ECU PEUGEOT 508 2021 Owner's Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2021, Model line: 508, Model: PEUGEOT 508 2021Pages: 292, PDF Size: 8.61 MB

Page 99 of 292

97

Safety

5– a carrycot fitted with an upper strap or a support leg.

For securing the upper strap using the ISOFIX mountings, refer to the corresponding section.

X:

Seat position not suitable for the installation of an ISOFIX seat or carrycot for the specified weight group.

(a) Refer to the current legislation in your country before placing a child\

in this seat position.

(b)

The installation of a carrycot on this seat may prevent the use of one o\

r more of the other seats in this row

.

(c)

Remove the head restraints.

(d) The front height-adjustable seat must be adjusted to its highest positio\

n and moved as far back as possible.

(e) To install a "rearward facing" or "forward facing" child seat on a rear s\

eat, move the front seat forward, then straighten the backrest to allow \

enough

room for the child seat and the child's legs.

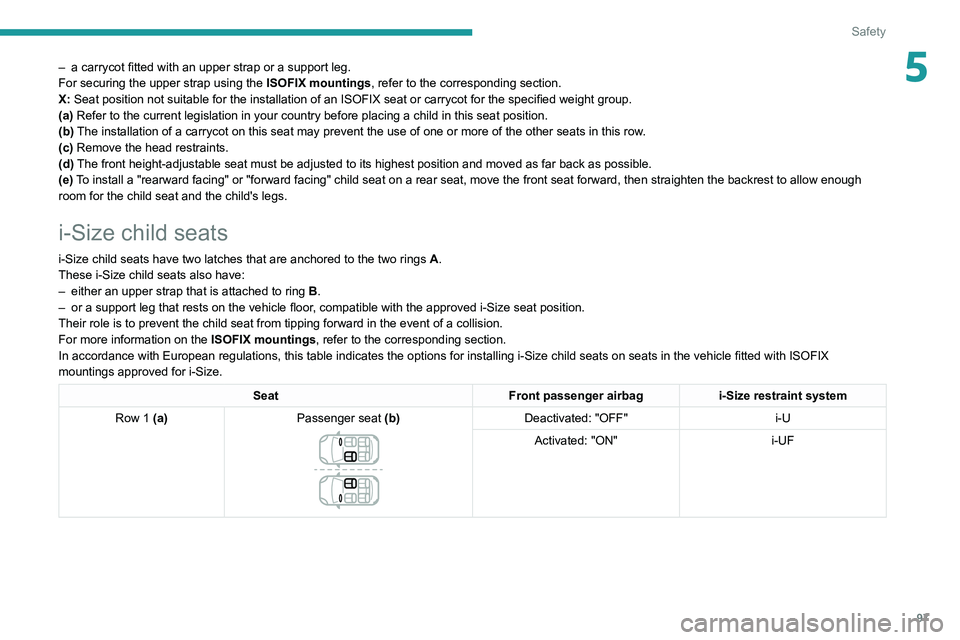

i-Size child seats

i-Size child seats have two latches that are anchored to the two rings A.

These i-Size child seats also have:

–

either an upper strap that is attached to ring B

.

–

or a support leg that rests on the vehicle floor

, compatible with the approved i-Size seat position.

Their role is to prevent the child seat from tipping forward in the even\

t of a collision.

For more information on the ISOFIX mountings, refer to the corresponding section.

In accordance with European regulations, this table indicates the options for installing i-Size child seats on seats in the vehicle fitted with ISOFIX

mountings approved for i-Size.

Seat Front passenger airbagi-Size restraint system

Row 1 (a) Passenger seat (b)

Deactivated: "OFF" i-U

Activated: "ON" i-UF

Page 119 of 292

11 7

Driving

6mirrors, always leave your feet close to the

pedals and take a break every 2 hours.

Manoeuvring aids

The driver must always check the

surroundings of the vehicle before and during

the whole manoeuvre, in particular using the

mirrors.

Radar(s)

The operation of the radar(s), along with

any associated functions, may be affected

by the accumulation of dirt (e.g.

mud, ice),

in poor weather conditions (e.g.

heavy rain,

snow), or if the bumpers are damaged.

If the front bumper is to be repainted, contact

a PEUGEOT dealer or a qualified workshop;

certain types of paint could interfere with the

operation of the radar(s).

Driving aids camera

This camera and its associated functions

may be impaired or not work if the windscreen

area in front of the camera is dirty, misty,

frosty, covered with snow, damaged or

masked by a sticker.

In humid and cold weather, demist the

windscreen regularly.

