oil change PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 10 of 1825

GENERAL INFORMATION OA-7

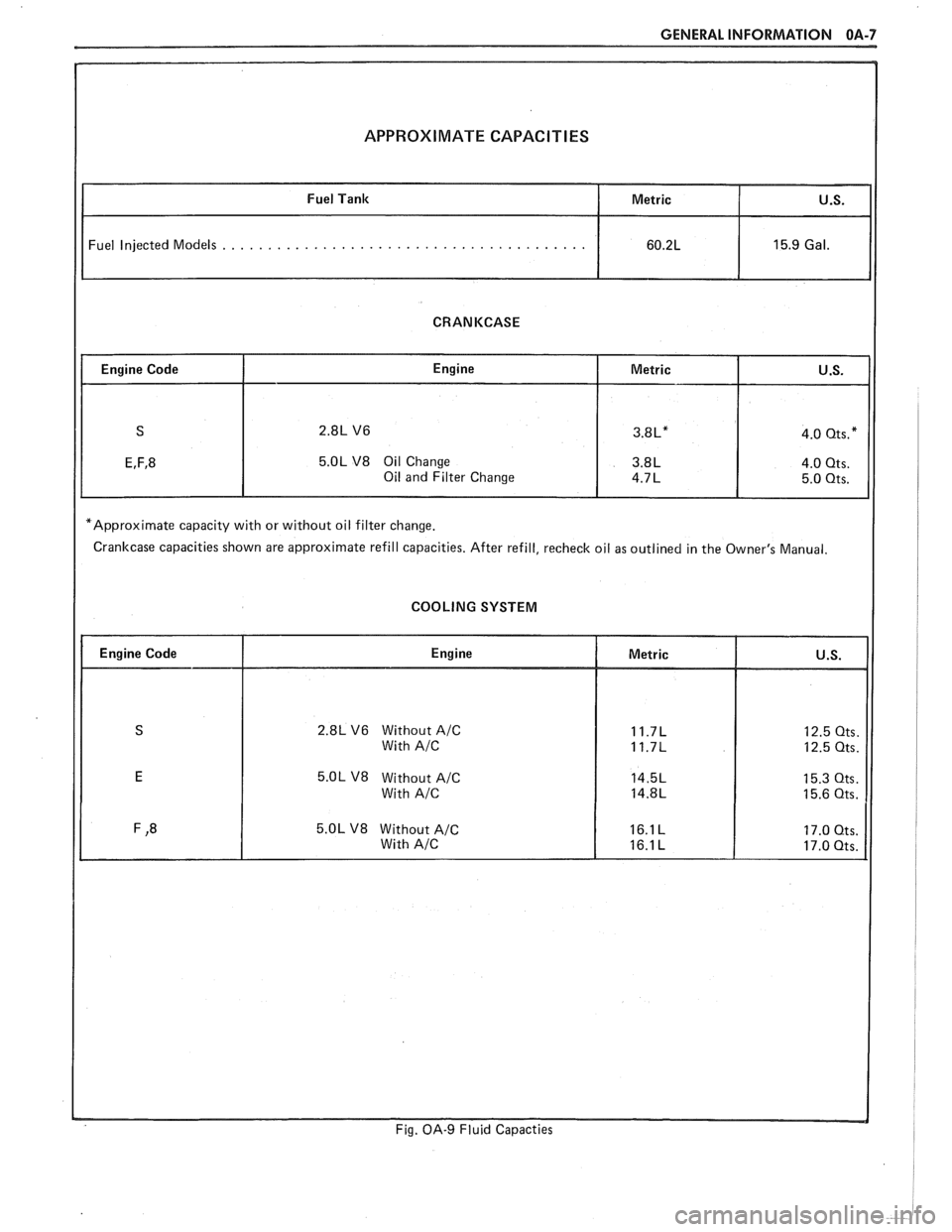

APPROXIMATE CAPACITIES

Fuel Injected Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRANKCASE

5.OL V8 Oil Change

*Approximate capacity with or without oil filter change.

Crankcase capacities shown are approximate refill capacities. After refill, recheck oil as outlined in the Owner's Manual.

COOLING SYSTEM

2.8L V6 Without A/C

5.OL V8 Without A/C

Fig. OA-9 Fluid Capacties

Page 18 of 1825

MAINTENANCE AND LUBRICATION OB-1

SECTION OB

NTENANCE AND LUBR

CONTENTS

Maintenance Schedule, Gasoline .............................................. OB-l

Maintenance Schedules I and 11 .............................................. OB-2

Owner Inspections

......................................................... OB-3

Recommended Fluids and Lubricants ......................................... OB-6

PASSENGER CAR MAINTENANCE SCHEDULE

VEHICLES

WITH GASOLINE ENGINE

NORMAL CAR USE ITEM 4

The maintenance services contained in Schedules I Carburetor or Throttle Body Mounting Bolt

and 11 are based on the assumption that your car will be Torque* used as designed:

Check torque of mounting bolts and/or nuts. @ To carry passengers and cargo within the limits

shown on the Tire Placard located on the edge of the ITEM 5 driver's door.

@ On reasonable road surfaces within legal driving Engine Idle Speed Adjustment*

limits. (Engines

without Idle Speed Control or Idle Air

Control) - Adjust to specifications shown on the under- @ On unleaded gasoline.

hood label. If no specifications are shown on the label, no

adjustment is necessary. Calibrated test equipment must

EXPLANATION OF SCHEDULED MAINTENANCE be used. SERVICES

The services listed in Maintenance Scheduies I and ITEM 6

11 are further explained below. When the following main- ~i~~ and wheel aotation tenance services are performed, make sure all parts are

replaced and all necessary repairs are done before driving To equalize wear and obtain maximum tire life,

your car. Be sure to use the proper fluid and lubricants as rotate in accordance with patterns shown in Owner's

shown in Figure OB-2. Manual.

