washer fluid PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 21 of 1825

OB-4 MAINTENANCE AND LUBRICATION

Tire and wheel operation - Be alert to a vibra-

tion of the steering wheel or seat at normal highway

speeds. This may mean a wheel balance is needed. Also, a

pull right or left on a straight, level road may show the

need for

a tire pressure adjustment or wheel alignment.

Steering system operation - Be alert to

changes in steering action. An inspection is needed when

the steering wheel is harder to turn or has too much free

play or if unusual sounds are noted when turning or

parking.

Headlight aim operation - Take note of light

pattern occasionally. If beam aim doesn't look right,

headlights should be adjusted.

AT EACH FUEL FILL

Engine oil level check - Check engine oil level

and add if necessary. See your Owner's

Manual for further

details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Engine coolant level and condition - Check

engine coolant level in coolant reservoir tank and add if

necessary. Replace if dirty or rusty. See your Owner's

Manual for further details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Windshield washer fluid level check -- Check

washer fluid level in container and add if necessary.

Hood latch operation - When opening hood on

cars equipped with hoods that open from the front, note

the operation of secondary latch. It should keep hood from

opening all the way when primary latch is released. Make

sure that hood closes firmly.

AT LEAST MONTI-ILY

Tire and wheel inspection and pressure

check--

Check tires for abnormal wear or damage. Also,

check for damaged wheels. Keep pressures as shown on

Tire Placard on the driver's door (include spare unless it is

a stowaway). Pressure should b\: checked when tires are

"cold". See "Tires" in Owner's Manual for further

infomation.

Light operation check - Check operation of

license plate light, side-marker lights, headlights includ-

ing high beams, parking lights, taillights, brake lights.

turn signals, backup lights, instrument panel and interior

lights and hazard warning flashers.

Fluid leak check - After the car has been parked

for a while, inspect the surface beneath the car for water,

oil, fuel or other fluids. Water dripping from the air

conditioning system after use is normal. If you notice fuel

leaks or fumes, the cause should be found and corrected at

once.

AT LEAST TWICE A YEAR (FOR EXAMPLE,

EVERY SPRING AND FALL)

Power steering pump fluid level check --

Check power steering pump fluid level in accordance with

Owner's Manual instructions and keep at proper level.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Brake master cylinder reservoir fluid level

check ---- Check fluid and keep at proper level. Note: It is

normal for the brake fluid level to go down slightly as the

brake pads wear

- so be sure to keep reservoir filled.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Clutch system service --- manual transmis-

sionltransaxle --- For cars equipped with hydraulic

clutch system, check the reservoir fluid level and add fluid

as required. All others, check clutch pedal free travel and

adjust as necessary. See your Owner's Manual for further

details.

~

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Weatherstrip Lubrication - Clean surface and

then apply a thin film of silicone grease with a clean cloth.

EACH TIME OIL IS CHANGED

Automatic and manual transmissionltrans-

axle fluid level check - Check transmission/transaxle

fluid level and add as required. (Corvette only) if equipped

with manual transmission

- check fluid in the overdrive

unit and add as required.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Brake systems inspection - For convenience,

the following should be done when wheels are removed

for rotation: Inspect lines and hoses for proper hookup,

binding, leaks, cracks, chafing, etc. Inspect disc brake

pads for wear and rotors for surface condition. Also in-

spect drum brake linings for wear and cracks. Inspect

other brake parts, including drums, wheel cylinders, park-

ing brake, etc. at the same time. Check parking brake

adjustment.

INSPECT BRAKES MORE OFTEN IF DRIVING

HABITS OR CONDITIONS RESULT IN FREQUENT

BRAKING.

Steering, suspension and front drive axle

boot and seal inspection

- Inspect front and rear

suspension and steering system for damaged, loose or

missing parts, signs of wear or lack of lubrication. Inspect

power steering lines and hoses for proper hookup, bind-

ing, leaks, cracks, chafing, etc. (On cars equipped with

manual steering gear, check for seal leakage.) On

front-

wheel-drive cars, clean then inspect drive axle boot seals

for damage, tears or leakage. Replace seals if necessary.

Exhaust system inspection - Inspect complete

system. Inspect body near the exhaust system. Look for

broken, damaged, missing or out-of-position parts as well

as open seams, holes, loose connections or other condi-

tions which could cause a heat buildup in the tloor pan or

could let exhaust fumes seep into the trunk or passenger

compartment.

