ESP PEUGEOT 308 2018 Owners Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2018, Model line: 308, Model: Peugeot 308 2018Pages: 360, PDF Size: 12.38 MB

Page 236 of 360

234

AdBlue® (BlueHDi

engines)

To respect the environment and ensure

compliance with the Euro 6 standard, without

adversely affecting the per formance or fuel

consumption of Diesel engines, PEUGEOT

has taken the decision to equip its vehicles

with a system that associates SCR (Selective

Catalytic Reduction) with a Diesel particle filter

(DPF) for the treatment of exhaust gases.

SCR system

Using a liquid called AdBlue® that contains

urea, a catalytic converter turns up to 85% of

the nitrogen oxides (NOx) into nitrogen and

water, which are harmless to health and the

environment.

The AdBlue

® is contained in

a special tank holding about

17

litres.

An alert system is triggered automatically once

the reser ve level is reached: you can then drive

for a further 1,500

miles (2,400 km) before the

tank is empty. Once the AdBlue

® tank is empty, a

s

ystem required by regulations prevents

starting of the engine.

If the SCR

system is defective, the level

of emissions from your vehicle will no

longer meet the Euro 6 standard: your

vehicle becomes polluting.

In the event of a confirmed fault with the

SCR system, you must go to a PEUGEOT

dealer or a qualified workshop as soon as

possible: after travelling the distance of

685

m

iles (1,100

k

m), a system preventing

the engine starting will be triggered

automatically.

In either case, a range indicator gives you

the distance you can travel before the

vehicle is immobilised.

For more information on the Warning

and indicator lamps and the associated

alerts, refer to the corresponding section.

Freezing of the AdBlue

®

AdBlue® freezes at temperatures below

around -11°C.

The SCR system includes a heater for the

AdBlue

® tank, allowing you to continue

driving in very cold conditions.

Supply of AdBlue®

It is recommended that the AdBlue® is

topped up as soon as the first alert is

issued indicating that the reser ve level

has been reached.

In order to ensure that the SCR system

operates correctly:

-

U

se only AdBlue

® fluid that meets the

ISO 22241 standard.

-

N

ever transfer AdBlue

® to another

container: it would lose its purity.

-

N

ever dilute AdBlue

® with water.

You can obtain AdBlue

® from a PEUGEOT

dealer or a qualified workshop.

You can also visit a ser vice station

equipped with AdBlue

® pumps specially

designed for private vehicles.

Never top up from an AdBlue

® dispenser

reserved for heavy goods vehicles.

Practical information

Page 239 of 360

237

Warning triangle

As a safety precaution, before leaving your

vehicle to set up and install the triangle, switch

on the hazard warning lamps and put on your

high visibility vest.