ITEM 1

Engine Oil and Oil Filter Change*

ALWAYS USE SFICC OR SF/CD ENERGY CON-

SERVING OILS OF PROPER VISCOSITY

- Also.

always change oil and filter as soon as possible after

driving in a dust storm. See your Owner's Manual for

further details.

ITEM 2

Chassis Lubrication

Lubricate all grease fittings in suspension and steer-

ing linkage. Lubricate

transmissionltransaxle shift

linkage, parking brake cable guides, underbody contact

points and linkage. Also lubricate clutch cross shaft lever

every

30,000 miles (50 000 km) on rear-wheel-drive cars

only.

ITEM 3

Carburetor Choke and Hoses*

If your car is equipped with a carburetor, verify that

choke and vacuum break work properly and are within

specifications. Correct any binding caused by damage or

gum on the choke shaft. Inspect hoses for proper hookup,

cracks, chafing or decay. Correct as necessary.

Vacuum or A.I.R. Pump Drive Belt Inspection*

When a separate belt is used to drive the vacuum or

A.I.R.

pump, inspect it for cracks, fraying, wear and

proper tension. Adjust or replace as needed.

ITEM 8

Cooling System Service*

Drain, flush and refill system with new coolant. See

your Owner's Manual

for further details.

ITEM 9

Wheel Bearing Repack (Rear-Wheel-Drive Cars

Only Except Corvette)

Clean and repack front wheel bearings at each brake

relining or 15,000 miles

(25 000 km), whichever comes

first, when car is used in such service as police, taxi or

door-to-door delivery. If you do not use your car in such

service, clean and repack bearings at each brake relining

or 30,000 miles

(50 000 km), whichever comes first.

Corvette models do not require wheel bearing repack.

Page 21 of 1825

OB-4 MAINTENANCE AND LUBRICATION

Tire and wheel operation - Be alert to a vibra-

tion of the steering wheel or seat at normal highway

speeds. This may mean a wheel balance is needed. Also, a

pull right or left on a straight, level road may show the

need for

a tire pressure adjustment or wheel alignment.

Steering system operation - Be alert to

changes in steering action. An inspection is needed when

the steering wheel is harder to turn or has too much free

play or if unusual sounds are noted when turning or

parking.

Headlight aim operation - Take note of light

pattern occasionally. If beam aim doesn't look right,

headlights should be adjusted.

AT EACH FUEL FILL

Engine oil level check - Check engine oil level

and add if necessary. See your Owner's

Manual for further

details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Engine coolant level and condition - Check

engine coolant level in coolant reservoir tank and add if

necessary. Replace if dirty or rusty. See your Owner's

Manual for further details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Windshield washer fluid level check -- Check

washer fluid level in container and add if necessary.

Hood latch operation - When opening hood on

cars equipped with hoods that open from the front, note

the operation of secondary latch. It should keep hood from

opening all the way when primary latch is released. Make

sure that hood closes firmly.

AT LEAST MONTI-ILY

Tire and wheel inspection and pressure

check--

Check tires for abnormal wear or damage. Also,

check for damaged wheels. Keep pressures as shown on

Tire Placard on the driver's door (include spare unless it is

a stowaway). Pressure should b\: checked when tires are

"cold". See "Tires" in Owner's Manual for further

infomation.

Light operation check - Check operation of

license plate light, side-marker lights, headlights includ-

ing high beams, parking lights, taillights, brake lights.

turn signals, backup lights, instrument panel and interior

lights and hazard warning flashers.

Fluid leak check - After the car has been parked

for a while, inspect the surface beneath the car for water,

oil, fuel or other fluids. Water dripping from the air

conditioning system after use is normal. If you notice fuel

leaks or fumes, the cause should be found and corrected at

once.

AT LEAST TWICE A YEAR (FOR EXAMPLE,

EVERY SPRING AND FALL)

Power steering pump fluid level check --

Check power steering pump fluid level in accordance with

Owner's Manual instructions and keep at proper level.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Brake master cylinder reservoir fluid level

check ---- Check fluid and keep at proper level. Note: It is

normal for the brake fluid level to go down slightly as the

brake pads wear

- so be sure to keep reservoir filled.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Clutch system service --- manual transmis-

sionltransaxle --- For cars equipped with hydraulic

clutch system, check the reservoir fluid level and add fluid

as required. All others, check clutch pedal free travel and

adjust as necessary. See your Owner's Manual for further

details.

~

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Weatherstrip Lubrication - Clean surface and

then apply a thin film of silicone grease with a clean cloth.

EACH TIME OIL IS CHANGED

Automatic and manual transmissionltrans-

axle fluid level check - Check transmission/transaxle

fluid level and add as required. (Corvette only) if equipped

with manual transmission

- check fluid in the overdrive

unit and add as required.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Brake systems inspection - For convenience,

the following should be done when wheels are removed

for rotation: Inspect lines and hoses for proper hookup,

binding, leaks, cracks, chafing, etc. Inspect disc brake

pads for wear and rotors for surface condition. Also in-

spect drum brake linings for wear and cracks. Inspect

other brake parts, including drums, wheel cylinders, park-

ing brake, etc. at the same time. Check parking brake

adjustment.

