ignition PEUGEOT 208 2021 Manual Online

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2021, Model line: 208, Model: PEUGEOT 208 2021Pages: 276, PDF Size: 8.02 MB

Page 157 of 276

155

Practical information

7All work must be carried out only by a

PEUGEOT dealer or a qualified workshop

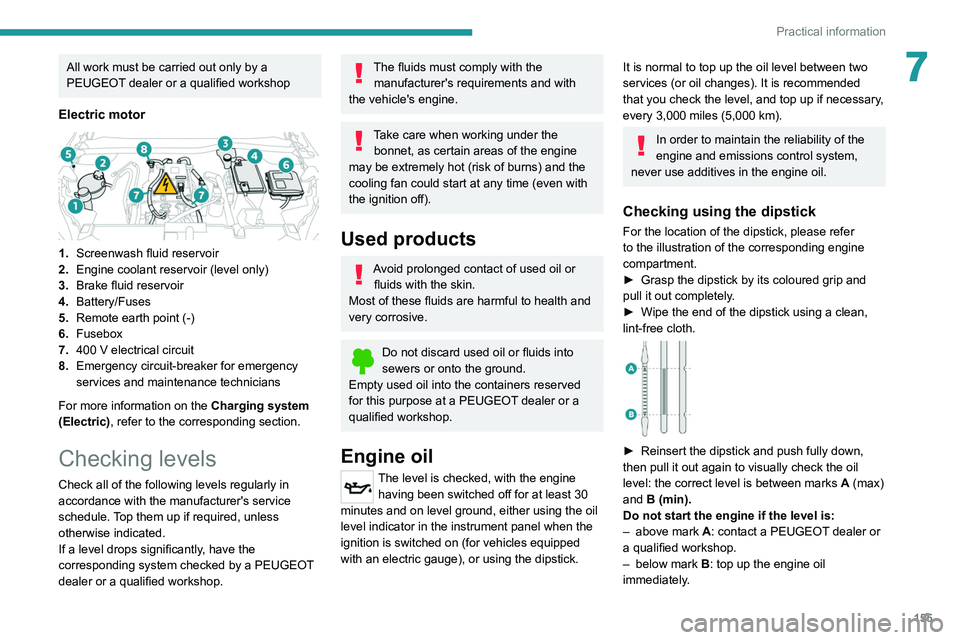

Electric motor

1.Screenwash fluid reservoir

2. Engine coolant reservoir (level only)

3. Brake fluid reservoir

4. Battery/Fuses

5. Remote earth point (-)

6. Fusebox

7. 400

V electrical circuit

8. Emergency circuit-breaker for emergency

services and maintenance technicians

For more information on the Charging system

(Electric), refer to the corresponding section.

Checking levels

Check all of the following levels regularly in

accordance with the manufacturer's service

schedule. Top them up if required, unless

otherwise indicated.

If a level drops significantly, have the

corresponding system checked by a PEUGEOT

dealer or a qualified workshop.

The fluids must comply with the manufacturer's requirements and with

the vehicle's engine.

Take care when working under the bonnet, as certain areas of the engine

may be extremely hot (risk of burns) and the

cooling fan could start at any time (even with

the ignition off).

Used products

Avoid prolonged contact of used oil or fluids with the skin.

Most of these fluids are harmful to health and

very corrosive.

Do not discard used oil or fluids into

sewers or onto the ground.

Empty used oil into the containers reserved

for this purpose at a PEUGEOT dealer or a

qualified workshop.

Engine oil

The level is checked, with the engine having been switched off for at least 30

minutes and on level ground, either using the oil

level indicator in the instrument panel when the

ignition is switched on (for vehicles equipped

with an electric gauge), or using the dipstick.

It is normal to top up the oil level between two

services (or oil changes). It is recommended

that you check the level, and top up if necessary,

every 3,000 miles (5,000 km).

In order to maintain the reliability of the

engine and emissions control system,

never use additives in the engine oil.

