Peugeot 508 2018 Owner's Manual

Manufacturer: PEUGEOT, Model Year: 2018, Model line: 508, Model: Peugeot 508 2018Pages: 320, PDF Size: 10.09 MB

Page 211 of 320

209

Manual gearbox

The gearbox does not require any

maintenance (no oil change).

Automatic gearbox

The gearbox does not require any

maintenance (no oil change).

Brake pads

Brake wear depends on the style

of driving, particularly in the case

of vehicles used in town, over short

distances. It may be necessary to

have the condition of the brakes

checked, even between vehicle

services.

Unless there is a leak in the circuit, a drop in

the brake fluid level indicates that the brake

pads are worn.

Brake disc/drum wear

For any information on checking

brake disc wear, contact a

PEUGEOT dealer or a qualified

workshop.

Electric parking brake

This system does not require any

specific check. However, in the

event of a problem, have the system

checked by a PEUGEOT dealer or a

qualified workshop.

For more information on the Electric

parking brake , refer to the corresponding

section.

Wheels and tyres

The pressure must be checked on

all tyres, including the spare wheel,

when the tyres are "cold", at least

once a month and before a long

j o u r n ey. Driving with worn or damaged tyres reduces

braking efficiency and control of the vehicle's

steering. Regular inspections of the condition

of tyres (tread and sides) and rims are

recommended as well as making sure that

valves are fitted.

Using different size wheels and tyres from

those specified can affect the lifetime of tyres,

wheel rotation, ground clearance and the

speedometer reading and have an adverse

effect on road holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

Only use products recommended by

PEUGEOT or products of equivalent

quality and specification.

In order to optimise the operation of

components as important as those in the

braking system, PEUGEOT selects and

offers very specific products.

After washing the vehicle, dampness, or

in wintry conditions, ice can form on the

brake discs and pads: braking efficiency

may be reduced. Make light brake

applications to dry and defrost the brakes.

The pressures given on the tyre pressure label

are valid for "cold" tyres. If you have driven for

more than 10 minutes or more than 6 miles (10

kilometres) at more than 31 mph (50 km/h),

0.3 bar (30 kPa) should be added to the values

given on the label.

Under-inflation increases fuel consumption.

Non-compliant tyre pressure causes premature

wear on tyres and has an adverse effect on the

vehicle's road holding – Risk of an accident!

7

Practical information

Page 212 of 320

210

Advice on care and

maintenance

Recommendations on the care and

maintenance of your vehicle are given in the

Warranty and Maintenance Record.

Headlamps and lamps

The headlamps have polycarbonate

lenses with a protective coating.

Do not clean them with a dry or abrasive

cloth, nor with detergent or solvent

products.

Use a sponge and soapy water.

The use of a high pressure jet wash for

cleaning the headlamps, lamps and their

surrounds may damage the lacquer and

seals.

Observe the recommendations on

pressure and distance for jet washing.

First clean persistent stains with a sponge

and warm soapy water.

Leather

Leather is a natural product. Appropriate

regular care and cleaning is essential for

its

durability. Refer to your vehicle's Warranty and

Maintenance Record for information on

all

the special precautions to obser ve.

AdBlue® (BlueHDi engines)

To respect the environment and ensure

compliance with the Euro 6 standard, without

adversely affecting the per formance or fuel

consumption of its Diesel engines, PEUGEOT

has taken the decision to equip its vehicles

with a system that associates SCR (Selective

Catalytic Reduction) with a Diesel particle filter

(DPF) for the treatment of exhaust gases.

SCR system

Using a fluid called AdBlue® that contains

urea, a catalytic converter turns up to 85%

of nitrogen oxides (NOx) into nitrogen and

water, which are harmless to health and the

environment.

The AdBlue

® is contained in

a

special tank holding about

17

litres. An alert system is triggered automatically once

the reser ve level is reached: you can then drive

for a further 1,500 miles (2,400

km) before the

tank is empty.

