ignition Peugeot 308 CC 2014 Workshop Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2014, Model line: 308 CC, Model: Peugeot 308 CC 2014Pages: 268, PDF Size: 15.33 MB

Page 137 of 268

9

!

i

135

CHECKS

CHECKING LEVELS

Engine oil level

The check is carried out either

when the ignition is switched

on using the oil level indicator

in the instrument panel for ve-

hicles with and electric oil level gauge,

or using the dipstick. It is normal to top up the oil level

between two services (or oil chang-

es). PEUGEOT recommends that

you check the level, and top up

if necessary, every 3 000 miles

(5 000 kms).

Take care when working under the

bonnet, as certain areas of the en-

gine may be extremely hot (risk of

burns) and the cooling fan could

start at any time (even with the ig-

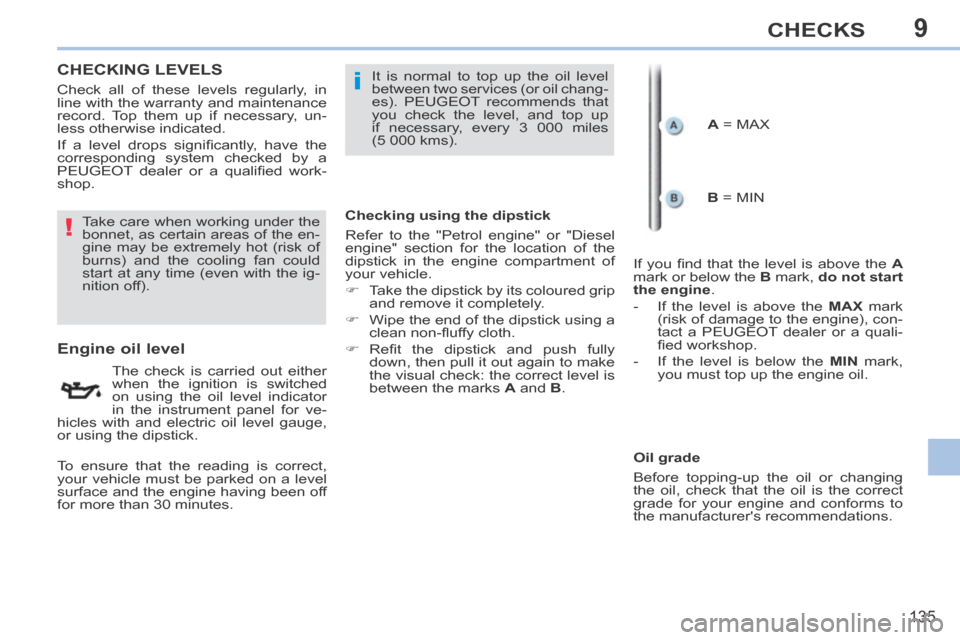

nition off). A = MAX

To ensure that the reading is correct,

your vehicle must be parked on a level

surface and the engine having been off

for more than 30 minutes. Check all of these levels regularly, in

line with the warranty and maintenance

record. Top them up if necessary, un-

less otherwise indicated.

If a level drops signifi cantly, have the

corresponding system checked by a

PEUGEOT dealer or a qualifi ed work-

shop. Checking using the dipstick

Refer to the "Petrol engine" or "Diesel

engine" section for the location of the

dipstick in the engine compartment of

your vehicle.

Take the dipstick by its coloured grip and remove it completely.

Wipe the end of the dipstick using a clean non-fl uffy cloth.

Refi t the dipstick and push fully down, then pull it out again to make

the visual check: the correct level is

between the marks A and B . B = MIN

If you fi nd that the level is above the A

mark or below the B mark, do not start

the engine .

- If the level is above the MAX mark

(risk of damage to the engine), con-

tact a PEUGEOT dealer or a quali-

fi ed workshop.

- If the level is below the MIN mark,

you must top up the engine oil.

Oil grade

Before topping-up the oil or changing

the oil, check that the oil is the correct

grade for your engine and conforms to

the manufacturer's recommendations.