Page 23 of 1825

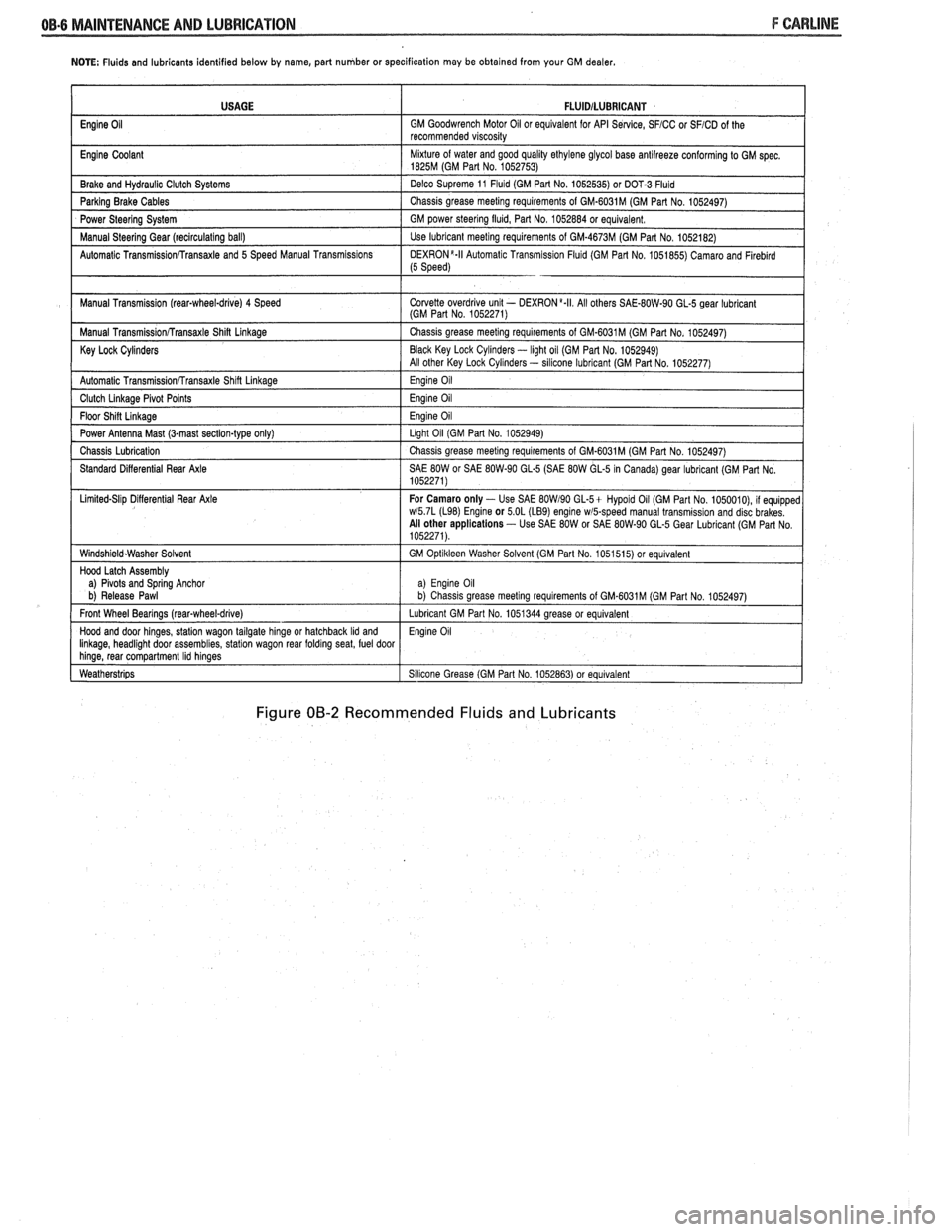

NOTE: Fluids and lubricants identified below by name, part number or specification may be obtained from your GM dealer.

Figure 00-2 Recommended Fluids and Lubricants

USAGE

Engine

Oil

Engine Coolant

Brake and

Hydraul~c Clutch Systems

Parking Brake Cables

Power Steering System

Manual

Steerlng Gear (reclrculat~ng ball)

Automatic

Transrn~ssionRransaxle and 5 Speed Manual Transm~ss~ons

Manual Transm~ssion (rear-wheel-drive) 4 Speed

Manual

Transm~ss~onRransaxle Shin Linkage

Key Lock Cylinders

Automatic Transmlss~onfrransaxle Shlft Llnkage

Clutch Llnkage Plvot Po~nts

Floor Sh~n L~nkage

Power Antenna Mast (3-mast sect~on-type only)

Chass~s Lubr~cation

Standard D~fferent~al Rear Axle

L~m~ted-Sl~p D~flerent~al Rear Axle

W~ndsh~eld.Washer Solvent

Hood Latch Assembly

a)

Plvots and Sprlng Anchor

b) Release Pawl

Front Wheel Bearings

(rearqwheel-drive)

Hood and door hlnges, statlon wagon tailgate hlnge or hatchback Ild and Ilnkage, headl~ght door assembl~es, statlon wagon rear foldrng seat, fuel door hlnge, rear compartment Ihd hlnges

Weatherstr~ps

FLUlDlLUBRlCANT

GM Goodwrench Motor 011 or equivalent for API Se~lce, SFICC or SFICD of the

recommended v~scos~ty

M~xture of water and good qual~ty ethylene glycol base antllreeze conforming to GM spec 1825M (GM Part No 1052753)