INSPECT BRAKES MORE OFTEN IF DRIVING

HABITS OR CONDITIONS RESULT IN FREQUENT

BRAKING.

Steering, suspension and front drive axle

boot and seal inspection

- Inspect front and rear

suspension and steering system for damaged, loose or

missing parts, signs of wear or lack of lubrication. Inspect

power steering lines and hoses for proper hookup, bind-

ing, leaks, cracks, chafing, etc. (On cars equipped with

manual steering gear, check for seal leakage.) On

front-

wheel-drive cars, clean then inspect drive axle boot seals

for damage, tears or leakage. Replace seals if necessary.

Exhaust system inspection - Inspect complete

system. Inspect body near the exhaust system. Look for

broken, damaged, missing or out-of-position parts as well

as open seams, holes, loose connections or other condi-

tions which could cause a heat buildup in the tloor pan or

could let exhaust fumes seep into the trunk or passenger

compartment.

Page 22 of 1825

MAINTENANCE AND LUBRICATION OB-5

Throttle linkage inspection -- Inspect for inter-

ference, binding, damaged or missing parts.

Engine drive belts inspection - Inspect all

belts for cracks, fraying and wear. Adjust or replace as

needed.

Rear axle service (if equipped) - Check gear

lubricant level and add if needed. For cars equipped with a

limited slip rear axle, fluid does not require changing

(except Caprice and Corvette

- change fluid and required

additive at first

7,500 miles (12 500 km). See your

Owner's Manual or "Recommended Fluids

& Lubricants

Chart" in this section.

IF YOU USE YOUR GAR TO PULL A TRAILER,

CHANGE GEAR LUBRICANT EVERY 7,500 MILES

(12 500 KM).

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Power antenna - Clean and then lubricate power

antenna mast. The proper lubricant as shown in Figure

OB-2 should be used.

AT LEAST ONCE A YEAR

Lap and shoulder belts condition and opera-

tion

- Inspect belt system, including webbing, buckles,

latch plates, retractors, guide loops and anchors.

Moveable head restraint operation - On cars

with moveable restraints, make sure restraints stay in the

desired position. (See adjustment instructions in your

Owner's Manual.)

Seatback latch and recliner operation on

cars equipped

with recliner seat --- Be sure seat-

backs latch on those cars with folding seats using mechan-

ical latches. Make sure the recliner is holding by pushing

and pulling on the top of the

seatback while it is reclined.

See your Owner's Manual for seat operating information.

Spare tire and jack storage- Be alert to rattles

in rear of car. Make sure the space tire, all jacking equip-

ment, any tire inflator and any covers or doors are securely

stowed at all times. Oil jack ratchet or screw mechanism

after each use.

Key lock service - Lubricate key lock cylinder at

least annually.

Body lubrication service - Lubricate all body

door hinges including the tailgate or hatchback lid (if

equipped). Also lubricate the body hood, fuel door and

rear compartment hinges and latches including interior

glove box and counsel doors, and any folding seat

hardware.

"Fansmissionltransaxle neutral or clutch

starl switch operation

CAUnON: Before pedorming the follow-

ing safety switch check, be sure to have

enough room around the car. Then, firmly

apply both the parking brake (see your

Owner's Manual for procedure) and the

regular brakes. Do not use the accelerator pedal.

If the engine

starls, be ready to turn

off the ignition promptly. Take these pre-

cautions because the car could move

without warning and possibly cause per-

sonal injury or properly damage. On auto-

matic transmissionltransaxle cars, try to

starl the engine in each gear. The starler

should crank only in "Park" or "Neutral."

On manual transmissionltransaxle cars,

place the

shiR lever in "Neutral," push the

clutch halfway and try to starl. The starler

should crank only when the clutch is fully

depressed.

Steering column lock operation

- While

parked, try to turn key to "Lock" in each gear range. The

key should turn to "Lock" only when gear is in "Park" on

automatic or "Reverse" on manual

transmissionltransax-

le. On cars with key release lever, try to turn key toULock"

without depressing the lever. The key should turn to

"Lock" only with the key lever depressed. On all vehicles,

the key should come out only in "Lock."

Parking brake and transmissionltransaxle

"Park" mechanism operation

CAUT1ON:Before checking the holding

ability of the parking brake and automatic

transmissionltransaxle "Park" mecha-

nism, park on a fairly steep hill with

enough room for movement in the down-

hill direction. To reduce the risk of person-

al injury or property damage, be prepared

to apply the regular brakes promptly if the

car begins to move.

To check the parking brake, with the engine running and

transmission/transaxle in "Neutral." slowly remove foot

pressure from the regular brake pedal (until the car is held

by only the parking brake).

To check the automatic transmissionltransaxle "Park"

mechanism holding ability, release all brakes after shift-

ing the transmissionltransaxle to "Park."

ljnderbody flushing - At least every spring,

tlush from the underbody with plain water any corrosive

materials used for ice and snow removal and dust control.

Take care to thoroughly clean any areas where mud and

other debris can collect.

Sediment packed in closed areas

of the vehicle should be loosened before being flushed.

Engine cooling system service - Inspect

coolant and freeze protection. If dirty or rusty, drain, flush

and refill with new coolant. Keep coolant

at the proper

mixture as specified in your Owner's Manual. This pro-

vides proper freeze protection. corrosion inhibitor level

and engine operating temperature. Inspect hoses and re-

place if cracked. swollen or deteriorated. Tighten hose

clamps. Clean outside of radiator and air conditioning

condensor. Wash radiator filler cap and neck.