Page 138 of 268

9

i

136

CHECKS

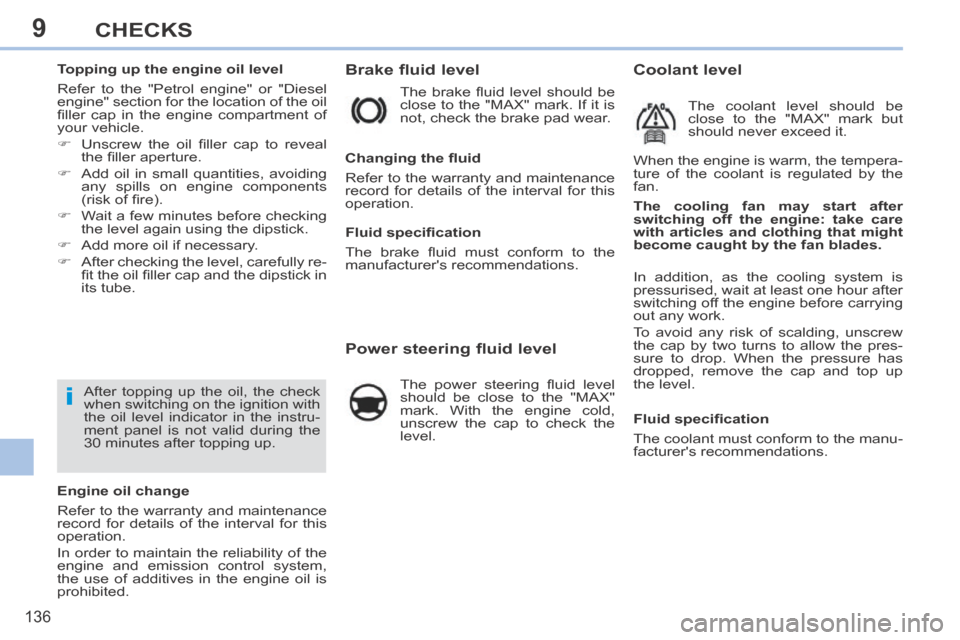

Brake fluid level

The brake fl uid level should be

close to the "MAX" mark. If it is

not, check the brake pad wear.

Power steering fluid level

The power steering fl uid level

should be close to the "MAX"

mark. With the engine cold,

unscrew the cap to check the

level.

Changing the fl uid

Refer to the warranty and maintenance

record for details of the interval for this

operation.

When the engine is warm, the tempera-

ture of the coolant is regulated by the

fan.

Coolant level

The coolant level should be

close to the "MAX" mark but

should never exceed it.

The cooling fan may start after

switching off the engine: take care

with articles and clothing that might

become caught by the fan blades.

Fluid specifi cation

The coolant must conform to the manu-

facturer's recommendations.

Fluid specifi cation

The brake fl uid must conform to the

manufacturer's recommendations.

In addition, as the cooling system is

pressurised, wait at least one hour after

switching off the engine before carrying

out any work.

To avoid any risk of scalding, unscrew

the cap by two turns to allow the pres-

sure to drop. When the pressure has

dropped, remove the cap and top up

the level.

Topping up the engine oil level

Refer to the "Petrol engine" or "Diesel

engine" section for the location of the oil

fi ller cap in the engine compartment of

your vehicle.

Unscrew the oil fi ller cap to reveal

the fi ller aperture.

Add oil in small quantities, avoiding any spills on engine components

(risk of fi re).

Wait a few minutes before checking the level again using the dipstick.

Add more oil if necessary.

After checking the level, carefully re- fi t the oil fi ller cap and the dipstick in

its tube.

After topping up the oil, the check

when switching on the ignition with

the oil level indicator in the instru-

ment panel is not valid during the

30 minutes after topping up.

Engine oil change

Refer to the warranty and maintenance

record for details of the interval for this

operation.

In order to maintain the reliability of the

engine and emission control system,

the use of additives in the engine oil is

prohibited.

Page 143 of 268

10

i!