Once the AdBlue

® tank is empty, a system

r

equired by regulations prevents starting

of the engine.

If the SCR system is defective, the level of

emissions from your vehicle will no longer

meet the Euro 6 standard: your vehicle

becomes polluting.

In the event of a confirmed fault with the

SCR system, you must go to a PEUGEOT

dealer or a qualified workshop as soon

as possible: after a running distance of

685 miles (1,100

km), a system will be

triggered automatically to prevent engine

starting.

In either case, a range indicator gives you

the distance you can travel before the

vehicle is immobilised.

For more information on the Warning and

indicator lamps and associated alerts,

refer to the corresponding section.

Practical information

Page 213 of 320

211

Freezing of the AdBlue®

AdBlue® freezes at temperatures below

around -11°C.

The SCR system includes a heater for the

AdBlue

® tank, allowing you to continue

driving in very cold conditions.

Supply of AdBlue®

It is recommended that the AdBlue® is

topped up as soon as the first alert is

issued indicating that the reser ve level

has

been reached.

In order to ensure that the SCR system

operates correctly:

-

U

se only AdBlue

® fluid that meets the

ISO 22241 standard.

-

N

ever transfer AdBlue

® to another

container: it would lose its purity.

-

N

ever dilute AdBlue

® with water.

You can obtain AdBlue

® from a PEUGEOT

dealer or a qualified workshop. You can also visit a ser vice station

equipped with AdBlue

® pumps specially

designed for passenger vehicles.

Never top up from an AdBlue

® dispenser

reserved for heavy goods vehicles.

Recommendations on storage

AdBlue® freezes at about -11°C and deteriorates

above 25°C. Containers should be stored in a

cool area and protected from direct sunlight.

Under these conditions, the fluid can be kept

for at least a year.

If the fluid has frozen, it can be used once it

has completely thawed out.

Never store AdBlue

® containers in your

vehicle.

Precautions for use

the event of contact with the eyes, immediately

rinse the eyes with large amounts of water

or with an eye wash solution for at least 15

minutes. If a burning sensation or irritation

persists, get medical attention.

If swallowed, immediately wash out the mouth

with clean water and then drink plenty of water.

In certain conditions (high temperature, for

example), the risk of release of ammonia

cannot be excluded: do not inhale the fluid.

Ammonia vapour has an irritant effect on

mucous membranes (eyes, nose and throat).

Keep AdBlue

® out of the reach of children,

in its original container.

Procedure

Before starting the top-up procedure, ensure

that the vehicle is parked on a flat and level

sur face.

In winter, check that the temperature of the

vehicle is above -11°C. If not, due to freezing,

the AdBlue

® cannot be poured into the tank.

Park your vehicle somewhere warmer for a few

hours before topping up.

AdBlue

® is a urea-based solution. This fluid

is non-flammable, colourless and odourless

(stored in a cool place).

In the event of contact with the skin, wash the

affected area with soap and running water. In

7

Practical information

Page 214 of 320

212

In the event of an AdBlue® breakdown,

confirmed by the message "Add AdBlue:

Starting impossible", you must top up with

at least 5 litres.

Never pour AdBlue

® into the Diesel fuel

tank.

If any AdBlue

® is splashed, or if there are

any spillages on the side of the body, rinse

immediately with cold water or wipe with a

damp cloth.

If the fluid has crystallised, clean it off

using a sponge and hot water.

Important: in the event of a top-up after

an AdBlue breakdown, you must wait

about five minutes before switching on the

ignition, without opening the driver's

door, unlocking the vehicle or bringing

the electronic key into the passenger

compartment.

Switch on the ignition, then wait for

10

seconds before starting the engine.

