ECU PEUGEOT 3008 2021 Owner's Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2021, Model line: 3008, Model: PEUGEOT 3008 2021Pages: 292, PDF Size: 9.65 MB

Page 108 of 292

106

Safety

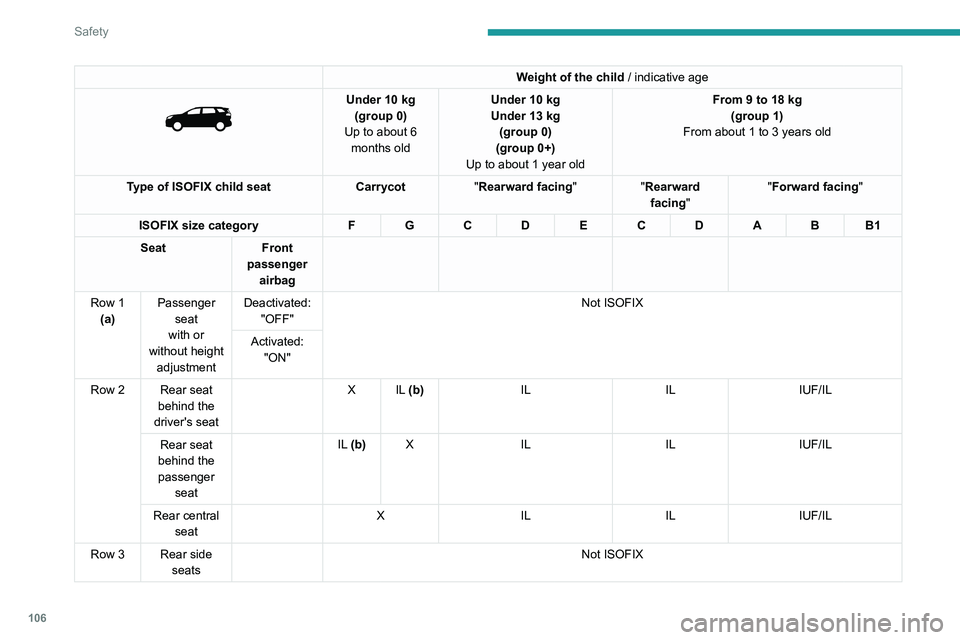

Weight of the child / indicative age

Under 10 kg

(group 0)

Up to about 6 months old Under 10

kg

Under 13 kg

(group 0)

(group 0+)

Up to about 1 year old From 9 to 18

kg

(group 1)

From about 1 to 3 years old

Type of ISOFIX child seat Carrycot"Rearward facing" "Rearward

facing" "Forward facing

"

ISOFIX size category F G C D E C D A B B1

Seat Front

passenger airbag

Row 1 (a) Passenger

seat

with or

without height adjustment Deactivated:

"OFF" Not ISOFIX

Activated: "ON"

Row 2 Rear seat behind the

driver's seat X

IL (b) IL ILIUF/IL

Rear seat

behind the

passenger seat IL (b)

X IL ILIUF/IL

Rear central seat X

IL ILIUF/IL

Row 3 Rear side seats Not ISOFIX

IUF: Seat position suitable for the installation of an

Isofix Universal seat, "Forward facing", secured using the upper strap.

IL: Seat position suitable for the installation of an Isofix Semi-Universal seat, either:

– "rearward facing" fitted with an upper strap or a support leg.

– “forward facing”, fitted with a support leg.

– a carrycot fitted with an upper strap or a support leg.

For securing the upper strap using the ISOFIX mountings, refer to the corresponding section.

X: Seat position not suitable for the installation of an ISOFIX seat or carrycot for the specified weight group.

(a) Refer to the current legislation in your country before placing a child\

in this seat position.

(b) The installation of a carrycot on this seat may prevent the use of one o\

r more of the other seats in this row.

i-Size child seats

i-Size child seats have two latches that are anchored to the two rings A.

These i-Size child seats also have:

– either an upper strap that is attached to ring B.

– or a support leg that rests on the vehicle floor, compatible with the approved i-Size seat position.

Their role is to prevent the child seat from tipping forward in the even\

t of a collision.

For more information on the ISOFIX mountings, refer to the corresponding section.

In accordance with European regulations, this table indicates the options for installing i-Size child seats on seats in the vehicle fitted with ISOFIX

mountings approved for i-Size.