Delco Supreme 11

Fluld (GM Part No 1052535) or DOT-3 Fluld

Chass~s grease meetlng requirements of GM-6031M (GM Part No 1052497)

GM power

steerlng flu~d, Part No 1052884 or equivalent

Use lubricant meetlng requirements of GM-4673M (GM Part No 1052182)

DEXR0N'-II Automat~c Transm~ss~on Flu~d (GM Part No 1051855) Camaro and Flreblrd (5 Speed)

Corvette overdr~ve unlt - DEXRON a.II All others SAE-80W-90 GL-5 gear lubr~cant (GM Part No 1052271)

Chass~s grease meetlng requirements of GM-6031M (GM Part No 1052497)

Black Key Lock

Cyl~nders - light oil (GM Par1 No. 1052949)

All other Key Lock Cyl~nders - sllicone lubrlcant (GM Part No 1052277)

Eng~ne 011

Eng~ne 011

Eng~ne 011

Llght 011 (GM Part No 1052949)

Chass~s grease meetlng requirements of GM-6031M (GM Part No 1052497)

SAE

80W or SAE 80W-90 GL-5 (SAE 80W GL-5 In Canada) gear lubricant (GM Part No

1052271)

For Camaro only

- Use SAE BOW190 GL-5+ Hypold 011 (GM Part No 1050010), 11 equ~pped wl5 7L (L98) Englne or 5 OL (LB9) engine wmpeed manual transm~ss~on and disc brakes

All other applications - Use SAE 80W or SAE 80W-90 GL-5 Gear Lubr~cant (GM Part No

1052271)

GM

Opt~kleen Washer Solvent (GM Part No 1051515) or equ~valent

a) Eng~ne 011 b) Chass~s grease meet~ng requirements of GM.6031M (GM Part No 1052497)

Lubricant GM Part No 1051344 grease or equivalent

Eng~ne 011

S~l~cone Grease (GM Part No 1052863) or equivalent

Page 103 of 1825

2B-2 BUMPERS

REAR BUMPER FASCIA

Removal

Place a jack stand under fascia before removing

bolts to prevent it from dropping down when fascia

attaching bolts are removed. Fascia will pivot on the

opposite end when one end is disconnected. Do not

rotate energy absorber any more than necessary to

align mounting holes.

1. Remove fascia attaching bolts and fascia to

fender attaching screws on right and left side, and

remove fascia and spacers.

2. If energy absorber is to be replaced, remove the

bolts and nuts from the front of the unit and the

nut from the stud at the rear. The stud at the rear

of the absorber is attached to a bracket in the

frame. Remove the bolt holding this bracket in

the frame to remove the absorber.

Installation

1. Install energy absorber if removed.

2. Support fascia during installation to prevent

rotation of energy absorbers.

3. Install spacers and bolts at fascia to energy

absorber brackets.

4. Install fascia to fender attaching screws.

5. Check for proper clearance.

6. If adjustment is required to align the fascia, use

shims as necessary. Vertical and lateral

adjustment can be made at slots in fascia and

absorber brackets. Torque all bolts and nuts. (See

Specifications.)

FRONT BUMPER

Removal

1. Remove

front end fascia as shown in Section 2C.

2. Remove bumper barlenergy absorber assembly

from body.

3. If energy absorber must be replaced, drill out pop

rivets, and install new absorber with nuts, bolts,

and locking washers.

4. To install, reverse above procedure.

REAR BUMPER

Removal

1. Remove left hand rear quarter trim panel.

2. Remove right hand rear quataer trim panel.

3. Remove spare tire assembly.

4. Remove rear center trim panel.

5. Remove right tail light assembly.

6. Remove left tail light assembly.

7. Remove tail light center piece.

8. Remove bumper cover lower retainers.

9. Remove right-side bumper cover fasteners from

inside of compartment.

10. Remove left side bumper cover fasteners from

inside of compartment.

11. Remove bumper cover upper retainers.

12. Remove cover.

13. To dissasemble impact bar, proceed as follows:

a. Remove bolts attataching impact bar to

rear end panel.

b. Remove rivets retaining pad to impact

bar.

14. To install, reverse above procedure.

BUMPER ENERGY ABSORBING UNITS

The absorbing capability for both front and rear

bumper systems is achieved through two energy

absorbing devices in each bumper. These units convert

the energy of an impact into heat and restoration. The

energy absorbing device consists of two main

subassemblies: the piston tube assembly and the

cylinder tube assembly. The piston tube assembly is

filled with an inert gas under pressure and consists of

a bumper bracket, piston tube, orifice, seal, piston seal,

piston, and stop-ring. The cylinder tube assembly is

filled with a hydraulic fluid and consists of a frame

bracket, cylinder tube, mounting stud, and metering

pin.

Upon impact, as the energy absorber is collapsed,

the hydraulic fluid in the cylinder tube is forced into

the piston tube through the orifice. The metering pin

controls the rate at which this fluid passes from the

cylinder tube through the orifice and into the piston

tube. This controlled passage of fluid provides the

energy absorbing action.