Poor visibility (inadequate street lighting,

heavy rain, thick fog, snowfall), dazzle

(headlamps of an oncoming vehicle, low sun,

reflections on a damp road, leaving a tunnel,

alternating shade and light) can also impair

detection performance.

In the event of a windscreen replacement,

contact a PEUGEOT dealer or a qualified

workshop to recalibrate the camera;

otherwise, the operation of the associated

driving aids may be disrupted.

Other cameras

The images from the camera(s)

displayed on the touch screen or on the

instrument panel may be distorted by the

terrain.

In the presence of areas in shade, or in

conditions of bright sunlight or inadequate

lighting, the image may be darkened and with

lower contrast.

Obstacles may appear further away than they

actually are.

Sensors

The operation of the sensors, as well as

any associated functions, may be disrupted

by noise pollution such as that emitted by

noisy vehicles and machinery (e.g. lorries,

pneumatic drills), by the accumulation of

snow or dead leaves on the road or in the

event of damaged bumpers and mirrors.

When reverse gear is engaged, an audible

signal (long beep) indicates that the sensors

may be dirty.

A front or rear impact to the vehicle can

upset the sensors’ settings, which is not

always detected by the system: distance

measurements may be distorted.

The sensors do not systematically detect

obstacles that are too low (pavements, studs)

or too thin (trees, posts, wire fences).

Certain obstacles located in the sensors’ blind

spots may not be detected or may no longer

be detected during the manoeuvre.

Certain materials (fabrics) absorb sound

waves: pedestrians may not be detected.

Maintenance

Clean the bumpers and door mirrors and

the field of vision of the cameras regularly.

When washing your vehicle at high pressure,

direct the spray from at least 30

cm away

from the radar, sensors and cameras.

Mats/Pedal trims

The use of mats or pedal trims not

approved by PEUGEOT may interfere with

the operation of the speed limiter or cruise

control.

To avoid any risk of jamming the pedals:

–

Ensure that the mat is secured correctly

.

–

Never fit one mat on top of another

.

Page 173 of 292

171

Practical information

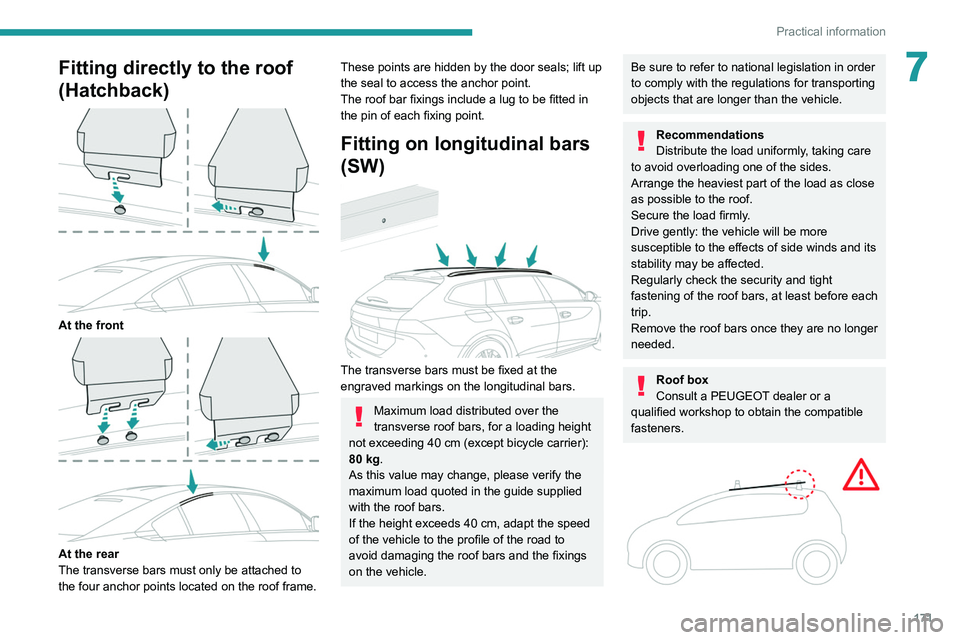

7Fitting directly to the roof

(Hatchback)

At the front

At the rear

The transverse bars must only be attached to

the four anchor points located on the roof frame.

These points are hidden by the door seals; lift up

the seal to access the anchor point.

The roof bar fixings include a lug to be fitted in

the pin of each fixing point.

Fitting on longitudinal bars

(SW)

The transverse bars must be fixed at the

engraved markings on the longitudinal bars.

