tow PEUGEOT 408 2023 Service Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2023, Model line: 408, Model: PEUGEOT 408 2023Pages: 244, PDF Size: 7.37 MB

Page 165 of 244

163

Practical information

7Fluid specification

The fluid must be topped up with a pre-mixed

product.

In winter (temperatures below zero), a fluid

containing an anti-freeze agent which is

appropriate for the temperature conditions

must be used in order to protect the system's

components (pump, tank, ducts, jets).

Filling with pure water is prohibited in all

circumstances (risk of freezing,

limescale, etc.).

Checks

Unless otherwise indicated, check these

components in accordance with the

Manufacturer's service schedule and according

to your engine.

Otherwise, have them checked by a PEUGEOT

dealer or a qualified workshop.

Only use products recommended by

PEUGEOT or products of equivalent

quality and specification.

In order to optimise the operation of

components as important as those in the

braking system, PEUGEOT selects and offers

very specific products.

12 V battery

The battery does not require any maintenance.

Check regularly that the terminals are correctly

tightened (versions without quick-release

terminals) and that the connections are clean.

For more information on the precautions

to take before any work on the 12 V

battery, refer to the corresponding section.

Versions equipped with Stop & Start are

fitted with a 12 V lead-acid battery with

special technology and specifications.

Its replacement should be carried out only by

a PEUGEOT dealer or a qualified workshop.

Passenger compartment

filter

Depending on the environment and the

use of the vehicle (e.g. dusty atmosphere,

city driving), change it twice as often, if

necessary .

A clogged passenger compartment filter

can adversely affect air conditioning

system performance and generate

undesirable odours.

Air filter

Depending on the environment and the

use of the vehicle (e.g. dusty atmosphere,

city driving), change it twice as often, if

necessary .

Oil filter

Change the oil filter each time the engine

oil is changed.

Automatic gearbox

The gearbox does not require any

maintenance (no oil change).

Brake pads

Brake wear depends on the style of

driving, particularly in the case of vehicles

used in town, over short distances. It may be

necessary to have the condition of the brakes

checked, even between vehicle services.

Unless there is a leak in the circuit, a drop in the

brake fluid level indicates that the brake pads

are worn.

After washing the vehicle, moisture, or in wintry conditions, ice can form on the

brake discs and pads: braking efficiency may

be reduced. Gently dab the brakes to dry and

defrost them. CarM an uals 2 .c o m

Page 166 of 244

164

Practical information

Brake disc wear

For information on checking brake disc

wear, contact a PEUGEOT dealer or a

qualified workshop.

Electric parking brake

This system does not require any routine servicing. However, in the event of a

problem, do not hesitate to have the system

checked by a PEUGEOT dealer or a qualified

workshop.

For more information on the Electric

parking brake, refer to the

corresponding section.

Wheels and tyres

The inflation pressure of all tyres, including the spare wheel, must be

checked on "cold” tyres.

The pressures indicated on the tyre pressure

label are valid for "cold" tyres. If you have driven

for more than 10 minutes or more than 6 miles

(10 kilometres) at over 31 mph (50

km/h), add

0.3 bar (30 kPa) to the values indicated on the

label.

Under-inflation increases energy

consumption. Non-compliant tyre

pressures cause tyres to wear prematurely

and have an adverse effect on the vehicle's

road holding - risk of accident! Driving with worn or damaged tyres reduces the

braking and road holding performance of the

vehicle. Regularly check the condition of the

tyres (tread and sidewalls) and rims as well as

the presence of the valve caps.

When the wear indicators no longer appear set

back from the tread, the depth of the grooves is

less than 1.6 mm; replace the tyres as soon as

possible.

Using different size wheels and tyres from those

specified can affect the lifetime of tyres, wheel

rotation, ground clearance, the speedometer

reading and have an adverse effect on road

holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

Always mark the direction of rotation on the tyres

that will be stored when fitting winter or summer

tyres. Store them in a cool, dry place and away

from direct exposure to the sun's rays.

Winter or 4-seasons tyres can be

identified by this symbol on their

sidewalls.

Shock absorbers

It is not easy for drivers to detect when

shock absorbers are worn. Nevertheless,

the shock absorbers have a major impact on

road holding and braking performance.

For your safety and driving comfort, it is

important to have them regularly checked by a

PEUGEOT dealer or a qualified workshop.

Timing and accessory kits

The timing and accessory kits are used

from the time the engine is started until it

is switched off. It is normal for them to wear over

time.