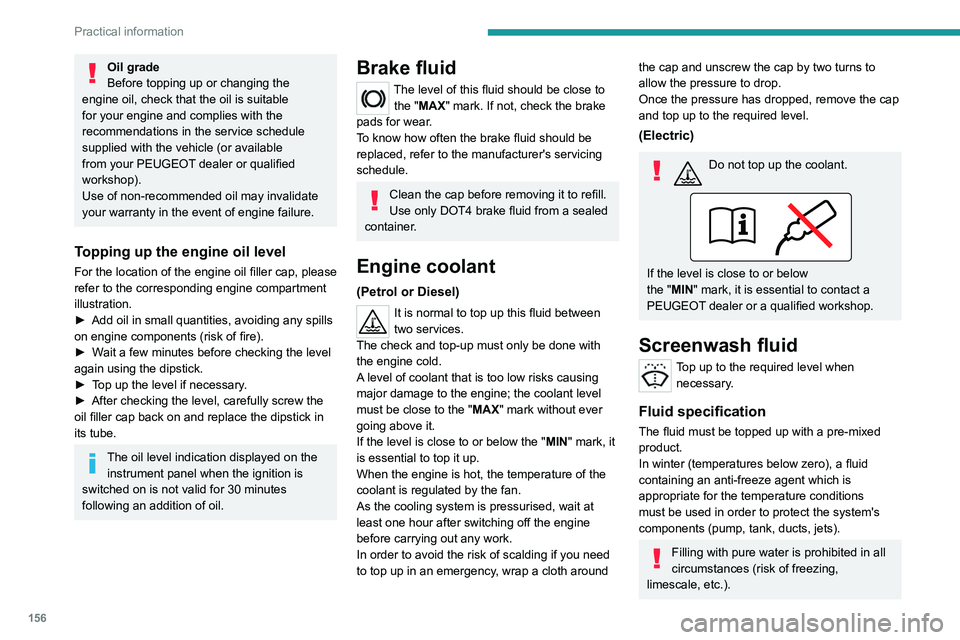

Checking using the dipstick

For the location of the dipstick, please refer

to the illustration of the corresponding engine

compartment.

►

Grasp the dipstick by its coloured grip and

pull it out completely

.

►

Wipe the end of the dipstick using a clean,

lint-free cloth.

► Reinsert the dipstick and push fully down,

then pull it out again to visually check the oil

level: the correct level is between marks A

(max)

and B (min).

Do not start the engine if the level is:

–

above mark

A: contact a PEUGEOT dealer or

a qualified workshop.

–

below mark B

: top up the engine oil

immediately.

Page 158 of 276

156

Practical information

AdBlue® (BlueHDi)

An alert is triggered when the reserve level is

reached.

For more information on the Indicators and in

particular the AdBlue range indicators, refer to

the corresponding section.

To avoid the vehicle being immobilised in

accordance with regulations, you must top up the

AdBlue tank.

For more information on AdBlue

® (BlueHDi),

and in particular the supply of AdBlue, refer to

the corresponding section.

Checks

Unless otherwise indicated, check these

components in accordance with the

manufacturer's service schedule and according

to your engine.

Otherwise, have them checked by a PEUGEOT

dealer or a qualified workshop.

Only use products recommended by

PEUGEOT or products of equivalent

quality and specification.

In order to optimise the operation of

components as important as those in the

braking system, PEUGEOT selects and offers

very specific products.

Oil grade

Before topping up or changing the

engine oil, check that the oil is suitable

for your engine and complies with the

recommendations in the service schedule

supplied with the vehicle (or available

from your PEUGEOT dealer or qualified

workshop).

Use of non-recommended oil may invalidate

your warranty in the event of engine failure.

Topping up the engine oil level

For the location of the engine oil filler cap, please

refer to the corresponding engine compartment

illustration.

►

Add oil in small quantities, avoiding any spills

on engine components (risk of fire).

►

W

ait a few minutes before checking the level

again using the dipstick.

►

T

op up the level if necessary.

►

After checking the level, carefully screw the

oil filler cap back on

and replace the dipstick in

its tube.

The oil level indication displayed on the instrument panel when the ignition is

switched on is not valid for 30 minutes

following an addition of oil.

Brake fluid

The level of this fluid should be close to

the "MAX" mark. If not, check the brake

pads for wear.

To know how often the brake fluid should be

replaced, refer to the manufacturer's servicing

schedule.

Clean the cap before removing it to refill.

Use only DOT4 brake fluid from a sealed

container.

Engine coolant

(Petrol or Diesel)

It is normal to top up this fluid between

two services.

The check and top-up must only be done with

the engine cold.

A level of coolant that is too low risks causing

major damage to the engine; the coolant level

must be close to the "MAX" mark without ever

going above it.

If the level is close to or below the " MIN" mark, it

is essential to top it up.

When the engine is hot, the temperature of the

coolant is regulated by the fan.

As the cooling system is pressurised, wait at

least one hour after switching off the engine

before carrying out any work.

In order to avoid the risk of scalding if you need

to top up in an emergency, wrap a cloth around

the cap and unscrew the cap by two turns to

allow the pressure to drop.

Once the pressure has dropped, remove the cap

and top up to the required level.

(Electric)

Do not top up the coolant.

If the level is close to or below

the "MIN" mark, it is essential to contact a

PEUGEOT dealer or a qualified workshop.

Screenwash fluid

Top up to the required level when necessary.

Fluid specification

The fluid must be topped up with a pre-mixed

product.

In winter (temperatures below zero), a fluid

containing an anti-freeze agent which is

appropriate for the temperature conditions

must be used in order to protect the system's

components (pump, tank, ducts, jets).

Filling with pure water is prohibited in all

circumstances (risk of freezing,

limescale, etc.).

Page 162 of 276

160

Practical information

Free-wheeling

In certain situations, it is necessary to put the

vehicle into free-wheeling mode (e.g. towing, on

a rolling road, automatic car wash (Wash mode),

rail or sea transport).

The procedure varies according to the type of

gearbox and parking brake.

With manual or EAT6

automatic gearbox and

electric parking brake

/

To release them

► With the engine running and while depressing

the brake pedal, move the gear selector to the

neutral position.

► While depressing the brake pedal, switch off

the ignition.

► Release the brake pedal, then switch on the

ignition again.

► While depressing the brake pedal, press the

control to release the parking brake.