The hydraulic fluid that is forced from the

cylinder tube into the piston tube displaces the floating

piston, compressing the gas behind the floating piston.

After impact, the pressure of the compressed gas

behind the floating piston forces the hydraulic fluid

back into the cylinder tube assembly, extending the

unit to its normal position.

Some front and rear bumpers (J and

F Models)

use a plastic honeycomb pad energy absorber (except

J wagon rear bumper). This energy absorber will

compress on impact, and both the energy absorber and

the urethane fascia will return to their original shape.

The energy absorber pad has no moving parts.

The J wagon rear bumper system uses a hydraulic

energy absorbing unit, more commonly known as a

"minisorber".

TESTING FRONT OR REAR ENERGY

ABSORBER OPERATION

The right and left energy absorbing devices are to

be diagnosed separately. The following checks are to be

made on each unit:

1. Leakage

Some oil wetting may be visible due to the grease

packed in the crimp recess. Therefore, a stain or trace

of oil on the piston tube near the crimp is normal.

However, if oil is dripping continuously from the crimp

or the stud end of the unit, a leak is indicated and the

unit should be replaced.

Page 196 of 1825

POWER STEERING 387-3

crocus cloth or fine hone. If the system 4. If the pump checks within specifications, leave

contains some dirt, flush it. If it is the valve open and turn (or have turned) the

exceptionally dirty, both the pump and the steering wheel into both corners. Record the

gear must be completely disassembled, highest pressures and compare with the

cleaned, flushed and reassembled before maximum pump pressure recorded. If this

further usage. pressure cannot be built in either (or one) side of

- the gear, the gear is leaking internally and must

c. If

the pressures recorded are constant, but

be disassembled and repaired. See "Unit Repair"

more than

100 PSI (690 kPa), below the

at the end of this section.

spec.9 rep1ace the flow 8. Shut off engine, remove testing gage, spare hose,

valve and recheck. If the pressures are still

low, replace the rotating group in the pump. reconnect pressure hose, check fluid

level and/or

make needed repairs.