Maximum load distributed over the

transverse roof bars, for a loading height

not exceeding 40 cm (except bicycle carrier):

80

kg.

As this value may change, please verify the

maximum load quoted in the guide supplied

with the roof bars.

If the height exceeds 40 cm, adapt the speed

of the vehicle to the profile of the road to

avoid damaging the roof bars and the fixings

on the vehicle.

Be sure to refer to national legislation in order

to comply with the regulations for transporting

objects that are longer than the vehicle.

Recommendations

Distribute the load uniformly, taking care

to avoid overloading one of the sides.

Arrange the heaviest part of the load as close

as possible to the roof.

Secure the load firmly.

Drive gently: the vehicle will be more

susceptible to the effects of side winds and its

stability may be affected.

Regularly check the security and tight

fastening of the roof bars, at least before each

trip.

Remove the roof bars once they are no longer

needed.

Roof box

Consult a PEUGEOT dealer or a

qualified workshop to obtain the compatible

fasteners.

Page 186 of 292

184

In the event of a breakdown

The jack must only be used to change a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with the vehicle.

If the vehicle does not have its original jack,

contact a PEUGEOT dealer or a qualified

workshop to obtain the one that was intended

by the manufacturer.

The jack meets European standards, as

defined in the Machinery Directive 2006/42/

CE.

The jack does not require any maintenance.

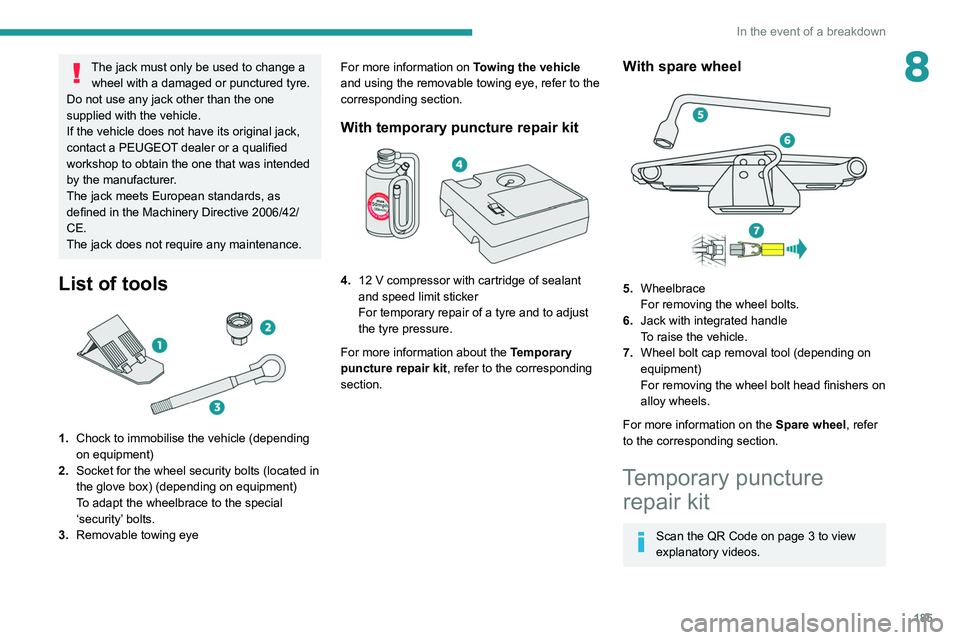

List of tools

1. Chock to immobilise the vehicle (depending

on equipment)

2. Socket for the wheel security bolts (located in

the glove box) (depending on equipment)

To adapt the wheelbrace to the special

‘security’ bolts.

3. Removable towing eye

Non-BlueHDi engines

► Open the bonnet and then, if necessary ,

unclip the cover to access the priming pump.

►

Loosen the degassing bolt.

► Operate the priming pump until fuel

appears in the transparent tube.

►

Retighten the degassing bolt.

►

Operate the starter motor until the engine

starts (if the engine does not start at the first

attempt, wait around 15

seconds before trying

again).

►

If the engine does not start after a few

attempts, operate the priming pump again, then

the starter motor

.

►

Put the cover back in place and clip it in, then

close the bonnet.