To help

ensure proper operation. a pressure test of both the cooling

system and cap is also recommended. (See maintenance

schedule charts in Figure

OB-l for the recommended

coolant change interval.)

Page 57 of 1825

18-14 AIR CONDITIONING

HANDLING OF REFRIGERANT LINES AND

FI-INGS

Tighten all tubing connections as shown in

torque chart (Figure 13). INSUFFICIENT OR

EXCESSIVE TORQUE WHEN TIGHTENING CAN

RESULT IN LOOSE JOINTS OR DEFORMED

JOINT PARTS. Either condition can result in refrig-

erant leakage.

All metal tubing lines should be free of dents or

kinks to prevent loss of system capacity due to line

restriction.

@ The flexible hose lines should never be bent to a

radius of less than four (4) times the diameter of

the hose.

@ The flexible hose lines should never be allowed

to come within a distance of

63.5mm (2-112") of

the exhaust manifold.

@ Flexible hose lines should be inspected regularly

for leaks or brittleness and replaced with new

lines if deterioration or leaking is found.

@ When disconnecting any fitting in the refrigera-

tion system, the system must first be discharged

of all Refrigerant- 12. Proceed very cautiously

regardless of gauge readings. Open very slowly,

keeping face and hands away so that no injury

can occur if there happens to be liquid

Refriger-

ant-12 in the line. If pressure is noticed when

fitting is loosened, allow it to bleed off as

described under DISCHARGING, ADDING

OIL, EVACUATING AND CHARGING PRO-

CEDURES FOR

A/C SYSTEMS.

@ In the event any refrigerant line is opened to the

atmosphere, it should be immediately capped or

taped to prevent entrance of moisture and dirt,

which can cause internal compressor wear or

plugged lines, in the condenser and evaporator

core and expansion (orifice) tubes or compressor

inlet screens.

@ The use of the proper wrenches when making

connections on O-ring fittings is important. The

opposing fitting should always be backed up

with a wrench to prevent distortion of connecting

lines or components. When connecting the flexi-

ble hose connections, it is important that the

swaged fitting and the flare nut, as well as the

coupling to which it is attached, be held at the

same time using three

(3) different wrenches to

prevent turning the fitting and damaging the

ground seat.

@ O-rings and seats must be in perfect condition. A

burr or piece of dirt may cause a refrigerant leak.

When replacing the O-ring, first dip it in clean

525 viscosity refrigeration oil.

MAINTAINING CHEMICAL STABILITY IN

THE

REFRIGERATION SYSTEM

The efficient operation and life of the air condi-

tioning system is dependent upon the chemical stabil-

ity of the refrigeration system. When foreign materials, such as

dirt, air, or moisture, contaminate

the refrigeration system, they will change the stability

of the Refrigerant-12 and 525 viscosity compressor

oil. They will also affect pressure-temperature rela-

tionship, reduce efficient operation and possibly cause

interior corrosion and abnormal wear of moving parts.

The following general practices should be

observed to insure chemical stability in the system:

1. Before disconnecting a refrigerant connection,

wipe away any dirt or oil at and near the connec-

tion to reduce the possibility of dirt entering the

system. Both sides of the connection should be

capped, plugged or taped as soon as possible to

prevent the entry of dirt, foreign material and

moisture.

2. Keep tools clean and dry. This includes the

manifold gauge set and replacement parts.

3. When adding 525 viscosity refrigerant oil (see

ADDING OIL in the DISCHARGING,

ADDING OIL, EVACUATING AND

CHARGING PROCEDURES FOR

AIC SYS-

TEMS, the transfer device and container should

be clean and dry to assure that refrigeration oil

remains as moisture-free as possible.

4. When it is necessary to "open" an

AIC system,

have everything needed ready and handy so that

as little time as possible will be required to per-

form the operation. Do not leave the

AIC system

open any longer than is necessary.

5. Any time the

A/C system has been "opened," it

should be properly evacuated before recharging

with Refrigerant- 12 according to the DIS-

CHARGING, ADDING OIL, EVACUATING

& CHARGING PROCEDURES FOR AIC

SYSTEMS.

All service parts are dehydrated and sealed

prior to shipping. They should remain sealed until just

prior to making connections. All parts should be at

room temperature before uncapping. (This prevents

condensation of moisture from the air entering the

system.) If, for any reason, caps are removed but the

connections are not made, parts should be resealed as

soon as possible.

DISCHARGING, ADDING OIL,

EVACUATING AND CHARGING

PROCEDURES FOR NC SYSTEMS

The refrigerant system may be discharged,

evacuated and charged using air conditioning service

charging station J-23500-01 or equivalent, or the

manifold and gauge set

5-23575-01 and 420ml (14

oz.) disposable cans of Refrigerant-12 (Figure 16).

Charging lines from the charging station or

manifold and gauge set require the use of gauge

adapters to connect to the system service fitting.

A

straight gauge adapter 5-5420 and a 90" angle gauge

adapter

5-9459 are available (see A/C Special Tools).

Always wear goggles and wrap a clean cloth

around fittings and connections when doing work that

Page 91 of 1825

4 Dl-I 2 R-4 AIR CONDITIONING COMPRESSOR OVERHAUL

MAJOR REPAIR PROCEDURES

Service repair procedures to the

Compressor Shaft Seal,

Pressure Relief Valve

or disassembly

of the Internal Compressor

Cylinder and Shaft Assembly are considered

"MAJOR" SINCE THE REFRIGERATION

SYSTEM MUST BE DISCHARGED,

EVACUATED AND RECHARGED to complete

service and/or because major internal

operating and sealing components of the

compressor are being disassembled and

serviced.