A

faulty timing or accessory kit can damage

the engine, rendering it unusable. Observe the

recommended replacement frequency, stated in

distance travelled or time elapsed, whichever is

reached first.

Free-wheeling

In certain situations, it is necessary to put the

vehicle into free-wheeling mode (e.g. towing, on

a rolling road, automatic car wash (Wash mode),

rail or sea transport).

Never leave the vehicle unattended with

the vehicle into free-wheeling mode.

/

Release procedure

With the vehicle stationary and the engine

running:

►

Depress and hold the brake pedal.

►

Select and hold the mode

N

on the push

selector.

►

Press the

START/STOP button around 1 s to

switch off the engine (confirmed by the flashing

of the P and N indicator lights). CarM an uals 2 .c o m

Page 171 of 244

169

In the event of a breakdown

8The jack meets European standards, as

defined in the Machinery Directive 2006/42/

CE.

The jack does not require any maintenance.

List of tools

1.Chock to immobilise the vehicle (depending

on equipment)

2. Socket for the security bolts (located in the

glove box) (depending on equipment)

To adapt the wheelbrace to the special

‘security’ bolts.

3. Removable towing eye

For more information on Towing the vehicle

and using the removable towing eye, refer to the

corresponding section.

With temporary puncture repair kit

4. 12 V compressor with cartridge of sealant

and speed limit sticker

For temporary repair of a tyre and to adjust

the tyre pressure.

For more information on the Temporary

puncture repair kit, refer to the corresponding

section.

With spare wheel

5. Wheelbrace

For removing the wheel bolts.

6.Jack with integrated handle

To raise the vehicle.

7. Wheel bolt cap removal tool (depending on

equipment)

For removing the wheel trim from steel

wheels or the central bolt cover from alloy

wheels.

For more information on the Spare wheel, refer

to the corresponding section.

Temporary puncture repair kit

Visit this link to view explanatory videos:

http://q-r.to/bagGl9

Made up of a compressor and a sealant

cartridge,

it allows you to carry out a temporary

repair of the tyre so that you can drive to the

nearest garage.

It is designed to repair most punctures located

on the tyre tread.

The vehicle's electric system allows the connection of the compressor to the 12 V

power supply for long enough to repair a tyre

after a puncture. CarM an uals 2 .c o m

Page 172 of 244

170

In the event of a breakdown

Only the 12 V socket located at the front

of the vehicle can be used to power the

compressor.

For more information on the Tool kit,

refer to the corresponding section.

Tyre inflation pressures are indicated on this label.

For more information on Identification

markings, particularly this label, refer to the

corresponding section.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-inflation

detection, refer to the corresponding section.

Repair procedure

Do not remove any foreign body

(e.g. nail, screw) which has penetrated

the tyre.

►

Park the vehicle without obstructing traffic

and apply the parking brake.

►

Follow the safety instructions (hazard

warning lamps, warning triangle, high visibility jacket, etc.) according to the legislation in force

in the country in which you are driving.

►

Switch the ignition off.

► Remove the transparent cap from the bottle

of sealant.

►

Lift the protective cover before installing the

bottle of sealant on the compressor

.

►

T

urn the bottle of sealant over and screw it a

quarter turn into the compressor.

►

Remove the valve cap from the tyre to be

repaired, and place it in a clean place.

► Uncoil the pipe stowed under the compressor.

► Connect the pipe from the compressor to the

valve of the tyre to be repaired and tighten firmly .

►

Check that the compressor switch is in

position

"O".

►

Fully uncoil the electric cable stowed under

the compressor

.

►

Connect the compressor's electric plug to the

vehicle's 12

V socket.

► Affix the speed limit sticker .

The speed limit sticker must be affixed

inside the vehicle in the area close to the

driver, to remind them that a wheel is in

temporary use.

►

Switch the ignition on.

► Switch on the compressor by moving the

switch to position "I" until the tyre pressure

reaches 2

bar. The sealant product is injected

under pressure into the tyre; do not disconnect

the pipe from the valve during this operation (risk

of blowback). CarM an uals 2 .c o m

Page 173 of 244

171

In the event of a breakdown

8If after approximately 7 minutes, the

pressure of 2 bar is not reached, this

indicates that the tyre is not repairable;

contact a PEUGEOT dealer or a qualified

workshop for assistance.

►

Move the switch to position

"O".

►

Disconnect the compressor's electric plug

from the vehicle's 12

V socket.

►

Remove the kit.

►

Refit the cap on the valve.

►

Remove and store the bottle of sealant.