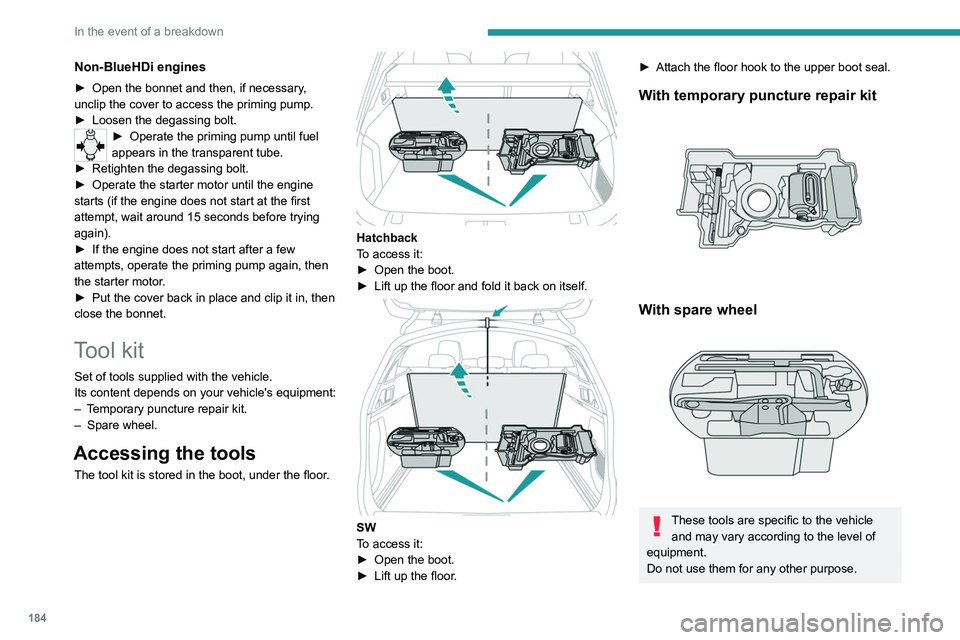

Tool kit

Set of tools supplied with the vehicle.

Its content depends on your vehicle's equipment:

–

T

emporary puncture repair kit.

–

Spare wheel.

Accessing the tools

The tool kit is stored in the boot, under the floor.

Hatchback

To access it:

►

Open the boot.

►

Lift up the floor and fold it back on itself.

SW

To access it:

►

Open the boot.

►

Lift up the floor

.

► Attach the floor hook to the upper boot seal.

With temporary puncture repair kit

With spare wheel

These tools are specific to the vehicle and may vary according to the level of

equipment.

Do not use them for any other purpose.

Page 187 of 292

185

In the event of a breakdown

8The jack must only be used to change a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with the vehicle.

If the vehicle does not have its original jack,

contact a PEUGEOT dealer or a qualified

workshop to obtain the one that was intended

by the manufacturer.

The jack meets European standards, as

defined in the Machinery Directive 2006/42/

CE.

The jack does not require any maintenance.

List of tools

1. Chock to immobilise the vehicle (depending

on equipment)

2. Socket for the wheel security bolts (located in

the glove box) (depending on equipment)

To adapt the wheelbrace to the special

‘security’ bolts.

3. Removable towing eye For more information on

Towing the vehicle

and using the removable towing eye, refer to the

corresponding section.

With temporary puncture repair kit

4. 12 V compressor with cartridge of sealant

and speed limit sticker

For temporary repair of a tyre and to adjust

the tyre pressure.

For more information about the Temporary

puncture repair kit, refer to the corresponding

section.

With spare wheel

5. Wheelbrace

For removing the wheel bolts.

6. Jack with integrated handle

To raise the vehicle.

7. Wheel bolt cap removal tool (depending on

equipment)

For removing the wheel bolt head finishers on

alloy wheels.

For more information on the Spare wheel, refer

to the corresponding section.

Temporary puncture repair kit

Scan the QR Code on page 3 to view

explanatory videos.