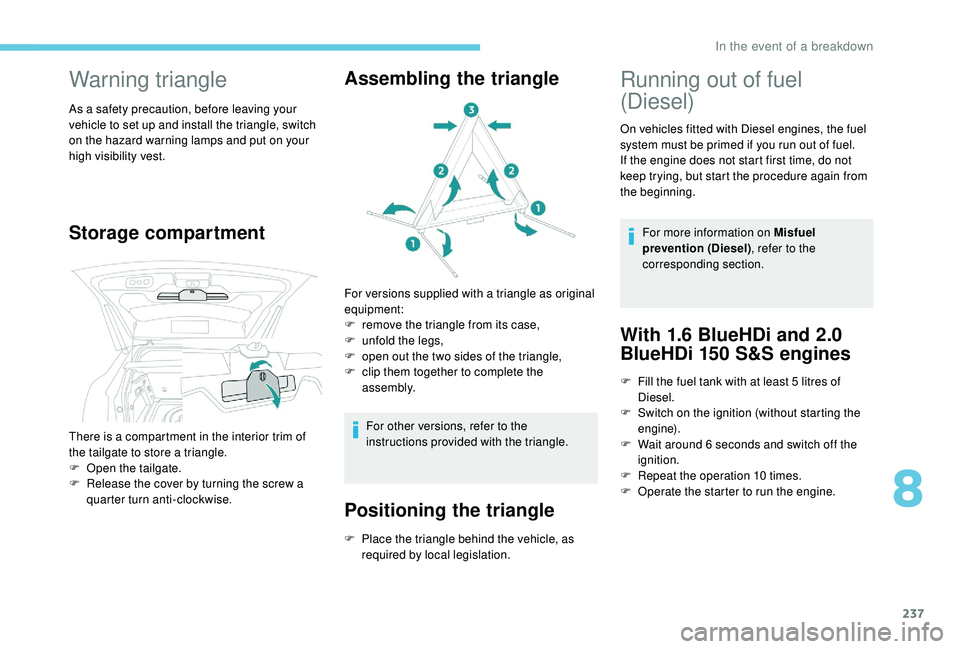

Storage compartmentAssembling the triangle

For versions supplied with a triangle as original

equipment:

F

r

emove the triangle from its case,

F

u

nfold the legs,

F

o

pen out the two sides of the triangle,

F

c

lip them together to complete the

assembly.

For other versions, refer to the

instructions provided with the triangle.

Positioning the triangle

There is a compartment in the interior trim of

the tailgate to store a triangle.

F

O

pen the tailgate.

F

R

elease the cover by turning the screw a

quarter turn anti-clockwise.

F

P

lace the triangle behind the vehicle, as

required by local legislation.

Running out of fuel

(Diesel)

On vehicles fitted with Diesel engines, the fuel

system must be primed if you run out of fuel.

If the engine does not start first time, do not

keep trying, but start the procedure again from

the beginning.

For more information on Misfuel

prevention (Diesel) , refer to the

corresponding section.

With 1.6 BlueHDi and 2.0

BlueHDi 150 S&S engines

F Fill the fuel tank with at least 5 litres of

Diesel.

F

S

witch on the ignition (without starting the

engine).

F

W

ait around 6 seconds and switch off the

ignition.

F

R

epeat the operation 10

times.

F

O

perate the starter to run the engine.

8

In the event of a breakdown

Page 241 of 360

239

All of these tools are specific to your

vehicle and may vary depending on

equipment.

Do not use them for any other purposes.

The jack must only be used to change a

wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original

jack, contact a PEUGEOT dealer or a

qualified workshop to obtain the correct

jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/CE.

The jack does not require any

maintenance.

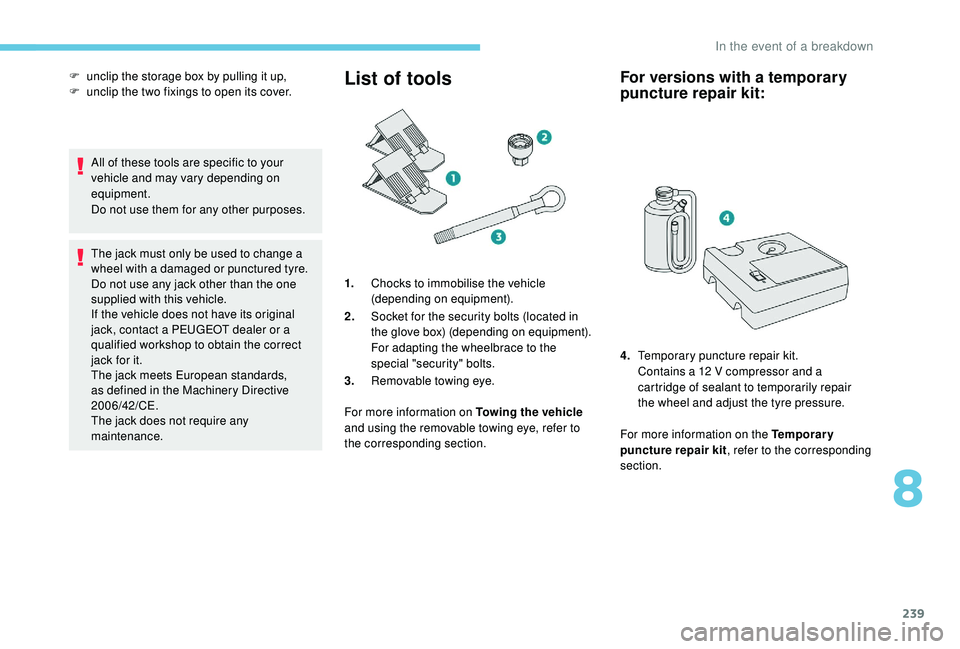

List of tools

1.Chocks to immobilise the vehicle

(depending on equipment).

