wheel PEUGEOT LANDTREK 2023 Service Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2023, Model line: LANDTREK, Model: PEUGEOT LANDTREK 2023Pages: 164, PDF Size: 6.1 MB

Page 113 of 164

111

Practical information

7– cleaning products directly on the throttle

bearings as well as on the body's connector;

–

hard, sharp or abrasive tools to remove

difficult deposits. Use a soft cloth with a

suitable detergent.

Refitting the throttle body

Before refitting the throttle body, check

the condition of the seal. If it is damaged,

replace it with a new one.

►

Install the seal on the intake manifold and fit

the throttle body

B, making sure that the seal

does not fall.

For reassembly, carry out the operations in the

reverse order to those for removal. Tighten the

screws to the correct tightening torque.

Free-wheeling

In certain situations, you must allow the vehicle

to free-wheel (while being towed, on a rolling

road, in an automatic car wash, or being

transported by rail or sea freight, etc.).

The procedure differs depending on the type of

gearbox and transmission.

Do not leave the vehicle unattended

while coasting.

/

To release them

► With the vehicle stationary and the engine

running, depress the brake pedal and release

the parking brake.

►

With a manual gearbox, move the gear lever

into neutral.

►

With an automatic gearbox, select position N

.

►

For 4-wheel drive vehicles (4x4), put the

transmission selector in 2H

mode.

►

Switch the ignition off.

Advice on care and maintenance

General recommendations

Observe the following recommendations to avoid

damaging the vehicle.

Exterior

Never use a high-pressure jet wash in

the engine compartment - risk of

damaging the electrical components!

Do not wash the vehicle in bright sunshine or

extremely cold conditions.

When washing the vehicle in an

automatic roller-brush car wash, be sure

to lock the doors and, depending on version,

move the electronic key away.

When using a pressure washer, keep the jet

nozzle at a minimum distance of 30 cm from

the vehicle (particularly when cleaning areas

containing chipped paint, sensors or seals).

Promptly clean up any stains containing

chemicals liable to damage the vehicle's

paintwork (including tree resin, bird

droppings, insect secretions, pollen and tar).

Depending on the environment, clean the

vehicle frequently to remove salty deposits

(in coastal areas), soot (in industrial areas)

and mud/salts (in wet or cold areas). These

substances can be highly corrosive.

Contact a PEUGEOT dealer or a qualified

workshop for advice on removing stubborn

stains requiring special products (such as tar

or insect removers).

Apply silicone oil to the door and window

seals every year and regularly lubricate the

door hinges and the locks.

To avoid damaging the seals when the vehicle

is parked for a long time, apply silicone-based

lubricant to the door seals and wax on the

bodywork in contact with the seals.

Preferably, have paint touch-ups performed

by a PEUGEOT dealer or a qualified

workshop.

Interior

When washing the vehicle, never use a

water hose or high-pressure jet to clean

the interior.

Liquids carried in cups or other open

containers can spill, presenting a risk of CarM an uals 2 .c o m

Page 118 of 164

11 6

In the event of a breakdown

► Open the passenger door.

► Fold down the seat backrest to access the

jack.

►

T

ake the rest of the tools from the pocket

behind the driver's seat backrest.

For more information on the Front bench seats,

Rear bench seats and Front seats, and in

particular their use, refer to the corresponding

section.