► Release the brake pedal, then switch off the

ignition.

Reverting to normal operation

► While depressing the brake pedal, restart the

engine.

Precautions for use

AdBlue® is a urea-based solution. This fluid is

non-flammable, colourless and odourless (when

kept in a cool place).

In the event of contact with the skin, wash the

affected area with soap and running water. In the

event of contact with the eyes, immediately rinse

the eyes with large amounts of water or with an

eye wash solution for at least 15 minutes. Seek

medical attention if you feel a persistent burning

sensation or irritation.

If swallowed, immediately wash out the mouth

with clean water and then drink plenty of water.

In certain conditions (high temperature, for

example), the risk of release of ammonia cannot

be excluded: do not inhale the fluid. Ammonia

vapours have an irritant effect on mucous

membranes (eyes, nose and throat).

Store AdBlue® out of the reach of

children, in its original container.

Procedure

Before starting the top-up procedure, ensure that

the vehicle is parked on a flat and level surface.

In wintry conditions, ensure that the temperature

of the vehicle is above -11°C. Otherwise the

AdBlue

® may be frozen and so cannot be poured

into the tank. Park the vehicle in a warmer area

for a few hours to allow the top-up to be carried

out.

Never pour the AdBlue® into the Diesel

fuel tank.

If any AdBlue® is splashed, or if there are

any spillages on the bodywork, rinse

immediately with cold water or wipe with a

damp cloth.

If the fluid has crystallised, clean it off using a

sponge and hot water.

Important: in the event of a top-up after

a breakdown because of a lack of

AdBlue, it is essential to wait around 5

minutes before switching on the ignition,

without opening the driver’s door,

unlocking the vehicle, inserting the key

into the ignition switch, or bringing the

key for the "Keyless Entry and Starting"

system into the passenger compartment.

Switch on the ignition, then wait for 10

seconds before starting the engine.

►

Switch off the ignition and remove the key

from the switch to switch off the engine.

or

►

With Keyless Entry and Starting, press the

"

START/STOP" button to switch off the engine.

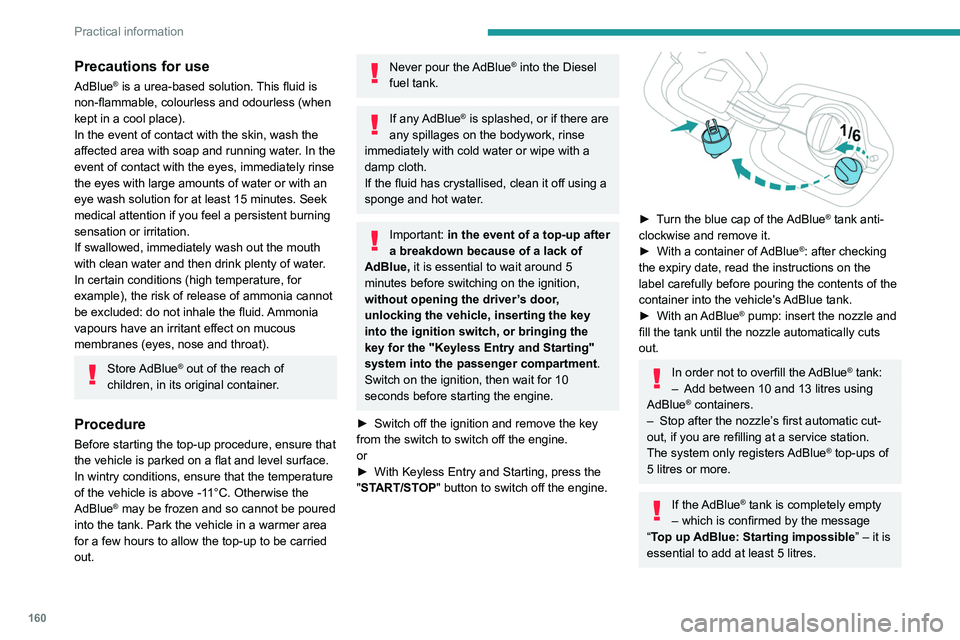

► Turn the blue cap of the AdBlue® tank anti-

clockwise and remove it.

►

With a container of

AdBlue

®: after checking

the expiry date, read the instructions on the

label carefully before pouring the contents of the

container into the vehicle's AdBlue tank.

►

With an

AdBlue® pump: insert the nozzle and

fill the tank until the nozzle automatically cuts

out.

In order not to overfill the AdBlue® tank:

–

Add between 10 and 13 litres using

AdBlue® containers.

–

Stop after the nozzle’ s first automatic cut-

out, if you are refilling at a service station.

The system only registers AdBlue

® top-ups of

5

litres or more.

If the AdBlue® tank is completely empty

– which is confirmed by the message

“Top up

AdBlue: Starting impossible ” – it is

essential to add at least 5 litres.

Page 163 of 276

161

Practical information

7Free-wheeling

In certain situations, it is necessary to put the

vehicle into free-wheeling mode (e.g. towing, on

a rolling road, automatic car wash (Wash mode),

rail or sea transport).

The procedure varies according to the type of

gearbox and parking brake.