2. Socket for the security bolts (located in

the glove box) (depending on equipment).

For adapting the wheelbrace to the

special "security" bolts.

3. Removable towing eye.

For more information on Towing the vehicle

and using the removable towing eye, refer to

the corresponding section.

For versions with a temporary

puncture repair kit:

For more information on the Temporary

puncture repair kit , refer to the corresponding

section.

F

u

nclip the storage box by pulling it up,

F

u

nclip the two fixings to open its cover.

4.Temporary puncture repair kit.

Contains a 12 V compressor and a

cartridge of sealant to temporarily repair

the wheel and adjust the tyre pressure.

8

In the event of a breakdown

Page 242 of 360

240

For more information on the Spare wheel, refer

to the corresponding section.

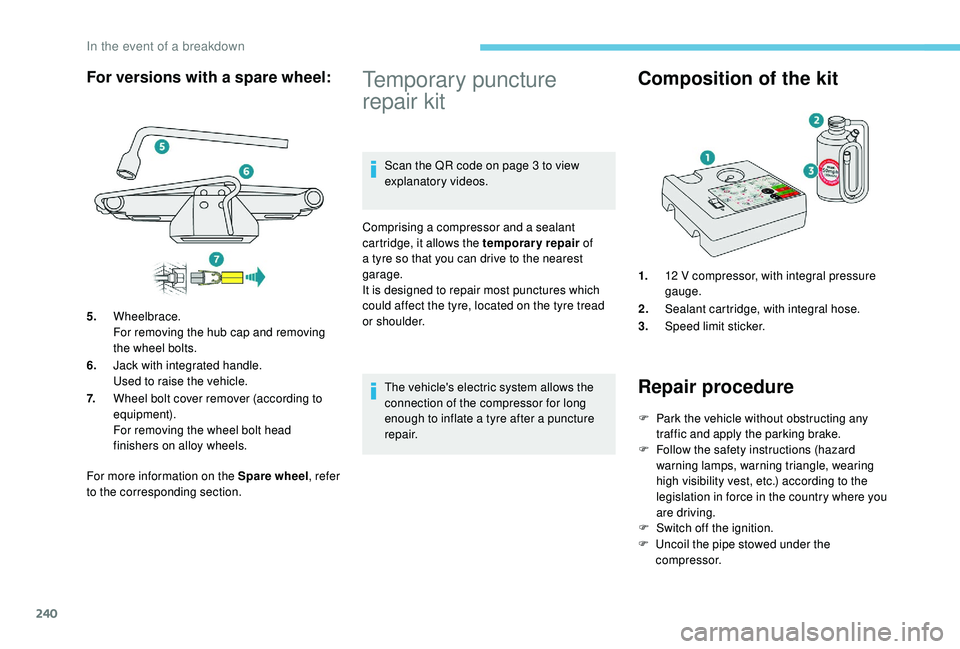

Temporary puncture

repair kit

Scan the QR code on page 3 to view

explanatory videos.

Comprising a compressor and a sealant

cartridge, it allows the temporary repair of

a tyre so that you can drive to the nearest

garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

The vehicle's electric system allows the

connection of the compressor for long

enough to inflate a tyre after a puncture

repair.

Composition of the kit

1. 12 V compressor, with integral pressure

gauge.

2. Sealant cartridge, with integral hose.

3. Speed limit sticker.

Repair procedure

F Park the vehicle without obstructing any

traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard

warning lamps, warning triangle, wearing

high visibility vest, etc.) according to the

legislation in force in the country where you

are driving.

F

S

witch off the ignition.

F

U

ncoil the pipe stowed under the

compressor.

For versions with a spare wheel:

5. Wheelbrace.

For removing the hub cap and removing

the wheel bolts.

6. Jack with integrated handle.

Used to raise the vehicle.

7. Wheel bolt cover remover (according to

equipment).