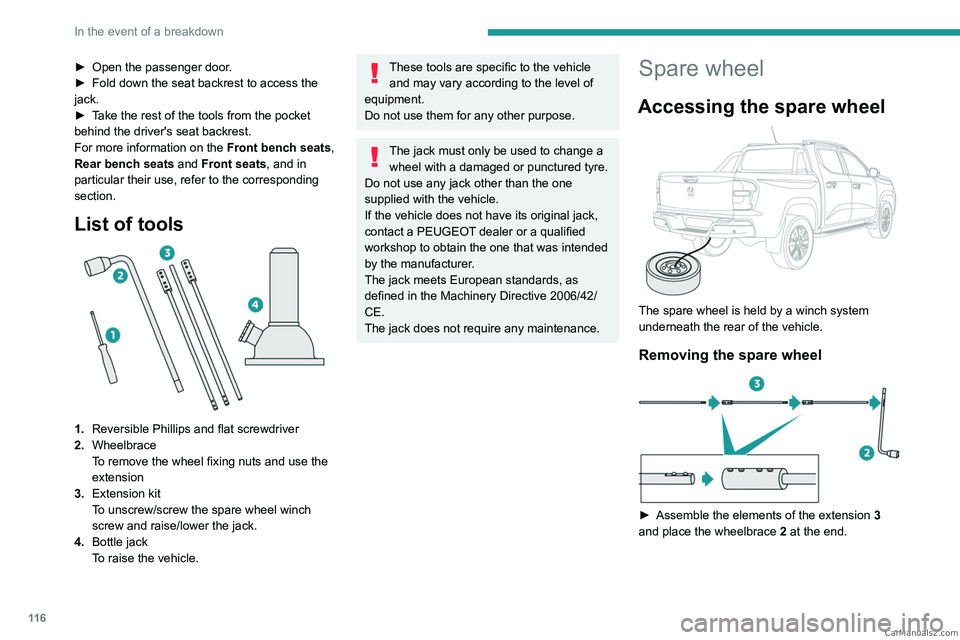

List of tools

1. Reversible Phillips and flat screwdriver

2. Wheelbrace

To remove the wheel fixing nuts and use the

extension

3. Extension kit

To unscrew/screw the spare wheel winch

screw and raise/lower the jack.

4. Bottle jack

To raise the vehicle.

These tools are specific to the vehicle

and may vary according to the level of

equipment.

Do not use them for any other purpose.

The jack must only be used to change a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with the vehicle.

If the vehicle does not have its original jack,

contact a PEUGEOT dealer or a qualified

workshop to obtain the one that was intended

by the manufacturer.

The jack meets European standards, as

defined in the Machinery Directive 2006/42/

CE.

The jack does not require any maintenance.

Spare wheel

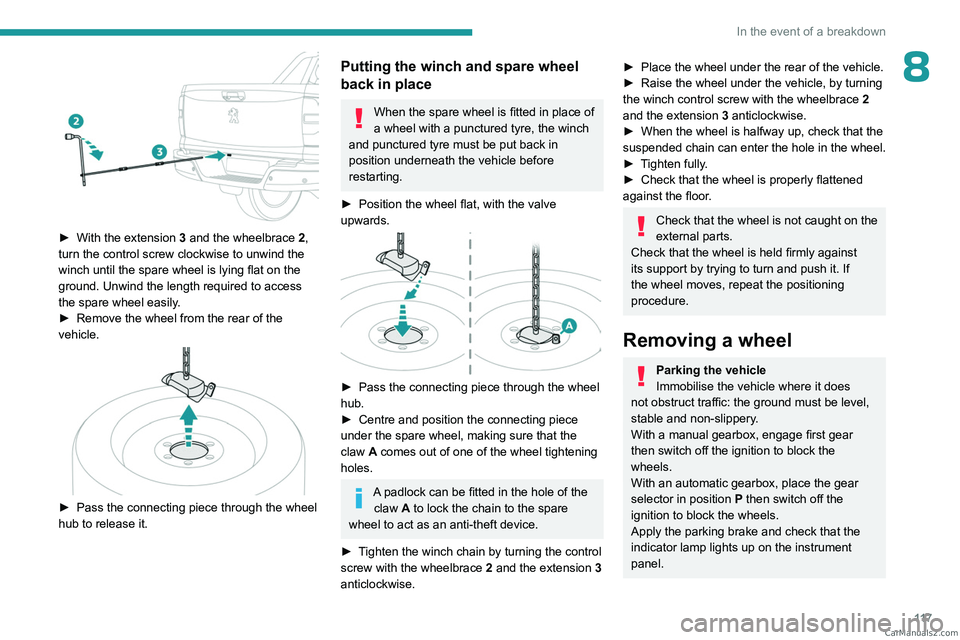

Accessing the spare wheel

The spare wheel is held by a winch system

underneath the rear of the vehicle.

Removing the spare wheel

► Assemble the elements of the extension 3

and place the wheelbrace 2 at the end.

CarM an uals 2 .c o m

Page 119 of 164

11 7

In the event of a breakdown

8

► With the extension 3 and the wheelbrace 2,

turn the control screw clockwise to unwind the

winch until the spare wheel is lying flat on the

ground. Unwind the length required to access

the spare wheel easily.