ON-VEHICLE SERVICE

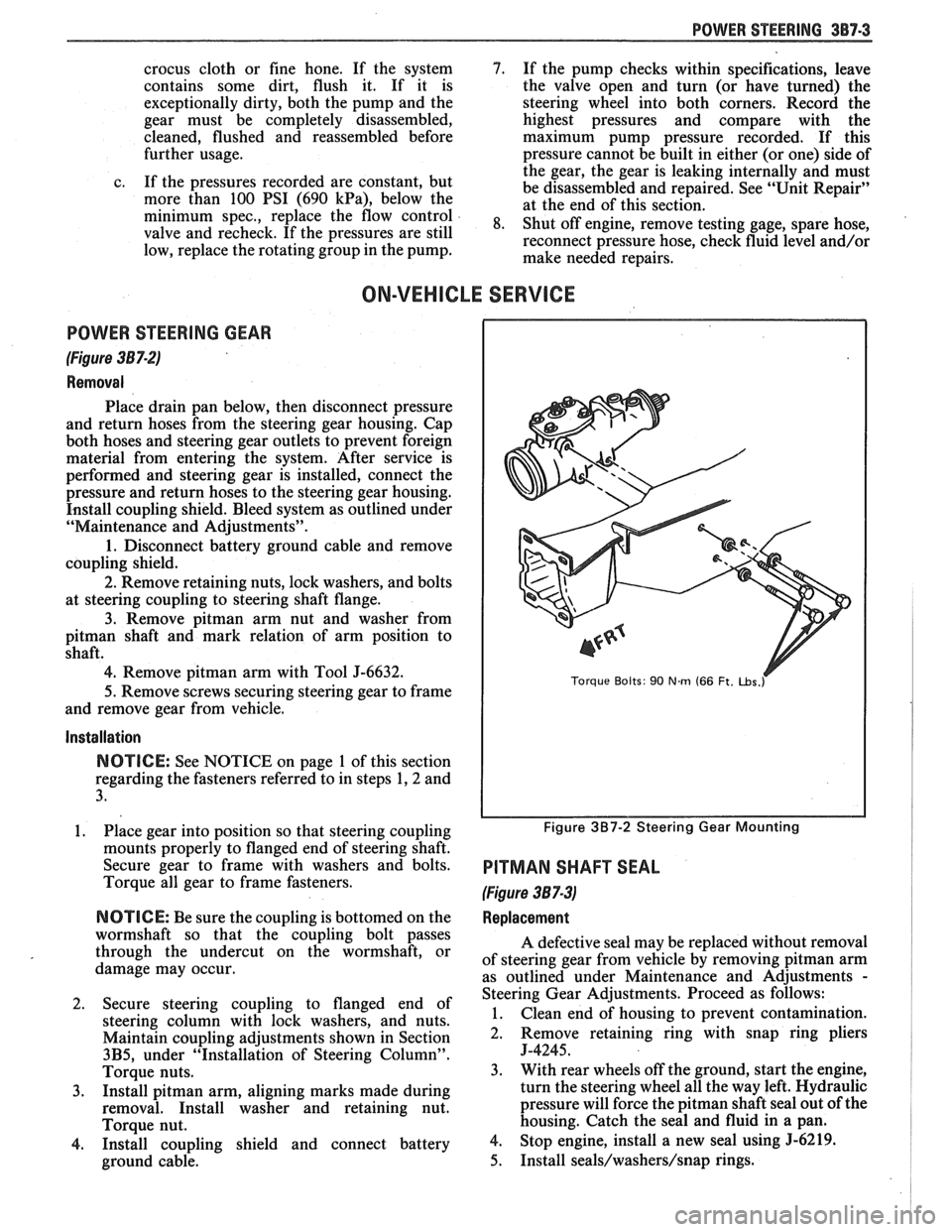

POWER STEERING GEAR

(Figure 387-2)

Removal

Place drain pan below, then disconnect pressure

and return hoses from the steering gear housing. Cap

both hoses and steering gear outlets to prevent foreign

material from entering the system. After service is

performed and steering gear is installed, connect the

pressure and return hoses to the steering gear housing.

Install coupling shield. Bleed system as outlined under

"Maintenance and Adjustments".

1. Disconnect battery ground cable and remove

coupling shield.

2. Remove retaining nuts, lock washers, and bolts

at steering coupling to steering shaft flange.

3. Remove pitman arm nut and washer from

pitman shaft and mark relation of arm position to

shaft.

4. Remove pitman arm with Tool J-6632.

5.

Remove screws securing steering gear to frame

and remove gear from vehicle.

Installation

NOTICE: See NOTICE on page 1 of this section

regarding the fasteners referred to in steps 1,2 and

3.

1. Place gear into position so that steering coupling

mounts properly to flanged end of steering shaft.

Secure gear to frame with washers and bolts.

Torque all gear to frame fasteners.

NOTICE: Be sure the coupling is bottomed on the

wormshaft so that the coupling bolt passes

through the undercut on the wormshaft, or

damage may occur.

2. Secure steering coupling to flanged end of

steering column with lock washers, and nuts.

Maintain coupling adjustments shown in Section

3B5, under "Installation of Steering Column".

Torque nuts.

3. Install pitman arm, aligning marks made during

removal. Install washer and retaining nut.

Torque nut.

4. Install coupling shield and connect battery

ground cable.

Torque Bolts: 90 Nm (66 Ft. ~bs.r

Figure 3B7-2 Steering Gear Mounting

PITMAN SHAFT SEAL

(Figure 387-3)

Replacement

A defective seal may be replaced without removal

of steering gear from vehicle by removing

pitman arm

as outlined under Maintenance and Adjustments

-

Steering Gear Adjustments. Proceed as follows:

1. Clean end of housing to prevent contamination.

2. Remove retaining

ring with snap ring pliers

J-4245.

3. With rear wheels off the ground, start the engine,

turn the steering wheel all the way left. Hydraulic

pressure will force the

pitman shaft seal out of the

housing. Catch the seal and fluid in a pan.

4. Stop engine, install a new seal using 5-6219.

5. Install seals/washers/snap rings.

Page 208 of 1825

POWER STEERING 387-1 6

7 1 1 9. DISASSEMBLE AND ASSEMBLE RACK

1 PISTON

I DISASSEMBLE ASSEMBLE

1 Disassemble parts 1 Assemble parts

as shown as shown

2 Clean and Inspect all parts for excessive wear The black balls are smaller than

the silver balls. The black and

silver balls must

be installed

alternately into the rack-piston

and return guide to maintain

rack piston to worm gear

praloed.

TEFLON SEAL AN0 0 RING--

If replaced lubricate new seal

and 0 rlng wlth power steerlng fluid

Turn worm until worm groove IS al~gned w~th the lower

I \ WORM-Slide all the way

I \

Into the ra~k-~lston

1

v Lubr~cate balls wlth

I / oower steerlno fluid install balls th;ough Before assembling rack

ball return gulde hole In houslng. ball retalner whlle rotatlng worm J-21552 must be lnserted counterclockw~se Into rack to allow

removal of worm

- GUIDE-Alternately ~nstall rema~nder of

balls and retaln w~th grease at each

end of gu~de

to 5 Newton Metres (4 Ft Lbs )

10. REMOVE AND INSTALL PITMAN SHAR

SEALS AND BEARING

REMOVE INSTALL

1 Clean end of 1 Coat seal Ilp and washer face houslng thoroughly with anhydrous calclum grease

to prevent dlrt from enterlng and be 2. Install parts as shown

extremelv careful not

to score

(he houslng

bore HOUSING ASSEMBLY

Inspect for burrs

2 Remove retalnlng rlng wlth snap rlng pllers J-4245

3 Uslng screw drlver. pry seals and washers

from bore

PITMAN SHAFT SEAL

(SINGLE LIP)

PITMAN SHAFT SEAL

(DOUBLE LIP)

RETAINING

RING 2

SEAL BACK UP WASHER NEEDLE BEARING

Remove onlv 11 ~t I - - - - - .- - - - . - . - . -. . - - 1 needs replacing.

