tow Peugeot 308 2016 Service Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2016, Model line: 308, Model: Peugeot 308 2016Pages: 398, PDF Size: 9.38 MB

Page 228 of 398

226

308_en_Chap07_info-pratiques_ed02-2015

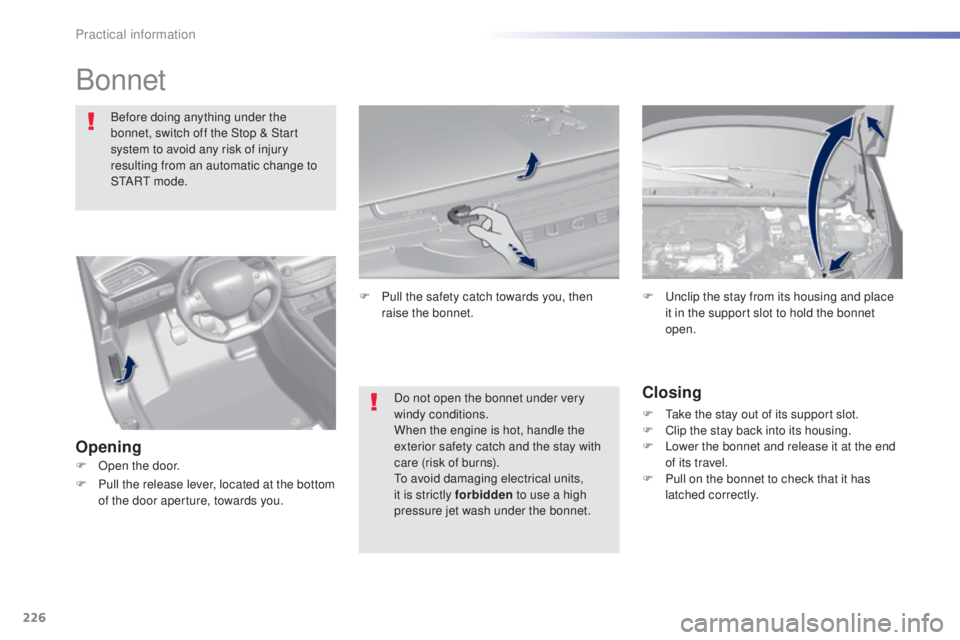

Bonnet

Before doing anything under the

bonnet, switch off the Stop & Start

system to avoid any risk of injury

resulting from an automatic change to

S

tA

R

t m o

d e .

Opening Closing

F take the stay out of its support slot.

F Cl ip the stay back into its housing.

F

Lo

wer the bonnet and release it at the end

of its travel.

F

Pu

ll on the bonnet to check that it has

latched correctly.

F

u

nc

lip the stay from its housing and place

it in the support slot to hold the bonnet

open.

Do not open the bonnet under very

windy conditions.

When the engine is hot, handle the

exterior safety catch and the stay with

care (risk of burns).

to a

void damaging electrical units,

it is strictly forbidden to use a high

pressure jet wash under the bonnet.

F

Pu

ll the safety catch towards you, then

raise the bonnet.

F

Op

en the door.

F

Pu

ll the release lever, located at the bottom

of the door aperture, towards you.

Practical information

Page 236 of 398

234

308_en_Chap07_info-pratiques_ed02-2015

Manual gearbox

the gearbox does not require any

m aintenance (no oil change).

Refer to the manufacturer's service

schedule for the checking interval for

this component. Brake wear depends on the style

of driving, particularly in the case

of vehicles used in town, over short

distances. It may be necessary to

Brake pads

For information on checking brake

disc wear, contact a Peu

geOt

d

ealer or a qualified workshop.

Brake disc wear Electric parking brake

this system does not require any

r outine servicing. However, in the

event of a problem, have the system

checked by a P

eu

ge

Ot d

ealer or a

qualified workshop.

Only use products recommended by

P

eu

ge

Ot o

r products of equivalent

quality and specification.

In order to optimise the operation of

units as important as those in the

braking system, P

eu

ge

Ot s

elects and

offers very specific products.

After washing the vehicle, dampness,

or in wintry conditions, ice can form

on the brake discs and pads: braking

efficiency may be reduced. Make light

brake applications to dry and defrost

the brakes.

