spare wheel PEUGEOT 3008 2014 Owners Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2014, Model line: 3008, Model: PEUGEOT 3008 2014Pages: 389, PDF Size: 22.92 MB

Page 20 of 389

123

Familiarisation

18

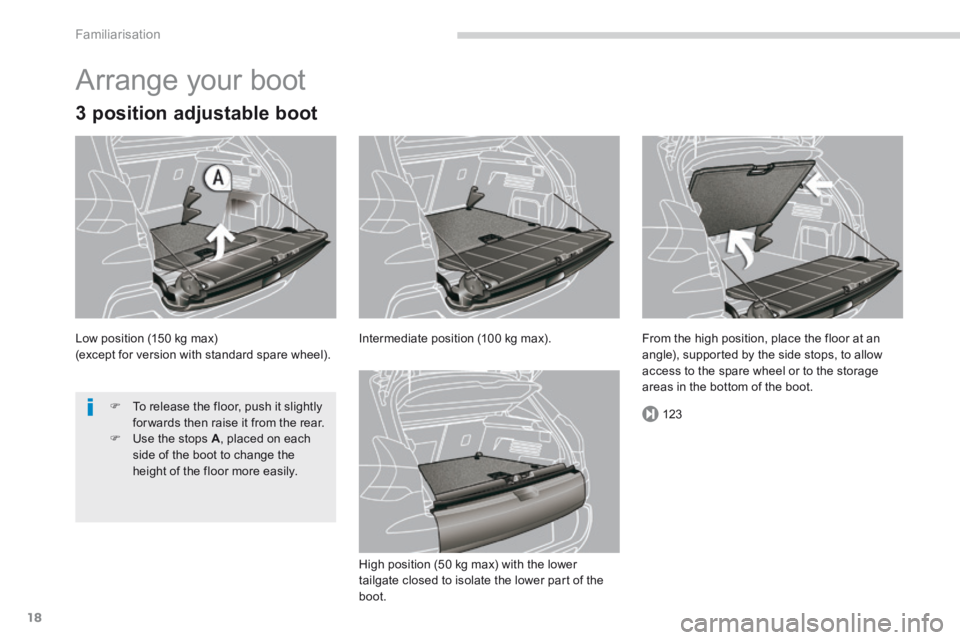

Arrange your boot

3 position adjustable boot

Low position (150 kg max) (except for version with standard spare wheel). Intermediate position (100 kg max).

High position (50 kg max) with the lower tailgate closed to isolate the lower part of the

boot.

From the high position, place the floor at an angle), supported by the side stops, to allow access to the spare wheel or to the storage areas in the bottom of the boot.

To release the floor, push it slightly for wards then raise it from the rear. Use the stops A , placed on each side of the boot to change the height of the floor more easily.

Page 28 of 389

Familiarisation

26

Limit the causes of excess

consumption

Spread loads throughout the vehicle; place the heaviest items in the bottom of the boot, as close as possible to the rear seats. Limit the loads carried in the vehicle and reduce wind resistance (roof bars, roof rack, bicycle carrier, trailer...). Use a roof box in preference. Remove roof bars and roof racks after use.

At the end of winter, remove snow tyres and refit your summer tyres.

Observe the recommendations

on maintenance

Check the tyre pressures regularly, when cold, referring to the label in the door aperture, driver's side.

Have your vehicle serviced regularly (engine oil, oil filter, air filter...) and observe the schedule of operations recommended by the manufacturer.

When refuelling, do not continue after the third cut-off of the nozzle to avoid any over flow.

At the wheel of your new vehicle, it is only after the first 1 800 miles (3 000 kilometres) that you will see the fuel consumption settle down to a consistent average.

Carry out this check in particular: - before a long journey, - at each change of season, - after a long period out of use. Don't forget the spare wheel and the tyres on any trailer or caravan.