Seat

Front passenger airbag i-Size restraint system i-Size restraint system

Row 1 (a) Passenger seat

with or without height adjustment

Deactivated: "OFF" i-UNot i-Size

Activated: "ON" i-UFNot i-Size

Page 109 of 292

107

Safety

5IUF: Seat position suitable for the installation of an Isofix Universal seat, "Forward facing", secured using the upper strap.

IL: Seat position suitable for the installation of an Isofix Semi-Universal seat, either:

–

"rearward facing" fitted with an upper strap or a support leg.

–

“forward facing”, fitted with a support leg.

–

a carrycot fitted with an upper strap or a support leg.

For securing the upper strap using the ISOFIX mountings, refer to the corresponding section.

X:

Seat position not suitable for the installation of an ISOFIX seat or carrycot for the specified weight group.

(a) Refer to the current legislation in your country before placing a child\

in this seat position.

(b)

The installation of a carrycot on this seat may prevent the use of one o\

r more of the other seats in this row

.

i-Size child seats

i-Size child seats have two latches that are anchored to the two rings A.

These i-Size child seats also have:

–

either an upper strap that is attached to ring B

.

–

or a support leg that rests on the vehicle floor

, compatible with the approved i-Size seat position.

Their role is to prevent the child seat from tipping forward in the even\

t of a collision.

For more information on the ISOFIX mountings, refer to the corresponding section.

In accordance with European regulations, this table indicates the options for installing i-Size child seats on seats in the vehicle fitted with ISOFIX

mountings approved for i-Size.

Seat

Front passenger airbag i-Size restraint system i-Size restraint system

Row 1 (a) Passenger seat

with or without height adjustment

Deactivated: "OFF" i-UNot i-Size

Activated: "ON" i-UFNot i-Size

Page 129 of 292

127

Driving

6Manoeuvring aids

The driver must always check the

surroundings of the vehicle before and during

the whole manoeuvre, in particular using the

mirrors.

Radar(s)

The operation of the radar(s), along with

any associated functions, may be affected

by the accumulation of dirt (e.g.

mud, ice),

in poor weather conditions (e.g.

heavy rain,

snow), or if the bumpers are damaged.

If the front bumper is to be repainted, contact

a PEUGEOT dealer or a qualified workshop;

certain types of paint could interfere with the

operation of the radar(s).

Driving aids camera

This camera and its associated functions

may be impaired or not work if the windscreen

area in front of the camera is dirty, misty,

frosty, covered with snow, damaged or

masked by a sticker.

In humid and cold weather, demist the

windscreen regularly.

Poor visibility (inadequate street lighting,

heavy rain, thick fog, snowfall), dazzle

(headlamps of an oncoming vehicle, low sun,

reflections on a damp road, leaving a tunnel,

alternating shade and light) can also impair

detection performance.

In the event of a windscreen replacement,

contact a PEUGEOT dealer or a qualified

workshop to recalibrate the camera;

otherwise, the operation of the associated

driving aids may be disrupted.

Other cameras

The images from the camera(s)

displayed on the touch screen or on the

instrument panel may be distorted by the

terrain.

In the presence of areas in shade, or in

conditions of bright sunlight or inadequate

lighting, the image may be darkened and with

lower contrast.

Obstacles may appear further away than they

actually are.

Sensors

The operation of the sensors, as well as

any associated functions, may be disrupted

by noise pollution such as that emitted by

noisy vehicles and machinery (e.g. lorries,

pneumatic drills), by the accumulation of

snow or dead leaves on the road or in the

event of damaged bumpers and mirrors.

When reverse gear is engaged, an audible

signal (long beep) indicates that the sensors

may be dirty.

A front or rear impact to the vehicle can

upset the sensors’ settings, which is not

always detected by the system: distance

measurements may be distorted.

The sensors do not systematically detect

obstacles that are too low (pavements, studs)

or too thin (trees, posts, wire fences).

Certain obstacles located in the sensors’ blind

spots may not be detected or may no longer

be detected during the manoeuvre.

Certain materials (fabrics) absorb sound

waves: pedestrians may not be detected.

Maintenance

Clean the bumpers and door mirrors and

the field of vision of the cameras regularly.

When washing your vehicle at high pressure,

direct the spray from at least 30

cm away

from the radar, sensors and cameras.

Mats

The use of mats not approved by

PEUGEOT may interfere with the operation of

the speed limiter or cruise control.

To avoid any risk of jamming the pedals:

–

Ensure that the mat is secured correctly

.

–

Never fit one mat on top of another

.

Units of speed

Ensure that the units of speed displayed

in the instrument panel (mph or km/h) are

those for the country you are driving in.