Parking brake

If excessive travel or a loss of

effectiveness of this system is

noticed, the parking brake must be

checked, even between two services.

Checking this system must be done by a

P

eu

ge

Ot d

ealer or a qualified workshop. have the condition of the brakes checked, even

between vehicle services.

unl

ess there is a leak in the circuit, a drop in

the brake fluid level indicates that the brake

pads are worn. For more information on the electric parking

brake, refer to the corresponding section.

Automatic gearbox

the gearbox does not require any

m aintenance (no oil change).

Refer to the manufacturer's service

schedule for details of the level

checking interval for this component.

Practical information

Page 245 of 398

243

308_en_Chap08_en-cas-de-panne_ed02-2015

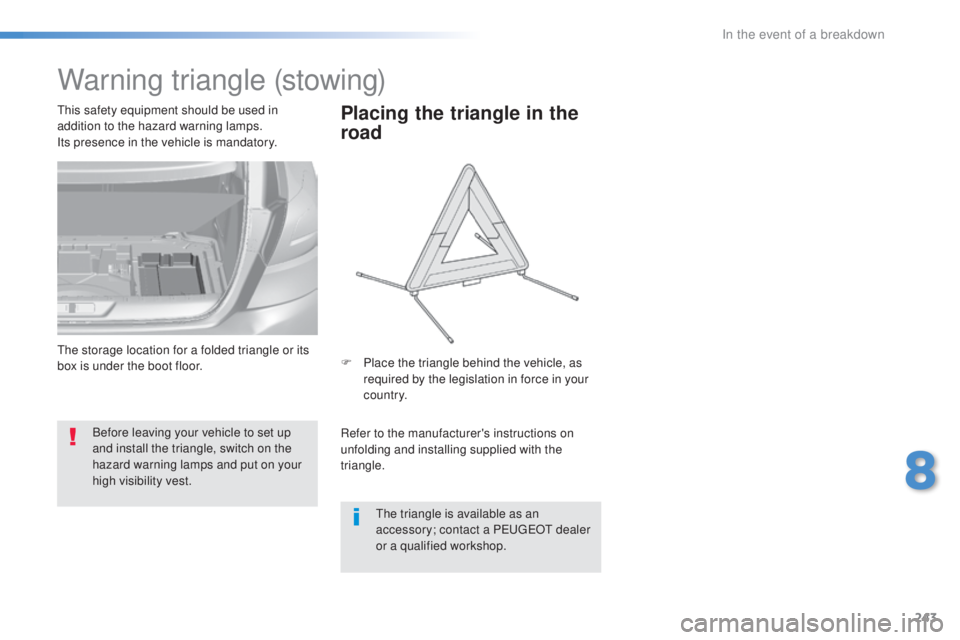

Warning triangle (stowing)

Before leaving your vehicle to set up

and install the triangle, switch on the

hazard warning lamps and put on your

high visibility vest.

thi

s safety equipment should be used in

addition to the hazard warning lamps.

Its presence in the vehicle is mandatory.

Placing the triangle in the

road

Refer to the manufacturer's instructions on

unfolding and installing supplied with the

triangle. F

Pl

ace the triangle behind the vehicle, as

required by the legislation in force in your

c o unt r y.

the t

riangle is available as an

accessory; contact a P

eu

ge

Ot d

ealer

or a qualified workshop.

the s

torage location for a folded triangle or its

box is under the boot floor.

