spare wheel Peugeot 508 Hybrid 2014 Owner's Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2014, Model line: 508 Hybrid, Model: Peugeot 508 Hybrid 2014Pages: 380, PDF Size: 10.94 MB

Page 13 of 380

11

Limit the causes of excess consumption

Spread loads throughout the vehicle; place the heaviest items in the

bottom of the boot, as close as possible to the rear seats.

Limit the loads carried in the vehicle and reduce wind resistance (roof

bars, roof rack, bicycle carrier, trailer...). u

s

e a roof box in preference.

Remove roof bars and roof racks after use.

At the end of winter, remove snow tyres and refit your summer tyres.

Observe the recommendations on

maintenance

Check the tyre pressures regularly, when cold, referring to the label in

the door aperture, driver's side.

Carry out this check in particular:

-

b

efore a long journey,

-

a

t each change of season,

-

a

fter a long period out of use.

Don't forget the spare wheel and the tyres on any trailer or caravan.

Have your vehicle serviced regularly (engine oil, oil filter, air filter,

passenger compartment filter...) and observe the schedule of

operations recommended in the warranty and maintenance record.

When refuelling, do not continue after the third cut-off of the nozzle to

avoid any over flow.

At the wheel of your new vehicle, it is only after the first 1 800 miles

(3 000 kilometres) that you will see the fuel consumption settle down to

a consistent average.

.

Eco-driving

Page 81 of 380

79

508_en_Chap03_confort_ed02-2014

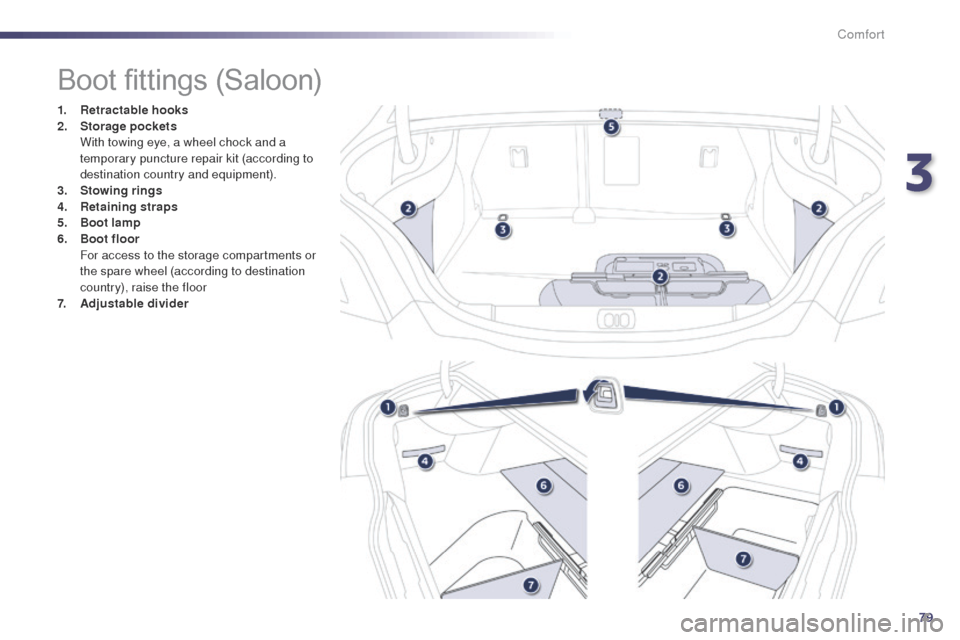

Boot fittings (Saloon)

1. Retractable hooks

2. Storage pockets

W

ith towing eye, a wheel chock and a

temporary puncture repair kit (according to

destination country and equipment).

3.

S

towing rings

4.

R

etaining straps

5.

B

oot lamp

6.

B

oot floor

F

or access to the storage compartments or

the spare wheel (according to destination

country), raise the floor

7.