Page 176 of 292

174

Practical information

Observe the legislation in force in the

country where you are driving.

Vehicle equipped with motorised

tailgate with Hands-Free Access

function

To avoid unintentionally opening the tailgate

while operating the towing device:

–

Deactivate this function in advance in your

vehicle's configuration menu.

–

Or remove the electronic key from the

recognition zone, with the tailgate closed.

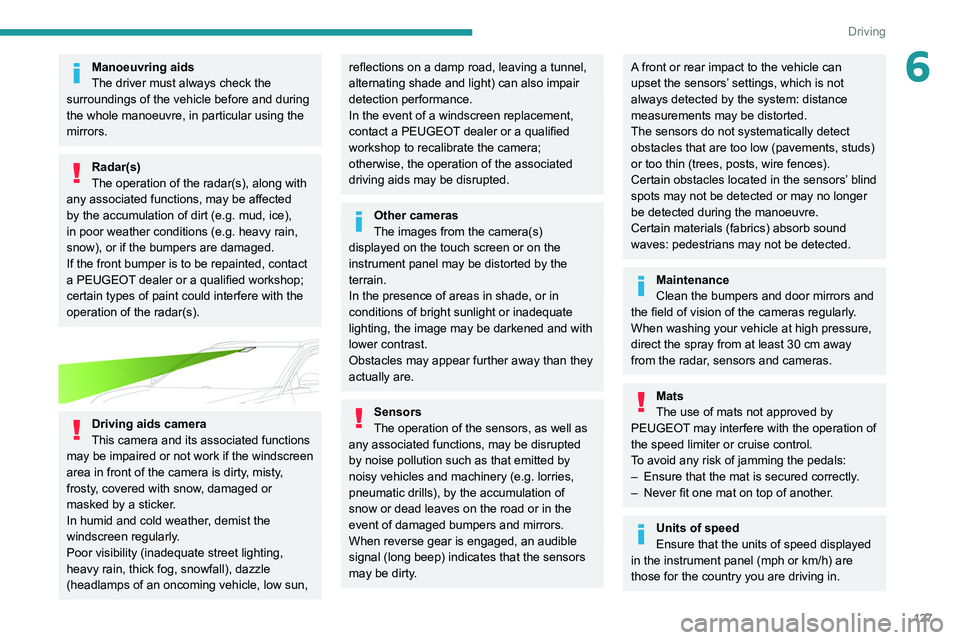

Towing device with quickly detachable towball

Presentation

No tools are required to install or remove this

genuine towing device.

1. Carrier

2. Protective plug

3. Connection socket

4. Safety eye

5. Detachable towball

6. Locking/unlocking wheel

7. Security key lock

8. Label to note the key references

A. Locked position (the green marks are

opposite each other); the wheel is in contact

with the towball (no gap).

B. Unlocked position (red mark opposite the green mark); the wheel is no longer

in contact with the towball (gap of around

5

mm).

Affix the enclosed label in a clearly visible location, close to the carrier or in the

boot.

Trailers with LED lamps are not compatible with the wiring harness of this

device.

To ensure complete safety while driving with a Towing device , refer to the

corresponding section.

Before each use

Verify that the towball is correctly fitted,

checking the follow points:

–

The green mark on the wheel is in line with

the green mark on the towball.

–

The wheel is in contact with the towball

(position A

).

–

The security key lock is closed and the

key removed; the wheel can no longer be

operated.

–

The towball must not be able to move in

its carrier; test by attempting to shake it with

your hand.

If the towball is not locked, the trailer can

become detached - risk of an accident!

During use

Never release the locking system with a

trailer or load carrier on the towball.

Never exceed the maximum authorised

weight for the vehicle - the Gross Train

Weight or GTW.

Always comply with the maximum authorised

load on the towing device: if it is exceeded,

this device may become detached from the

vehicle - risk of an accident!

Before driving, check the headlamp height

adjustment and check that the lamps on the

trailer operate correctly.

For more information on Headlamp height

adjustment, refer to the corresponding

section.

After use

When travelling without a trailer or

load carrier, remove the towball and fit the

protective plug into the carrier, to provide

clear visibility of the number plate and/or its

lighting.

Fitting the towball

► Below the rear bumper, remove the protective

plug 2 from the carrier 1.