8

In the event of a breakdown

Page 246 of 398

244

308_en_Chap08_en-cas-de-panne_ed02-2015

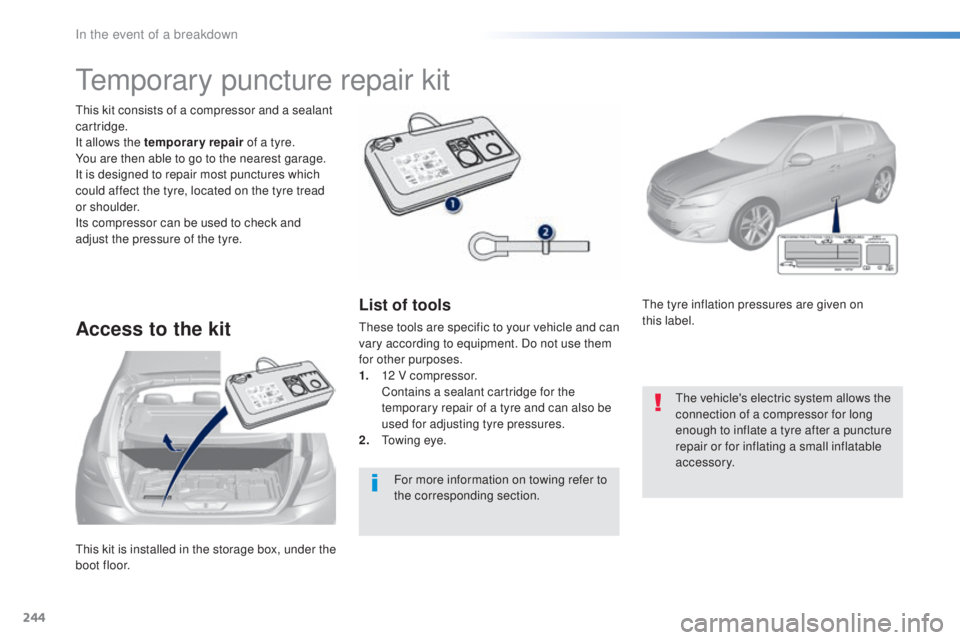

this kit is installed in the storage box, under the

bo ot floor.

thi

s kit consists of a compressor and a sealant

cartridge.

It allows the temporary repair of a tyre.

You are then able to go to the nearest garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

Its compressor can be used to check and

adjust the pressure of the tyre.

temporary puncture repair kit

Access to the kit

List of tools

these tools are specific to your vehicle and can

v ary according to equipment. Do not use them

for other purposes.

1.

12 V c

ompressor.

Co

ntains a sealant cartridge for the

temporary repair of a tyre and can also be

used for adjusting tyre pressures.

2.

tow

ing eye.

the t

yre inflation pressures are given on

this lab el.

the v

ehicle's electric system allows the

connection of a compressor for long

enough to inflate a tyre after a puncture

repair or for inflating a small inflatable

accessory.

For more information on towing refer to

the corresponding section.

In the event of a breakdown

Page 250 of 398

248

308_en_Chap08_en-cas-de-panne_ed02-2015

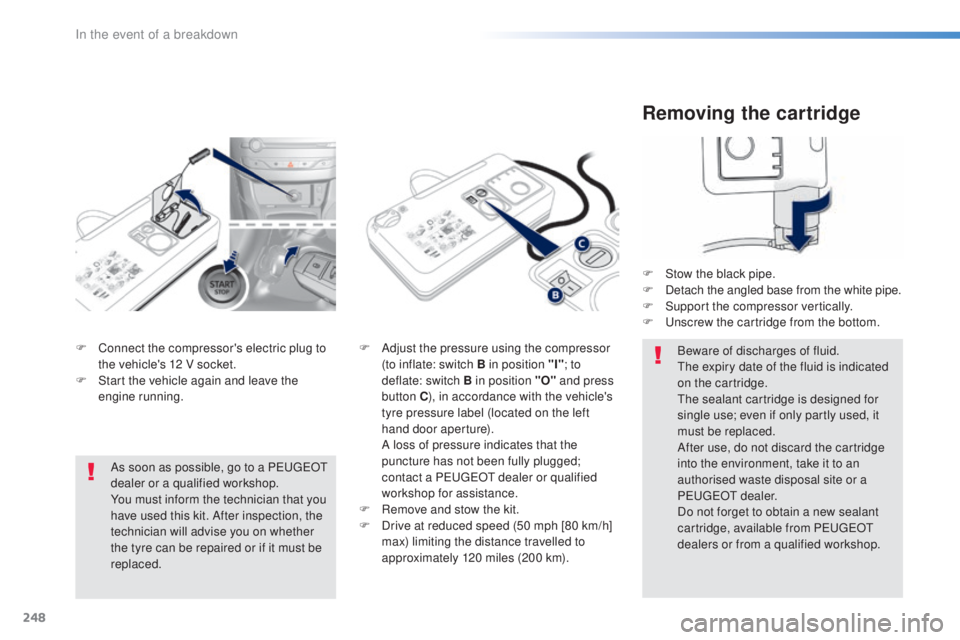

F Connect the compressor's electric plug to

t

he vehicle's 12 V socket.