►

Remove the wheel from the rear of the

vehicle.

► Pass the connecting piece through the wheel

hub to release it.

Putting the winch and spare wheel

back in place

When the spare wheel is fitted in place of

a wheel with a punctured tyre, the winch

and punctured tyre must be put back in

position underneath the vehicle before

restarting.

►

Position the wheel flat, with the valve

upwards.

► Pass the connecting piece through the wheel

hub.

►

Centre and position the connecting piece

under the spare wheel, making sure that the

claw

A comes out of one of the wheel tightening

holes.

A padlock can be fitted in the hole of the claw A to lock the chain to the spare

wheel to act as an anti-theft device.

►

T

ighten the winch chain by turning the control

screw with the wheelbrace 2 and the extension 3

anticlockwise.

► Place the wheel under the rear of the vehicle.

► Raise the wheel under the vehicle, by turning

the winch control screw with the wheelbrace 2

and the extension 3 anticlockwise.

►

When the wheel is halfway up, check that the

suspended

chain can enter the hole in the wheel.

►

T

ighten fully.

►

Check that the wheel is properly flattened

against the floor

.

Check that the wheel is not caught on the

external parts.

Check that the wheel is held firmly against

its support by trying to turn and push it. If

the wheel moves, repeat the positioning

procedure.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does

not obstruct traffic: the ground must be level,

stable and non-slippery.

With a manual gearbox, engage first gear

then switch off the ignition to block the

wheels.

With an automatic gearbox, place the gear

selector in position P then switch off the

ignition to block the wheels.

Apply the parking brake and check that the

indicator lamp lights up on the instrument

panel. CarM an uals 2 .c o m

Page 120 of 164

11 8

In the event of a breakdown

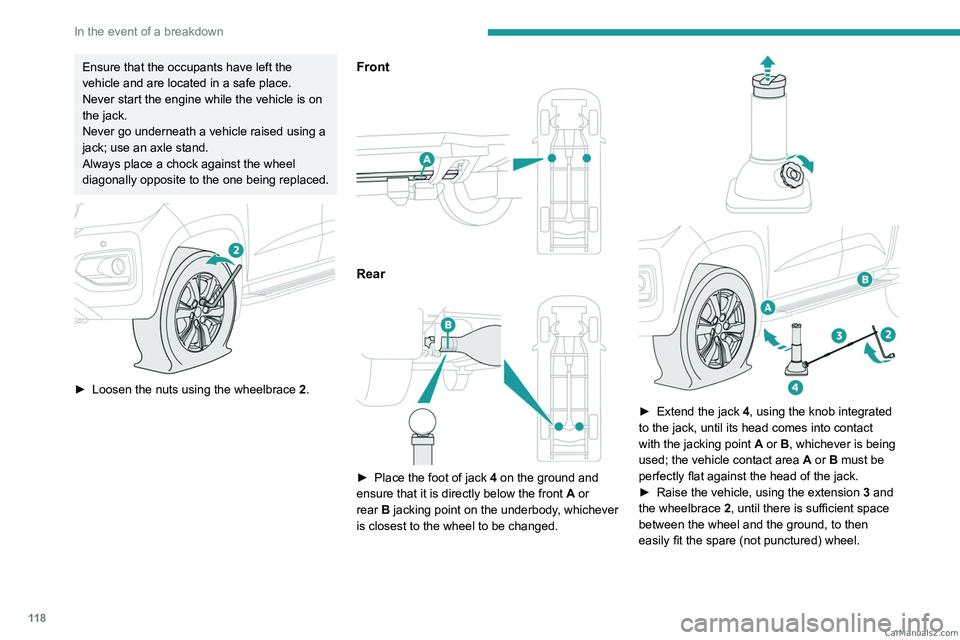

Ensure that the occupants have left the

vehicle and are located in a safe place.

Never start the engine while the vehicle is on

the jack.

Never go underneath a vehicle raised using a

jack; use an axle stand.

Always place a chock against the wheel

diagonally opposite to the one being replaced.

► Loosen the nuts using the wheelbrace 2 .

Front

Rear

► Place the foot of jack 4 on the ground and

ensure that it is directly below the front A or

rear

B jacking point on the underbody, whichever

is closest to the wheel to be changed.