Page 123 of 389

6

Fittings121

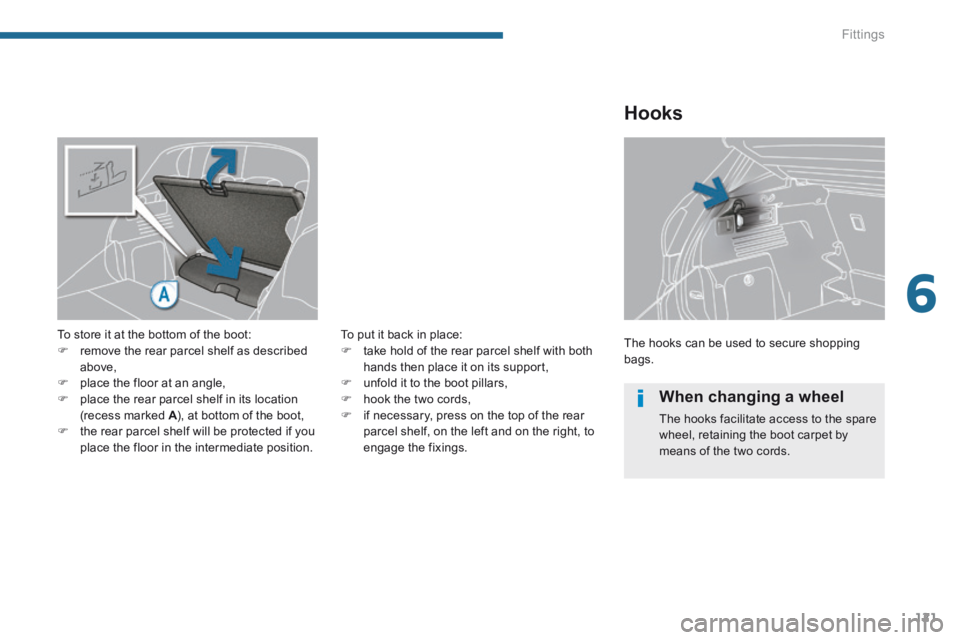

The hooks can be used to secure shopping bags.

Hooks

To store it at the bottom of the boot: remove the rear parcel shelf as described above, place the floor at an angle, place the rear parcel shelf in its location (recess marked A ), at bottom of the boot, A ), at bottom of the boot, A the rear parcel shelf will be protected if you place the floor in the intermediate position.

To put it back in place: take hold of the rear parcel shelf with both hands then place it on its support, unfold it to the boot pillars, hook the two cords, if necessary, press on the top of the rear parcel shelf, on the left and on the right, to engage the fixings.

When changing a wheel

The hooks facilitate access to the spare

wheel, retaining the boot carpet by means of the two cords.

Page 125 of 389

6

Fittings123

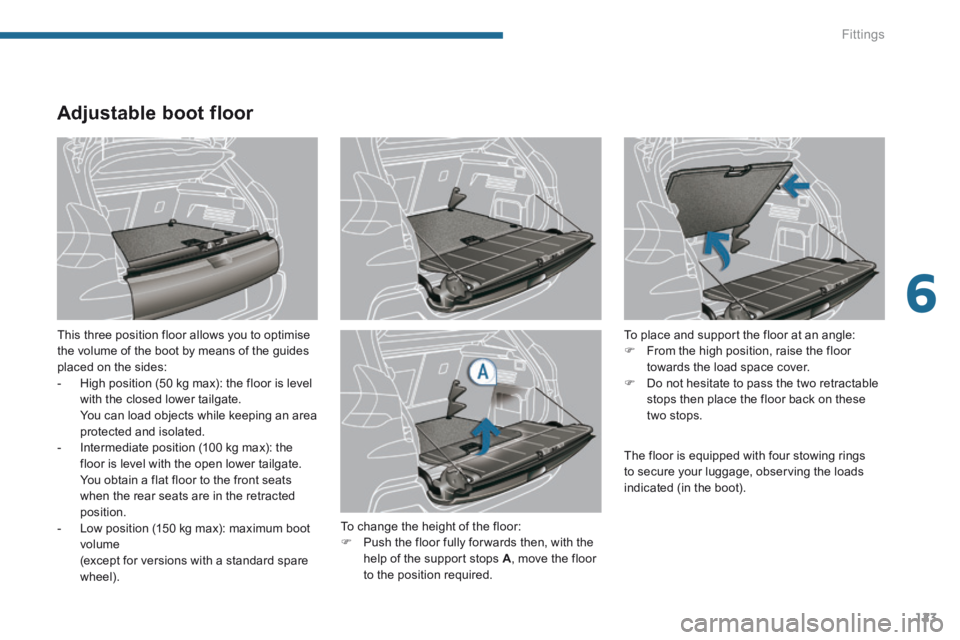

Adjustable boot floor

This three position floor allows you to optimise the volume of the boot by means of the guides placed on the sides: - High position (50 kg max): the floor is level with the closed lower tailgate. You can load objects while keeping an area protected and isolated. - Intermediate position (100 kg max): the floor is level with the open lower tailgate. You obtain a flat floor to the front seats when the rear seats are in the retracted position. - Low position (150 kg max): maximum boot volume (except for versions with a standard spare wheel).

To place and support the floor at an angle: From the high position, raise the floor towards the load space cover. Do not hesitate to pass the two retractable stops then place the floor back on these two stops.