F

W

ith Keyless Entry and Starting, press the

" START/STOP " button to switch off the

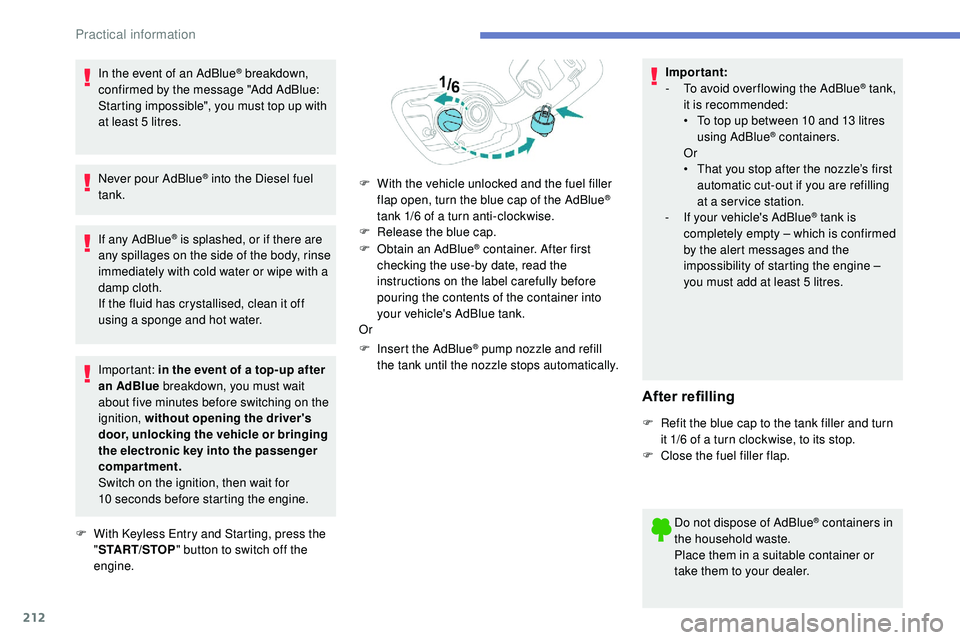

engine. F

O btain an AdBlue® container. After first

checking the use-by date, read the

instructions on the label carefully before

pouring the contents of the container into

your vehicle's AdBlue tank.

Or

F

I

nsert the AdBlue

® pump nozzle and refill

the tank until the nozzle stops automatically. Important:

-

T

o avoid over flowing the AdBlue

® tank,

i

t is recommended:

•

T

o top up between 10 and 13 litres

using AdBlue

® containers.

Or

•

T

hat you stop after the nozzle’s first

automatic cut-out if you are refilling

at a ser vice station.

-

I

f your vehicle's AdBlue

® tank is

completely empty – which is confirmed

by the alert messages and the

impossibility of starting the engine –

you must add at least 5 litres.

After refilling

F Refit the blue cap to the tank filler and turn it 1/6 of a turn clockwise, to its stop.

F

C

lose the fuel filler flap.

Do not dispose of AdBlue

® containers in

the household waste.

Place them in a suitable container or

take them to your dealer.

F

W

ith the vehicle unlocked and the fuel filler

flap open, turn the blue cap of the AdBlue

®

tank 1/6 of a turn anti-clockwise.

F

R

elease the blue cap.

Practical information

Page 215 of 320

213

Warning triangle

As a safety precaution, before leaving your

vehicle to set up and install the triangle, switch

on the hazard warning lamps and put on your

high visibility vest.

Storage compartment

There is a compartment in the interior trim of

the tailgate to store a triangle.

F

O

pen the tailgate.

F

R

elease the cover by turning the screw a

quarter turn anti-clockwise.