F

St

art the vehicle again and leave the

engine running. F Ad

just the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B

i

n position "O" and press

button C ), in accordance with the vehicle's

tyre pressure label (located on the left

hand door aperture).

A lo

ss of pressure indicates that the

puncture has not been fully plugged;

contact a P

eu

ge

Ot d

ealer or qualified

workshop for assistance.

F

Re

move and stow the kit.

F

Dr

ive at reduced speed (50 mph [80 km/h]

max) limiting the distance travelled to

approximately 120 miles (200 km).

As soon as possible, go to a P

eu

ge

Ot

d

ealer or a qualified workshop.

You must inform the technician that you

have used this kit. After inspection, the

technician will advise you on whether

the tyre can be repaired or if it must be

replaced.

Removing the cartridge

F Stow the black pipe.

F De tach the angled base from the white pipe.

F

Su

pport the compressor vertically.

F

u

ns

crew the cartridge from the bottom.

Beware of discharges of fluid.

the e

xpiry date of the fluid is indicated

on the cartridge.

the s

ealant cartridge is designed for

single use; even if only partly used, it

must be replaced.

After use, do not discard the cartridge

into the environment, take it to an

authorised waste disposal site or a

P

eu

ge

Ot dea

ler.

Do not forget to obtain a new sealant

cartridge, available from P

eu

ge

Ot

d

ealers or from a qualified workshop.

In the event of a breakdown

Page 251 of 398

249

308_en_Chap08_en-cas-de-panne_ed02-2015

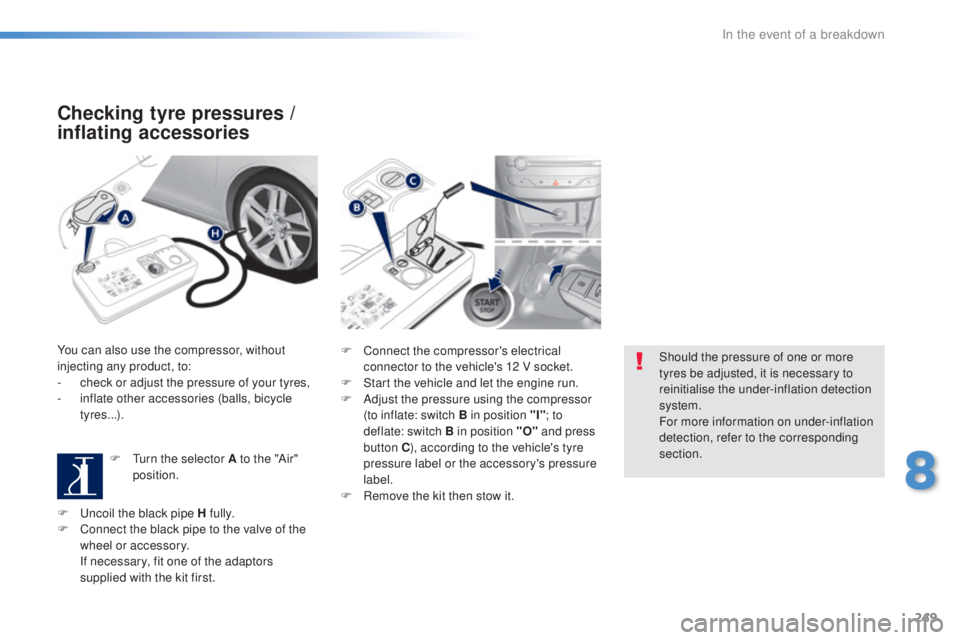

Checking tyre pressures /

inflating accessories

You can also use the compressor, without

injecting any product, to:

-

ch

eck or adjust the pressure of your tyres,

-

in

flate other accessories (balls, bicycle

tyres...).

F

t

ur

n the selector A to the "Air"

position. F Con

nect the compressor's electrical

connector to the vehicle's 12 V socket.

F

St

art the vehicle and let the engine run.

F

Ad

just the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B in position "O" and press

button C ), according to the vehicle's tyre

pressure label or the accessory's pressure

label.

F

Re

move the kit then stow it.Should the pressure of one or more

tyres be adjusted, it is necessary to

reinitialise the under-inflation detection

system.