When replacing the shaft seal assembly or

pressure relief valve, even if the compressor remains on

the vehicle during the operation, it will be necessary to

discharge the system of refrigerant (see Section

1B).

Other than clutch repair procedures, the same holds

true for any disassembly of the compressor.

If the compressor shell, front head or cylinder

and shaft assembly are to be serviced or replaced, the

oil in the compressor must be drained, measured and

replaced (see Section

1B) to determine addition of

proper oil quantity to new assembly.

A clean workbench, preferably covered with a

sheet of clean paper, orderliness in the work area and

a place for all parts being removed and replaced is of

great importance, as is the use of the proper, clean

service tools.

NOTICE: Any attempt to use make-shift or

inadequate equipment may result in damage

and/or improper compressor operation.

All parts required for servicing the internal

compressor are protected by a preservation process and

packaged in a manner which will eliminate the

necessity of cleaning, washing or flushing of the parts.

The parts can be used in the internal assembly just as

they are removed from the service package.

Seals and

protective packaging should be left in tact un

ti1 just

prior to installation.

SI-IAFT SEAL

Fig. 35 thru 40

Shaft Seal Design

The shaft seal is a one piece design.

Seal Leak Detection

A shaft seal should not be changed because of an

oil-line on the hood insulator. The Seal is designed to

seep some oil for lubrication purposes. Only change a

Shaft Seal when a leak is detected by evidence of oil

sprayed in large amounts and then only after actual

refrigerant leakage is found by using an approved leak

Detector such as J-29547 or equivalent.

Should an R-4 compressor shaft seal ever have to

be replaced, the accumulator in this R-4 system must

also be removed from the vehicle. The oil in the

accumulator then must be drained, measured and

replaced according to the directions in Section

1B to

determine oil loss.

On-Car

Remove

or Disconnect

1. Discharge A/C system

2. Loosen and reposition compressor in mounting

brackets

3. Clutch Plate and Hub assembly

4. Shaft seal seat retainer ring, using Snap Ring

Pliers J-5403-A

5. Thoroughly clean inside of compressor neck area

and O-ring groove surrounding the shaft, the

exposed portion of the seal seat and the shaft

itself. Any dirt or foreign material getting into

compressor may cause damage.

6. Remove Lip Seal:

e Fully engage the knurled tangs of Seal

Remover-Installer J-23 128-A into the

recessed portion of the Seal by turning the

handle clockwise. Remove the Seal from the

compressor with a rotary-pulling motion.

Discard the Seal. The handle must be

hand-tightened securely. Do not use a

wrench or pliers.

7. Discard the seal seat O-ring from the compressor

neck using 0-Ring Remover J-9553-01.

8. Recheck the shaft and inside of the compressor

neck and O-ring groove for dirt or foreign

material and be sure these areas are perfectly

clean before installing new parts.

Inspection

Seals should not be reused. Always use a new

specification service seal kit on rebuild. Care should be

taken to prevent damage to the lip of the one piece seal.

Make sure that the Seal Seat and Seal Lip are free of

lint and dirt that could damage the seal surface or

prevent sealing.

On-Car

Install

or Connect

1. Dip

the new seal O-ring in clean 525 viscosity

refrigerant oil and assemble onto 0-Ring

Installer J-33011.

2. Insert

the 0-Ring Installer

5-3301 1 completely

down into the compressor neck until the Installer

"bottoms." Lower the moveable slide of the

0-Ring Installer to release the 0-Ring into the

seal seat O-ring lower groove. (The compressor

neck top groove is for the shaft seal retainer ring.)

Rotate the Installer to seat the O-ring and remove

the Installer.

3. Prepare Lip Seal:

Assemble seal to Seal Installer J-23128-A,

by turning handle clockwise, and then push

Seal Protector J-34614, into seal lip. The

stamped steel case side of the lip seal must

be engaged with knurled tangs of installer so

that flared-out side of lip seal is facing and

installed towards the compressor.