141

PRACTICAL INFORMATION

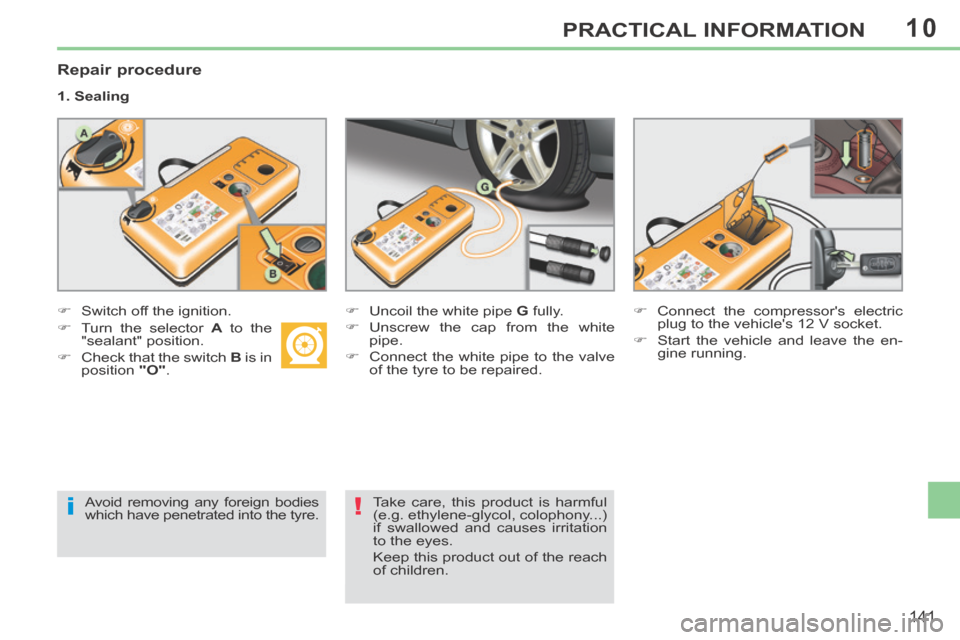

Repair procedure

1. Sealing

Switch off the ignition. Uncoil the white pipe G fully.

Unscrew the cap from the white pipe.

Connect the white pipe to the valve of the tyre to be repaired. Connect the compressor's electric

plug to the vehicle's 12 V socket.

Start the vehicle and leave the en- gine running.

Avoid removing any foreign bodies

which have penetrated into the tyre. Take care, this product is harmful

(e.g. ethylene-glycol, colophony...)

if swallowed and causes irritation

to the eyes.

Keep this product out of the reach

of children.

Turn the selector

A to the

"sealant" position.

Check that the switch B is in

position "O" .

Page 149 of 268

10

i

147

PRACTICAL INFORMATION

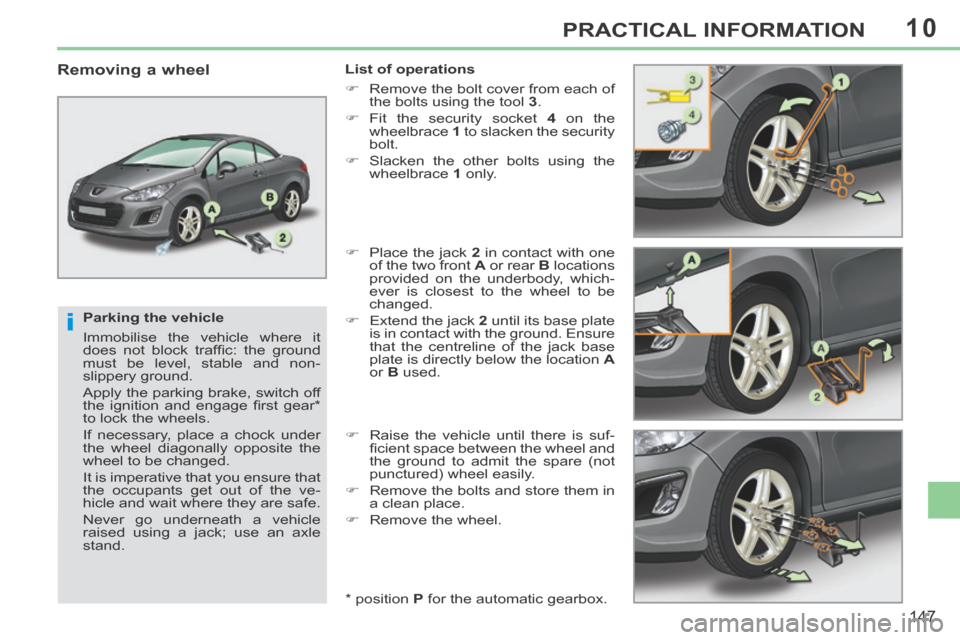

Parking the vehicle

Immobilise the vehicle where it

does not block traffi c: the ground

must be level, stable and non-

slippery ground.