For removing the wheel bolt head

finishers on alloy wheels.

In the event of a breakdown

Page 245 of 360

243

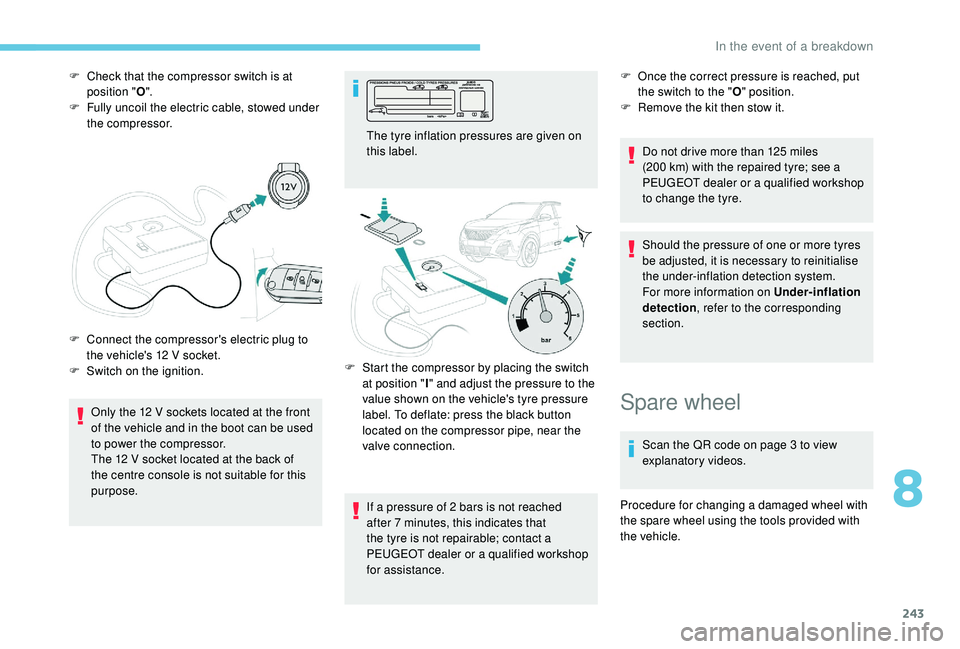

F Check that the compressor switch is at position " O".

F

F

ully uncoil the electric cable, stowed under

the compressor.

Only the 12

V sockets located at the front

of the vehicle and in the boot can be used

to power the compressor.

The 12

V socket located at the back of

the centre console is not suitable for this

purpose.

F

C

onnect the compressor's electric plug to

the vehicle's 12

V socket.

F

S

witch on the ignition. The tyre inflation pressures are given on

this label.

If a pressure of 2

bars is not reached

after 7

minutes, this indicates that

the tyre is not repairable; contact a

PEUGEOT dealer or a qualified workshop

for assistance. F

O nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it.

Do not drive more than 125

miles

(200

km) with the repaired tyre; see a

PEUGEOT dealer or a qualified workshop

to change the tyre.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Under-inflation

detection , refer to the corresponding

section.

F

S

tart the compressor by placing the switch

at position " I" and adjust the pressure to the

value shown on the vehicle's tyre pressure

label. To deflate: press the black button

located on the compressor pipe, near the

valve connection.

Spare wheel

Scan the QR code on page 3 to view

explanatory videos.

Procedure for changing a damaged wheel with

the spare wheel using the tools provided with

the vehicle.

8

In the event of a breakdown

Page 251 of 360

249

Changing direction indicator

bulbs (on models with halogen

headlamps)

Quicker flashing of the direction indicator

lamp (left or right) indicates the failure of

one of the bulbs on the corresponding

side.

F

T

urn the bulb holder a quarter turn and pull

it out.

F

T

urn the bulb a quarter turn, pull it out and

fit a new bulb.

To refit, carry out these operations in reverse

o r d e r.

Amber colour bulbs, such as the direction

indicators, must be replaced by bulbs

with identical colour and specifications. To refit, close the protective cover very

carefully to guarantee the leak-tightness

of the lamp.