Page 188 of 292

186

In the event of a breakdown

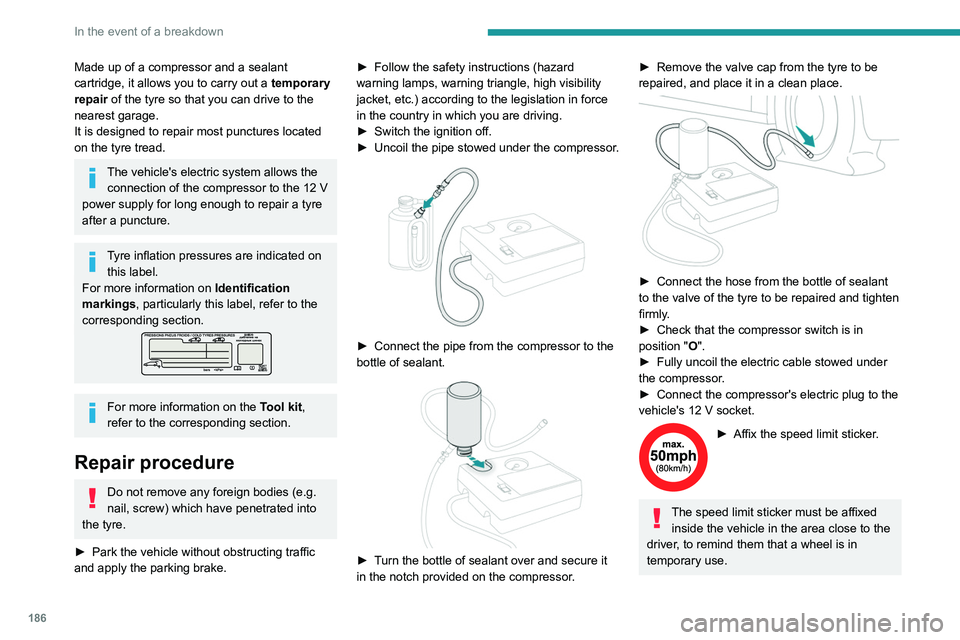

Made up of a compressor and a sealant

cartridge, it allows you to carry out a temporary

repair of the tyre so that you can drive to the

nearest garage.

It is designed to repair most punctures located

on the tyre tread.

The vehicle's electric system allows the connection of the compressor to the 12 V

power supply for long enough to repair a tyre

after a puncture.

Tyre inflation pressures are indicated on this label.

For more information on Identification

markings, particularly this label, refer to the

corresponding section.

For more information on the Tool kit,

refer to the corresponding section.

Repair procedure

Do not remove any foreign bodies (e.g.

nail, screw) which have penetrated into

the tyre.

►

Park the vehicle without obstructing traffic

and apply the parking brake. ►

Follow the safety instructions (hazard

warning lamps, warning triangle, high visibility

jacket, etc.) according to the legislation in force

in the country in which you are driving.

►

Switch the ignition off.

►

Uncoil

the pipe stowed under the compressor.

► Connect the pipe from the compressor to the

bottle of sealant.

► Turn the bottle of sealant over and secure it

in the notch provided on the compressor.

► Remove the valve cap from the tyre to be

repaired, and place it in a clean place.

► Connect the hose from the bottle of sealant

to the valve of the tyre to be repaired and tighten

firmly

.

►

Check that the compressor switch is in

position

"O".

►

Fully uncoil the electric cable stowed under

the compressor

.

►

Connect the compressor's electric plug to the

vehicle's 12

V socket.

► Affix the speed limit sticker .

The speed limit sticker must be affixed

inside the vehicle in the area close to the

driver, to remind them that a wheel is in

temporary use.

Page 191 of 292

189

In the event of a breakdown

8

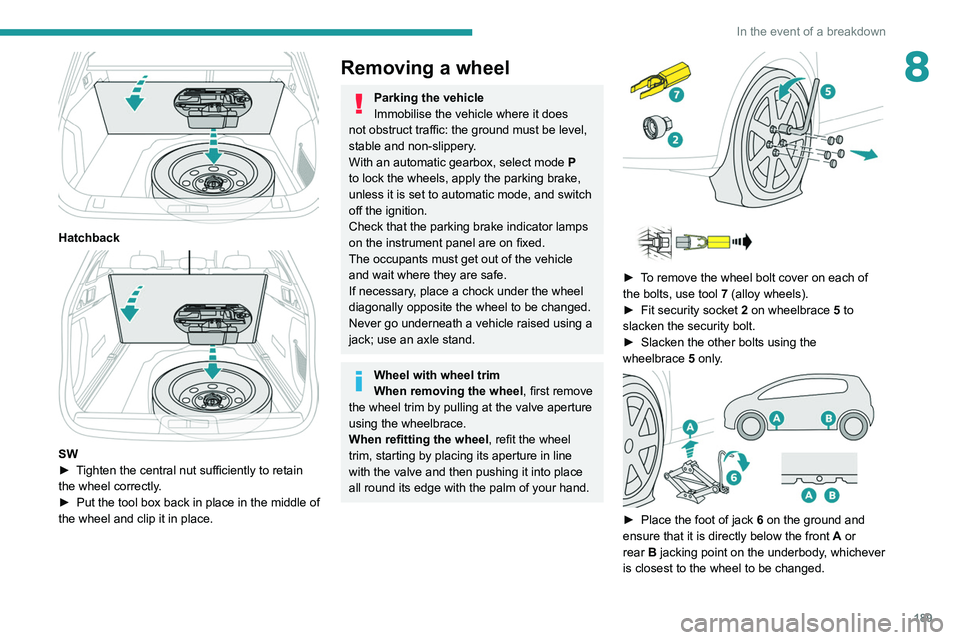

Hatchback

SW

► T ighten the central nut sufficiently to retain

the wheel correctly.