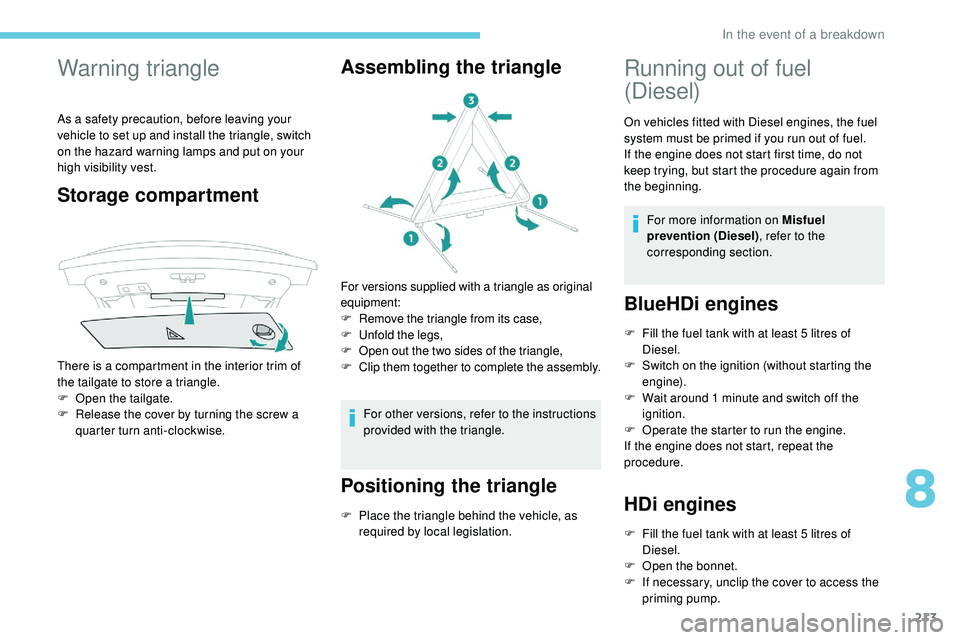

Assembling the triangle

For versions supplied with a triangle as original

equipment:

F

R

emove the triangle from its case,

F

U

nfold the legs,

F

O

pen out the two sides of the triangle,

F

C

lip them together to complete the assembly.

For other versions, refer to the instructions

provided with the triangle.

Positioning the triangle

F Place the triangle behind the vehicle, as required by local legislation.

Running out of fuel

(Diesel)

On vehicles fitted with Diesel engines, the fuel

system must be primed if you run out of fuel.

If the engine does not start first time, do not

keep trying, but start the procedure again from

the beginning.

For more information on Misfuel

prevention (Diesel) , refer to the

corresponding section.

BlueHDi engines

F Fill the fuel tank with at least 5 litres of Diesel.

F

S

witch on the ignition (without starting the

engine).

F

W

ait around 1 minute and switch off the

ignition.

F

O

perate the starter to run the engine.

If the engine does not start, repeat the

procedure.

HDi engines

F Fill the fuel tank with at least 5 litres of Diesel.

F

O

pen the bonnet.

F

I

f necessary, unclip the cover to access the

priming pump.

8

In the event of a breakdown

Page 216 of 320

214

F Loosen the degassing bolt.

F O perate the priming pump until fuel appears

in the transparent tube.

F

R

etighten the degassing bolt.

F

O

perate the starter until the engine starts (if

the engine does not start at the first attempt,

wait around 15 seconds before trying

again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again

then start the engine.

F

P

ut the cover back in place, clip it and

ensure it is clipped in.

F

C

lose the bonnet.

Tool kit

This is a set of tools provided with the vehicle.

Its content depends on your vehicle's

equipment:

-

t

emporary puncture repair kit,

-

spar

e wheel.