Apply the parking brake, switch off

the ignition and engage fi rst gear *

to lock the wheels.

If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

It is imperative that you ensure that

the occupants get out of the ve-

hicle and wait where they are safe.

Never go underneath a vehicle

raised using a jack; use an axle

stand.

Removing a wheel List of operations

Remove the bolt cover from each of the bolts using the tool 3 .

Fit the security socket 4 on the

wheelbrace 1 to slacken the security

bolt.

Slacken the other bolts using the wheelbrace 1 only.

Place the jack 2 in contact with one

of the two front A or rear B locations

provided on the underbody, which-

ever is closest to the wheel to be

changed.

Extend the jack 2 until its base plate

is in contact with the ground. Ensure

that the centreline of the jack base

plate is directly below the location A

or B used.

Raise the vehicle until there is suf- fi cient space between the wheel and

the ground to admit the spare (not

punctured) wheel easily.

Remove the bolts and store them in a clean place.

Remove the wheel.

* position P for the automatic gearbox.

Page 155 of 268

10

!

153

PRACTICAL INFORMATION

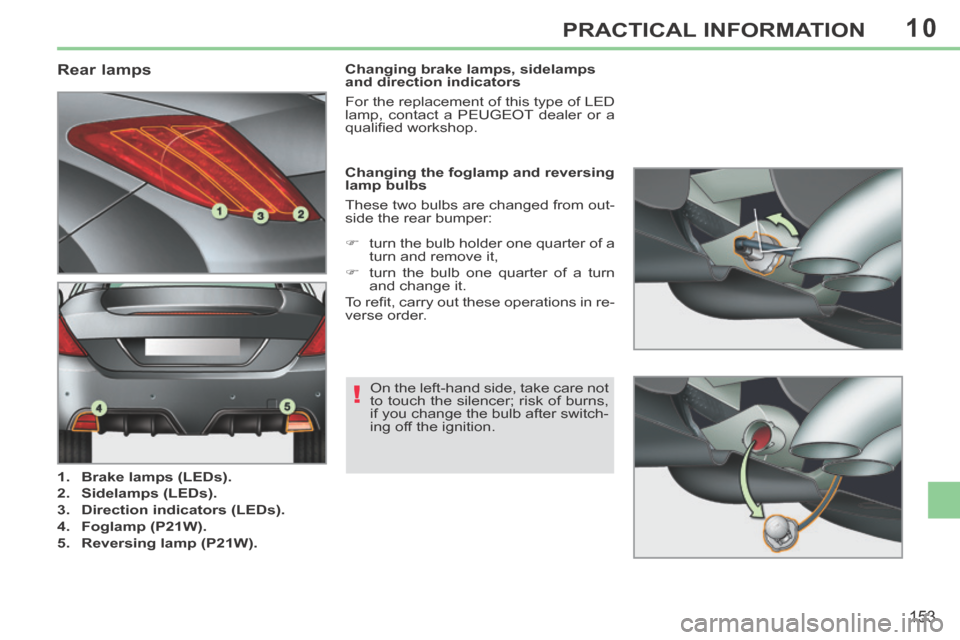

Rear lamps

1. Brake lamps (LEDs).

2. Sidelamps (LEDs).

3. Direction indicators (LEDs).

4. Foglamp (P21W).

5. Reversing lamp (P21W). Changing the foglamp and reversing

lamp bulbs

These two bulbs are changed from out-

side the rear bumper:

On the left-hand side, take care not

to touch the silencer; risk of burns,

if you change the bulb after switch-

ing off the ignition.

turn the bulb holder one quarter of a

turn and remove it,

turn the bulb one quarter of a turn and change it.

To refi t, carry out these operations in re-

verse order. Changing brake lamps, sidelamps

and direction indicators

For the replacement of this type of LED

lamp, contact a PEUGEOT dealer or a

qualifi ed workshop.