►

Put the tool box back in place in the middle of

the wheel and clip it in place.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does

not obstruct traffic: the ground must be level,

stable and non-slippery.

With an automatic gearbox, select mode

P

to lock the wheels, apply the parking brake,

unless it is set to automatic mode, and switch

off the ignition.

Check that the parking brake indicator lamps

on the instrument panel are on fixed.

The occupants must get out of the vehicle

and wait where they are safe.

If necessary, place a chock under the wheel

diagonally opposite the wheel to be changed.

Never go underneath a vehicle raised using a

jack; use an axle stand.

Wheel with wheel trim

When removing the wheel , first remove

the wheel trim by pulling at the valve aperture

using the wheelbrace.

When refitting the wheel , refit the wheel

trim, starting by placing its aperture in line

with the valve and then pushing it into place

all round its edge with the palm of your hand.

► To remove the wheel bolt cover on each of

the bolts, use tool 7 (alloy wheels).

►

Fit security socket

2 on wheelbrace

5

to

slacken the security bolt.

►

Slacken the other bolts using the

wheelbrace

5

only.

► Place the foot of jack 6 on the ground and

ensure that it is directly below the front A or

rear

B jacking point on the underbody, whichever

is closest to the wheel to be changed.

Page 192 of 292

190

In the event of a breakdown

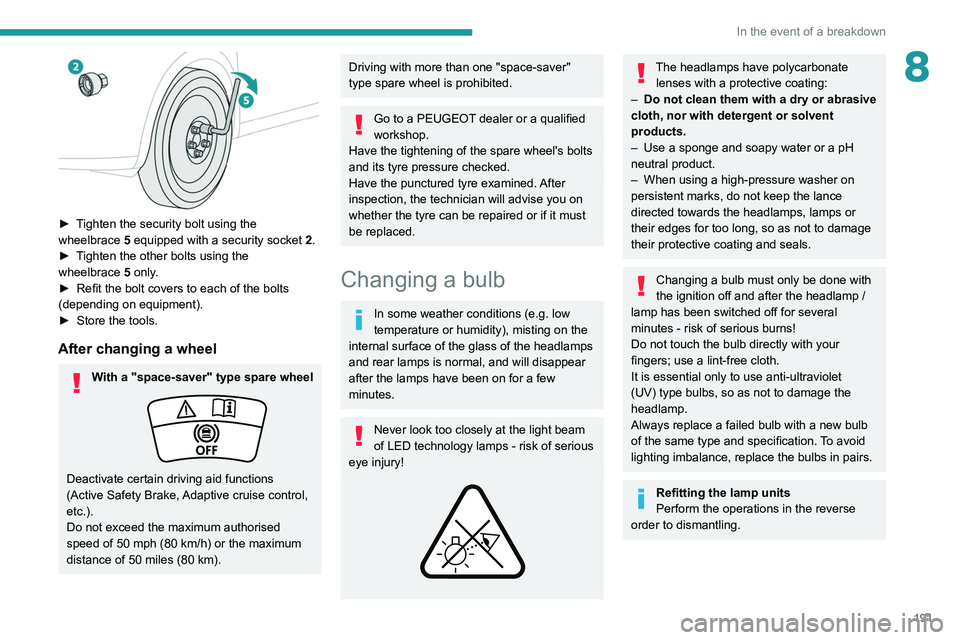

► Tighten the security bolt using the

wheelbrace 5 equipped with a security socket 2.

► Tighten the other bolts using the

wheelbrace 5 only.

► Refit the bolt covers to each of the bolts

(depending on equipment).

► Store the tools.

After changing a wheel

With a "space-saver" type spare wheel

Deactivate certain driving aid functions

(Active Safety Brake, Adaptive cruise control,

etc.).

Do not exceed the maximum authorised

speed of 50 mph (80 km/h) or the maximum

distance of 50 miles (80 km).