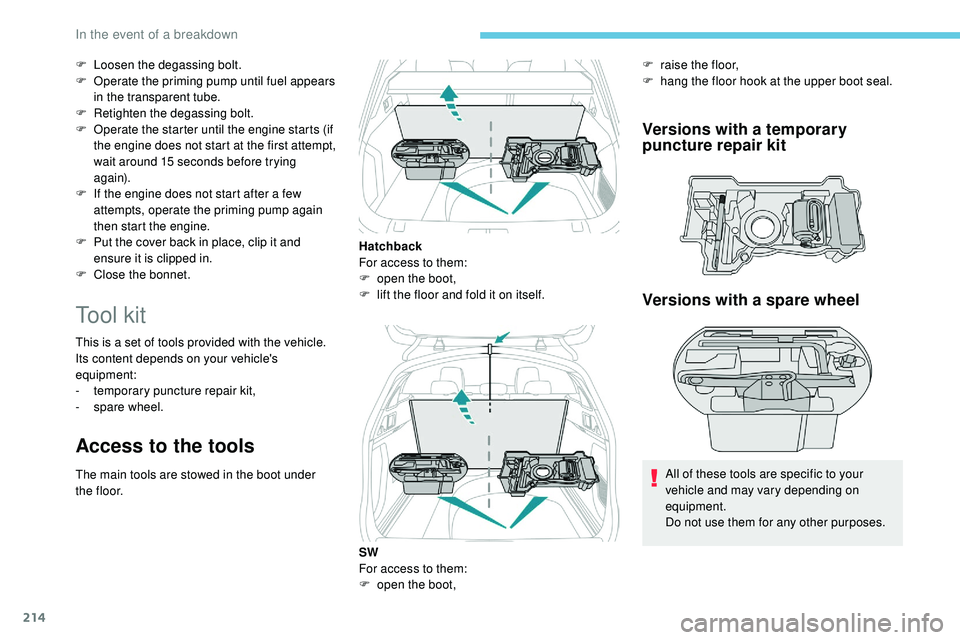

Access to the tools

The main tools are stowed in the boot under

t h e f l o o r.

Versions with a temporary

puncture repair kit

Hatchback

For access to them:

F

o

pen the boot,

F

l

ift the floor and fold it on itself.

SW

For access to them:

F

o

pen the boot,

Versions with a spare wheel

All of these tools are specific to your

vehicle and may vary depending on

equipment.

Do not use them for any other purposes.

F

r

aise the floor,

F

h

ang the floor hook at the upper boot seal.

In the event of a breakdown

Page 217 of 320

215

The jack must only be used to change a

wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original jack,

contact a PEUGEOT dealer or a qualified

workshop to obtain the correct jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/CE.

The jack does not require any

maintenance.

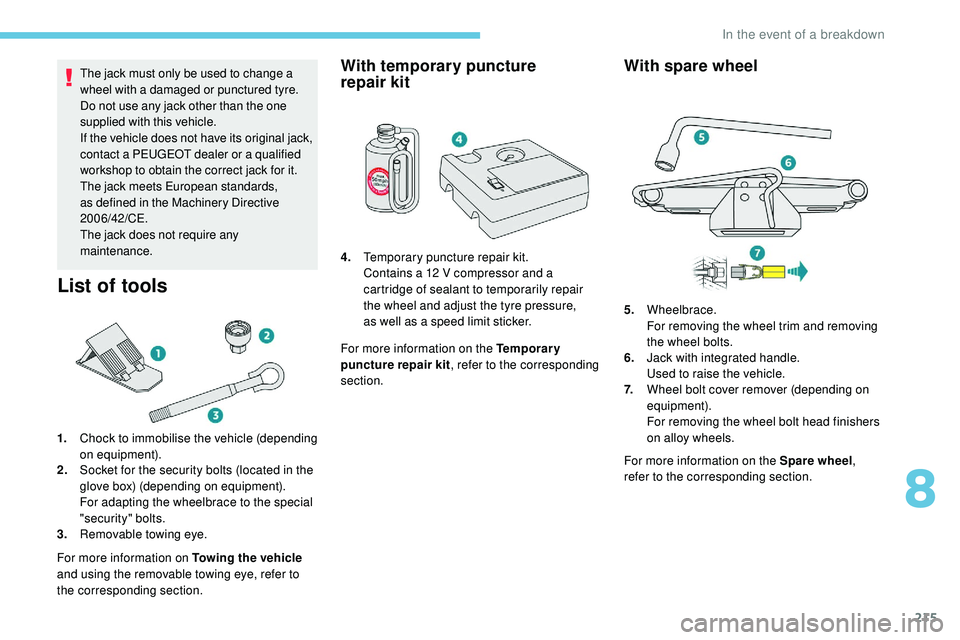

List of tools

1.Chock to immobilise the vehicle (depending

on equipment).