To change the height of the floor:

Push the floor fully for wards then, with the help of the support stops A , move the floor to the position required.

The floor is equipped with four stowing rings to secure your luggage, observing the loads indicated (in the boot).

Page 142 of 389

Safety

140

Tyre under-infl ation detection

System which automatically checks the pressures of the tyres while driving. The system continuously monitors the pressures of the four tyres, as soon as the vehicle is moving. A pressure sensor is located in the valve of a each tyres (except the spare wheel). The system triggers an alert if a drop in pressure is detected in one or more tyres.

This system does not avoid the need to check the tyre pressures regularly (including the spare wheel) and before a long journey. Driving with under-inflated tyres adversely affects road holding, extends braking distances and causes premature tyre wear, particularly under arduous conditions (vehicle loaded, high speed, long journey).

The tyre pressures for your vehicle can be found on the tyre pressure label (see the "Identification markings" section). The tyre pressures must be checked when the tyres cold (vehicle stopped for 1 hour or after driving for less then 6 miles (10 km) at moderate speed). Other wise, add 0.3 bar to the values indicated on the label.

Driving with under-inflated tyres increases fuel consumption.

The tyre under-inflation detection system is an aid to driving which does not replace the need for the driver to be vigilant or to drive responsibly.

Page 143 of 389

8

Safety141

The flashing and then fixed illumination of the under-inflation warning lamp accompanied by the illumination of the "service" warning lamp indicates a fault with the system.

This alert is also displayed when one or more wheels is not fitted with a sensor (for example, a space-saver or steel spare wheel).

Under-inflation alert

The alert is given by the fixed illumination of this warning lamp, accompanied by an audible signal, and depending on equipment, the display of a message.

In the event of a problem on one of the tyres , the symbol or the message appears, according to equipment, to identify it.

Reduce speed, avoid sudden steering movements or harsh brake applications. Stop as soon as it is safe to do so. In the event of a puncture, use the temporary puncture repair kit or the spare

wheel (according to equipment), or if you have a compressor, the one in the temporary puncture repair kit for example, check the four tyre pressures when cold, or if it is not possible to check the tyre pressures at the time, drive carefully at reduced speed.

The loss of pressure detected does not always lead to visible deformation of the tyre. Do not rely on just a visual check.

The alert is maintained until the tyre or tyres concerned is reinflated, repaired or replaced. The spare wheel (space-saver type or a steel rim) does not have a sensor.

Operating fault

Go to a PEUGEOT dealer or a qualified workshop to have the system checked or, following the repair of a puncture, to have the original wheel, equipped with a sensor, refitted.

In this case, monitoring of the tyre pressures is not assured.

Page 209 of 389

11

Practical information207

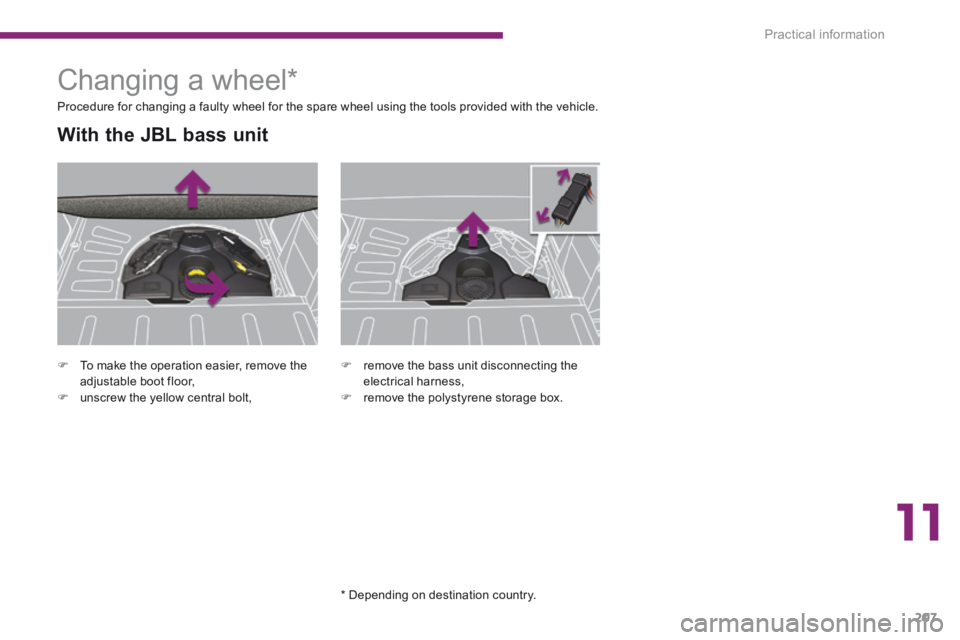

To make the operation easier, remove the adjustable boot floor, unscrew the yellow central bolt,

With the JBL bass unit

remove the bass unit disconnecting the electrical harness, remove the polystyrene storage box.