4. Install Lip Seal:

Page 149 of 1825

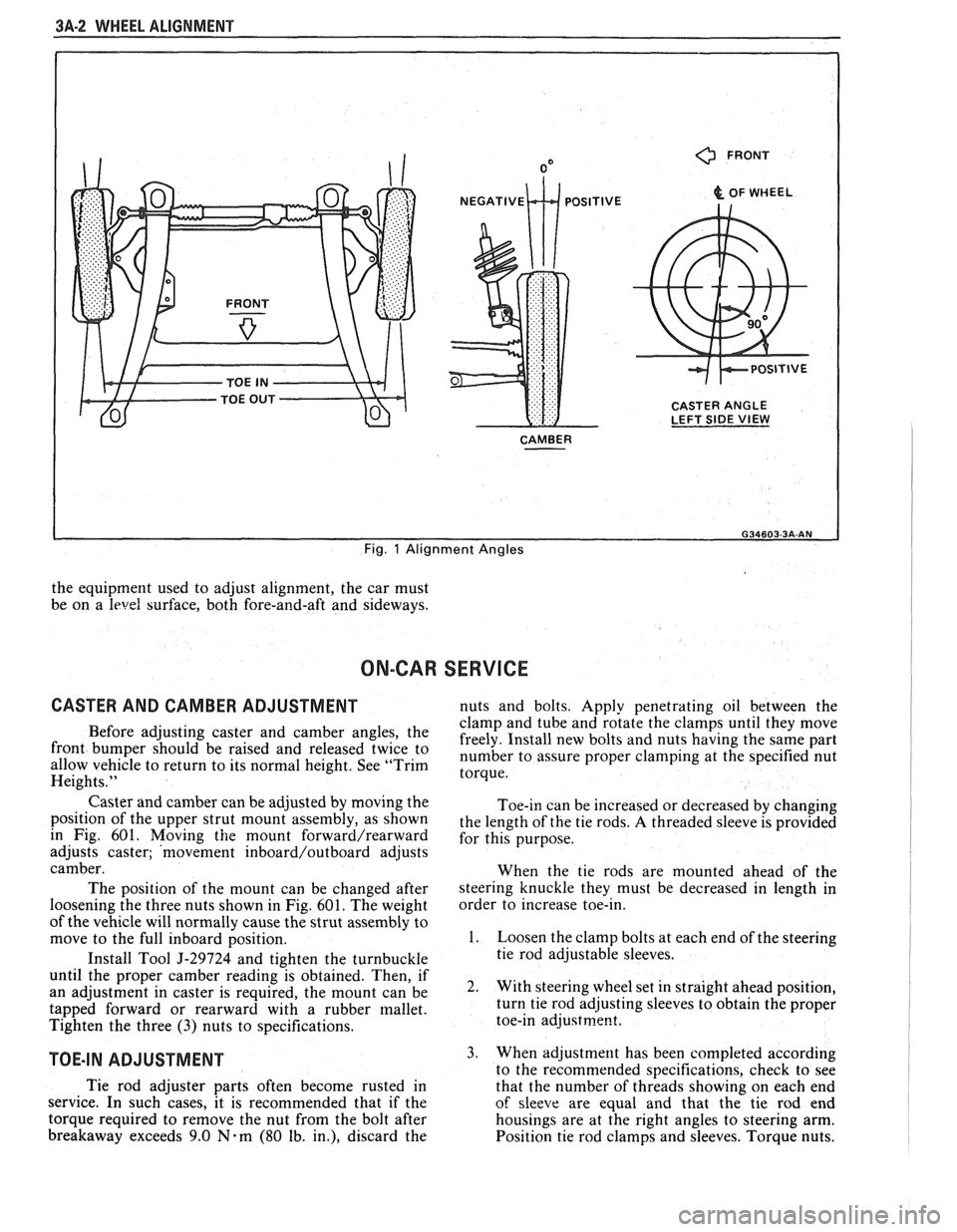

3A-2 WHEEL ALIGNMENT

0 FRONT

& OF WHEEL

CASTER ANGLE

LEFT SIDE

VIEW

CAMBER

I

Fig. 1 Alignment Angles

the equipment used to adjust alignment, the car must

be on a

level surface, both fore-and-aft and sideways.

ON-CAR SERVICE

CASTER AND CAMBER ADJUSTMENT nuts and bolts. Apply penetrating oil between the

clamp and tube and rotate the clamps until they move

Before adjusting caster and camber the freely. Install new bolts and nuts having the same part front be 'aised and twice to number to assure proper at the specified nut allow vehicle to return to its normal height. See "Trim torque. Heights."

Caster and camber can be adjusted by moving the

position of the upper strut mount assembly, as shown

in Fig. 601. Moving

the mount forward/rearward

adjusts caster; 'movement inboard/outboard adjusts

camber.

The position of the mount can be changed after

loosening the three nuts shown in Fig.

601. The weight

of the vehicle will normally cause the strut assembly to

move to the full inboard position.

Install Tool

5-29724 and tighten the turnbuckle

until the proper camber reading is obtained. Then, if

an adjustment in caster is required, the mount can be

tapped forward or rearward with a rubber mallet.

Tighten the three

(3) nuts to specifications.

TOE-IN ADJUSTMENT

Toe-in can be increased or decreased by changing

the length of the tie rods.

A threaded sleeve is provided

for this purpose.

When the tie rods are mounted ahead of the

steering knuckle they must be decreased in length in

order to increase toe-in.

1. Loosen the clamp bolts at each end of the steering

tie rod adjustable sleeves.

2. With steering wheel set in straight ahead position,

turn tie rod adjusting sleeves to obtain the proper

toe-in

adjustrne~t.

3. When adjustment has been completed according

to the recommended snecifications. check to see

Tie rod adjuster parts often become rusted in

that the number of thrkads showing on each end

service. In such cases, it is recommended that if the

of sleeve are equal and that the tie rod end

torque required to remove the nut from the bolt after housings are at the right angles to steering arm.

breakaway exceeds 9.0

Nam (80 lb. in.), discard the

Position tie rod clamps and sleeves. Torque nuts.

Page 212 of 1825

FRONT SUSPENSION 3C-1

SEC"T0RI 3C

FRONT SUSPENS

NOTICE: All front suspension fasteners are an important attaching part in that it could affect the

performance of vital parts and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified during reassembly

to assure proper retention of this part.

NOTICE: Never attempt to heat, quench or straighten any front suspension part. Replace it with a new part

or

damage to the part may result.