With manual or EAT6

automatic gearbox and

electric parking brake

/

To release them

► With the engine running and while depressing

the brake pedal, move the gear selector to the

neutral position.

►

While depressing the brake pedal, switch off

the ignition.

►

Release the brake pedal, then switch on the

ignition again.

►

While depressing the brake pedal, press the

control to release the parking brake.

►

Release the brake pedal, then switch off the

ignition.

Reverting to normal operation

► While depressing the brake pedal, restart the

engine.

With EAT8 automatic

gearbox and manual parking

brake

/

Release procedure

► With the vehicle stationary and the engine

running, select mode N and switch off the

ignition.

Within 5

seconds:

►

Switch on the ignition again.

►

While depressing the brake pedal, move the

push selector forwards or backwards to confirm

mode

N.

►

Switch off the ignition.

If the 5-second time limit is exceeded, the

gearbox engages mode P

; it is then necessary to

restart the procedure.

Reverting to normal operation

► Press button P on the selector.

With EAT8 automatic

gearbox or drive selector

and electric parking brake

/

Release procedure

► With the vehicle stationary and the engine

running, select mode N and switch off the

ignition.

Within 5

seconds:

►

Switch on the ignition again.

►

While depressing the brake pedal, move the

push selector forwards or backwards to confirm

mode

N.

►

While depressing the brake pedal, press the

control to release the parking brake.

►

Release the brake pedal, switch off the

ignition.

If the 5-second time limit is exceeded, the

gearbox engages mode P

; it is then necessary to

restart the procedure.

Reverting to normal operation

► While depressing the brake pedal, restart the

engine.

Keyless Entry and Starting

You must not depress the brake pedal

while switching the ignition on again, then

switching it off. If you do, the engine will start,

requiring you to restart the procedure.

Page 166 of 276

164

In the event of a breakdown

Warning triangle

This reflective and dismantlable device is to be

installed on the side of the road when a vehicle

is broken down or damaged.

Before getting out of the vehicle

Turn on the hazard warning lamps, then

put on the safety vest to assemble and install

the triangle.

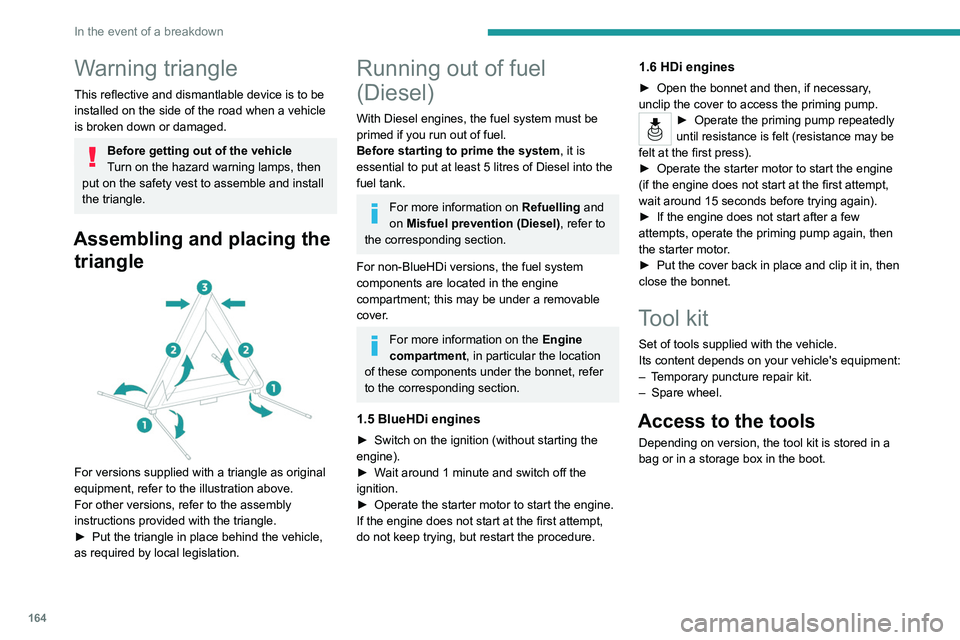

Assembling and placing the triangle

For versions supplied with a triangle as original

equipment, refer to the illustration above.

For other versions, refer to the assembly

instructions provided with the triangle.

►

Put the triangle in place behind the vehicle,

as required by local legislation.

Running out of fuel

(Diesel)

With Diesel engines, the fuel system must be

primed if you run out of fuel.

Before starting to prime the system, it is

essential to put at least 5 litres of Diesel into the

fuel tank.

For more information on Refuelling and

on Misfuel prevention (Diesel), refer to

the corresponding section.

For non-BlueHDi versions, the fuel system

components are located in the engine

compartment; this may be under a removable

cover.

For more information on the Engine

compartment, in particular the location

of these components under the bonnet, refer

to the corresponding section.

1.5 BlueHDi engines

► Switch on the ignition (without starting the

engine).

►

W

ait around 1 minute and switch off the

ignition.

►

Operate the starter motor to start the engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

1.6 HDi engines

► Open the bonnet and then, if necessary ,

unclip the cover to access the priming pump.

► Operate the priming pump repeatedly

until resistance is felt (resistance may be

felt at the first press).