For more information on under-inflation

detection, refer to the corresponding

section.

F

u

nc

oil the black pipe H fully.

F

Co

nnect the black pipe to the valve of the

wheel or accessory.

If n

ecessary, fit one of the adaptors

supplied with the kit first.

8

In the event of a breakdown

Page 252 of 398

250

308_en_Chap08_en-cas-de-panne_ed02-2015

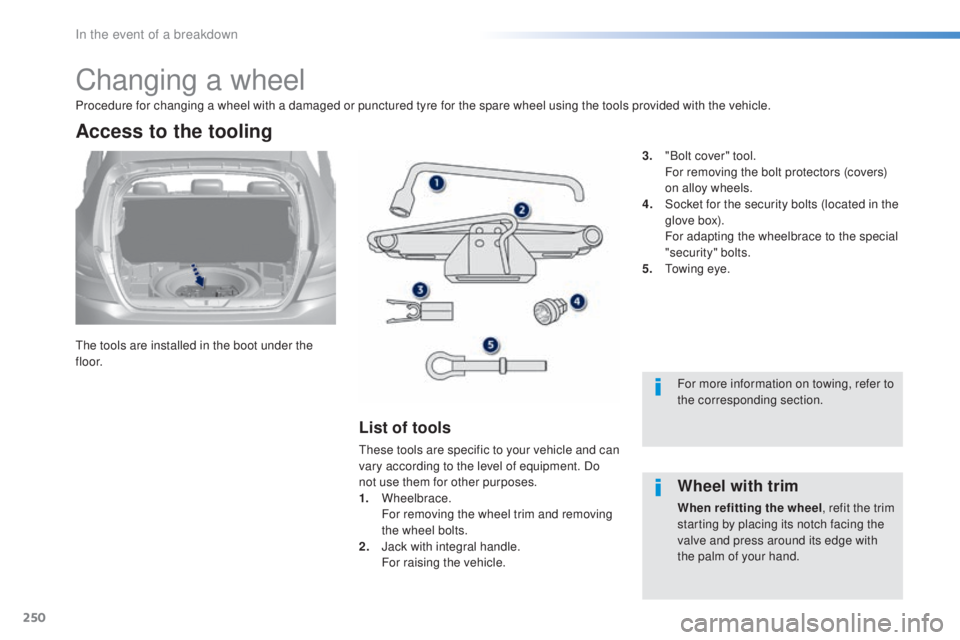

Changing a wheel

the tools are installed in the boot under the

f l o o r.

Access to the tooling

List of tools

these tools are specific to your vehicle and can

v ary according to the level of equipment. Do

not use them for other purposes.

1.

W

heelbrace.

Fo

r removing the wheel trim and removing

the wheel bolts.

2.

Ja

ck with integral handle.

Fo

r raising the vehicle. 3.

"B

olt cover" tool.

Fo

r removing the bolt protectors (covers)

on alloy wheels.

4.

So

cket for the security bolts (located in the

glove box).

Fo

r adapting the wheelbrace to the special

"security" bolts.

5.

tow

ing eye.

Procedure for changing a wheel with a damaged or punctured tyre for the spare wheel using the tools provided with the vehicle.

For more information on towing, refer to

the corresponding section.

Wheel with trim

When refitting the wheel, refit the trim

starting by placing its notch facing the

valve and press around its edge with

the palm of your hand.