Changing a wheel *

Procedure for changing a faulty wheel for the spare wheel using the tools provided with the vehicle.

* Depending on destination country.

Page 212 of 389

Practical information

210

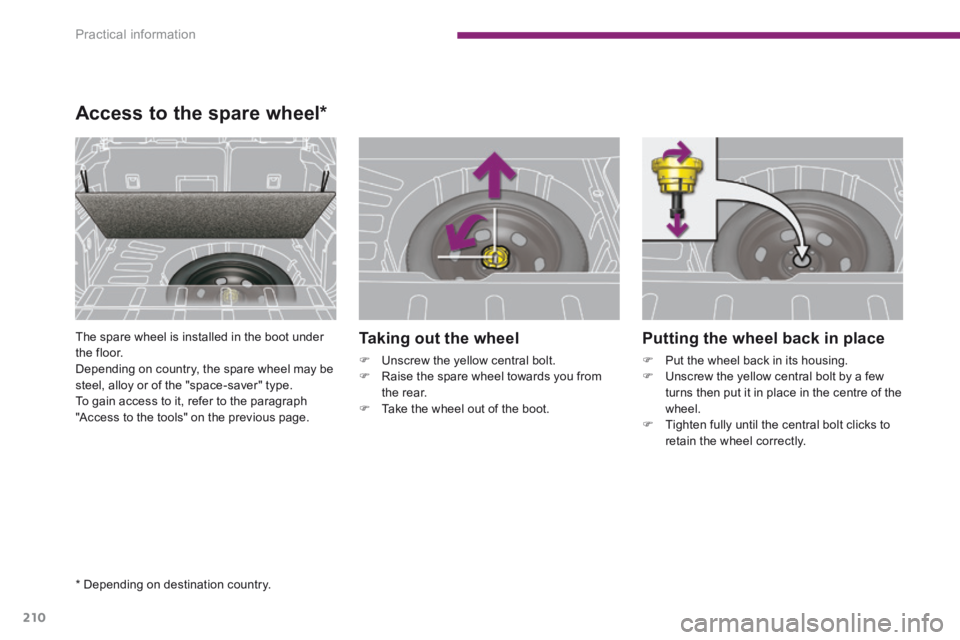

Putting the wheel back in place

Put the wheel back in its housing. Unscrew the yellow central bolt by a few turns then put it in place in the centre of the wheel. Tighten fully until the central bolt clicks to retain the wheel correctly.

Access to the spare wheel *

The spare wheel is installed in the boot under the floor. Depending on country, the spare wheel may be steel, alloy or of the "space-saver" type. To gain access to it, refer to the paragraph "Access to the tools" on the previous page.

Taking out the wheel

Unscrew the yellow central bolt. Raise the spare wheel towards you from the rear. Take the wheel out of the boot.

* Depending on destination country.

