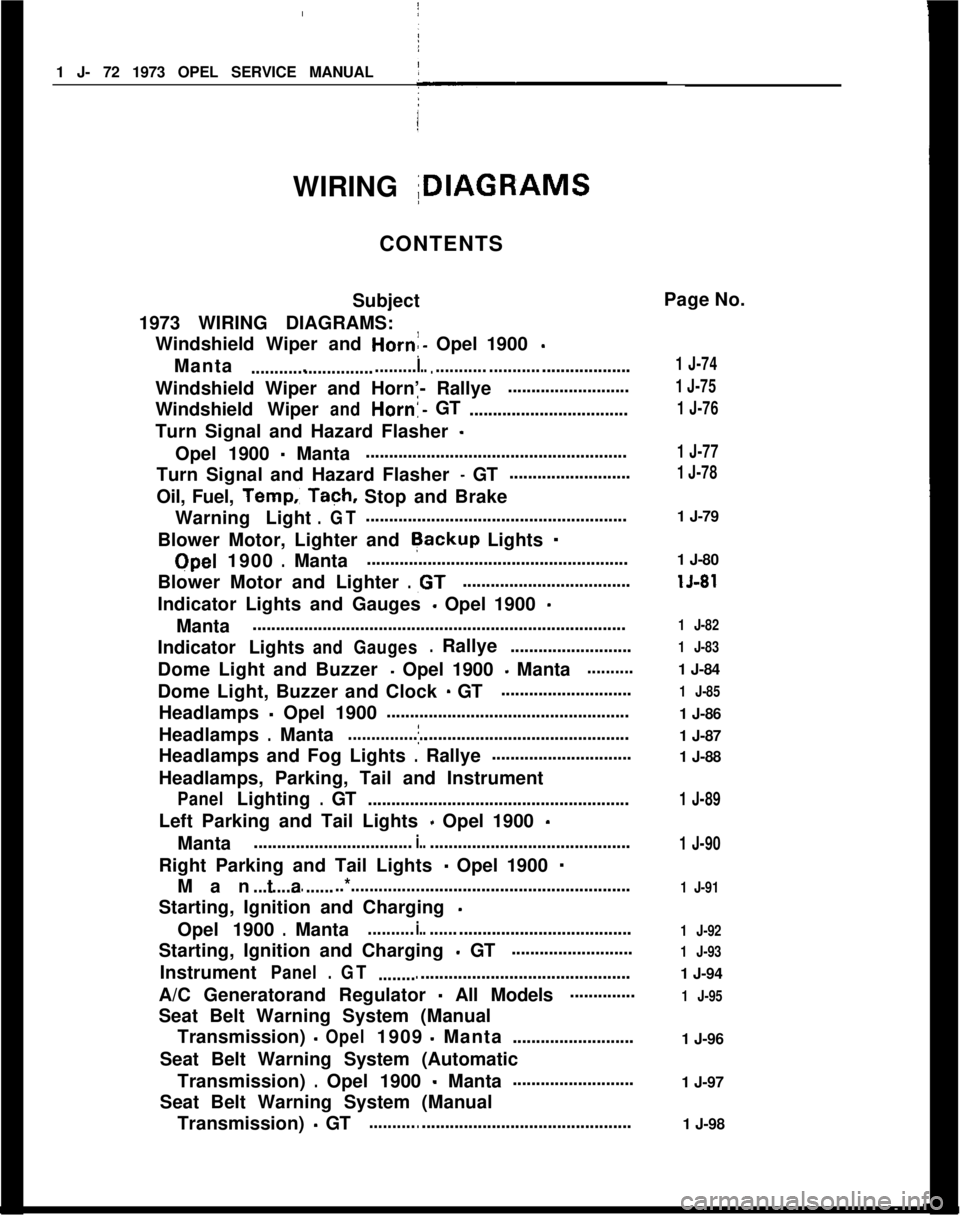

1 J- 72 1973 OPEL SERVICE MANUAL

I

WIRING IDIAGRAMS

CONTENTS

Subject

1973 WIRING DIAGRAMS: Windshield Wiper and

Horn:- Opel 1900 -

Manta....................................I.............. ..............................