A

djustable divider

3

Comfort

Page 82 of 380

80

508_en_Chap03_confort_ed02-2014

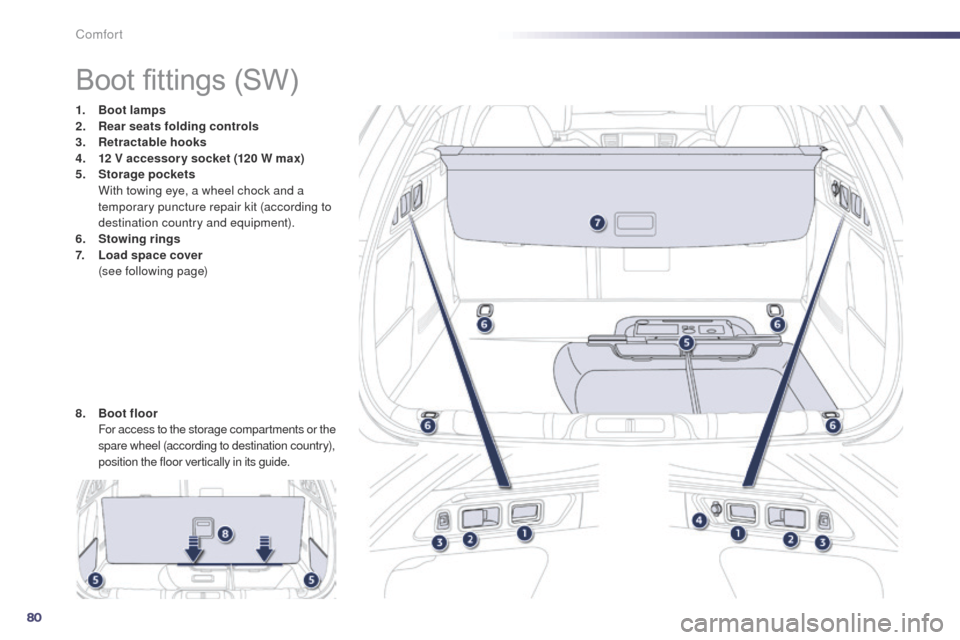

Boot fittings (SW)

1. Boot lamps

2. Rear seats folding controls

3.

R

etractable hooks

4.

1

2 V accessor y socket (120 W max)

5.

Sto

rage pockets

W

ith towing eye, a wheel chock and a

temporary puncture repair kit (according to

destination country and equipment).

6.

S

towing rings

7.

L

oad space cover

(

see following page)

8.

B

oot floor

F

or access to the storage compartments or the

spare wheel (according to destination country),

position the floor vertically in its guide.