Page 178 of 292

176

Practical information

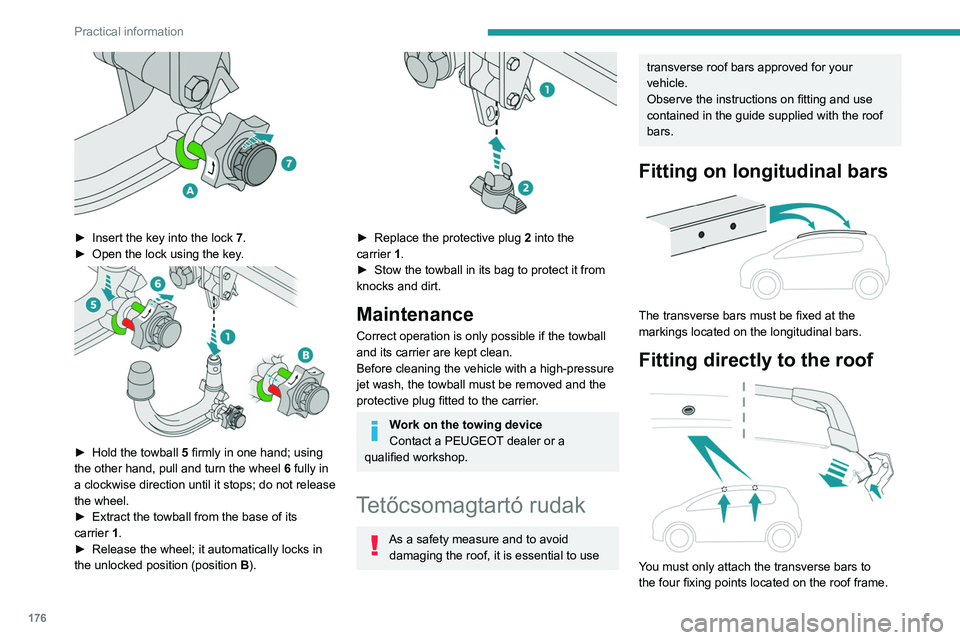

► Insert the key into the lock 7.

► Open the lock using the key .

► Hold the towball 5 firmly in one hand; using

the other hand, pull and turn the wheel 6 fully in

a clockwise direction until it stops; do not release

the wheel.

►

Extract the towball from the base of its

carrier

1.

►

Release the wheel; it automatically locks in

the unlocked position (position B

).

► Replace the protective plug 2 into the

carrier 1.

►

Stow the towball in its bag to protect it from

knocks and dirt.

Maintenance

Correct operation is only possible if the towball

and its carrier are kept clean.

Before cleaning the vehicle with a high-pressure

jet wash, the towball must be removed and the

protective plug fitted to the carrier.

Work on the towing device

Contact a PEUGEOT dealer or a

qualified workshop.

Tetőcsomagtartó rudak

As a safety measure and to avoid damaging the roof, it is essential to use

transverse roof bars approved for your

vehicle.

Observe the instructions on fitting and use

contained in the guide supplied with the roof

bars.

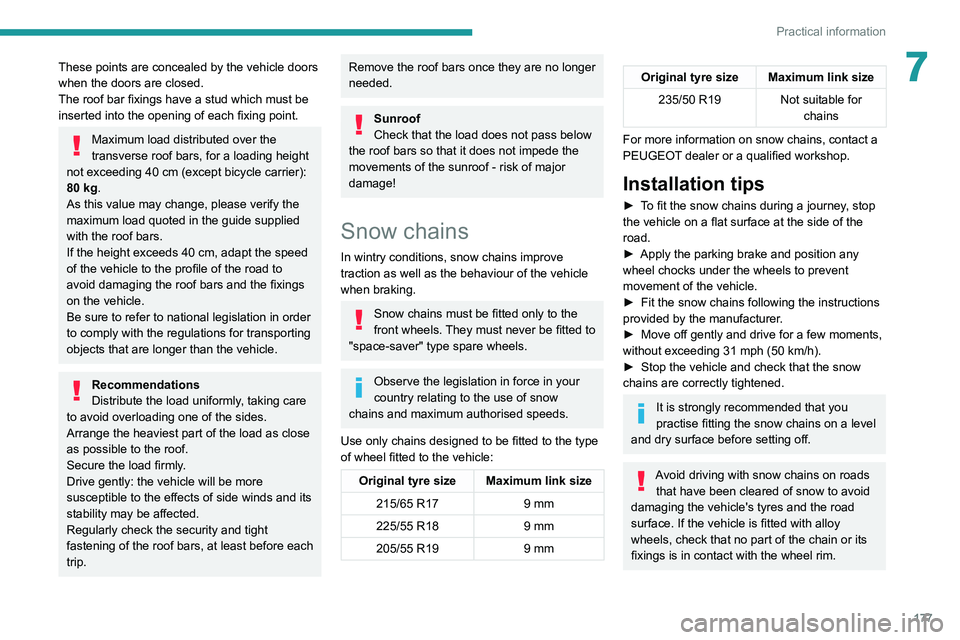

Fitting on longitudinal bars

The transverse bars must be fixed at the

markings located on the longitudinal bars.