►

Operate the starter motor to start the engine

(if the engine does not start at the first attempt,

wait around 15 seconds before trying again).

►

If the engine does not start after a few

attempts, operate the priming pump again, then

the starter motor

.

►

Put the cover back in place and clip it in, then

close the bonnet.

Tool kit

Set of tools supplied with the vehicle.

Its content depends on your vehicle's equipment:

–

T

emporary puncture repair kit.

–

Spare wheel.

Access to the tools

Depending on version, the tool kit is stored in a

bag or in a storage box in the boot.

On the boot carpet

Under the boot carpet

► Raise the boot carpet by pulling the strap to

access the tools.

With temporary puncture repair kit

Page 168 of 276

166

In the event of a breakdown

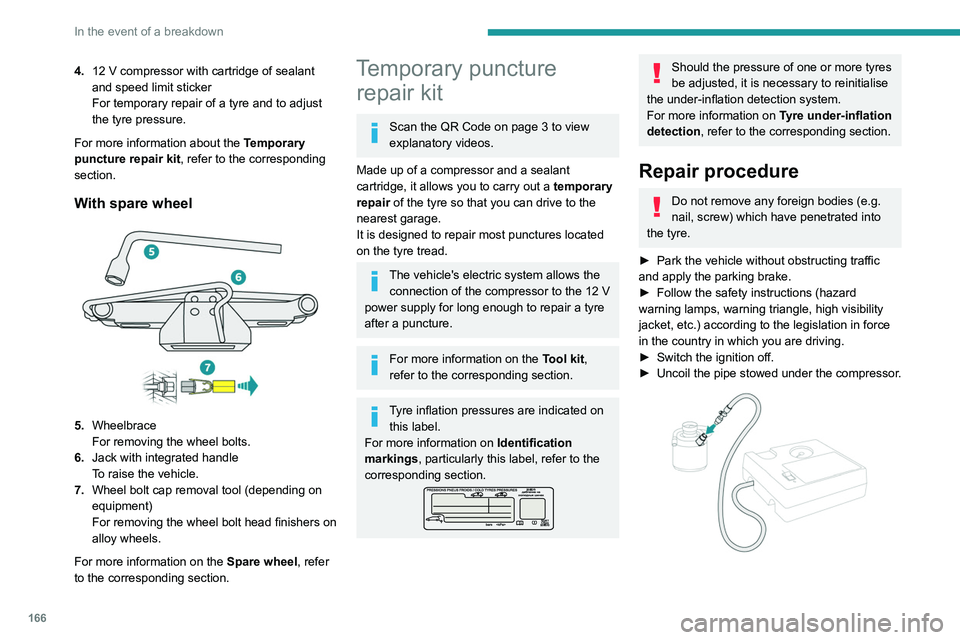

4.12 V compressor with cartridge of sealant

and speed limit sticker

For temporary repair of a tyre and to adjust

the tyre pressure.

For more information about the Temporary

puncture repair kit, refer to the corresponding

section.

With spare wheel

5. Wheelbrace

For removing the wheel bolts.

6. Jack with integrated handle

To raise the vehicle.

7. Wheel bolt cap removal tool (depending on

equipment)

For removing the wheel bolt head finishers on

alloy wheels.

For more information on the Spare wheel, refer

to the corresponding section.

Temporary puncture repair kit

Scan the QR Code on page 3 to view

explanatory videos.

Made up of a compressor and a sealant

cartridge,

it allows you to carry out a temporary

repair of the tyre so that you can drive to the

nearest garage.

It is designed to repair most punctures located

on the tyre tread.

The vehicle's electric system allows the connection of the compressor to the 12 V

power supply for long enough to repair a tyre

after a puncture.

For more information on the Tool kit,

refer to the corresponding section.

Tyre inflation pressures are indicated on this label.

For more information on Identification

markings, particularly this label, refer to the

corresponding section.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-inflation

detection, refer to the corresponding section.

Repair procedure

Do not remove any foreign bodies (e.g.

nail, screw) which have penetrated into

the tyre.

►

Park the vehicle without obstructing traffic

and apply the parking brake.

►

Follow the safety instructions (hazard

warning lamps, warning triangle, high visibility

jacket, etc.) according to the legislation in force

in the country in which you are driving.

►

Switch the ignition off.

►

Uncoil

the pipe stowed under the compressor.