Comfort

Page 176 of 380

174

508_en_Chap07_securite_ed02-2014

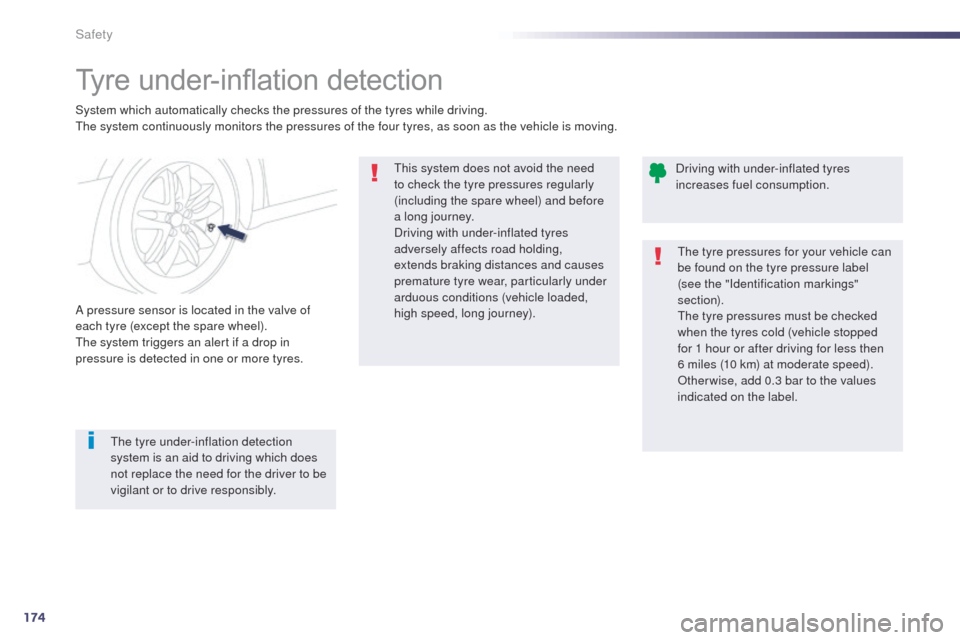

Tyre under-inflation detection

System which automatically checks the pressures of the tyres while driving.the system continuously monitors the pressures of the four tyres, as soon as the vehicle is moving.

th

e tyre under-inflation detection

system is an aid to driving which does

not replace the need for the driver to be

vigilant or to drive responsibly.

A pressure sensor is located in the valve of

each tyre (except the spare wheel).

th

e system triggers an alert if a drop in

pressure is detected in one or more tyres.

th

is system does not avoid the need

to check the tyre pressures regularly

(including the spare wheel) and before

a long journey.

Driving with under-inflated tyres

adversely affects road holding,

extends braking distances and causes

premature tyre wear, particularly under

arduous conditions (vehicle loaded,

high speed, long journey). Driving with under-inflated tyres

increases fuel consumption.

th

e tyre pressures for your vehicle can

be found on the tyre pressure label

(see the "Identification markings"

section).

th

e tyre pressures must be checked

when the tyres cold (vehicle stopped

for 1 hour or after driving for less then

6 miles (10 km) at moderate speed).

Other wise, add 0.3 bar to the values

indicated on the label.

Safety

Page 177 of 380

175

508_en_Chap07_securite_ed02-2014

the loss of pressure detected does not

always lead to visible deformation of the

tyre. Do not rely on just a visual check.

th

e alert is maintained until the tyre or

tyres concerned is reinflated, repaired

or replaced.

th

e spare wheel (space-saver type or a

steel rim) does not have a sensor.

Operating fault

the flashing and then fixed

illumination of the under-inflation

warning lamp accompanied by the

illumination of the "service" warning

lamp indicates a fault with the system.

th

is alert is also displayed when one or more

wheels is not fitted with a sensor (for example,

a space-saver or steel spare wheel).

go t

o a P

e

uge

Ot

dealer or a qualified

workshop

to have the system checked

or, following the repair of a puncture, to

have the original wheel, equipped with a

sensor, refitted.

Under-inflation alert

the alert is given by the fixed illumination

of this warning lamp, accompanied by

an audible signal, and depending on

equipment, the display of a message.

In the event of a problem on one of the tyres,

the symbol or the message appears, according

to equipment, to identify it.

F

R

educe speed, avoid sudden steering

movements or harsh brake applications.

F

S

top as soon as it is safe to do so.

F

I

f you have a compressor (the one in the

temporary puncture repair kit for example),

check the four tyre pressures when cold.

I

f it is not possible to check the tyre

pressures at the time, drive carefully at

reduced speed.

or

F

I

n the event of a puncture, use the

temporary puncture repair kit or the spare

wheel (according to equipment). Any tyre repair or replacement on a

wheel fitted with this system must be

carried out by a P

e

uge

Ot

dealer or a

qualified workshop.

If after changing a tyre, a wheel is not

detected by your vehicle (fitting snow

tyres for example), you must have the

system reinitialised by a P

e

uge

Ot

dealer or a qualified workshop.

In this case, monitoring of the tyre pressures is

not assured.

7

Safety

Page 194 of 380

192

508_en_Chap08_info-pratiques_ed02-2014

Changing a wheel

the tools are installed in the boot under the

f l o o r.

to g

ain access to them:

F

o

pen the boot,

F

p

osition the floor vertically (SW: in its

guide) for access to the tools.

Procedure for changing a faulty wheel for the spare wheel using the tools provided with the vehicle.