Windshield Wiper and Horn’- Rallye ..........................

Windshield Wiper

andHorn!-GT

..................................

Turn Signal and Hazard Flasher

-

Opel 1900 - Manta !

........................................................

Turn Signal and Hazard Flasher

- GT ..........................

Oil, Fuel,

Temp.: Tach, Stop and Brake

Warning Light

.GT........................................................

Blower Motor, Lighter and

Rackup Lights -

Qpel 1900.Manta ........................................................

Blower Motor and Lighter

.,GT....................................

Indicator Lights and Gauges

- Opel 1900 -

Manta ........................................................................\

........

Indicator Lights

andGauges.Rallye ..........................

Dome Light and Buzzer

- Opel 1900 - Manta..........

Dome Light, Buzzer and Clock - GT ............................

Headlamps

- Opel 1900 ’

....................................................

Headlamps

.Mantaj............................................................

Headlamps and Fog Lights

.Rallye ..............................

Headlamps, Parking, Tail and Instrument

PanelLighting.GT ........................................................

Left Parking and Tail Lights

- Opel 1900 -

Manta ..................................i.............................................

Right Parking and Tail Lights

- Opel 1900 -

Manta................. ..*............................................................

Starting, Ignition and Charging

-

Opel 1900.Manta..........i.............................................

Starting, Ignition and Charging

- GT ..........................

Instrument

Panel.GT ......................................................

A/C Generatorand Regulator

- All Models..............

Seat Belt Warning System (Manual Transmission)

-Opel1909-Manta ..........................

Seat Belt Warning System (Automatic Transmission)

.Opel 1900 - Manta..........................

Seat Belt Warning System (Manual Transmission)

- GT........................................................ Page No.

1 J-74

1 J-75

1 J-76

1 J-77

1 J-78

1 J-79

1 J-80

lJ-81

1 J-82

1 J-83

1 J-84

1 J-85

1 J-86

1 J-87

1 J-88

1 J-89

1 J-90

1 J-91

1 J-92

1 J-93

1 J-94

1 J-95

1 J-96

1 J-97

1 J-98

Page 100 of 625

I

WIRING DIAGRAMS15.79

IIFigure lJ-6

Oil. Fuel. Temp. Tach, Stop and Brake Warning Light. GT

I

Page 273 of 625

5B- 141973 OPEL SERVICE MANUALConditionPossible CauseCorrection2. Partial system failure.2. Check front and rear brake system

and repair, if necessary. Also, check

brake warning light, if a failed

system is found and light did not

function.

3. Excessively worn shoe

and lining.3. Check and replace in axle sets.

4. Piston in caliper stuck

or sluggish.4. Remove caliper and rebuild.

5. Fading brakes due to

incorrect lining.

6. Vacuum leak.5. Remove and replace with original

equipment lining.

6. Check for ruptured hose or loose

attachment.

Excessive Pedal Travel1. Partial brake system

failure.1. Check both front and rear system

for a failure and repair. Also, check

warning light

- it should have indi-

cated a failure.

2. Insufficient fluid in

master cylinder.

3. Poor rear brake

adjustment.2. Fill reservoirs with approved

brake fluid. Check for leaks.

3. Adjust rear brake per

specifications.

4. Air trapped in system.4. Bleed system.

5. Bent shoe and lining.5. Replace axle set of shoe and

lining.

Dragging Brakes (A very

light drag is present in

all disc brakes

immediately after pedal

is released.)1. Master cylinder pistons

not returning correctly.1. With reservoir cover off, check

for fluid spurt at bypass holes as

pedal is depressed. Adjust push rod,

if necessary, or rebuild master

cylinder.

2. Restricted brake tubes2. Check for soft hoses or damaged

or hoses.tubes and replace with new hoses and

new double-walled steel brake tubing.

3. Incorrect parking brake

adjustment on rear brakes.3. Check and readjust to correct

specifications.

Grabbing or Uneven Braking

Action (All conditions

listed under “Pulls”

.)4. Check valve installed in

outlet to front disc brakes.

1. Malfunction of power

brake unit.4. Check master cylinder outlet and

remove check valve if present.

1. Check operation and repair, if

necessary.