Page 157 of 268

10

!

i

155

PRACTICAL INFORMATION

PEUGEOT will not accept responsi-

bility for the cost incurred in repairing

your vehicle or for rectifying malfunc-

tions resulting from the installation

of accessories not supplied and not

recommended by PEUGEOT and

not installed in accordance with its

instructions, in particular when the

combined consumption of all of the

additional equipment connected ex-

ceeds 10 milliamperes. Installing electrical accessories

Your vehicle's electrical system is

designed to operate with standard

or optional equipment.

Before installing other electrical

equipment or accessories on your

vehicle, contact a PEUGEOT dealer

or a qualifi ed workshop.

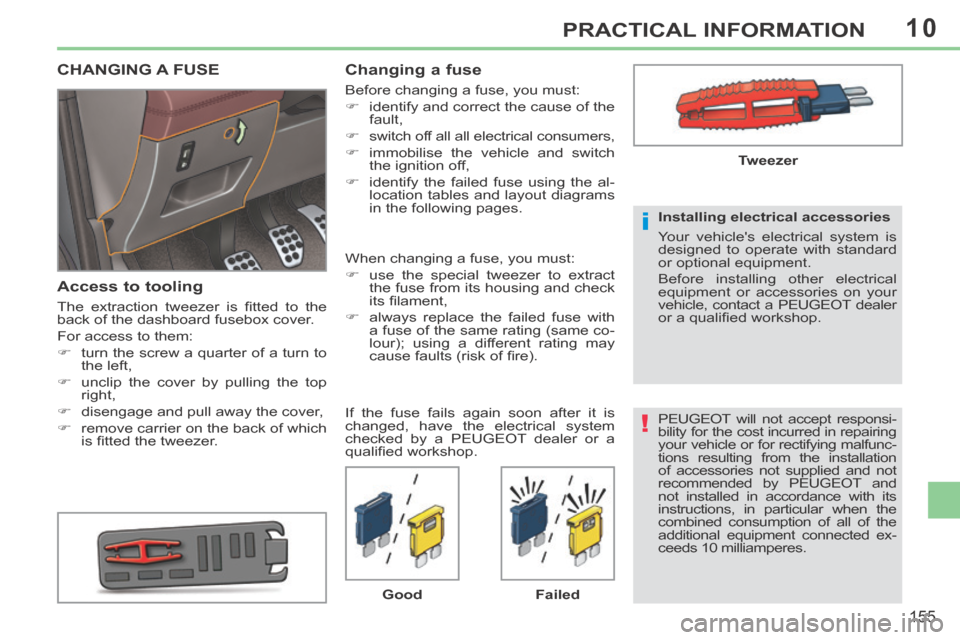

CHANGING A FUSE

Access to tooling

The extraction tweezer is fi tted to the

back of the dashboard fusebox cover.

For access to them:

turn the screw a quarter of a turn to the left,

unclip the cover by pulling the top right,

disengage and pull away the cover,

remove carrier on the back of which is fi tted the tweezer.

Changing a fuse

Before changing a fuse, you must:

identify and correct the cause of the fault,

switch off all all electrical consumers,

immobilise the vehicle and switch the ignition off,

identify the failed fuse using the al- location tables and layout diagrams

in the following pages.

Good Failed Tweezer

When changing a fuse, you must:

use the special tweezer to extract the fuse from its housing and check

its fi lament,

always replace the failed fuse with a fuse of the same rating (same co-

lour); using a different rating may

cause faults (risk of fi re).

If the fuse fails again soon after it is

changed, have the electrical system

checked by a PEUGEOT dealer or a

qualifi ed workshop.