2. Socket for the security bolts (located in the

glove box) (depending on equipment).

For adapting the wheelbrace to the special

"security" bolts.

3. Removable towing eye.

For more information on Towing the vehicle

and using the removable towing eye, refer to

the corresponding section.

With temporary puncture

repair kit

For more information on the Temporary

puncture repair kit , refer to the corresponding

section.

With spare wheel

For more information on the Spare wheel ,

refer to the corresponding section.

4.

Temporary puncture repair kit.

Contains a 12

V compressor and a

cartridge of sealant to temporarily repair

the wheel and adjust the tyre pressure,

as

well as a speed limit sticker.

5.

Wheelbrace.

For removing the wheel trim and removing

the wheel bolts.

6. Jack with integrated handle.

Used to raise the vehicle.

7. Wheel bolt cover remover (depending on

equipment).

For removing the wheel bolt head finishers

on alloy wheels.

8

In the event of a breakdown

Page 218 of 320

216

Temporary puncture

repair kit

Scan the QR code on page 3 to view

explanatory videos.

Comprising a compressor and a sealant

cartridge, it allows the temporary repair of

a tyre so that you can drive to the nearest

garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

The vehicle's electric system allows the

connection of the compressor for long

enough to inflate a tyre after a puncture

repair.

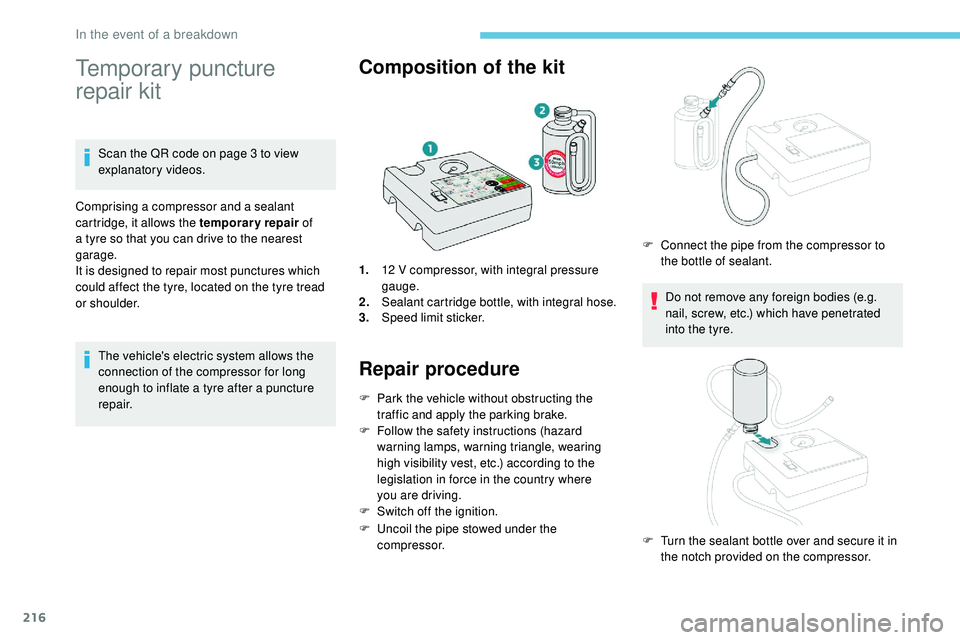

Composition of the kit

1. 12 V compressor, with integral pressure

gauge.