The sealant product is harmful if swallowed and causes irritation to the

eyes.

Keep this product out of the reach of children.

The use-by date of the fluid is marked on the

bottle.

After use, do not discard the bottle into the

environment; take it to a PEUGEOT dealer or

an authorised waste disposal site.

Do not forget to obtain a new bottle of

sealant, available from a PEUGEOT dealer or

a qualified workshop.

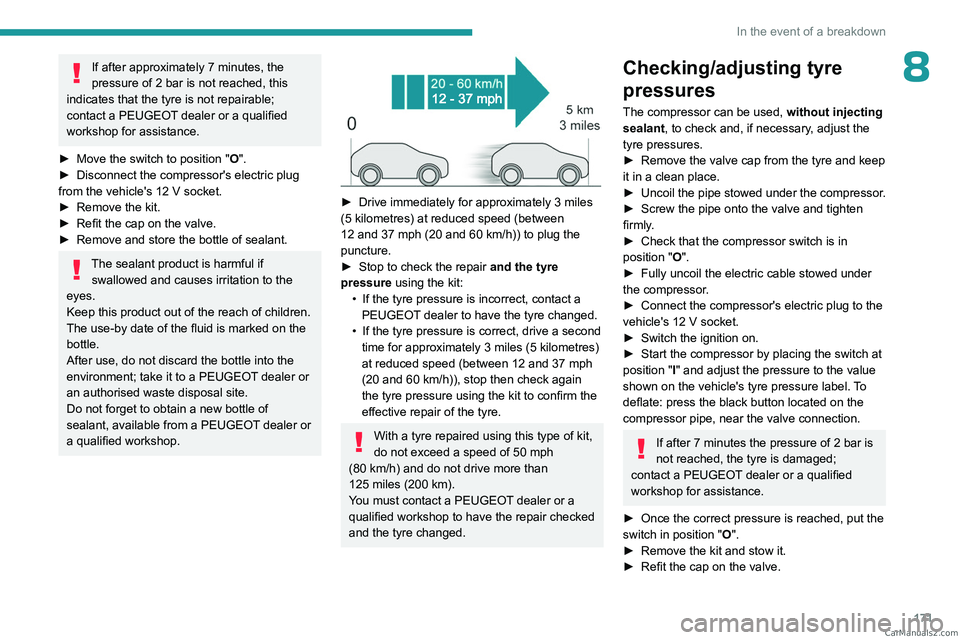

► Drive immediately for approximately 3 miles

(5 kilometres) at reduced speed (between

12 and 37

mph (20 and 60 km/h)) to plug the

puncture.

►

Stop to check the repair

and the tyre

pressure using the kit:

•

If the tyre pressure is incorrect, contact a

PEUGEOT

dealer to have the tyre changed.

•

If the tyre pressure is correct, drive a second

time for approximately 3

miles (5 kilometres)

at reduced speed (between 12 and 37

mph

(20 and 60

km/h)), stop then check again

the tyre pressure using the kit to confirm the

effective repair of the tyre.

With a tyre repaired using this type of kit,

do not exceed a speed of 50 mph

(80

km/h) and do not drive more than

125

miles (200 km).

You must contact a PEUGEOT dealer or a

qualified workshop to have the repair checked

and the tyre changed.

Checking/adjusting tyre

pressures

The compressor can be used, without injecting

sealant, to check and, if necessary, adjust the

tyre pressures.

►

Remove the valve cap from the tyre and keep

it in a clean place.

►

Uncoil

the pipe stowed under the compressor.

►

Screw the pipe onto the valve and tighten

firmly

.

►

Check that the compressor switch is in

position

"O".

►

Fully uncoil the electric cable stowed under

the compressor

.

►

Connect the compressor's electric plug to the

vehicle's 12

V socket.

►

Switch the ignition on.

►

Start the compressor by placing the switch at

position

"I" and adjust the pressure to the value

shown on the vehicle's tyre pressure label. To

deflate: press the black button located on the

compressor pipe, near the valve connection.

If after 7 minutes the pressure of 2 bar is

not reached, the tyre is damaged;

contact a PEUGEOT

dealer or a qualified

workshop for assistance.

►

Once the correct pressure is reached, put the

switch in position

"O".

►

Remove the kit and stow it.

►

Refit the cap on the valve. CarM an uals 2 .c o m

Page 174 of 244

172

In the event of a breakdown

Spare wheel

Visit this link to view explanatory videos:

http://q-r.to/bagGl9

For more information on the Tool kit,

refer to the corresponding section.