Page 213 of 389

11

Practical information211

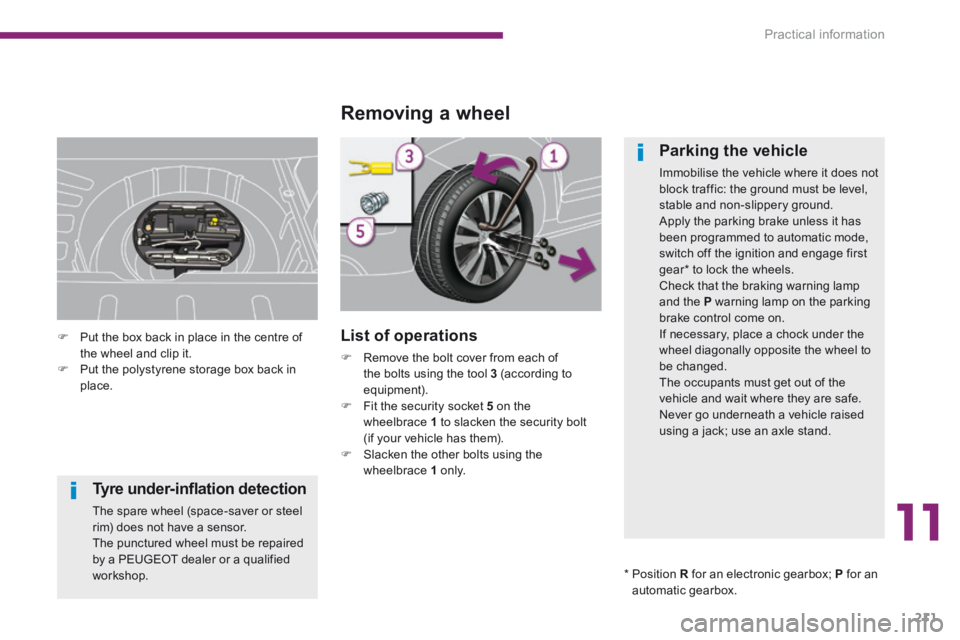

Tyre under-infl ation detection

The spare wheel (space-saver or steel rim) does not have a sensor. The punctured wheel must be repaired by a PEUGEOT dealer or a qualified workshop.

Removing a wheel

List of operations

Remove the bolt cover from each of the bolts using the tool 3 (according to equipment). Fit the security socket 5 on the wheelbrace 1 to slacken the security bolt (if your vehicle has them). Slacken the other bolts using the wheelbrace 1 o n l y.

Parking the vehicle

Immobilise the vehicle where it does not block traffic: the ground must be level, stable and non-slippery ground. Apply the parking brake unless it has been programmed to automatic mode, switch off the ignition and engage first gear * to lock the wheels. Check that the braking warning lamp and the P warning lamp on the parking brake control come on. If necessary, place a chock under the wheel diagonally opposite the wheel to be changed. The occupants must get out of the vehicle and wait where they are safe. Never go underneath a vehicle raised using a jack; use an axle stand.

Put the box back in place in the centre of the wheel and clip it. Put the polystyrene storage box back in place.

* Position R for an electronic gearbox; P for an automatic gearbox.

Page 214 of 389

Practical information

212

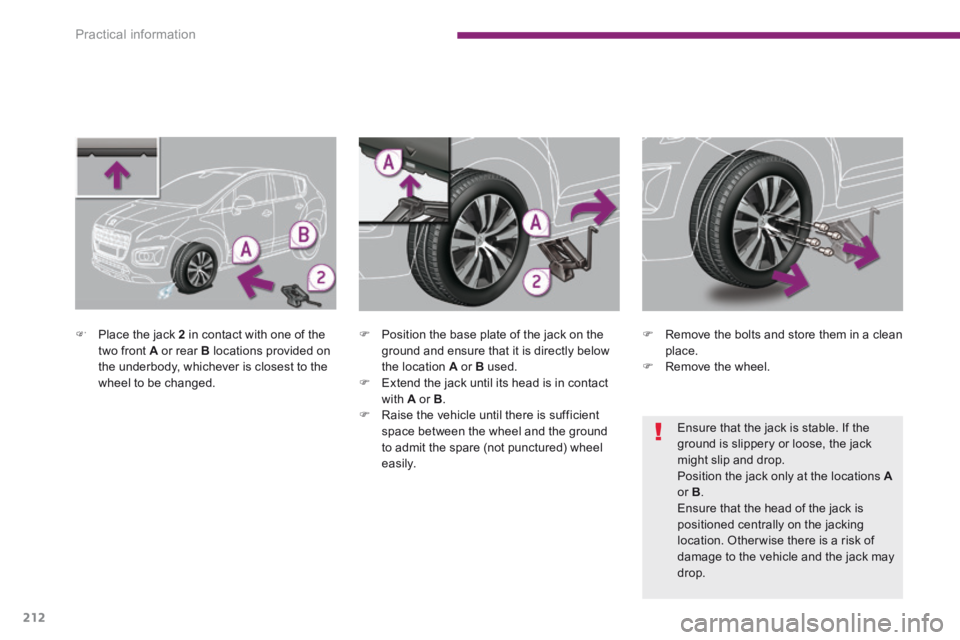

Place the jack 2 in contact with one of the two front A or rear B locations provided on the underbody, whichever is closest to the wheel to be changed.

Position the base plate of the jack on the ground and ensure that it is directly below the location A or B used. Extend the jack until its head is in contact with A or B . Raise the vehicle until there is sufficient space between the wheel and the ground to admit the spare (not punctured) wheel easily.

Remove the bolts and store them in a clean place. Remove the wheel.

Ensure that the jack is stable. If the ground is slippery or loose, the jack might slip and drop. Position the jack only at the locations Aor B . Ensure that the head of the jack is positioned centrally on the jacking

location. Otherwise there is a risk of damage to the vehicle and the jack may drop.