2. Sealant cartridge bottle, with integral hose.

3. Speed limit sticker.

Repair procedure

F Park the vehicle without obstructing the

traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard

warning lamps, warning triangle, wearing

high visibility vest, etc.) according to the

legislation in force in the country where

you

are driving.

F

S

witch off the ignition.

F

U

ncoil the pipe stowed under the

compressor. Do not remove any foreign bodies (e.g.

nail, screw, etc.) which have penetrated

into the tyre.

F

C

onnect the pipe from the compressor to

the bottle of sealant.

F

T

urn the sealant bottle over and secure it in

the notch provided on the compressor.

In the event of a breakdown

Page 219 of 320

217

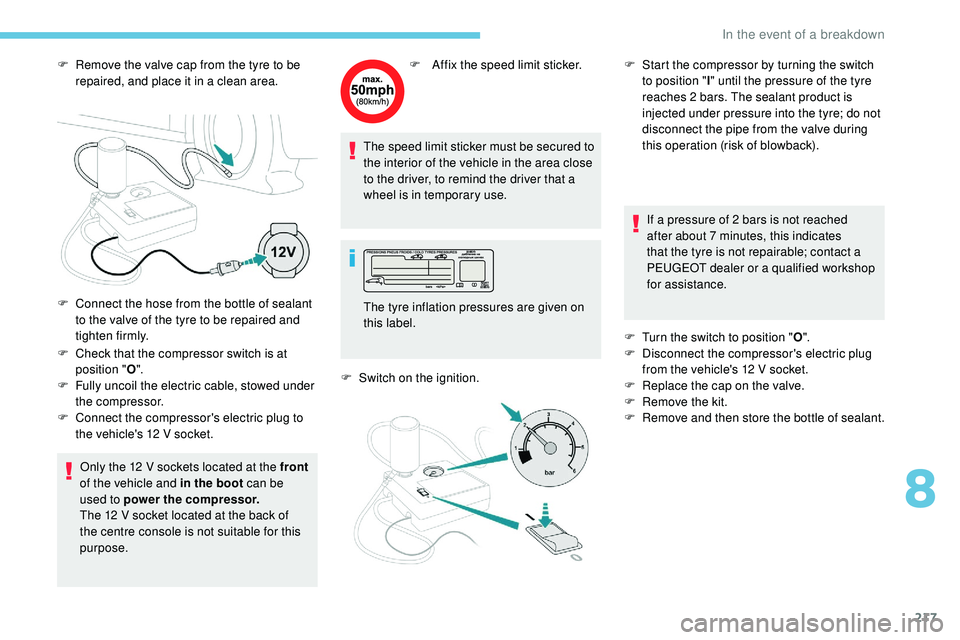

F Remove the valve cap from the tyre to be repaired, and place it in a clean area.

F

C

heck that the compressor switch is at

position " O".

F

F

ully uncoil the electric cable, stowed under

the compressor.

F

C

onnect the compressor's electric plug to

the vehicle's 12

V socket.

Only the 12

V sockets located at the front

of the vehicle and in the boot can be

used to power the compressor.

The 12

V socket located at the back of

the centre console is not suitable for this

purpose. F

A ffix the speed limit sticker.

The speed limit sticker must be secured to

the interior of the vehicle in the area close

to the driver, to remind the driver that a

wheel is in temporary use.

F

S

witch on the ignition.If a pressure of 2 bars is not reached

after about 7 minutes, this indicates

that the tyre is not repairable; contact a

PEUGEOT dealer or a qualified workshop

for assistance.

F

T

urn the switch to position "O".

F

D

isconnect the compressor's electric plug

from the vehicle's 12

V socket.

F

R

eplace the cap on the valve.

F

R

emove the kit.

F

R

emove and then store the bottle of sealant.