Accessing the spare wheel

The spare wheel is stored in the boot, under the

floor.

To access the spare wheel, first refer to the Tool

kit section.

Depending on version, the spare wheel

may be a standard (steel or aluminium)

or 'space-saver' wheel.

Removing the spare wheel

► Slacken the central nut.

► Remove the fastening device (nut and bolt).

►

Lift the spare wheel towards you from the

rear

.

►

T

ake the wheel out of the boot.

Putting the spare wheel back in place

The punctured wheel cannot be put under the boot floor.

► Put the spare wheel back in place in its

housing.

►

Slacken the nut on the bolt by a few turns.

► Position the fastening device (nut and bolt) in

the middle of the wheel.

► Tighten the central nut sufficiently to retain

the wheel correctly.

►

Put the tool box back in place in the middle of

the wheel and clip it in place.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does

not obstruct traffic: the ground must be level,

stable and non-slippery.

Select mode

P on the automatic gearbox

to lock the wheels, apply the parking brake,

unless it is set to automatic mode, and switch

off the ignition.

Check that the parking brake indicator lamps

on the instrument panel are on fixed.

The occupants must get out of the vehicle

and wait where they are safe.

If necessary, place a chock under the wheel

diagonally opposite the wheel to be changed. CarM an uals 2 .c o m

Page 177 of 244

175

In the event of a breakdown

8Do not exceed the maximum authorised

speed of 50 mph (80 km/h) or the maximum

distance of 50 miles (80 km).

Driving with more than one "space-saver"

type spare wheel is prohibited.

Go to a PEUGEOT dealer or a qualified

workshop.

Have the tightening of the spare wheel's bolts

and its tyre pressure checked.

Have the punctured tyre examined. After

inspection, the technician will advise you on

whether the tyre can be repaired or if it must

be replaced.

Changing a bulb

In some weather conditions (e.g. low

temperature or humidity), misting on the

internal surface of the glass of the headlamps

and rear lamps is normal, and will disappear

after the lamps have been on for a few

minutes.

Never look too closely at the light beam

of LED technology lamps - risk of serious

eye injury!

The headlamps have polycarbonate lenses with a protective coating:

–

Do not clean them with a dry or abrasive

cloth, nor with detergent or solvent

products.

–

Use a sponge and soapy water or a pH

neutral product.

–

When using a high-pressure washer on

persistent marks, do not keep the lance

directed towards the headlamps, lamps or

their edges for too long, so as not to damage

their protective coating and seals.

Light-emitting diode (LED)

headlamps and lamps

Depending on version, the affected types of

headlamps/lamps are:

–

LED technology headlamps.

–

Full LED technology headlamps.

–

Offset daytime running lamps/sidelamps/

direction indicators.

–

Direction indicator side repeaters.

–

Side spotlamps.

– Brake lamps.

– Full LED technology rear lamps.

–

LED technology rear lamps.

–

Third brake lamp.

–

Number plate lamps.

Replacement of this type of bulb

Contact a PEUGEOT dealer or a

qualified workshop.

Do not touch LED or Full LED

technology

headlamps - risk of electrocution!