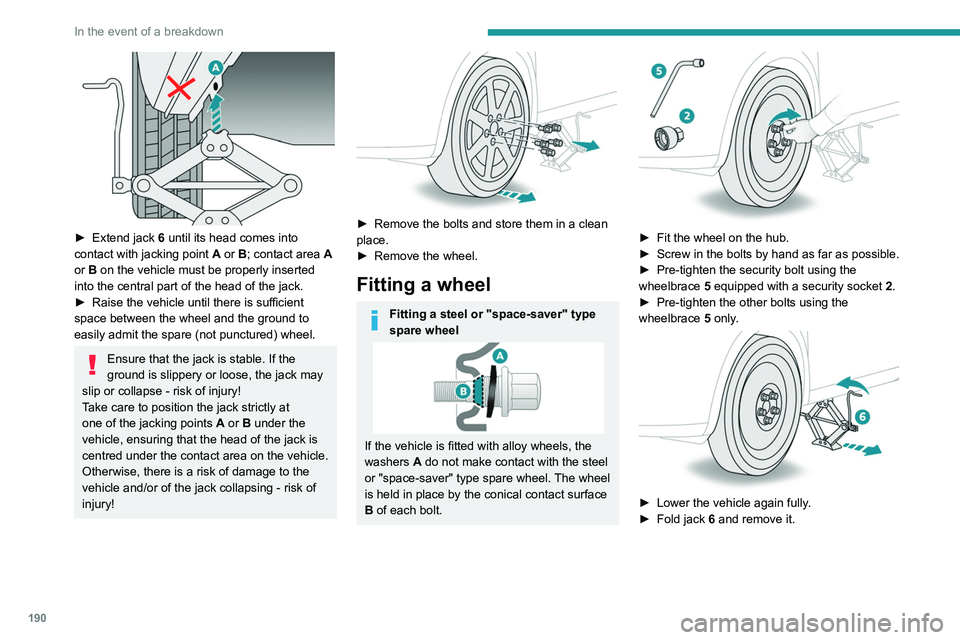

► Extend jack 6 until its head comes into

contact with jacking point A or B; contact area A

or B on the vehicle must be properly inserted

into the central part of the head of the jack.

►

Raise the vehicle until there is sufficient

space between the wheel and the ground to

easily admit the spare (not punctured) wheel.

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or collapse - risk of injury!

Take care to position the jack strictly at

one of the jacking points

A

or B under the

vehicle, ensuring that the head of the jack is

centred under the contact area on the vehicle.

Otherwise, there is a risk of damage to the

vehicle and/or of the jack collapsing - risk of

injury!

► Remove the bolts and store them in a clean

place.

►

Remove the wheel.

Fitting a wheel

Fitting a steel or "space-saver" type

spare wheel

If the vehicle is fitted with alloy wheels, the

washers A do not make contact with the steel

or "space-saver" type spare wheel. The wheel

is held in place by the conical contact surface

B of each bolt.

► Fit the wheel on the hub.

► Screw in the bolts by hand as far as possible.

►

Pre-tighten the security bolt using the

wheelbrace

5

equipped with a security socket

2

.

►

Pre-tighten the other bolts using the

wheelbrace

5

only.

► Lower the vehicle again fully .

► Fold jack 6 and remove it.

Page 193 of 292

191

In the event of a breakdown

8

► Tighten the security bolt using the

wheelbrace 5 equipped with a security socket 2 .

►

T

ighten the other bolts using the

wheelbrace

5

only.

►

Refit the bolt covers to each of the bolts

(depending on equipment).

►

Store the tools.

After changing a wheel

With a "space-saver" type spare wheel

Deactivate certain driving aid functions

(Active Safety Brake, Adaptive cruise control,

etc.).

Do not exceed the maximum authorised

speed of 50 mph (80 km/h) or the maximum

distance of 50 miles (80 km).

Driving with more than one "space-saver"

type spare wheel is prohibited.

Go to a PEUGEOT dealer or a qualified

workshop.

Have the tightening of the spare wheel's bolts

and its tyre pressure checked.

Have the punctured tyre examined. After

inspection, the technician will advise you on

whether the tyre can be repaired or if it must

be replaced.

Changing a bulb

In some weather conditions (e.g. low

temperature or humidity), misting on the

internal surface of the glass of the headlamps

and rear lamps is normal, and will disappear

after the lamps have been on for a few

minutes.

Never look too closely at the light beam

of LED technology lamps - risk of serious

eye injury!

The headlamps have polycarbonate lenses with a protective coating:

–

Do not clean them with a dry or abrasive

cloth, nor with detergent or solvent

products.

–

Use a sponge and soapy water or a pH

neutral product.

–

When using a high-pressure washer on

persistent marks, do not keep the lance

directed towards the headlamps, lamps or

their edges for too long, so as not to damage

their protective coating and seals.