► Extend the jack 4, using the knob integrated

to the jack, until its head comes into contact

with the jacking point

A

or B, whichever is being

used; the vehicle contact area

A

or B must be

perfectly flat against the head of the jack.

►

Raise the vehicle, using the extension 3

and

the wheelbrace 2, until there is sufficient space

between the wheel and the ground, to then

easily fit the spare (not punctured) wheel. CarM an uals 2 .c o m

Page 121 of 164

11 9

In the event of a breakdown

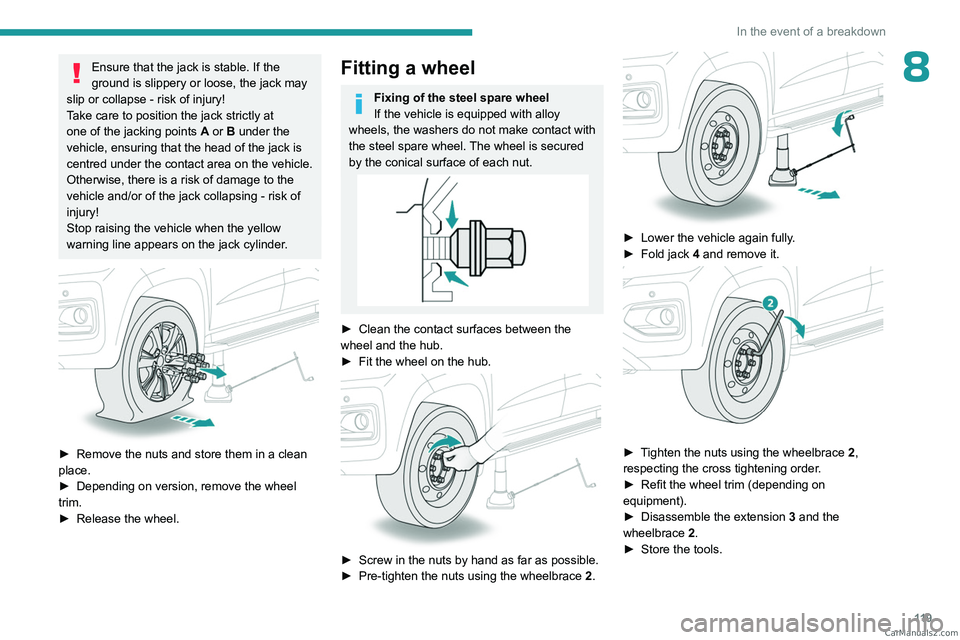

8Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or collapse - risk of injury!

Take care to position the jack strictly at

one of the jacking points

A

or B under the

vehicle, ensuring that the head of the jack is

centred under the contact area on the vehicle.

Otherwise, there is a risk of damage to the

vehicle and/or of the jack collapsing - risk of

injury!

Stop raising the vehicle when the yellow

warning line appears on the jack cylinder.

► Remove the nuts and store them in a clean

place.

►

Depending on version, remove the wheel

trim.

►

Release the wheel.

Fitting a wheel

Fixing of the steel spare wheel

If the vehicle is equipped with alloy

wheels, the washers do not make contact with

the steel spare wheel. The wheel is secured

by the conical surface of each nut.

► Clean the contact surfaces between the

wheel and the hub.

►

Fit the wheel on the hub.

► Screw in the nuts by hand as far as possible.

► Pre-tighten the nuts using the wheelbrace 2

.

► Lower the vehicle again fully.

► Fold jack 4 and remove it.

► Tighten the nuts using the wheelbrace 2,

respecting the cross tightening order.

►

Refit the wheel trim (depending on

equipment).

►

Disassemble the extension 3

and the

wheelbrace 2.

►

Store the tools. CarM an uals 2 .c o m

Page 122 of 164

120

In the event of a breakdown

After changing a wheel

The use of the non-standard steel spare wheel is temporary. The driver must drive

carefully at a moderate speed and limit the

distance covered.

Visit a PEUGEOT dealer or a qualified

workshop as soon as possible to have the

tightness of the nuts and the pressure of the

spare wheel checked.

Have the punctured tyre examined. After

inspection, the technician will advise you on

whether the tyre can be repaired or if it must

be replaced.