Changing dipped beam headlamp

bulbs (on models with halogen

headlamps)

F Remove the protective cover by pulling the

tongue.

F

P

ull the connector back to disconnect it.

F

P

ull the bulb back to extract it.

F

R

eplace the bulb.

To refit, carry out these operations in reverse

o r d e r.

Changing main beam headlamp

bulbs (on models with halogen

headlamps)

F Remove the protective cover by pulling the tongue.

F

T

urn the bulb holder a quarter turn and pull

it out.

F

P

ull the bulb out and replace it.

To refit, carry out these operations in reverse

o r d e r.

8

In the event of a breakdown

Page 254 of 360

252

If changing a bulb within a few minutes

of switching off the ignition, take care not

to touch the exhaust – there is a risk of

burns!

Third brake lamp (LED)

Licence plate lamps

F Insert a thin screwdriver into the slot in the lens.

F

P

ush it out to unclip it.

F

R

emove the lens.

F

P

ull the bulb out and change it.

Changing a wiper blade

Before removing a front

wiper

Removing

F Lift the corresponding wiper arm away from the windscreen.

F

U

nclip and remove the wiper blade.

Refitting

F Position and clip the new wiper blade to the arm.

F

C

arefully lower the wiper arm.

Foglamps

These bulbs are replaced from outside the rear

bumper:

F

P

ass your hand under the bumper,

F

T

urn the bulb holder a quarter turn and

remove it,

F

T

urn the bulb a quarter turn, pull it out and

change it.

To refit, carry out these operations in reverse

o r d e r. F

W

ithin one minute after switching off the

ignition, operate the wiper control stalk to

position the wiper blades in the middle of

the windscreen (maintenance position).

In the event of a breakdown

Page 255 of 360

253

After refitting a front wiper

F Switch on the ignition.

F O perate the wiper control stalk again to

park the wiper blades.

Changing a fuse

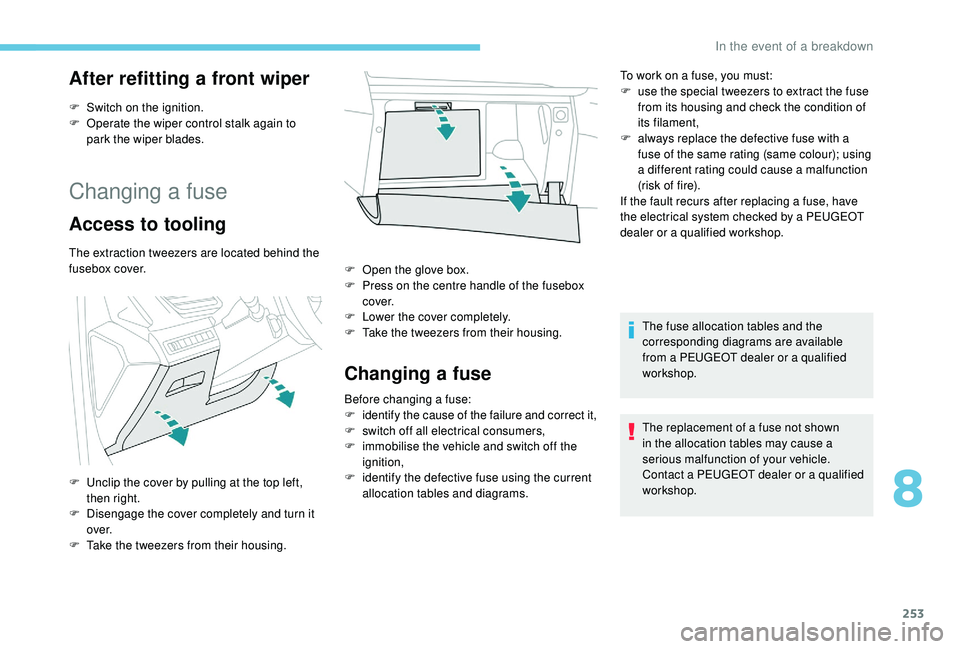

Access to tooling

The extraction tweezers are located behind the

fusebox cover.

F

U

nclip the cover by pulling at the top left,

then right.