Changing a bulb must only be done with

the ignition off and after the headlamp /

lamp has been switched off for several

minutes - risk of serious burns!

Do not touch the bulb directly with your

fingers; use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

of the same type and specification. To avoid

lighting imbalance, replace the bulbs in pairs.

Refitting the lamp units

Perform the operations in the reverse

order to dismantling.

Page 202 of 292

200

In the event of a breakdown

Accessing the tools

Hatchback

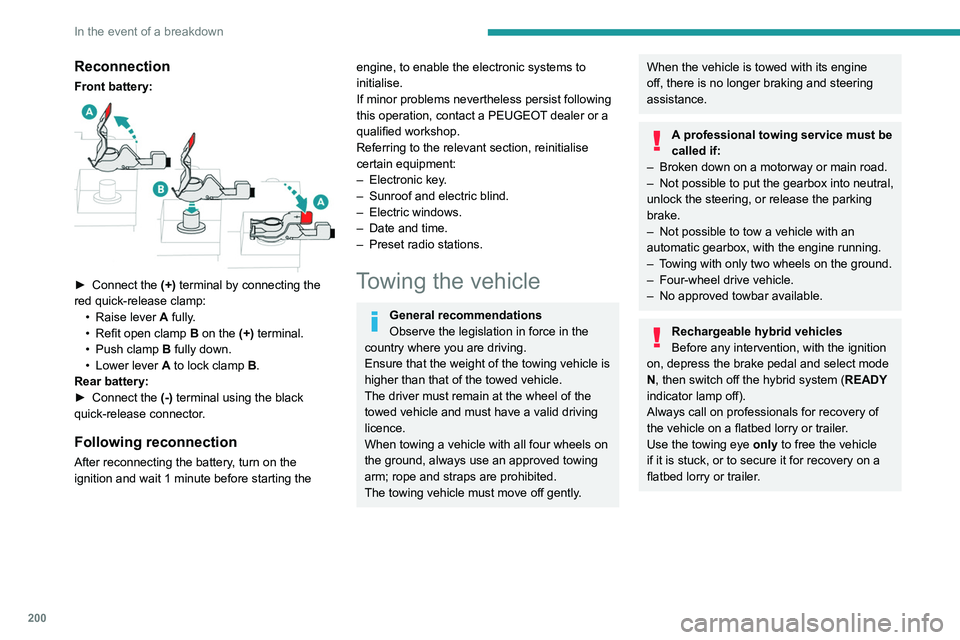

Reconnection

Front battery:

► Connect the (+) terminal by connecting the

red quick-release clamp: •

Raise lever

A

fully.

•

Refit open clamp

B

on the (+) terminal.

•

Push clamp

B fully down.

•

Lower lever

A

to lock clamp B.

Rear battery:

►

Connect the

(-) terminal using the black

quick-release connector.

Following reconnection

After reconnecting the battery, turn on the

ignition and wait 1 minute before starting the

engine, to enable the electronic systems to

initialise.

If minor problems nevertheless persist following

this operation, contact a PEUGEOT dealer or a

qualified workshop.

Referring to the relevant section, reinitialise

certain equipment:

–

Electronic key

.

–

Sunroof and electric blind.

–

Electric windows.

–

Date and time.

–

Preset radio stations.

Towing the vehicle

General recommendations

Observe the legislation in force in the

country where you are driving.

Ensure that the weight of the towing vehicle is

higher than that of the towed vehicle.

The driver must remain at the wheel of the

towed vehicle and must have a valid driving

licence.

When towing a vehicle with all four wheels on

the ground, always use an approved towing

arm; rope and straps are prohibited.

The towing vehicle must move off gently.

When the vehicle is towed with its engine

off, there is no longer braking and steering

assistance.

A professional towing service must be

called if:

–

Broken down on a motorway or main road.

–

Not possible to put

the gearbox into neutral,

unlock the steering, or release the parking

brake.

–

Not possible to tow a vehicle with an

automatic gearbox, with the engine running.

–

T

owing with only two wheels on the ground.

–

Four-wheel drive vehicle.

–

No approved towbar available.

Rechargeable hybrid vehicles

Before any intervention, with the ignition

on, depress the brake pedal and select mode

N, then switch off the hybrid system (READY

indicator lamp off).

Always call on professionals for recovery of

the vehicle on a flatbed lorry or trailer.

Use the towing eye only

to free the vehicle

if it is stuck, or to secure it for recovery on a

flatbed lorry or trailer.