Changing a bulb

In some weather conditions (e.g. low

temperature or humidity), misting on the

internal surface of the glass of the headlamps

and rear lamps is normal, and will disappear

after the lamps have been on for a few

minutes.

The headlamps have polycarbonate lenses with a protective coating:

–

Do not clean them with a dry or abrasive

cloth, nor with detergent or solvent

products.

–

Use a sponge and soapy water or a pH

neutral product.

– When using a high-pressure washer on

persistent marks, do not keep the lance

directed towards the headlamps, lamps or

their edges for too long, so as not to damage

their protective coating and seals.

Changing a bulb must only be done with

the ignition off and after the headlamp /

lamp has been switched off for several

minutes - risk of serious burns!

Do not touch the bulb directly with your

fingers; use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

of the same type and specification. To avoid

lighting imbalance, replace the bulbs in pairs.

After changing a bulb

To refit, carry out the operations in

reverse order to removal.

Close the protective cover very carefully to

guarantee the sealing of the lamps.

Light-emitting diode (LED)

headlamps and lamps

Depending on version, the affected types of

headlamps/lamps are:

–

Offset daytime running lamps.

–

Direction indicator side repeaters.

– Rear sidelamps.

– Third brake lamp and loading bay lighting.

If you need to replace this type of bulb,

you must contact a PEUGEOT dealer or

a qualified workshop.

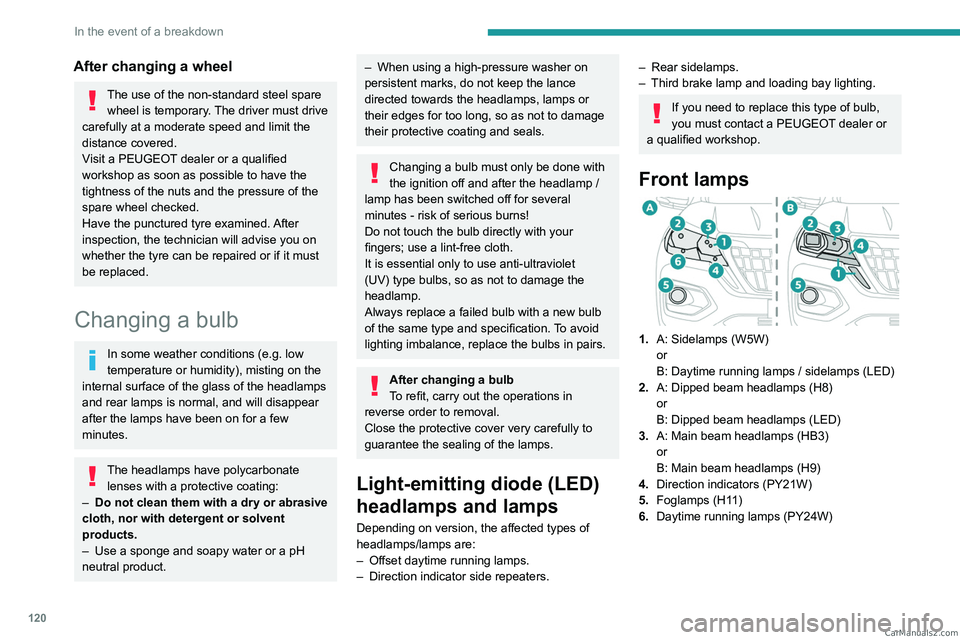

Front lamps

1. A: Sidelamps (W5W)

or

B: Daytime running lamps / sidelamps (LED)

2. A: Dipped beam headlamps (H8)

or

B: Dipped beam headlamps (LED)

3. A: Main beam headlamps (HB3)

or

B: Main beam headlamps (H9)