F

D

isengage the cover completely and turn it

ove r.

F

T

ake the tweezers from their housing. F

O

pen the glove box.

F

P

ress on the centre handle of the fusebox

c ove r.

F

L

ower the cover completely.

F

T

ake the tweezers from their housing.

Changing a fuse

Before changing a fuse:

F identify the cause of the failure and correct it,

F

s

witch off all electrical consumers,

F

i

mmobilise the vehicle and switch off the

ignition,

F

i

dentify the defective fuse using the current

allocation tables and diagrams. To work on a fuse, you must:

F

u

se the special tweezers to extract the fuse

from its housing and check the condition of

its filament,

F

a

lways replace the defective fuse with a

fuse of the same rating (same colour); using

a different rating could cause a malfunction

(risk of fire).

If the fault recurs after replacing a fuse, have

the electrical system checked by a PEUGEOT

dealer or a qualified workshop.

The fuse allocation tables and the

corresponding diagrams are available

from a PEUGEOT dealer or a qualified

workshop.

The replacement of a fuse not shown

in the allocation tables may cause a

serious malfunction of your vehicle.

Contact a PEUGEOT dealer or a qualified

workshop.

8

In the event of a breakdown

Page 256 of 360

254

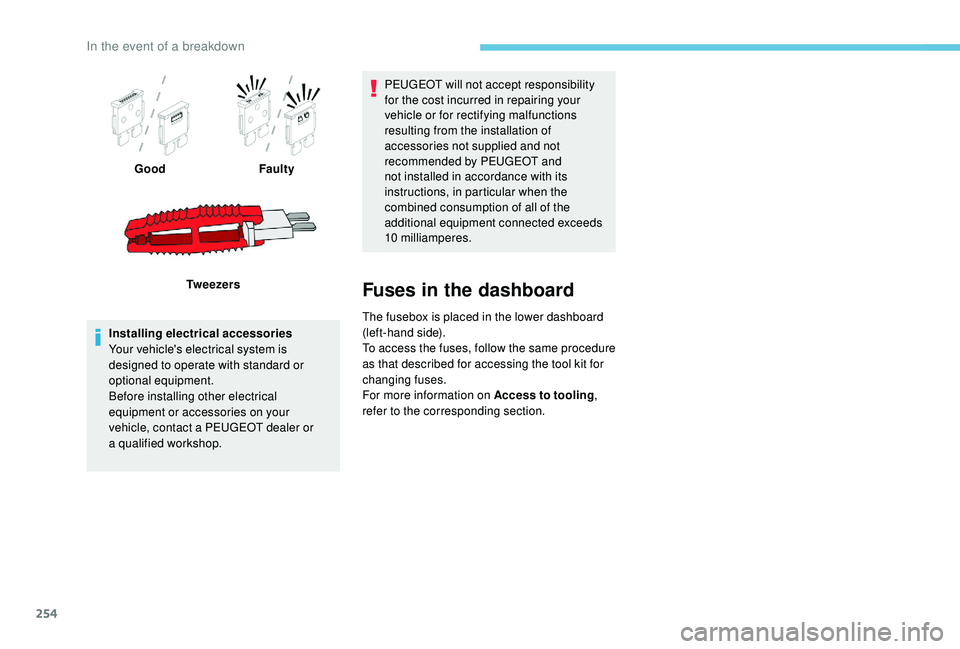

GoodFaulty

Tw e e z e r s

Installing electrical accessories

Your vehicle's electrical system is

designed to operate with standard or

optional equipment.

Before installing other electrical

equipment or accessories on your

vehicle, contact a PEUGEOT dealer or

a

qualified workshop. PEUGEOT will not accept responsibility

for the cost incurred in repairing your

vehicle or for rectifying malfunctions

resulting from the installation of

accessories not supplied and not

recommended by PEUGEOT and

not installed in accordance with its

instructions, in particular when the

combined consumption of all of the

additional equipment connected exceeds

10

milliamperes.

Fuses in the dashboard

The fusebox is placed in the lower dashboard

(left-hand side).

To access the fuses, follow the same procedure

as that described for accessing the tool kit for

changing fuses.