Page 158 of 268

10

156

PRACTICAL INFORMATION

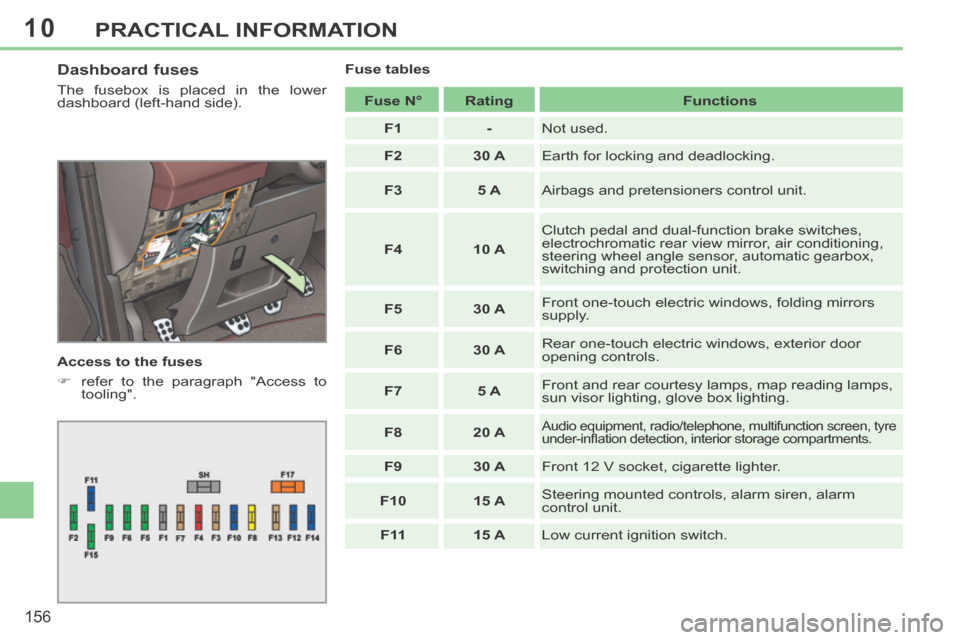

Dashboard fuses

The fusebox is placed in the lower

dashboard (left-hand side).

Access to the fuses

refer to the paragraph "Access to tooling". Fuse tables

Fuse N° Rating Functions

F1 - Not used.

F2 30 A Earth for locking and deadlocking.

F3 5 A Airbags and pretensioners control unit.

F4 10 A Clutch pedal and dual-function brake switches,

electrochromatic rear view mirror, air conditioning,

steering wheel angle sensor, automatic gearbox,

switching and protection unit.

F5 30 A Front one-touch electric windows, folding mirrors

supply.

F6 30 A Rear one-touch electric windows, exterior door

opening controls.

F7 5 A Front and rear courtesy lamps, map reading lamps,

sun visor lighting, glove box lighting.

F8 20 A

Audio equipment, radio/telephone, multifunction screen, tyre

under-infl ation detection, interior storage compartments.

F9 30 A Front 12 V socket, cigarette lighter.

F10 15 A Steering mounted controls, alarm siren, alarm

control unit.

F 11 15 A Low current ignition switch.