List of tools

All of these tools are specific to your

vehicle and can vary according to the level

of equipment. Do not use them for other

purposes.

1.

Wheelbrace.

F

or removing the wheel trim and removing

the wheel bolts.

2.

J

ack with integral handle.

F

or raising the vehicle. 3.

"

Bolt cover" tool.

F

or removing the bolt protectors (covers)

on alloy wheels.

4.

S

ocket for the security bolts (located in the

glove box).

F

or adapting the wheelbrace to the special

"security" bolts.

5.

A w

heel chock for immobilising the vehicle*.

6.

t

o

wing eye.

S

ee "

to

wing the vehicle".

Access to the tools

* Depending on country of sale or equipment.

Practical information

Page 195 of 380

193

508_en_Chap08_info-pratiques_ed02-2014

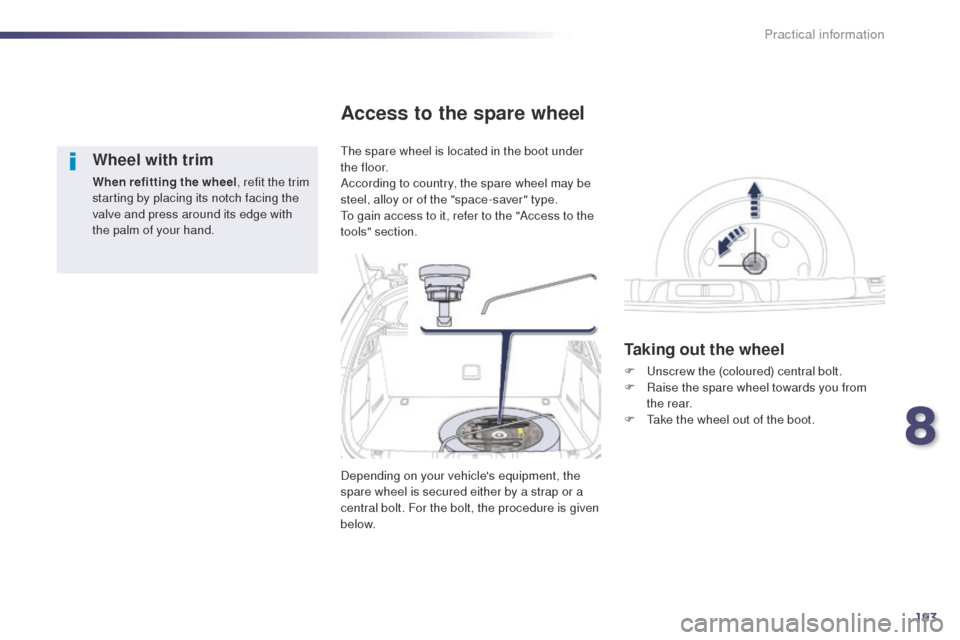

Wheel with trim

When refitting the wheel, refit the trim

starting by placing its notch facing the

valve and press around its edge with

the palm of your hand.

th

e spare wheel is located in the boot under

t h e f l o o r.

According to country, the spare wheel may be

steel, alloy or of the "space-saver" type.

to g

ain access to it, refer to the "Access to the

tools" section.

Access to the spare wheel

Taking out the wheel

F unscrew the (coloured) central bolt.

F R aise the spare wheel towards you from

the rear.

F

t

a

ke the wheel out of the boot.

Depending on your vehicle's equipment, the

spare wheel is secured either by a strap or a

central bolt. For the bolt, the procedure is given

below.

8

Practical information

Page 196 of 380

194

508_en_Chap08_info-pratiques_ed02-2014

Putting the wheel back in place

F Put the box back in place in the centre of the wheel and clip it.

F

P

ut the polystyrene storage box back in

place.

F

P

ut the wheel back in its housing.

F

un

screw the (coloured) central bolt by a

few turns then put it in place in the centre

of the wheel.

F

t

i

ghten fully until the central bolt clicks to

retain the wheel correctly.Tyre under-inflation

detection

the spare wheel (space-saver or steel

rim) does not have a sensor.

th

e punctured wheel must be repaired

by a P

e

uge

Ot

dealer or a qualified

workshop.