For more information on Access to tooling,

refer to the corresponding section.

In the event of a breakdown

Page 262 of 360

260

Some functions, including Stop & Start,

are not available if the battery is not

sufficiently charged.

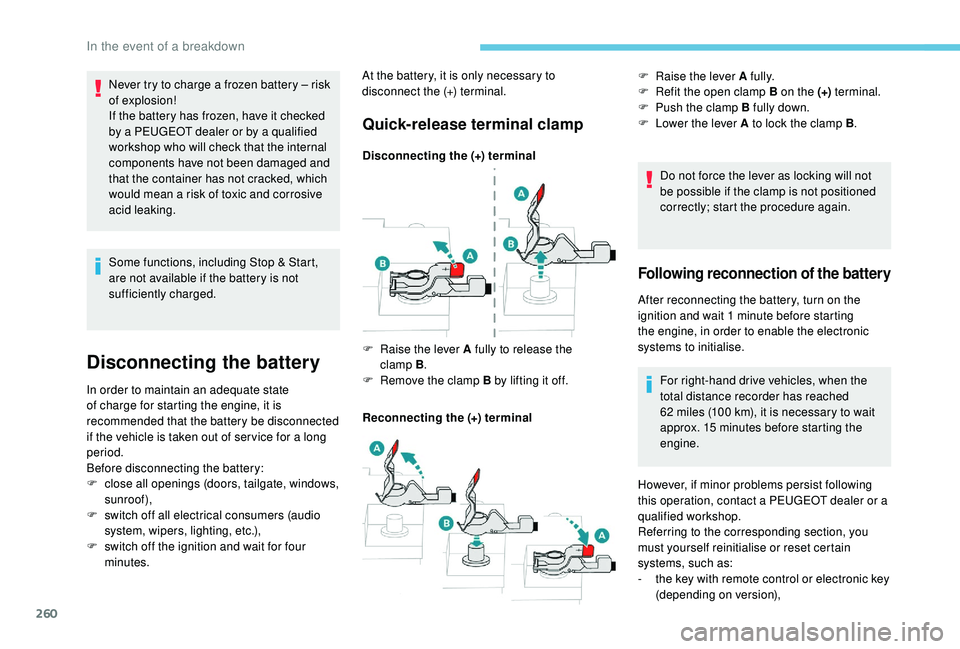

Disconnecting the battery

In order to maintain an adequate state

of charge for starting the engine, it is

recommended that the battery be disconnected

if the vehicle is taken out of ser vice for a long

period.

Before disconnecting the battery:

F

c

lose all openings (doors, tailgate, windows,

sunroof),

F

s

witch off all electrical consumers (audio

system, wipers, lighting, etc.),

F

s

witch off the ignition and wait for four

minutes.

Quick-release terminal clamp

Disconnecting the (+) terminal

Reconnecting the (+) terminal Do not force the lever as locking will not

be possible if the clamp is not positioned

correctly; start the procedure again.

F

Ra

ise the lever A fully to release the

clamp

B.

F

R

emove the clamp B by lifting it off. F

Ra

ise the lever A fully.

F

R

efit the open clamp B on the (+)

terminal.

F

P

ush the clamp B fully down.

F

L

ower the lever A to lock the clamp B

.

Following reconnection of the battery

After reconnecting the battery, turn on the

ignition and wait 1

minute before starting

the engine, in order to enable the electronic

systems to initialise.

For right-hand drive vehicles, when the

total distance recorder has reached

62

miles (100 km), it is necessary to wait

approx. 15

minutes before starting the

engine.

Never try to charge a frozen battery

– risk

of explosion!

If the battery has frozen, have it checked

by a PEUGEOT dealer or by a qualified

workshop who will check that the internal

components have not been damaged and

that the container has not cracked, which

would mean a risk of toxic and corrosive

acid leaking. At the battery, it is only necessary to

disconnect the (+) terminal.

However, if minor problems persist following

this operation, contact a PEUGEOT dealer or a

qualified workshop.

Referring to the corresponding section, you

must yourself reinitialise or reset certain

systems, such as:

-

t

he key with remote control or electronic key

(depending on version),

In the event of a breakdown