In the event of a breakdown

Page 253 of 398

251

308_en_Chap08_en-cas-de-panne_ed02-2015

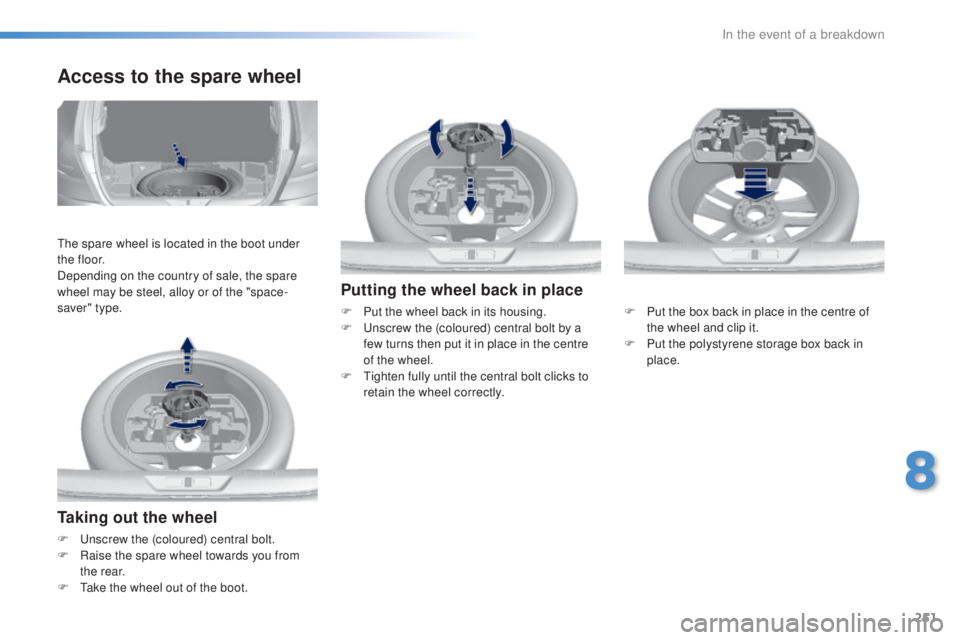

Taking out the wheel

F unscrew the (coloured) central bolt.

F Ra ise the spare wheel towards you from

the rear.

F

t

ak

e the wheel out of the boot.

Access to the spare wheel

the spare wheel is located in the boot under

t h e f l o o r.

Depending on the country of sale, the spare

wheel may be steel, alloy or of the "space-

saver" type.

Putting the wheel back in place

F Put the wheel back in its housing.

F uns crew the (coloured) central bolt by a

few turns then put it in place in the centre

of the wheel.

F

t

ig

hten fully until the central bolt clicks to

retain the wheel correctly. F Pu

t the box back in place in the centre of

the wheel and clip it.

F

Pu

t the polystyrene storage box back in

place.

8

In the event of a breakdown

Page 259 of 398

257

308_en_Chap08_en-cas-de-panne_ed02-2015

In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal sur face of the

glass of the headlamps and rear lamps

is normal; it disappears after the lamps

have been on for a few minutes.the h

eadlamps are fitted with

polycarbonate glass with a protective

coating:

F

do n

ot clean them using a dr y

or abrasive cloth, nor with a

detergent or solvent product,

F

us

e a sponge and soapy water or a

pH neutral product,

F

wh

en using a high pressure washer

on persistent marks, do not keep

the lance directed towards the

lamps or their edges for too long,

so as not to damage their protective

coating and seals.

Changing a bulb should only be done

after the headlamp has been switched

off for several minutes (risk of serious

burns).

F

Do n

ot touch the bulb directly with

your fingers, use a lint-free cloth.

It is imperative to use only anti-

ultraviolet (

uV) t

ype bulbs to avoid

damaging the headlamp.

Always replace a failed bulb with a

new bulb with the same type and

specification.