4. Direction indicators (PY21W)

5. Foglamps (H11)

6. Daytime running lamps (PY24W) CarM an uals 2 .c o m

Page 130 of 164

128

In the event of a breakdown

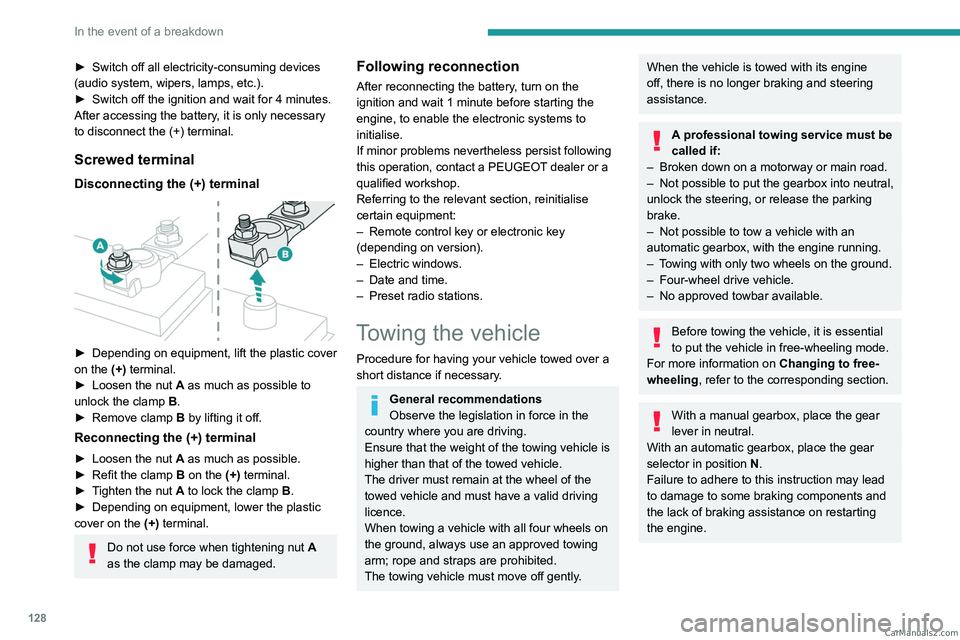

► Switch off all electricity-consuming devices

(audio system, wipers, lamps, etc.).

►

Switch off the ignition and wait for 4

minutes.

After accessing the battery, it is only necessary

to disconnect the (+) terminal.

Screwed terminal

Disconnecting the (+) terminal

► Depending on equipment, lift the plastic cover

on the (+) terminal.

►

Loosen the nut

A as much as possible to

unlock the clamp B.

►

Remove clamp

B

by lifting it off.

Reconnecting the (+) terminal

► Loosen the nut A as much as possible.

► Refit the clamp B on the (+) terminal.

►

T

ighten the nut A to lock the clamp B.

►

Depending on equipment, lower the plastic

cover on the

(+) terminal.

Do not use force when tightening nut A

as the clamp may be damaged.

Following reconnection

After reconnecting the battery, turn on the

ignition and wait 1 minute before starting the

engine, to enable the electronic systems to

initialise.

If minor problems nevertheless persist following

this operation, contact a PEUGEOT dealer or a

qualified workshop.

Referring to the relevant section, reinitialise

certain equipment:

–

Remote control key or electronic key

(depending on version).

–

Electric windows.

–

Date and time.

–

Preset radio stations.

Towing the vehicle

Procedure for having your vehicle towed over a

short distance if necessary.

General recommendations

Observe the legislation in force in the

country where you are driving.

Ensure that the weight of the towing vehicle is

higher than that of the towed vehicle.

The driver must remain at the wheel of the

towed vehicle and must have a valid driving

licence.

When towing a vehicle with all four wheels on

the ground, always use an approved towing

arm; rope and straps are prohibited.

The towing vehicle must move off gently.

When the vehicle is towed with its engine

off, there is no longer braking and steering

assistance.

A professional towing service must be

called if:

–

Broken down on a motorway or main road.

–

Not possible to put

the gearbox into neutral,

unlock the steering, or release the parking

brake.

–

Not possible to tow a vehicle with an

automatic gearbox, with the engine running.

–

T

owing with only two wheels on the ground.

–

Four-wheel drive vehicle.

–

No approved towbar available.

Before towing the vehicle, it is essential

to put the vehicle in free-wheeling mode.

For more information on Changing to free-

wheeling , refer to the corresponding section.

With a manual gearbox, place the gear

lever in neutral.

With an automatic gearbox, place the gear

selector in position N.