Practical information

Page 198 of 380

196

508_en_Chap08_info-pratiques_ed02-2014

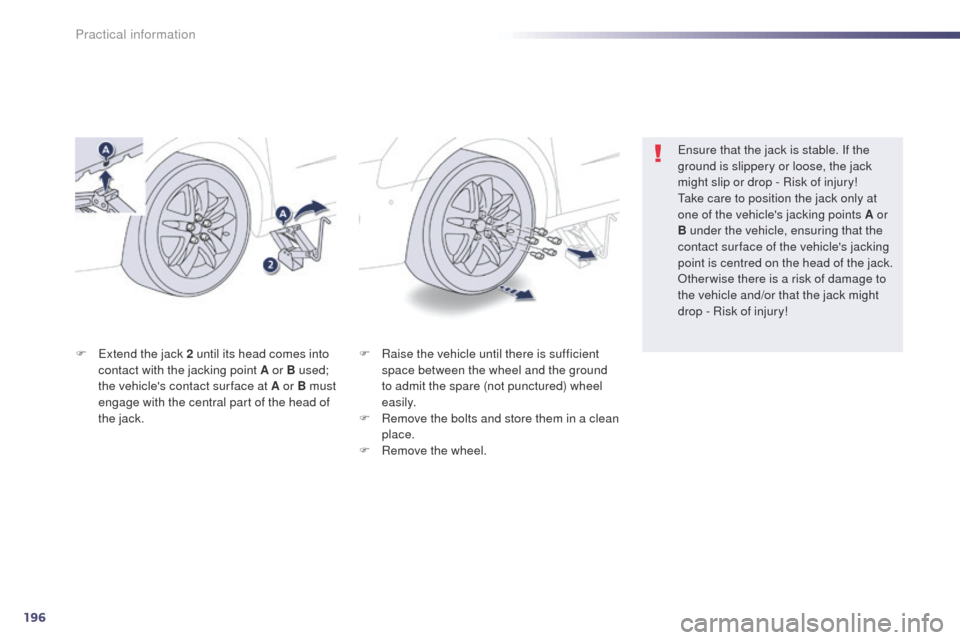

F Raise the vehicle until there is sufficient space between the wheel and the ground

to admit the spare (not punctured) wheel

easily.

F

R

emove the bolts and store them in a clean

place.

F

R

emove the wheel.

F

ex

tend the jack 2 until its head comes into

contact with the jacking point A or B used;

the vehicle's contact sur face at A or B must

engage with the central part of the head of

the jack.

en

sure that the jack is stable. If the

ground is slippery or loose, the jack

might slip or drop - Risk of injury!

ta

ke care to position the jack only at

one of the vehicle's jacking points A or

B under the vehicle, ensuring that the

contact sur face of the vehicle's jacking

point is centred on the head of the jack.

Otherwise there is a risk of damage to

the vehicle and/or that the jack might

drop - Risk of injury!

Practical information

Page 199 of 380

197

508_en_Chap08_info-pratiques_ed02-2014

Fitting a wheel

Fitting the "space-saver"

spare wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting, it

is normal to notice that the washers

do not come into contact with the

"space-saver" spare wheel. t

h

e wheel

is secured by the conical sur face of

each bolt.

After changing a wheel

to store the punctured wheel in the

boot correctly, first remove the central

c ove r.

When using the "space-saver" type

spare wheel, do not exceed 50 mph

(80

km/h).

Have the tightening of the bolts and the

pressure of the spare wheel checked

by a P

e

uge

Ot

dealer or a qualified

workshop without delay.

Have the punctured wheel repaired

and refitted to the vehicle as soon as

possible.

List of operations

F Put the wheel in place on the hub.

F S crew in the bolts fully by hand.

F

P

re-tighten the security bolt using the

wheelbrace 1 fitted with the security

socket

4.

F

P

re-tighten the other bolts using the

wheelbrace 1 o n l y.

8

Practical information