Fitting directly to the roof

You must only attach the transverse bars to

the four fixing points located on the roof frame.

These points are concealed by the vehicle doors

when the doors are closed.

The roof bar fixings have a stud which must be

inserted into the opening of each fixing point.

Maximum load distributed over the

transverse roof bars, for a loading height

not exceeding 40 cm (except bicycle carrier):

80 kg.

As this value may change, please verify the

maximum load quoted in the guide supplied

with the roof bars.

If the height exceeds 40 cm, adapt the speed

of the vehicle to the profile of the road to

avoid damaging the roof bars and the fixings

on the vehicle.

Be sure to refer to national legislation in order

to comply with the regulations for transporting

objects that are longer than the vehicle.

Recommendations

Distribute the load uniformly, taking care

to avoid overloading one of the sides.

Arrange the heaviest part of the load as close

as possible to the roof.

Secure the load firmly.

Drive gently: the vehicle will be more

susceptible to the effects of side winds and its

stability may be affected.

Regularly check the security and tight

fastening of the roof bars, at least before each

trip.

Page 179 of 292

177

Practical information

7These points are concealed by the vehicle doors

when the doors are closed.

The roof bar fixings have a stud which must be

inserted into the opening of each fixing point.

Maximum load distributed over the

transverse roof bars, for a loading height

not exceeding 40 cm (except bicycle carrier):

80

kg.

As this value may change, please verify the

maximum load quoted in the guide supplied

with the roof bars.

If the height exceeds 40 cm, adapt the speed

of the vehicle to the profile of the road to

avoid damaging the roof bars and the fixings

on the vehicle.

Be sure to refer to national legislation in order

to comply with the regulations for transporting

objects that are longer than the vehicle.

Recommendations

Distribute the load uniformly, taking care

to avoid overloading one of the sides.

Arrange the heaviest part of the load as close

as possible to the roof.

Secure the load firmly.

Drive gently: the vehicle will be more

susceptible to the effects of side winds and its

stability may be affected.

Regularly check the security and tight

fastening of the roof bars, at least before each

trip.

Remove the roof bars once they are no longer

needed.

Sunroof

Check that the load does not pass below

the roof bars so that it does not impede the

movements of the sunroof - risk of major

damage!

Snow chains

In wintry conditions, snow chains improve

traction as well as the behaviour of the vehicle

when braking.

Snow chains must be fitted only to the

front wheels. They must never be fitted to

"space-saver" type spare wheels.

Observe the legislation in force in your

country relating to the use of snow

chains and maximum authorised speeds.

Use only chains designed to be fitted to the type

of wheel fitted to the vehicle:

Original tyre size Maximum link size 215/65 R17 9 mm

225/55 R18 9 mm

205/55 R19 9 mm

Original tyre size Maximum link size

235/50 R19 Not suitable for

chains

For more information on snow chains, contact a

PEUGEOT dealer or a qualified workshop.

Installation tips

► To fit the snow chains during a journey, stop

the vehicle on a flat surface at the side of the

road.

►

Apply the parking brake and position any

wheel chocks under the wheels to prevent

movement of the vehicle.

►

Fit the snow chains following the instructions

provided by the manufacturer

.

►

Move off gently and drive for a few moments,

without exceeding 31

mph (50 km/h).

►

Stop the vehicle and check that the snow

chains are correctly tightened.

It is strongly recommended that you

practise fitting the snow chains on a level

and dry surface before setting off.

Avoid driving with snow chains on roads that have been cleared of snow to avoid

damaging the vehicle's tyres and the road

surface. If the vehicle is fitted with alloy

wheels, check that no part of the chain or its

fixings is in contact with the wheel rim.