Page 169 of 276

167

In the event of a breakdown

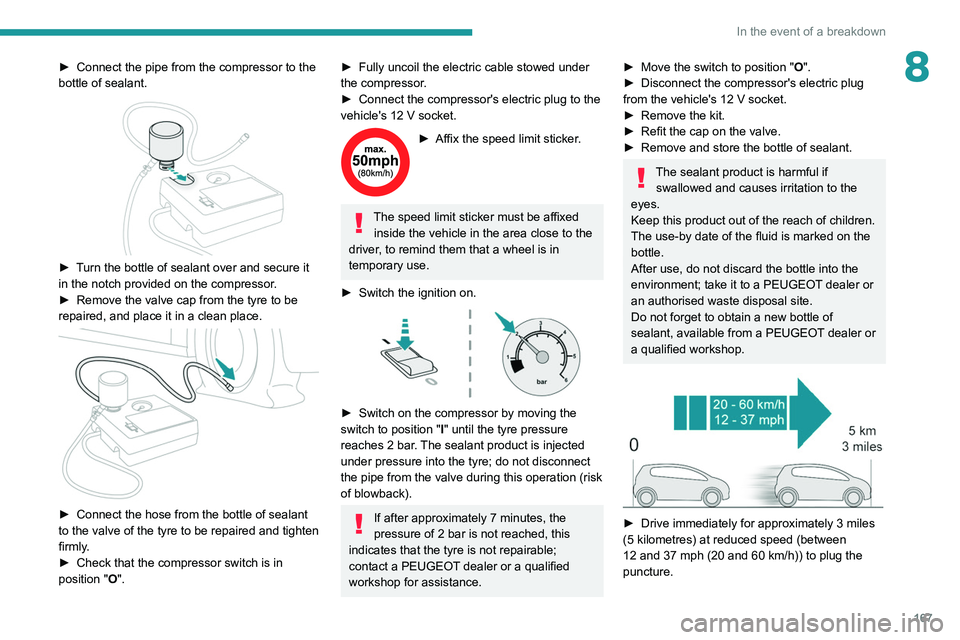

8► Connect the pipe from the compressor to the

bottle of sealant.

► Turn the bottle of sealant over and secure it

in the notch provided on the compressor.

►

Remove the valve cap from the tyre to be

repaired, and place it in a clean place.

► Connect the hose from the bottle of sealant

to the valve of the tyre to be repaired and tighten

firmly

.

►

Check that the compressor switch is in

position

"O".

► Fully uncoil the electric cable stowed under

the compressor .

►

Connect the compressor's electric plug to the

vehicle's 12

V socket.

► Affix the speed limit sticker .

The speed limit sticker must be affixed

inside the vehicle in the area close to the

driver, to remind them that a wheel is in

temporary use.

►

Switch the ignition on.

► Switch on the compressor by moving the

switch to position " I

" until the tyre pressure

reaches 2 bar. The sealant product is injected

under pressure into the tyre; do not disconnect

the pipe from the valve during this operation (risk

of blowback).

If after approximately 7 minutes, the

pressure of 2 bar is not reached, this

indicates that the tyre is not repairable;

contact a PEUGEOT dealer or a qualified

workshop for assistance.

► Move the switch to position " O ".

► Disconnect the compressor's electric plug

from the vehicle's 12

V socket.

►

Remove the kit.

►

Refit the cap on the valve.

►

Remove and store the bottle of sealant.

The sealant product is harmful if swallowed and causes irritation to the

eyes.

Keep this product out of the reach of children.

The use-by date of the fluid is marked on the

bottle.

After use, do not discard the bottle into the

environment; take it to a PEUGEOT dealer or

an authorised waste disposal site.

Do not forget to obtain a new bottle of

sealant, available from a PEUGEOT dealer or

a qualified workshop.

► Drive immediately for approximately 3 miles

(5 kilometres) at reduced speed (between

12 and 37 mph (20 and 60

km/h)) to plug the

puncture.

Page 170 of 276

168

In the event of a breakdown

► Stop to check the repair and the tyre

pressure using the kit.

With a tyre repaired using this type of kit,

do not exceed a speed of 50

mph

(80

km/h) and do not drive more than

50

miles (80 km).

You must contact a PEUGEOT dealer or a

qualified workshop to have the repair checked

and the tyre changed.

Checking/adjusting tyre

pressures

The compressor can be used, without injecting

sealant, to check and, if necessary, adjust the

tyre pressures.

►

Remove the valve cap from the tyre and keep

it in a clean place.

►

Uncoil

the pipe stowed under the compressor.

►

Screw the pipe onto the valve and tighten

firmly

.

►

Check that the compressor switch is in

position " O

".

►

Fully uncoil the electric cable stowed under

the compressor

.

►

Connect the compressor's electric plug to the

vehicle's 12

V socket.

►

Switch the ignition on.

►

Start the compressor by placing the switch at

position " I

" and adjust the pressure to the value

shown on the vehicle's tyre pressure label. To

deflate: press the black button located on the

compressor pipe, near the valve connection.

If after 7 minutes the pressure of 2 bar is

not reached, the tyre is damaged;

contact a PEUGEOT dealer or a qualified

workshop for assistance.

►

Once the correct pressure is reached, put the

switch in position " O

".

►

Remove the kit and stow it.

►

Refit the cap on the valve.

Spare wheel

Scan the QR Code on page 3 to view

explanatory videos.

For more information on the Tool kit,

refer to the corresponding section.

Spare wheel tyre pressure

The inflation pressure for the spare

wheel is indicated on the tyre pressure label

- ensure that its inflation pressure is checked

regularly.

For more information on Identification

markings, particularly the tyre pressure label,

refer to the corresponding section.