F

C

onnect the hose from the bottle of sealant

to the valve of the tyre to be repaired and

tighten firmly. The tyre inflation pressures are given on

this label.F

S tart the compressor by turning the switch

to position " l" until the pressure of the tyre

reaches 2 bars. The sealant product is

injected under pressure into the tyre; do not

disconnect the pipe from the valve during

this operation (risk of blowback).

8

In the event of a breakdown

Page 220 of 320

218

Take care, the sealant product is harmful

if swallowed and causes irritation to the

eyes.

Keep this product out of the reach of

children.

The use-by date of the fluid is marked on

the bottle.

After use, do not discard the bottle in

standard waste, take it to a PEUGEOT

dealer or an authorised waste disposal

site.

Do not forget to obtain a new bottle of

sealant, available from a PEUGEOT

dealer or a qualified workshop.Do not exceed the speed of 50 mph

(80

km/h) when driving with a tyre repaired

using this type of kit.

Checking/adjusting tyre

pressures

You can also use the compressor,

without injecting sealant, to check and,

if

necessary, adjust the tyre pressures.

F

R

emove the valve cap from the tyre and

keep it in a clean place.

F

U

ncoil the pipe stowed under the

compressor. F

C

heck that the compressor switch is in the

" O " position.

F

F

ully uncoil the electric cable, stowed under

the compressor.

F

C

onnect the compressor's electric plug to

the vehicle's 12 V socket.

F

S

witch on the ignition.

Only the 12 V sockets located at the front

of the vehicle and in the boot can be

used to power the compressor.

The 12 V socket located at the back of

the centre console is not suitable for this

purpose.

F

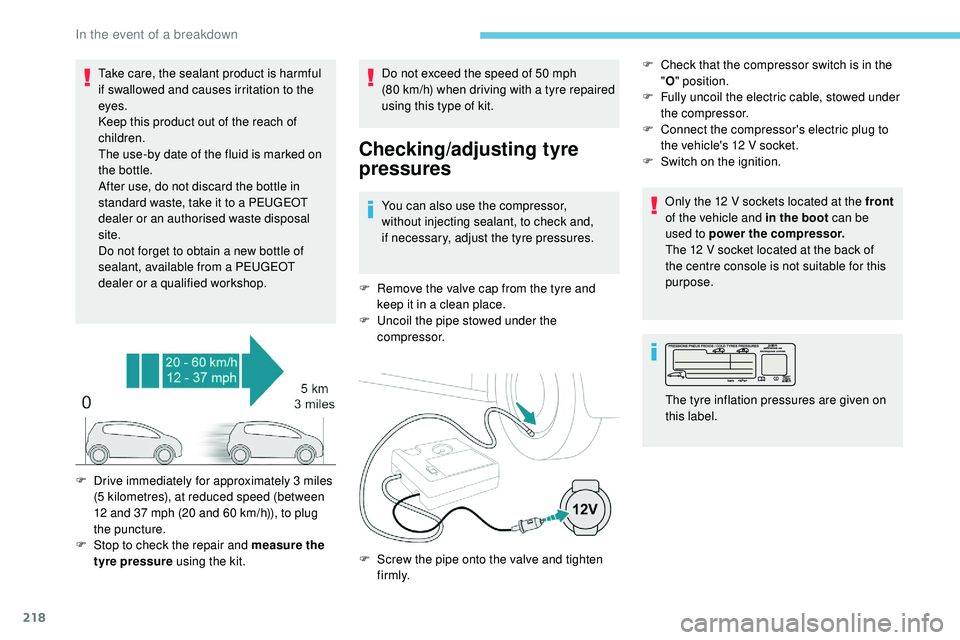

D

rive immediately for approximately 3 miles

(5 kilometres), at reduced speed (between

12 and 37 mph (20 and 60

km/h)), to plug

the puncture.

F

S

top to check the repair and measure the

tyre pressure using the kit. F

S

crew the pipe onto the valve and tighten

f i r m l y. The tyre inflation pressures are given on

this label.

In the event of a breakdown