I

When tool bottoms on

fully Installed

I I

L ------------ J L ----------- J

Install Pltman shaft bearlng Install Pttman shaft seals

CI I J

Figure 387-16 Overhaul 800f808 Gear, Chart E

Page 257 of 1825

481-4 REAR AXLE

Gear Noise

Gear noise (whine) is audible from 20 to 55 mph

under four driving conditions:

1. Light Acceleration - Accelerate slowly.

2. Road Load

- Car

driving load or constant speed.

3. Float - Using enough throttle to keep the car from

driving the engine

- car slows down gradually but

engine still pulls slightly.

4. Coast - Throttle closed and car in gear.

Bearing Noise

Bad bearings generally produce more of a rough

growl or grating sound, rather than the whine typical

of gear noise. Bearing noise frequently "wow-wows" at

bearing rpm, indicating a defective pinion or rear axle

case side bearing. This noise could easily be confused

with rear wheel bearing noise. Inspect and replace as

required.

Rear Wheel Bearing Noise

A rough rear wheel bearing produces a noise

which continues with car coasting at low speed and

transmission in neutral. Noise may diminish some by

gentle braking. With rear wheels jacked up, spin rear

wheels by hand while listening at hubs for evidence of

rough (noisy) wheel bearing.

Knock At Low Speeds

Low speed knock can be caused by worn

universal joints or a side gear hub counterbore in a case

that has worn oversize. Inspect and replace universal

joint or case and side gear as required.

Backlash Clunk

Excessive clunk with acceleration and deceleration

is caused by worn differential pinion gear shaft, excessive

clearance between axle shaft and side gear splines, exces-

sive clearance between side gear hub and counterbore in

case, worn pinion and side gear teeth, worn thrust washers

and excessive drive pinion and ring gear backlash. Re-

move worn parts and replace as required, selecting close

fitting parts when possible. Adjust pinion and ring gear

backlash.

DIAGNOSIS

1. Noise

is the same in "Light Acceleration" or

"Coast".

a. Road noise.

b. Tire noise.

c. Front wheel bearing noise.

d. Rear axle bearing noise.

2. Noise changes on a different type of road.

a. Road noise.

b. Tire noise.

3. Noise tone lowers as car speed is lowered.

a. Tire noise.

b. Front

wheel bearings and rear axle bearings.

c. Gear noise.

4. Similar noise is produced with car standing and

driving. a.

Engine noise.

b. Transmission noise.

c. Exhaust noise.

5. Vibration.

a. Rough rear axle bearing.

b. Unbalanced or damaged propeller shaft.

c. Tire unbalance.

d. Worn universal joint in propeller shaft.

e. Mis-indexed propeller shaft at pinion

flange.

f. Pinion flange runout too great.

6. A knock or click approximately every two

revolutions of the rear wheel.

a. A rear axle bearing.

b. Worn case.

7. Noise most pronounced on turns.

a. Rear axle side gear and pinion noise,

differential gear noise.

b. Axle bearings.

8. A continuous low pitch whirring or scraping

noise starting at relatively low speed.

a. All bearing noise.

9. Drive noise, coast noise or float noise.

a. Ring

and pinion gear noise.

b. Front

pinion bearing noise, coast or drive.

c. Axle bearing noise.

10. Clunk

on

acceleration or deceleration.

a. Worn

rear axle pinion shaft splines.

b. Side

gear hub counterbore in case worn

oversize.

c. Worn U-joints.

d. Excessive transmission backlash.

e. Worn axle shaft splines.

11. Chatter on turns.

a. Wrong

lube in rear axle.

b. Clutch

cone worn or spalled.

12. Clunk

or knock on rough road operation.

a. Worn suspension bushings.

PRE-REPAIR INVESTIGATION AND TROUBLE

DIAGNOSIS

A carefull diagnosis of the rear axle prior to

disassembly will often reveal valuable information as to

the extent and type of repairs or adjustments necessary.

Since frequent causes of axle noises are improper

backlash, pinion bearing pre-load, or side bearing

pre-load, or a combination, a few simple adjustments

may be all that are necessary to correct a problem.

Before disassembling the rear axle, the following

checks should be made with the results recorded and

analyzed: 1) Backlash;

2) Total Assembly Preload; 3)

Tooth Contact Pattern Test; 4) Fluid Level; and 5)

Fluid Contamination.

If axle shaft end play is excessive then check

bearings, retainer, and bolts securing backing plate.

The axle bearings could be worn and need replacement.

The four bolts or nuts securing the brake backing plate

may be loose, stripped, or missing. If the inner bearing

retainer worked loose it must be replaced.

Use care at all times to keep dirt and other foreign

matter, such as grinder dust, soot or sand, away from

differential to prevent possibility of subsequent failure.