Page 160 of 268

10

158

PRACTICAL INFORMATION

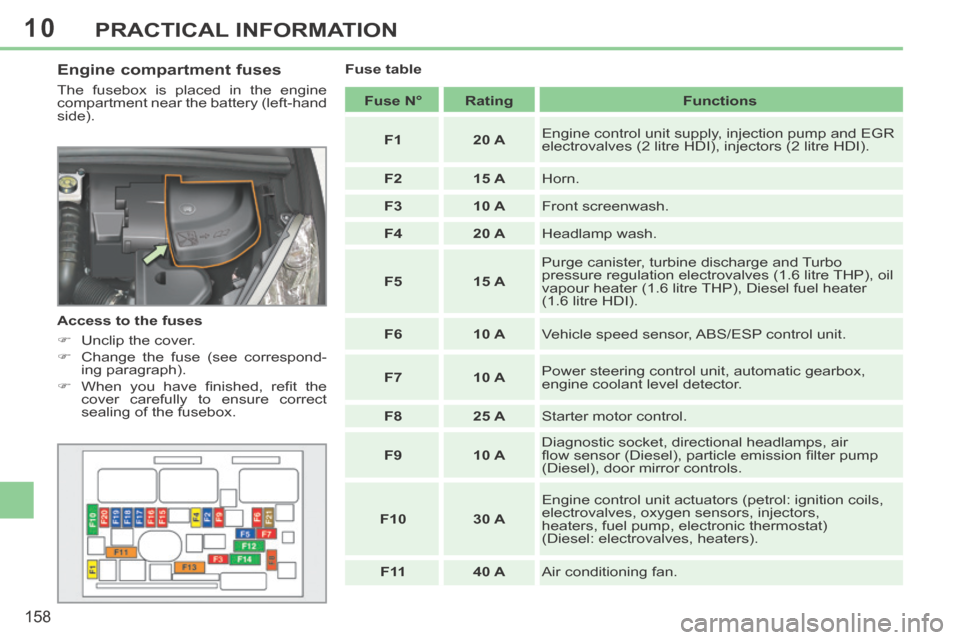

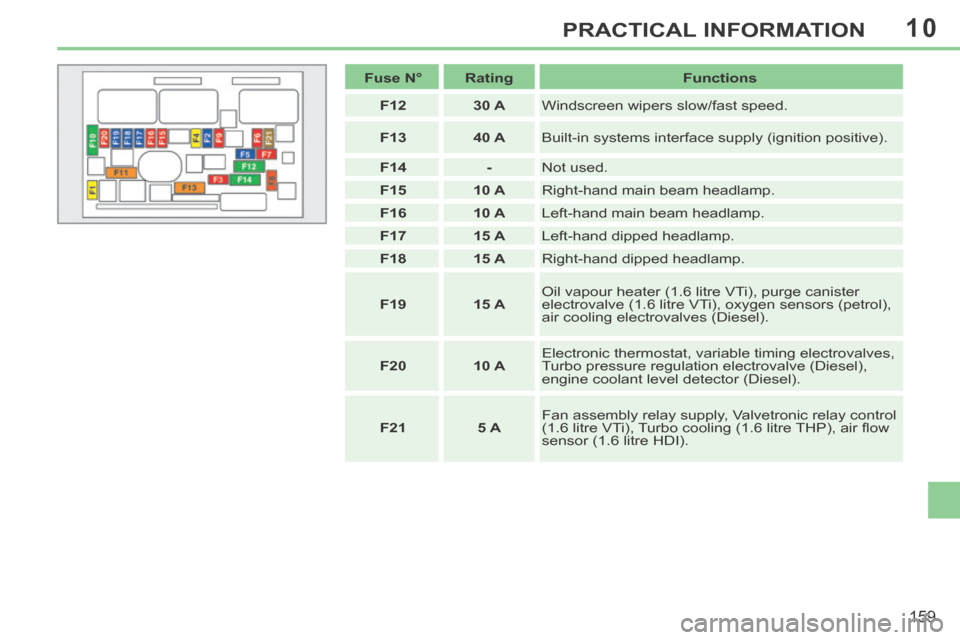

Engine compartment fuses

The fusebox is placed in the engine

compartment near the battery (left-hand

side).

Access to the fuses

Unclip the cover.

Change the fuse (see correspond-ing paragraph).

When you have fi nished, refi t the cover carefully to ensure correct

sealing of the fusebox. Fuse table

Fuse N° Rating Functions

F1 20 A Engine control unit supply, injection pump and EGR

electrovalves (2 litre HDI), injectors (2 litre HDI).

F2 15 A Horn.

F3 10 A Front screenwash.

F4 20 A Headlamp wash.

F5 15 A Purge canister, turbine discharge and Turbo

pressure regulation electrovalves (1.6 litre THP), oil

vapour heater (1.6 litre THP), Diesel fuel heater

(1.6 litre HDI).

F6 10 A Vehicle speed sensor, ABS/ESP control unit.

F7 10 A Power steering control unit, automatic gearbox,

engine coolant level detector.

F8 25 A Starter motor control.

F9 10 A Diagnostic socket, directional headlamps, air

fl ow sensor (Diesel), particle emission fi lter pump

(Diesel), door mirror controls.

F10 30 A Engine control unit actuators (petrol: ignition coils,

electrovalves, oxygen sensors, injectors,

heaters, fuel pump, electronic thermostat)

(Diesel: electrovalves, heaters).

F 11 40 A Air conditioning fan.

Page 161 of 268

10

159

PRACTICAL INFORMATION

Fuse N° Rating Functions

F12 30 A Windscreen wipers slow/fast speed.

F13 40 A Built-in systems interface supply (ignition positive).

F14 - Not used.

F15 10 A Right-hand main beam headlamp.

F16 10 A Left-hand main beam headlamp.

F17 15 A Left-hand dipped headlamp.

F18 15 A Right-hand dipped headlamp.