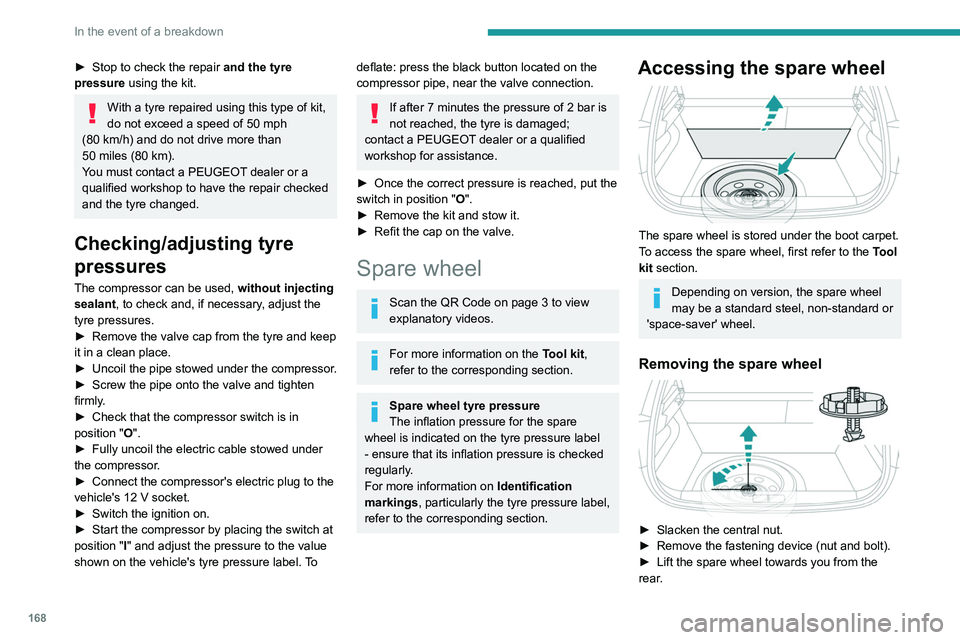

Accessing the spare wheel

The spare wheel is stored under the boot carpet.

To access the spare wheel, first refer to the Tool

kit

section.

Depending on version, the spare wheel

may be a standard steel, non-standard or

'space-saver' wheel.

Removing the spare wheel

► Slacken the central nut.

► Remove the fastening device (nut and bolt).

►

Lift the spare wheel towards you from the

rear

.

► Take the wheel out of the boot.

Putting the spare wheel back in place

The punctured wheel cannot be put

under the boot floor.

► Put the spare wheel back in place in its

housing.

► Slacken the nut on the bolt by a few turns.

► Position the fastening device (nut and bolt) in

the middle of the wheel.

► Tighten the central nut sufficiently to retain

the wheel correctly.

► Depending on version, put the tool box back

in place in the middle of the wheel and clip it in

place.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does

not obstruct traffic: the ground must be level,

stable and non-slippery.

Page 171 of 276

169

In the event of a breakdown

8► Take the wheel out of the boot.

Putting the spare wheel back in place

The punctured wheel cannot be put under the boot floor.

► Put the spare wheel back in place in its

housing.

►

Slacken the nut on the bolt by a few turns.

►

Position the fastening device (nut and bolt) in

the middle of the wheel.

►

T

ighten the central nut sufficiently to retain

the wheel correctly.

►

Depending on version, put the tool box back

in place

in the middle of the wheel and clip it in

place.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does

not obstruct traffic: the ground must be level,

stable and non-slippery.

With a manual gearbox, engage first gear

to lock the wheels, apply the parking brake,

unless it is set to automatic mode, and switch

off the ignition.

With an automatic gearbox, select mode

P

to lock the wheels, apply the parking brake,

unless it is set to automatic mode, and switch

off the ignition.

Check that the parking brake indicator lamps

on the instrument panel are on fixed.

The occupants must get out of the vehicle

and wait where they are safe.

If necessary, place a chock under the wheel

diagonally opposite the wheel to be changed.

Never go underneath a vehicle raised using a

jack; use an axle stand.

Wheel with wheel trim

When removing the wheel , first remove

the wheel trim by pulling at the valve aperture

using the wheelbrace.

When refitting the wheel , refit the wheel

trim, starting by placing its aperture in line

with the valve and then pushing it into place

all round its edge with the palm of your hand.