CONTENTS

General lnformation ....................................................................................................... 3C-I

On-Car Service ................................................................................................................... 3C- I

Specifications ..................................................................................................................... 3C- 10

GENERAL INFORMATION

The front suspension is designed to allow each

wheel to compensate for changes in the road surface ON-CAR SERVICE

level without appreciably affecting the opposite wheel. WHEEL BEARINGS

Each wheel is independently connected to the frame by

The proper functioning of the front suspension

a steering

kunckle, strut assembly, ball joint, and lower cannot be maintained unless the front wheel tapered arm. The steering in a roller bearings are correctly adjusted. The bearings

prescribed three dimensional arc. The front wheels are

must be a slip fit on the spindle and the inside diameter held in proper relationship to each other by two tie rods of the bearings should be lubricated to insure proper which are connected to steering arms on the knuckles ~h~ spindle nut must be a free-running fit and to the relay rod assembly.

on the threads.

Coil chassis springs are mounted between the

spring housings on the front crossmember and the

lower control arms. Ride control is provided by double,

direct acting strut assemblies. The upper portion of

each strut assembly extends through the fender well

and attaches to the upper mount assembly with a nut.

Side roll of the front suspension is controlled by

a spring steel stabilizer shaft. It is mounted in rubber

bushings which are held to the frame side rails by

brackets. The ends of the stabilizer are connected to the

lower control arms by link bolts and are isolated by

rubber grommets.

The inner ends of the lower control arms have

pressed in bushings. Bolts (passing through the

bushings) attach the arm to the suspension

crossmember. The lower ball joint assembly is a press

fit in the arm and attaches to the steering knuckle with

a torque prevailing nut.

Rubber grease seals are provided at ball socket

assemblies to keep dirt and moisture from entering the

joint and damaging bearing surfaces.

Adjustment

Figure 602

NOTICE: See NOTICE on Page 3C-1

of this

section.

1. Remove dust cap from hub.

2. Remove cotter pin from spindle and spindle nut.

3. Tighten the spindle nut to 16 Nsm (12 lb. ft.)

while turning the wheel assembly forward by

hand to fully seat the bearings. This will remove

any grease or burrs which could cause excessive

wheel bearing play later.

4. Back off the nut to the "just loose" position.

5. Hand tighten the spindle nut. Loosen spindle nut

until either hole in the spindle lines up with a slot

in the nut. Not

nlore than 1/2 flat.

6. Install

new cotter pin. Bend the ends of the cotter

pin against nut, cut off extra length to ensure ends

will not interfere with the dust cap.

7. Measure the looseness in the hub assembly. There

will be

from .03 to . l3mm (.001 to .005 inches)

end play when properly adjusted.

8. Install dust cap on hub.

FRONT SUSPENSION

Refer to Fig. 610 for illustration of attachment

provisions for the bolted-on front suspension

suspension

crossmember.

Page 277 of 1825

4B-4 REAR AXLE

d. Incorrect driveline angle.

Noise changes on a different type of road.

a. Road noise.

b. Tire noise.

Noise tone lowers as car speed is lowered.

a. Tire noise.

Similar noise is produced with car standing and

driving.

a. Engine noise.

b. Transmission noise.

Vibration. a. Rough rear wheel bearing.

b. Unbalanced

or damaged propeller shaft.

c. Tire unbalance.

d. Worn

universal joint in propeller shaft.

e. Incorrect driveline angle.

f. Mis-indexed propeller shaft at pinion

flange.

g. Pinion

flange

runout too great.

A knock or click approximately every two

revolutions of the rear wheel.

a. A rear wheel bearing.

Noise most pronounced on turns.

a. Rear

axle side gear and pinion noise.

A continuous low pitch whirring or scraping

noise starting at relatively low speed.

a. Pinion bearing noise.

Drive noise, coast noise or float noise.

a. Ring and

pinion gear noise.

Clunk on acceleration or deceleration.

a. Worn rear

axle pinion shaft in case or side

gear hub counterbore in case worn oversize.

b. Insufficient

lubrication on propeller shaft

slip yoke.

c. Worn U-joints on

propeller shaft. Front or

rear.

Groan in "Forward" or "Reverse".

a. Wrong

or contaminated lube in rear axle.

b. Worn bushings.

Chatter on turns.

a. Wrong

or contaminated lube in rear axle.

b. Clutch

cone worn and/or

spring(s) worn.

Clunk or knock on rough road operation.

a. Excessive end play of axle shafts to

differential cross shaft.

b. Worn bushings.

PRE-REPAIR INVESTIGATION AND TROUBLE

DIAGNOSIS

A careful1 diagnosis of the rear axle prior to

disassembly will often reveal valuable information as to

the extent and type of repairs or adjustments necessary.

Since frequent causes of axle noises are improper

backlash, pinion bearing pre-load, or side bearing

pre-load, or a combination, a few simple adjustments

may be all that are necessary to correct a problem.

Therefore, before removing the rear axle from the

housing, the following checks should be made with the

results recorded and analyzed:

1) Backlash; 2) Total Assembly

Preload; 3) Tooth Contact Pattern Test;

4)

Fluid Level; and 5) Fluid Contamination.

Use care at all times to keep dirt and other foreign

matter, such as grinder dust, soot or sand, away from

differential to prevent possibility of subsequent failure.

The pinion and ring gear must be completely

assembled, installed and all pre-load and backlash

adjustments completed prior to the start of this method

of pinion depth setting. The following procedure can

be used in place of the gage method of pinion depth

setting.

Gear Tooth Nomenclature

The side of the ring gear tooth which curves

outward, or is convex, is referred to as the "drive" side.

The concave side is the "coast" side. The end of the

tooth nearest center of ring gear is referred to as the

"toe" end. The end of the tooth farthest away from the

center is the "heel" end. Toe end of tooth is smaller

than heel end.

It is very important that tooth contact be tested

before the rear axle carrier assembly is disassembled.