Page 282 of 1825

REAR AXLE 48-9

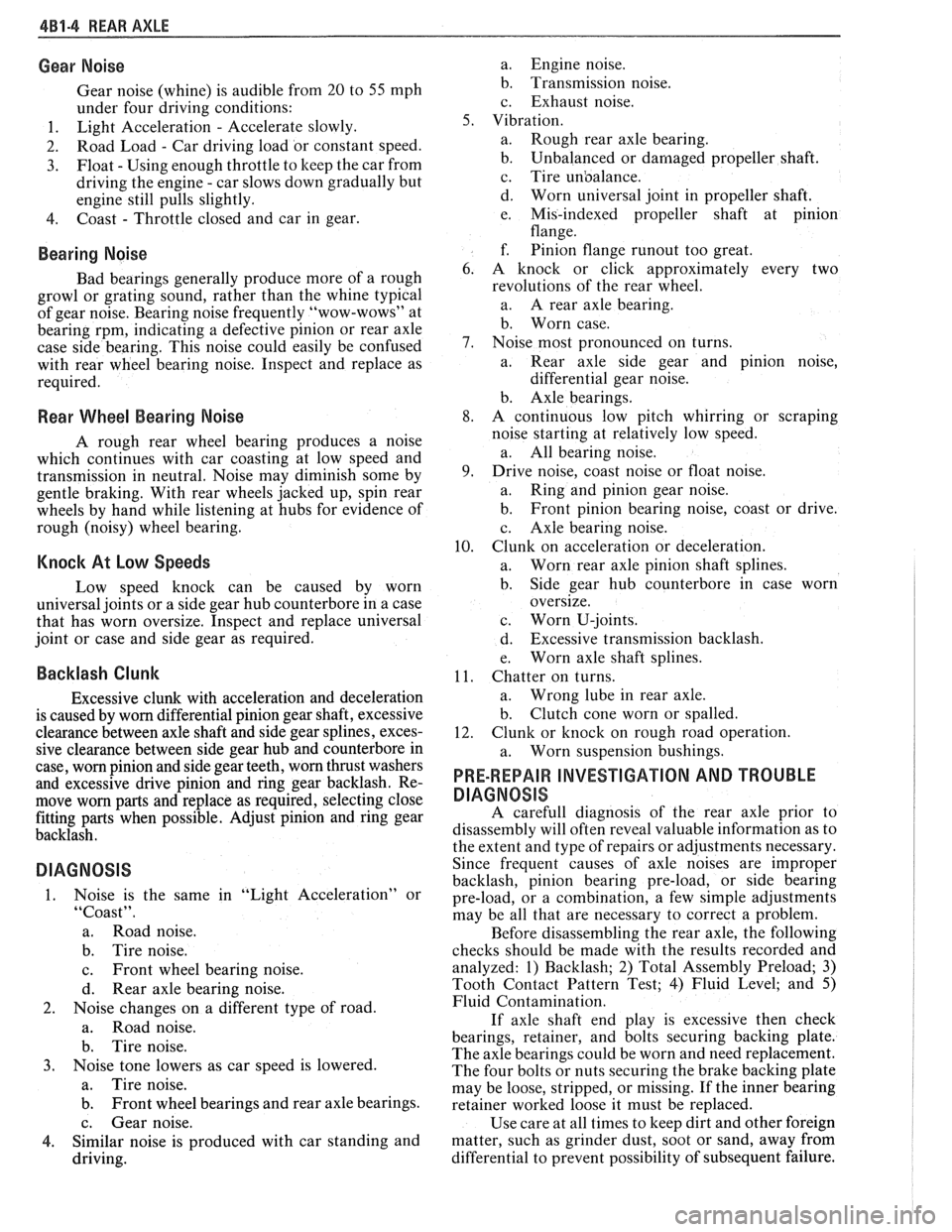

lnstall or Connect

1. Slide axle shaft into place taking care that splines

on end of shaft do not damage oil seal and that

they engage with splines of rear axle side gear.

2. Install

axle shaft

"C" lock on bottom end of axle

shaft and push shaft outward so that shaft lock

seats in counterbore of rear axle side gear.