Failure to adhere to this instruction may lead

to damage to some braking components and

the lack of braking assistance on restarting

the engine. CarM an uals 2 .c o m

Page 131 of 164

129

In the event of a breakdown

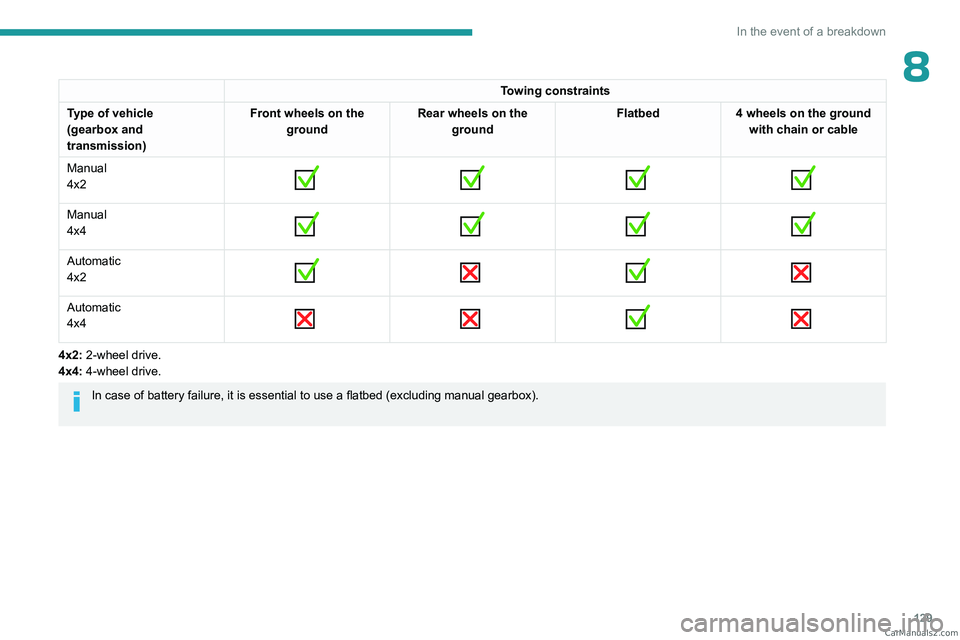

8Towing constraints

Type of vehicle

(gearbox and

transmission) Front wheels on the

ground Rear wheels on the

ground Flatbed

4 wheels on the ground

with chain or cable

Manual

4x2

Manual

4x4

Automatic

4x2

Automatic

4x4

4x2: 2-wheel drive.

4x4: 4-wheel drive.

In case of battery failure, it is essential to use a flatbed (excluding manua

l gearbox). CarM an uals 2 .c o m

Page 132 of 164

130

In the event of a breakdown

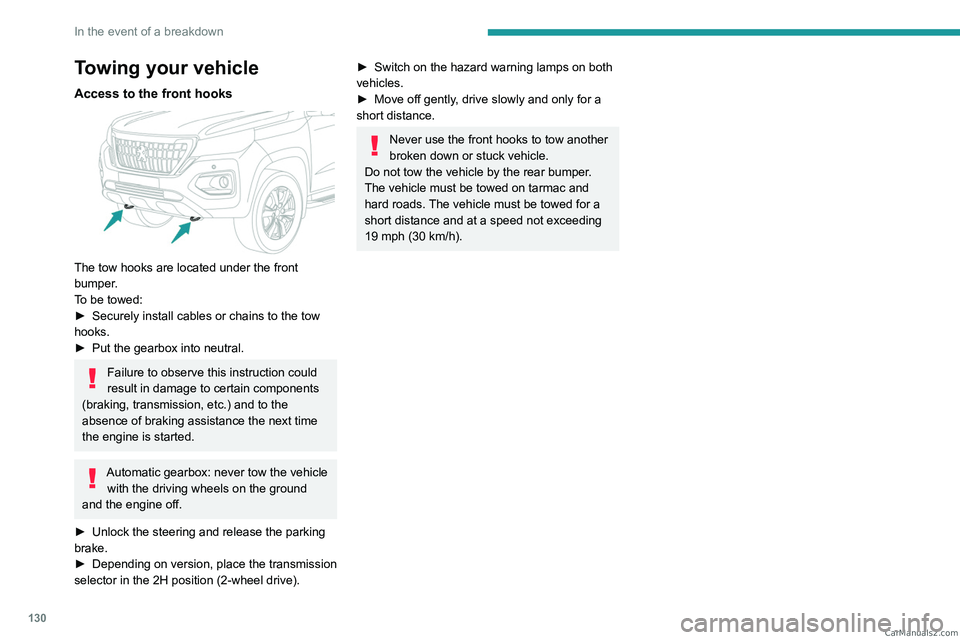

Towing your vehicle

Access to the front hooks

The tow hooks are located under the front

bumper.