Variations in the carrier or pinion rear bearing may

cause the pinion to be too far away from, or close to,

the ring gear. Thus, the tooth contact must be tested

and corrected, if necessary, or the gears may be noisy.

Tooth Contact Pattern Test

1. Wipe oil out of carrier and carefully clean each

tooth of ring gear.

2. Use gear marking compound part number

1052351 or equivalent and apply this mixture

sparingly to all ring gear teeth, using a medium

stiff brush. When properly used, the area of

pinion tooth contact will be visible when hand

load is applied.

3. Tighten bearing cap bolts to 75

N.m (55 lb. ft.).

4. Expand

brake shoes using parking brake cables

until a torque of 54 to

70 N-m (40-50 lb. ft.) is

required to turn the pinion.

A test made without loading the gears will not

give a satisfactory pattern. Turn pinion flange

with wrench so that ring gear rotates one full

revolution, then reverse rotation so that ring gear

rotates one revolution in opposite direction.

5. Observe

pattern on ring gear teeth and compare

with Fig. 3.

Effects of Increasing Load on Teeth Contact

Pattern

When "load" on ring and pinion gear is

increased, such as when car is accelerated forward

from standstill or from normal drive, the tooth contact

will tend to spread out and, under very heavy load, will

extend from near toe to near heel on the drive side. The

entire contact also tends to shift toward heel under

increasingly heavier loads and will become somewhat

broader with respect to tops and bottoms of teeth. The

patterns obtained by this tooth contact pattern test

approximate a light load and, for this reason, they will

extend only about halfway.

Page 347 of 1825

6-2 ENGINE GENERAL INFORMATION

6E3 - Fuel Injection (Ported) This section has information

on all exhaust

system parts, such as tailpipes, mufflers, and the

SECTION 6F - EXHAUST SYSTEM catalytic converter.

GENERAL INFORMAflION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousandths of

an inch. When any internal engine parts are serviced,

care and cleanliness are important. A liberal coating of

engine oil should be applied to friction areas during

assembly, to protect and lubricate the surfaces on

initial operation. Throughout this section, it should be

understood that proper cleaning and protection of

machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice, even if not specifically stated. PREVENTING

DAMAGE AND IN

CONTRIBUTING TO RELIABLE ENGINE

PERFORMANCE.

When raising or supporting the engine for any

reason, do not use a jack under the oil pan. Due to the

small clearance between the oil pan and the oil pump

screen, jacking against the oil pan may cause it to be

bent against the pump screen resulting in a damaged

oil pick-up unit.

When working on the engine, remember that the

12-volt electrical system is capable of causing short

circuits. When performing any work where electrical terminals could possibly be grounded, the ground cable

of the battery should be disconnected at the battery.

Any time the carburetor or air cleaner is

train components are removed removed, the intake opening should be covered. This for service, they should be in order' will protect against entrance of foreign be installed in the same locations, and with the same material, which could follow the intake passage into mating surfaces, as when removed

the cylinder and cause extensive damage when the -

Battery cables should be disconnected before any engin; is started.

major work is performed on the engine. Failure to IN THE MECHANICAL PROCEDURES

disconnect cables may result in damage to wire harness DESCRIBED IN THIS SECTION, GENERALLY

or other electrical parts. NO

REFERENCES WILL BE MADE TO THE

REMOVAL OF OPTIONAL EQUIPMENT SUCH

ENGINE SERVICE AS POWER STEERING PUMP, AIR

CONDITIONING COMPRESSOR, ETC.

THE FOLLOWING INFORMATION ON SHOULD IT BECOME NECESSARY TO

ENGINE SERVICE SHOULD BE NOTED REMOVE ANY SUCH ITEM TO

PERFORM

CAREFULLY, AS IT IS IMPORTANT IN OTHER SERVICE, REFER TO THE

APPROPRIATE SECTION OF THIS SERVICE

MANUAL FOR SPECIFIC INFORMATION.

ENGINE PERFORMANCE DIAGNOSIS

INTRODUCTION interchangeably for so long, it was necessary to decide

on the most common usage and then define them. If the

Engine Performance procedures are definition is not understood, and the exact Symptom is

guides that will lead to the most probable causes of not used, the Diagnostic procedure will not work. engine performance complaints. They cover the

components of the fuel, ignition, and mechanical It

is important to keep two facts in mind:

systems that could cause a particular

complaint, and 1. The procedures are written to diagnose problems

then outline repairs in a logical sequence. on cars

that have

"run well at one time" and

that time and wear have created the condition.

It is important to determine if the

"Service ~~~i~~ soon- light is "ON,~' or has come for 2. All possible causes cannot be covered,

a short interval while driving. If the

"Service Engine particularly with regard to emission controls. If

Soon" light has come "ON," the Computer doing the work prescribed does not correct the

Command Control System or DECS should be complaint, then either the wrong Symptom was

checked for stored

"Trouble Codes" (See Diagnostic used, or a more detailed analysis will have to be

Circuit Check, Section 6E, for the engine you are made.

working on) which may indicate the cause for the All of the Symptoms can be caused by worn out

performance

complaint.Each Symptom is defined, and or defective parts such as Spark Plugs, Ignition

it is important that the correct one be selected, based Wiring, etc. If time and/or mileage indicate that

on the complaints reported or found. The definition of parts should be replaced, it is recommended that

each symptom is included with the symptom. it

be done.

The words used may not be what you are used to Refer to:

in all cases, but because these terms have been used

@ Section 6E - Driveability and Emissions