Page 193 of 292

191

In the event of a breakdown

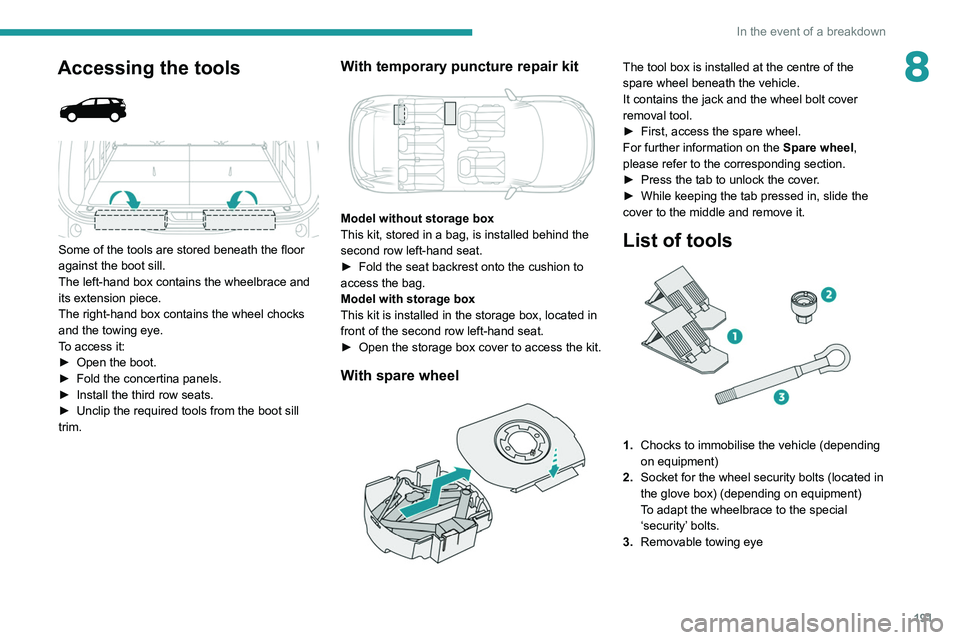

8Accessing the tools

Some of the tools are stored beneath the floor

against the boot sill.

The left-hand box contains the wheelbrace and

its extension piece.

The right-hand box contains the wheel chocks

and the towing eye.

To access it:

►

Open the boot.

►

Fold the concertina panels.

►

Install the third row seats.

►

Unclip the required tools from the boot sill

trim.

With temporary puncture repair kit

Model without storage box

This kit, stored in a bag, is installed behind the

second row left-hand seat.

►

Fold the seat backrest onto the cushion to

access the bag.

Model with storage box

This kit is installed in the storage box, located in

front of the second row left-hand seat.

►

Open the storage box cover to access the kit.

With spare wheel

The tool box is installed at the centre of the

spare wheel beneath the vehicle.

It contains the jack and the wheel bolt cover

removal tool.

►

First, access the spare wheel.

For further information on the

Spare wheel,

please refer to the corresponding section.

►

Press the tab to unlock the cover

.

►

While keeping the tab pressed in, slide the

cover to the middle and remove it.

List of tools

1. Chocks to immobilise the vehicle (depending

on equipment)

2. Socket for the wheel security bolts (located in

the glove box) (depending on equipment)

To adapt the wheelbrace to the special

‘security’ bolts.

3. Removable towing eye

Page 195 of 292

193

In the event of a breakdown

8The vehicle's electric system allows the connection of the compressor to the 12 V

power supply for long enough to repair a tyre

after a puncture.

Only the 12 V socket located at the front

of the vehicle can be used to power the

compressor.

For more information on the Tool kit,

refer to the corresponding section.

Tyre inflation pressures are indicated on this label.

For more information on Identification

markings, particularly this label, refer to the

corresponding section.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-inflation

detection, refer to the corresponding section.