To be towed:

►

Securely install cables or chains to the tow

hooks.

►

Put the gearbox into neutral.

Failure to observe this instruction could

result in damage to certain components

(braking, transmission, etc.) and to the

absence of braking assistance the next time

the engine is started.

Automatic gearbox: never tow the vehicle with the driving wheels on the ground

and the engine off.

►

Unlock the steering and release the parking

brake.

►

Depending on version, place the transmission

selector in the 2H position (2-wheel drive).

► Switch on the hazard warning lamps on both

vehicles.

►

Move off gently

, drive slowly and only for a

short distance.

Never use the front hooks to tow another

broken down or stuck vehicle.

Do not tow the vehicle by the rear bumper.

The vehicle must be towed on tarmac and

hard roads. The vehicle must be towed for a

short distance and at a speed not exceeding

19 mph (30 km/h). CarM an uals 2 .c o m

Page 137 of 164

135

Technical data

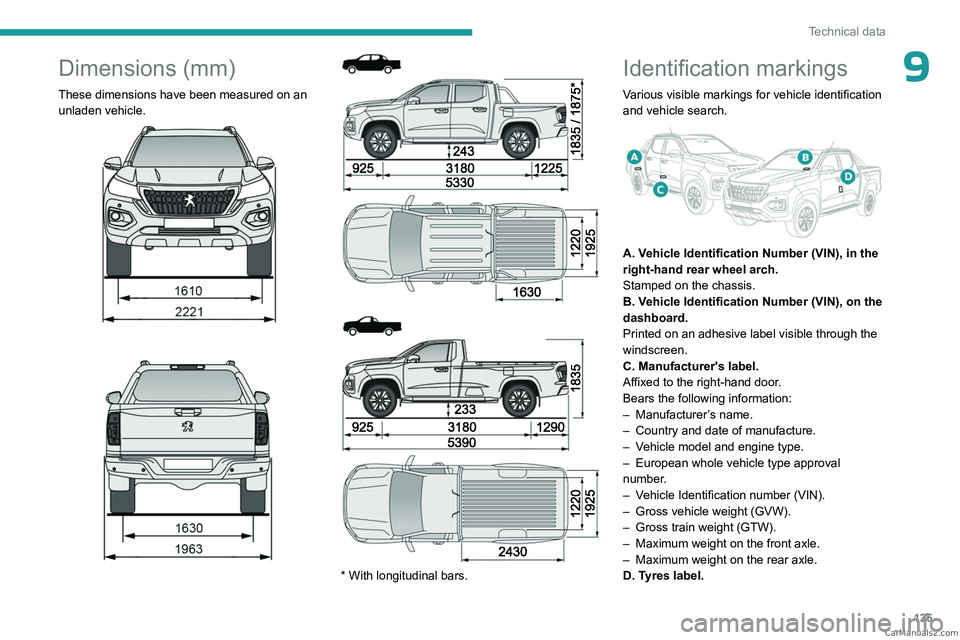

9Dimensions (mm)

These dimensions have been measured on an unladen vehicle.

* With longitudinal bars.

Identification markings

Various visible markings for vehicle identification

and vehicle search.

A. Vehicle Identification Number (VIN), in the

right-hand rear wheel arch.

Stamped on the chassis.

B. Vehicle Identification Number (VIN), on the

dashboard.

Printed on an adhesive label visible through the

windscreen.

C. Manufacturer's label.

Affixed to the right-hand door.

Bears the following information:

–

Manufacturer

’s name.

–

Country and date of manufacture.

–

V

ehicle model and engine type.

–

European whole vehicle type approval

number

.

–

V

ehicle Identification number (VIN).

–

Gross vehicle weight (GVW).

–

Gross train weight (GTW).

–

Maximum weight on the front axle.

–

Maximum weight on the rear axle.

D. T

yres label. CarM an uals 2 .c o m