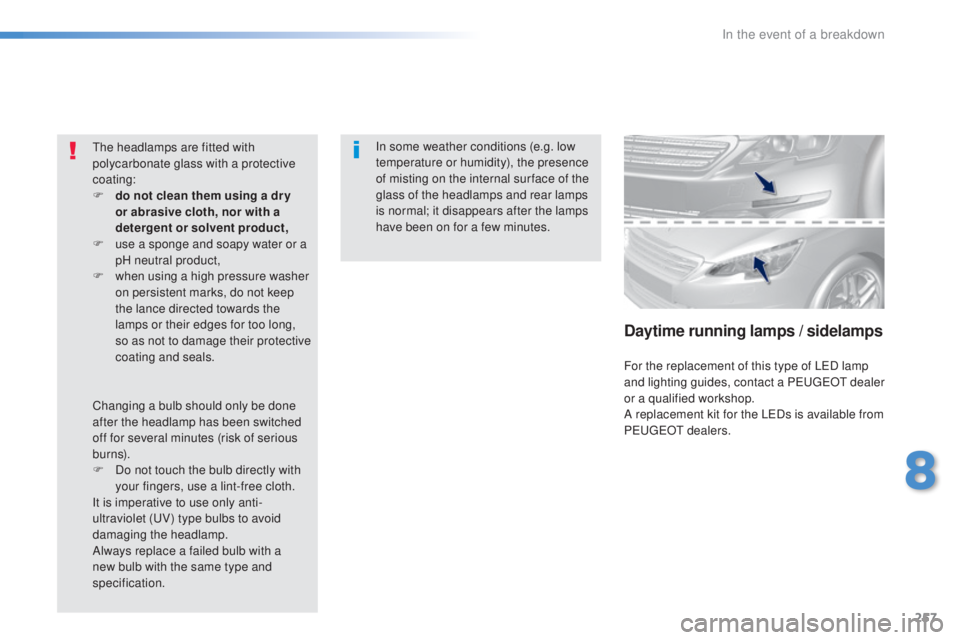

Daytime running lamps / sidelamps

For the replacement of this type of LeD la mp

and lighting guides, contact a Peu geOt d ealer

or a qualified workshop.

A replacement kit for the L

eDs i

s available from

P

eu

ge

Ot dea

lers.

8

In the event of a breakdown

Page 260 of 398

258

308_en_Chap08_en-cas-de-panne_ed02-2015

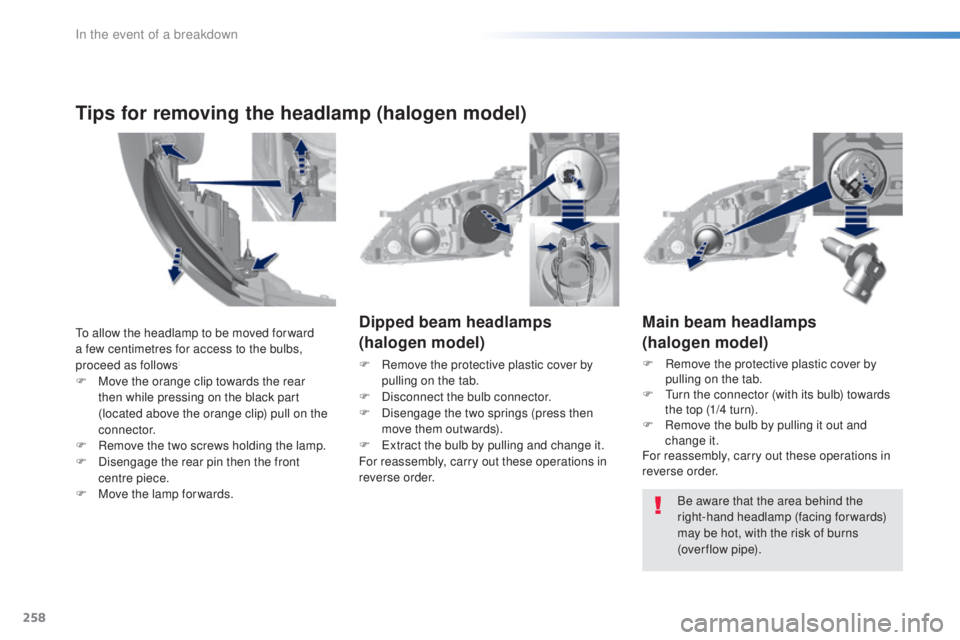

Main beam headlamps

(halogen model)

F Remove the protective plastic cover by

p

ulling on the tab.

F

t

ur

n the connector (with its bulb) towards

the top (1/4 turn).

F

Re

move the bulb by pulling it out and

change it.

For reassembly, carry out these operations in

reverse order.

Dipped beam headlamps

(halogen model)

F Remove the protective plastic cover by

p

ulling on the tab.

F

Di

sconnect the bulb connector.

F

Disenga

ge the two springs (press then

move them outwards).

F

e

xt

ract the bulb by pulling and change it.

For reassembly, carry out these operations in

reverse order.

Be aware that the area behind the

right-hand headlamp (facing forwards)

may be hot, with the risk of burns

(over flow

p

ipe).

to al

low the headlamp to be moved for ward

a few centimetres for access to the bulbs,

proceed as follows:

F Move the orange clip towards the rear

t hen while pressing on the black part

(located above the orange clip) pull on the

connector.

F

Re

move the two screws holding the lamp.

F

Disenga

ge the rear pin then the front

centre piece.

F

Mov

e the lamp for wards.

Tips for removing the headlamp (halogen model)

In the event of a breakdown