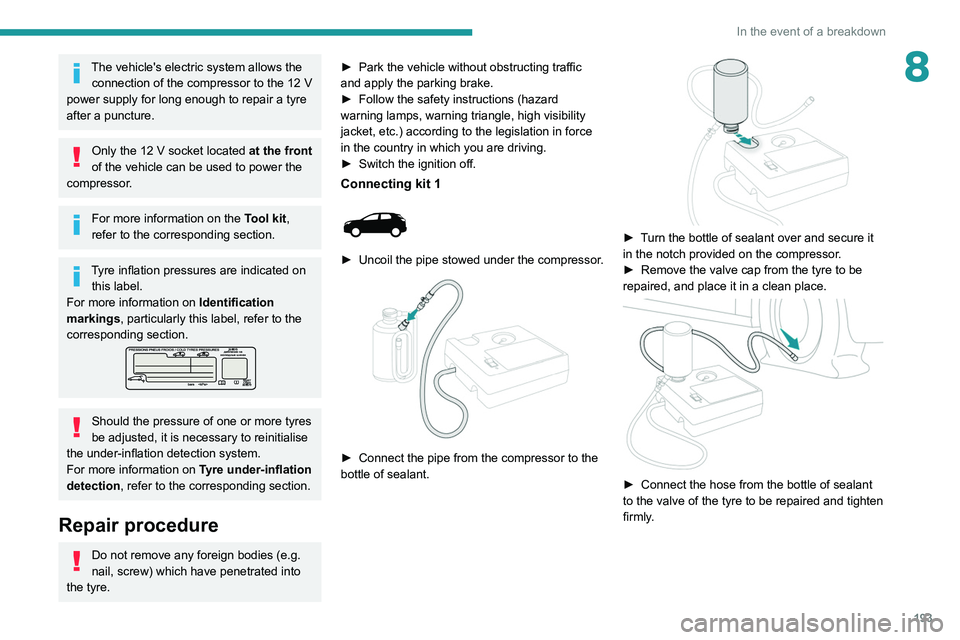

Repair procedure

Do not remove any foreign bodies (e.g.

nail, screw) which have penetrated into

the tyre. ►

Park the vehicle without obstructing traffic

and apply the parking brake.

►

Follow the safety instructions (hazard

warning lamps, warning triangle, high visibility

jacket, etc.) according to the legislation in force

in the country in which you are driving.

►

Switch the ignition off.

Connecting kit 1

► Uncoil the pipe stowed under the compressor.

► Connect the pipe from the compressor to the

bottle of sealant.

► Turn the bottle of sealant over and secure it

in the notch provided on the compressor.

►

Remove the valve cap from the tyre to be

repaired, and place it in a clean place.

► Connect the hose from the bottle of sealant

to the valve of the tyre to be repaired and tighten

firmly

.

Page 198 of 292

196

In the event of a breakdown

► Reel in the winch by loosening the winch

control nut with wheelbrace 5 and extension

piece 8: the nut should rotate freely once the

cable is completely reeled in.

► Store the rest of the tools in the storage

areas in the boot sill trim.

The punctured wheel cannot be secured beneath the vehicle; it must be stored in

the boot (use a cover to protect the inside of

the boot).

Putting the winch and spare wheel

back in place

► Place the appropriate tools in the box and

close the cover.

► Place the tool box on the ground.

When the spare wheel is fitted in place of

a wheel with a punctured tyre, the winch

and tool box must be placed beneath the

vehicle again before restarting.

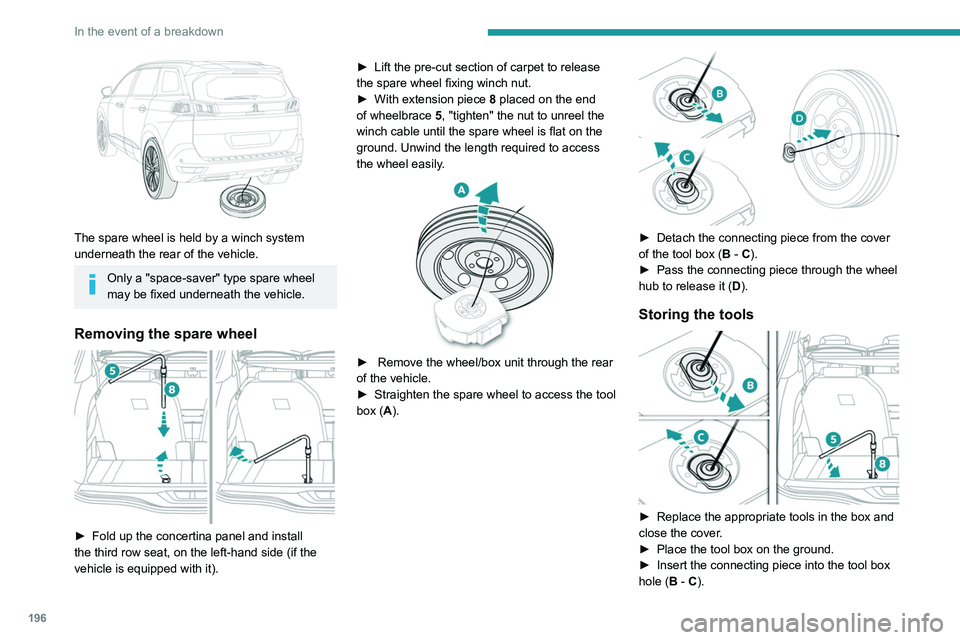

The spare wheel is held by a winch system

underneath the rear of the vehicle.