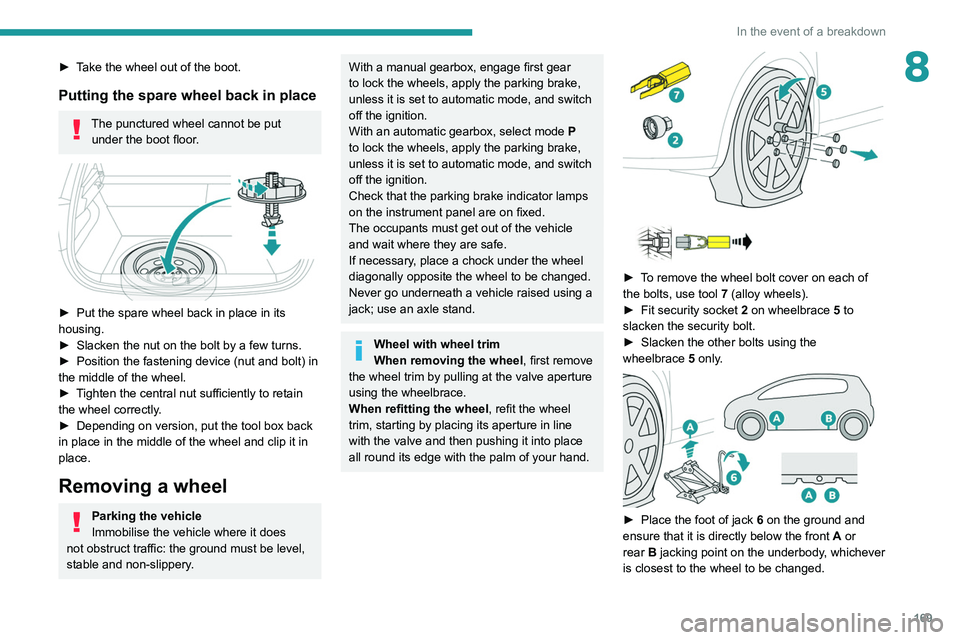

► To remove the wheel bolt cover on each of

the bolts, use tool 7 (alloy wheels).

►

Fit security socket

2 on wheelbrace

5

to

slacken the security bolt.

►

Slacken the other bolts using the

wheelbrace

5

only.

► Place the foot of jack 6 on the ground and

ensure that it is directly below the front A or

rear

B jacking point on the underbody, whichever

is closest to the wheel to be changed.

Page 173 of 276

171

In the event of a breakdown

8

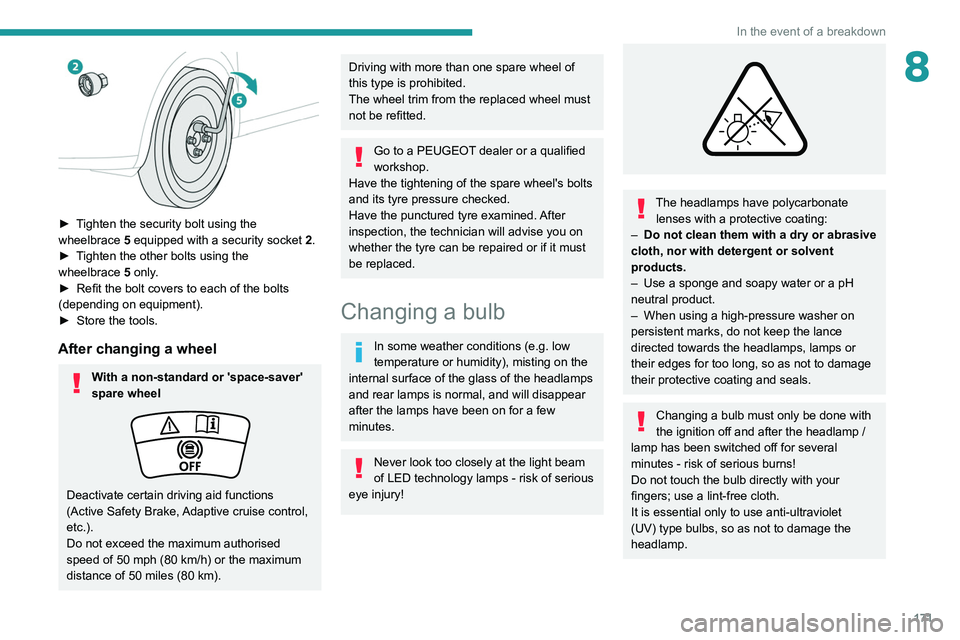

► Tighten the security bolt using the

wheelbrace 5 equipped with a security socket 2 .

►

T

ighten the other bolts using the

wheelbrace

5

only.

►

Refit the bolt covers to each of the bolts

(depending on equipment).

►

Store the tools.

After changing a wheel

With a non-standard or 'space-saver'

spare wheel

Deactivate certain driving aid functions

(Active Safety Brake, Adaptive cruise control,

etc.).

Do not exceed the maximum authorised

speed of 50 mph (80 km/h) or the maximum

distance of 50 miles (80 km).

Driving with more than one spare wheel of

this type is prohibited.

The wheel trim from the replaced wheel must

not be refitted.

Go to a PEUGEOT dealer or a qualified

workshop.

Have the tightening of the spare wheel's bolts

and its tyre pressure checked.

Have the punctured tyre examined. After

inspection, the technician will advise you on

whether the tyre can be repaired or if it must

be replaced.

Changing a bulb

In some weather conditions (e.g. low

temperature or humidity), misting on the

internal surface of the glass of the headlamps

and rear lamps is normal, and will disappear

after the lamps have been on for a few

minutes.

Never look too closely at the light beam

of LED technology lamps - risk of serious

eye injury!

The headlamps have polycarbonate lenses with a protective coating:

–

Do not clean them with a dry or abrasive

cloth, nor with detergent or solvent

products.

–

Use a sponge and soapy water or a pH

neutral product.

–

When using a high-pressure washer on

persistent marks, do not keep the lance

directed towards the headlamps, lamps or

their edges for too long, so as not to damage

their protective coating and seals.

Changing a bulb must only be done with

the ignition off and after the headlamp /

lamp has been switched off for several

minutes - risk of serious burns!

Do not touch the bulb directly with your

fingers; use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.