F19 15 A Oil vapour heater (1.6 litre VTi), purge canister

electrovalve (1.6 litre VTi), oxygen sensors (petrol),

air cooling electrovalves (Diesel).

F20 10 A Electronic thermostat, variable timing electrovalves,

Turbo pressure regulation electrovalve (Diesel),

engine coolant level detector (Diesel).

F21 5 A Fan assembly relay supply, Valvetronic relay control

(1.6 litre VTi), Turbo cooling (1.6 litre THP), air fl ow

sensor (1.6 litre HDI).

Page 163 of 268

10

!

i

i

!

161

PRACTICAL INFORMATION

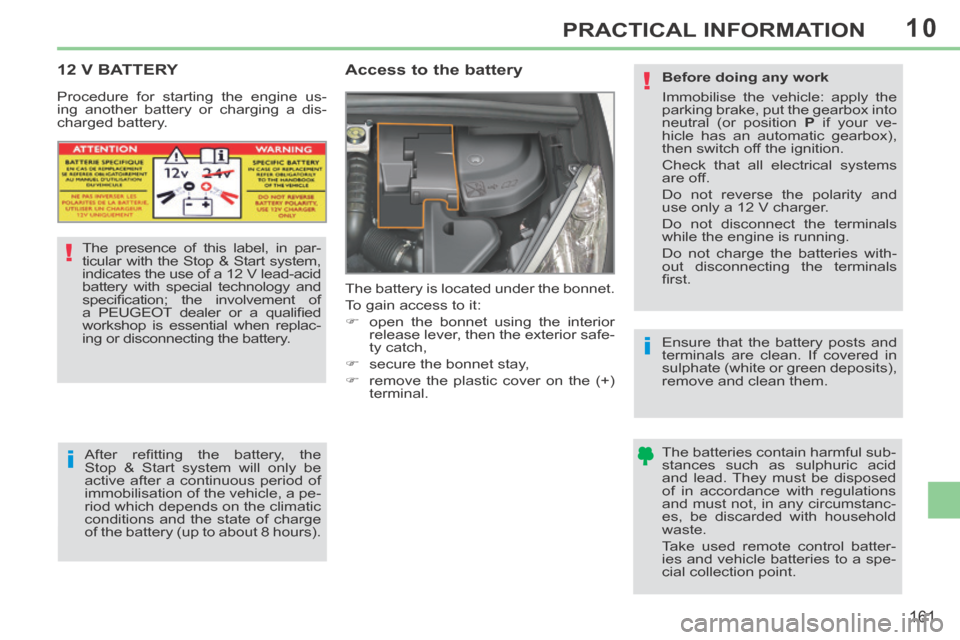

12 V BATTERY

Access to the battery

The battery is located under the bonnet.

To gain access to it:

open the bonnet using the interior release lever, then the exterior safe-

ty catch,

secure the bonnet stay,

remove the plastic cover on the (+) terminal.

The presence of this label, in par-

ticular with the Stop & Start system,

indicates the use of a 12 V lead-acid

battery with special technology and

specifi cation; the involvement of

a PEUGEOT dealer or a qualifi ed

workshop is essential when replac-

ing or disconnecting the battery.

After refi tting the battery, the

Stop & Start system will only be

active after a continuous period of

immobilisation of the vehicle, a pe-

riod which depends on the climatic

conditions and the state of charge

of the battery (up to about 8 hours).

Procedure for starting the engine us-

ing another battery or charging a dis-

charged battery.

Before doing any work

Immobilise the vehicle: apply the

parking brake, put the gearbox into

neutral (or position

P if your ve-

hicle has an automatic gearbox),

then switch off the ignition.

Check that all electrical systems

are off.

Do not reverse the polarity and

use only a 12 V charger.

Do not disconnect the terminals

while the engine is running.

Do not charge the batteries with-

out disconnecting the terminals

fi rst.

Ensure that the battery posts and

terminals are clean. If covered in

sulphate (white or green deposits),

remove and clean them.

The batteries contain harmful sub-

stances such as sulphuric acid

and lead. They must be disposed

of in accordance with regulations

and must not, in any circumstanc-

es, be discarded with household

waste.

Take used remote control batter-

ies and vehicle batteries to a spe-

cial collection point.