Only a "space-saver" type spare wheel

may be fixed underneath the vehicle.

Removing the spare wheel

► Fold up the concertina panel and install

the third row seat, on the left-hand side (if the

vehicle is equipped with it). ►

Lift the pre-cut section of carpet to release

the spare wheel

fixing winch nut.

►

With extension piece

8

placed on the end

of wheelbrace 5, "tighten" the nut to unreel the

winch cable until the spare wheel is flat on the

ground. Unwind the length required to access

the wheel easily.

► Remove the wheel/box unit through the rear

of the vehicle.

►

Straighten the spare wheel to access the tool

box (

A).

► Detach the connecting piece from the cover

of the tool box ( B - C).

►

Pass the connecting piece through the wheel

hub to release it ( D

).

Storing the tools

► Replace the appropriate tools in the box and

close the cover .

►

Place the tool box on the ground.

►

Insert the connecting piece into the tool box

hole (

B - C).

Page 199 of 292

197

In the event of a breakdown

8► Reel in the winch by loosening the winch

control nut with wheelbrace 5

and extension

piece 8: the nut should rotate freely once the

cable is completely reeled in.

►

Store the rest of the tools in the storage

areas in the boot sill trim.

The punctured wheel cannot be secured beneath the vehicle; it must be stored in

the boot (use a cover to protect the inside of

the boot).

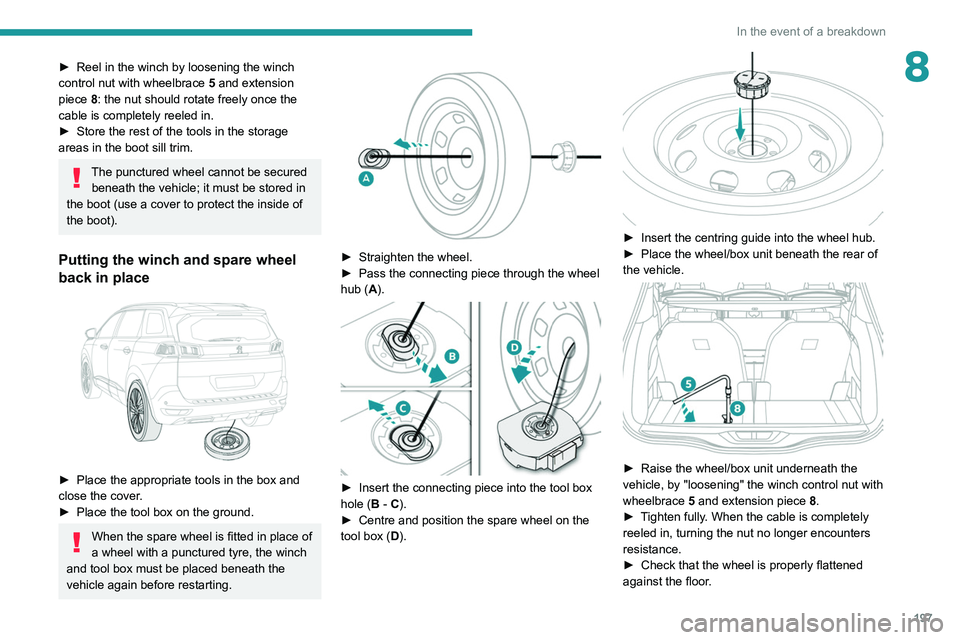

Putting the winch and spare wheel

back in place

► Place the appropriate tools in the box and

close the cover .

►

Place the tool box on the ground.

When the spare wheel is fitted in place of

a wheel with a punctured tyre, the winch

and tool box must be placed beneath the

vehicle again before restarting.

► Straighten the wheel.

► Pass the connecting piece through the wheel

hub (

A).

► Insert the connecting piece into the tool box

hole ( B - C).

►

Centre and position the spare wheel on the

tool box (

D).

► Insert the centring guide into the wheel hub.

► Place the wheel/box unit beneath the rear of

the vehicle.

► Raise the wheel/box unit underneath the

vehicle, by "loosening" the winch control nut with

wheelbrace 5

and extension piece 8.

►

T

ighten fully. When the cable is completely

reeled in, turning the nut no longer encounters

resistance.

►

Check that the wheel is properly flattened

against the floor

.