Front lamps

Model with LED technology

headlamps

1. Main beam headlamps

2. Dipped beam headlamps

3. Direction indicators

4. Daytime running lamps/Sidelamps CarM an uals 2 .c o m

Page 184 of 244

182

In the event of a breakdown

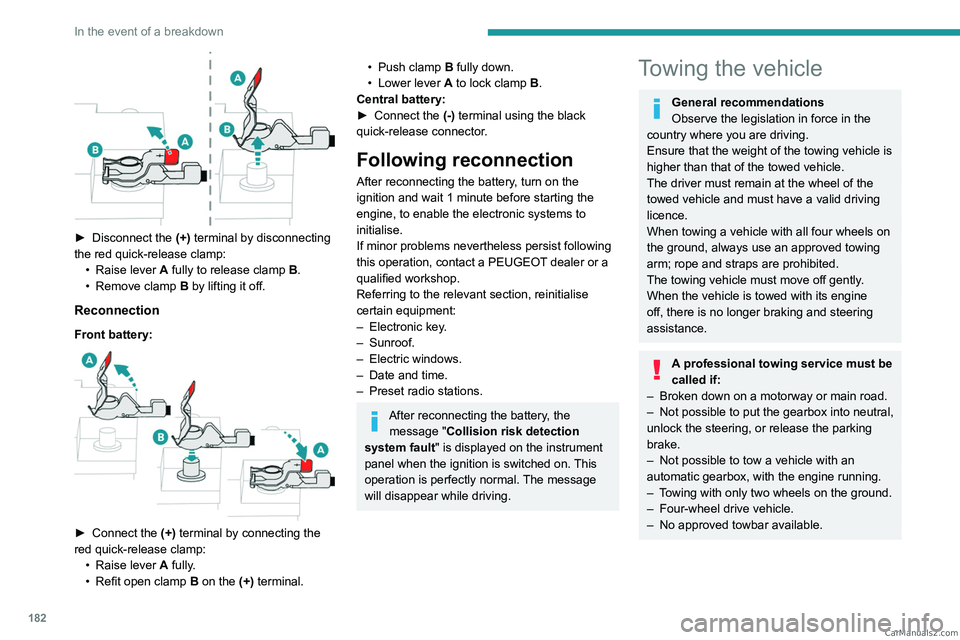

► Disconnect the (+) terminal by disconnecting

the red quick-release clamp: •

Raise lever

A

fully to release clamp

B

.

•

Remove clamp

B

by lifting it off.

Reconnection

Front battery:

► Connect the (+) terminal by connecting the

red quick-release clamp: •

Raise lever

A

fully.

•

Refit open clamp

B

on the (+) terminal.

• Push clamp B fully down.

• Lower lever A to lock clamp B.

Central battery:

►

Connect the

(-) terminal using the black

quick-release connector.

Following reconnection

After reconnecting the battery, turn on the

ignition and wait 1 minute before starting the

engine, to enable the electronic systems to

initialise.

If minor problems nevertheless persist following

this operation, contact a PEUGEOT dealer or a

qualified workshop.

Referring to the relevant section, reinitialise

certain equipment:

–

Electronic key

.

–

Sunroof.

–

Electric windows.

–

Date and time.

–

Preset radio stations.

After reconnecting the battery, the message "Collision risk detection

system fault" is displayed on the instrument

panel when the ignition is switched on. This

operation is perfectly normal. The message

will disappear while driving.

Towing the vehicle

General recommendations

Observe the legislation in force in the

country where you are driving.

Ensure that the weight of the towing vehicle is

higher than that of the towed vehicle.

The driver must remain at the wheel of the

towed vehicle and must have a valid driving

licence.

When towing a vehicle with all four wheels on

the ground, always use an approved towing

arm; rope and straps are prohibited.

The towing vehicle must move off gently.

When the vehicle is towed with its engine

off, there is no longer braking and steering

assistance.

A professional towing service must be

called if:

–

Broken down on a motorway or main road.

–

Not possible to put

the gearbox into neutral,

unlock the steering, or release the parking

brake.

–

Not possible to tow a vehicle with an

automatic gearbox, with the engine running.

–

T

owing with only two wheels on the ground.

–

Four-wheel drive vehicle.

–

No approved towbar available. CarM an uals 2 .c o m

Page 185 of 244

183

In the event of a breakdown

8Rechargeable hybrid vehicles

Before any intervention, with the ignition

on, depress the brake pedal and select mode N, then switch off the hybrid system (READY

indicator lamp off).

Always call on professionals for recovery of

the vehicle on a flatbed lorry or trailer.Use the towing eye only to free the vehicle

if it is stuck, or to secure it for recovery on a

flatbed lorry or trailer.

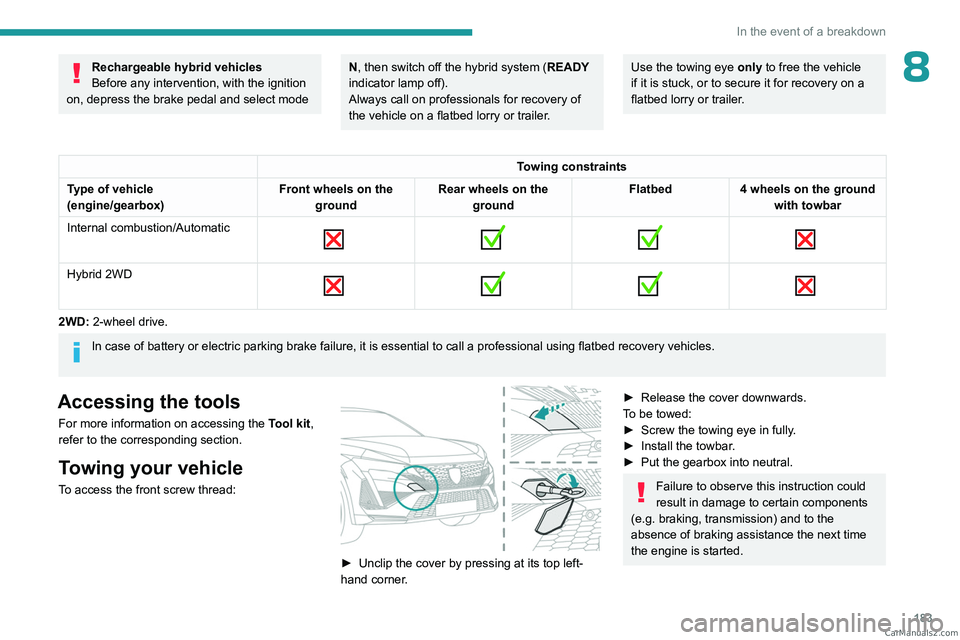

Towing constraints

Type of vehicle

(engine/gearbox) Front wheels on the

ground Rear wheels on the

ground Flatbed

4 wheels on the ground

with towbar

Internal combustion/Automatic

Hybrid 2WD

2WD: 2-wheel drive.

In case of battery or electric parking brake failure, it is essential to call a p

rofessional using flatbed recovery vehicles.

Accessing the tools

For more information on accessing the Tool kit,

refer to the corresponding section.

Towing your vehicle

To access the front screw thread:

► Unclip the cover by pressing at its top left-

hand corner .

► Release the cover downwards.

T o be towed:

►

Screw the towing eye in fully

.

►

Install the towbar

.

►

Put the gearbox into neutral.

Failure to observe this instruction could

result in damage to certain components

(e.g. braking, transmission) and to the

absence of braking assistance the next time

the engine is started. CarM an uals 2 .c o m

Page 186 of 244

184

In the event of a breakdown

Never tow the vehicle with the driving

wheels on the ground and the engine off.

►

Unlock the steering and release the parking

brake.

►

Switch on the hazard warning lamps on both

vehicles in accordance with the legislation in

force in the country in which you are driving.

►

Move off gently

, drive slowly and only for a

short distance.

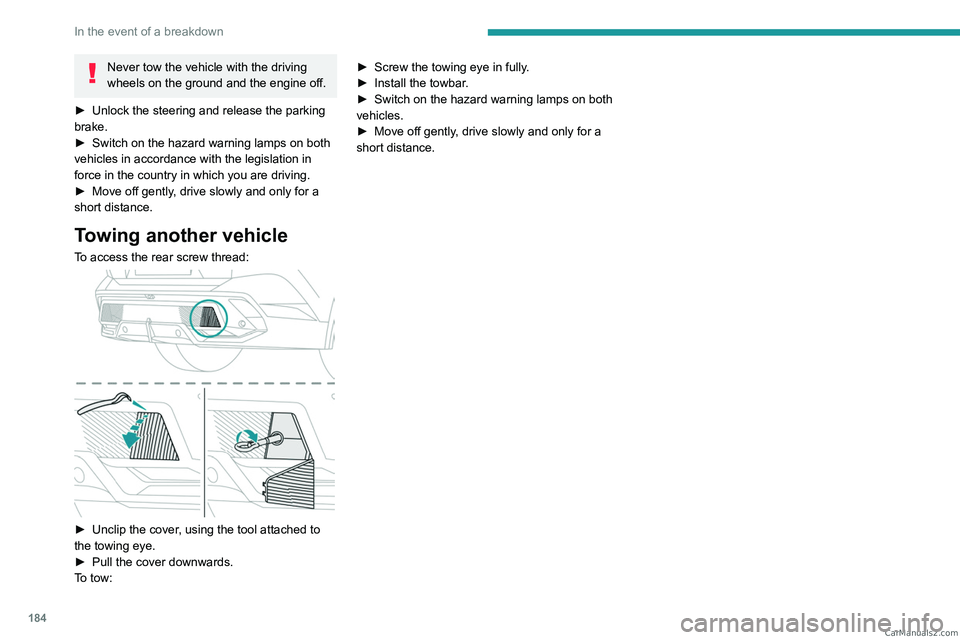

Towing another vehicle

To access the rear screw thread:

► Unclip the cover , using the tool attached to

the towing eye.

►

Pull the cover downwards.

T

o tow: ►

Screw the towing eye in fully

.

►

Install the towbar

.

►

Switch on the hazard warning lamps on both

vehicles.

►

Move off gently

, drive slowly and only for a

short distance. CarM an uals 2 .c o m