3. Position

rear axle pinion shaft through case and

pinions, aligning hole in shaft with lock screw

hole. Install lock screw and torque to 27

N-m (20

1b.ft.l

4. using a new gasket, install carrier cover and

torque

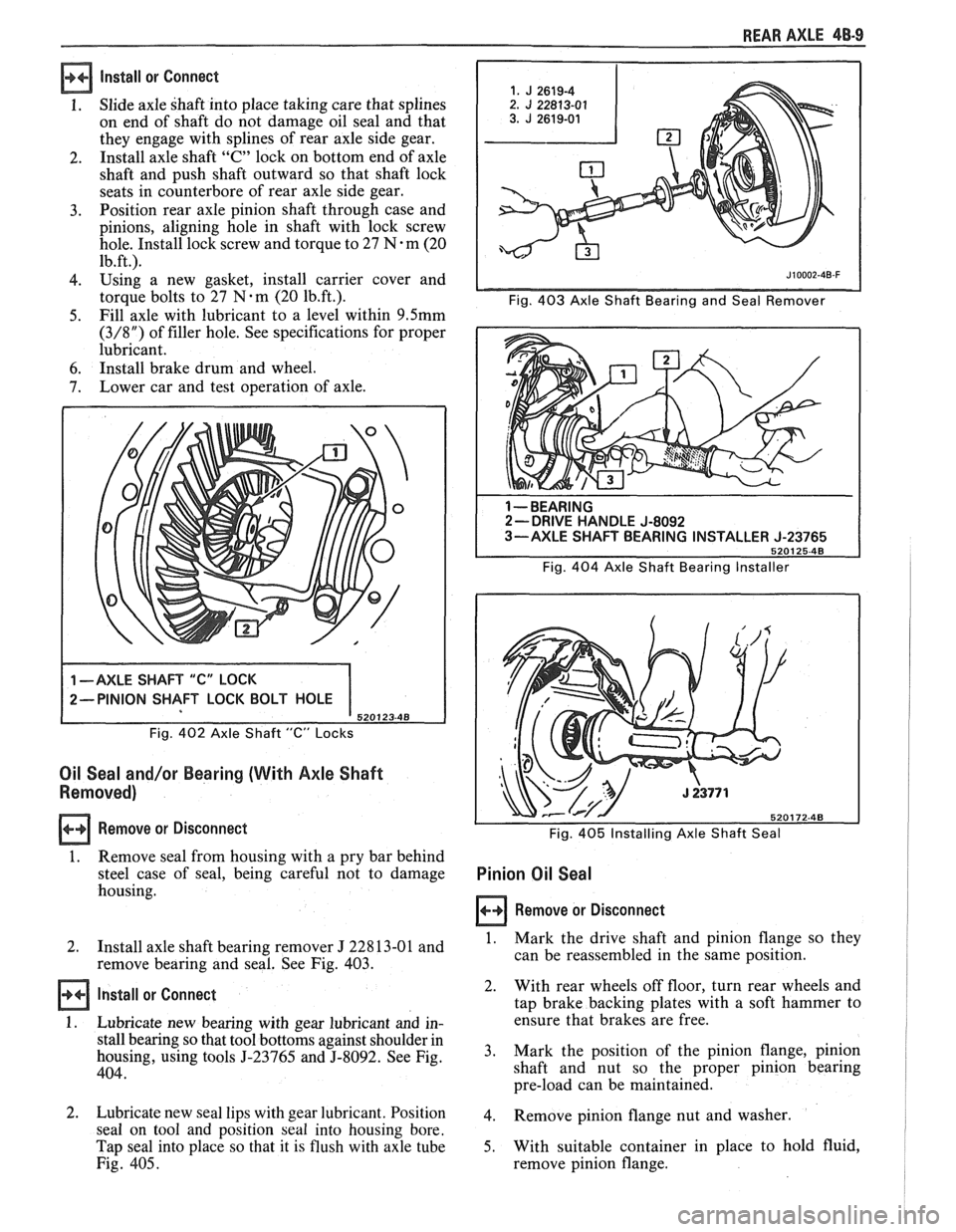

bolts to 27 N-m (20 1b.ft.). Fig. 403 Axle Shaft Bearing and Seal Remover

5. Fill

axle with lubricant to a level within 9.5mm

(3/8") of filler hole. See specifications for proper

lubricant.

6. Install brake drum and wheel.

7. Lower

car and test operation of axle.

Fig. 402 Axle Shaft "C" Locks

Oil Seal and/or Bearing (With Axle Shaft

Removed)

Remove or Disconnect

1. Remove seal

from housing with a pry bar behind

steel case of seal, being careful not to damage

housing.

1 --BEARING 2- DRIVE HANDLE J-8092

3-AXLE SHAFT BEARING INSTALLER J-23765

5201 25-48

Fig. 404 Axle Shaft Bearing Installer

Fig.

405 Installing Axle Shaft Seal

Pinion Oil Seal

Remove or Disconnect

I

2.

Install axle shaft bearing remover J 22813-01 and 1. Mark the drive shaft and pinion flange so they I

remove bearing and seal. See Fig. 403. can

be reassembled in the same position. I

Install or Connect

1. Lubricate new bearing with gear lubricant and in-

stall bearing so that tool bottoms against shoulder in

housing, using tools

5-23765 and 5-8092. See Fig.

404.

2. Lubricate new seal lips with gear lubricant. Position

seal on tool and position

seal into housing bore.

Tap seal into place so that it is flush with axle tube

Fig. 405. 2.

With rear

wheels off floor, turn rear wheels and

tap brake backing plates with a soft hammer to

ensure that brakes are free.

3. Mark

the position of the pinion flange, pinion

shaft and nut so the proper pinion bearing

pre-load can be maintained.

4. Remove pinion flange nut and washer.

5. With suitable container in place to hold fluid,

remove pinion flange.

Page 283 of 1825

48-10 REAR AXLE

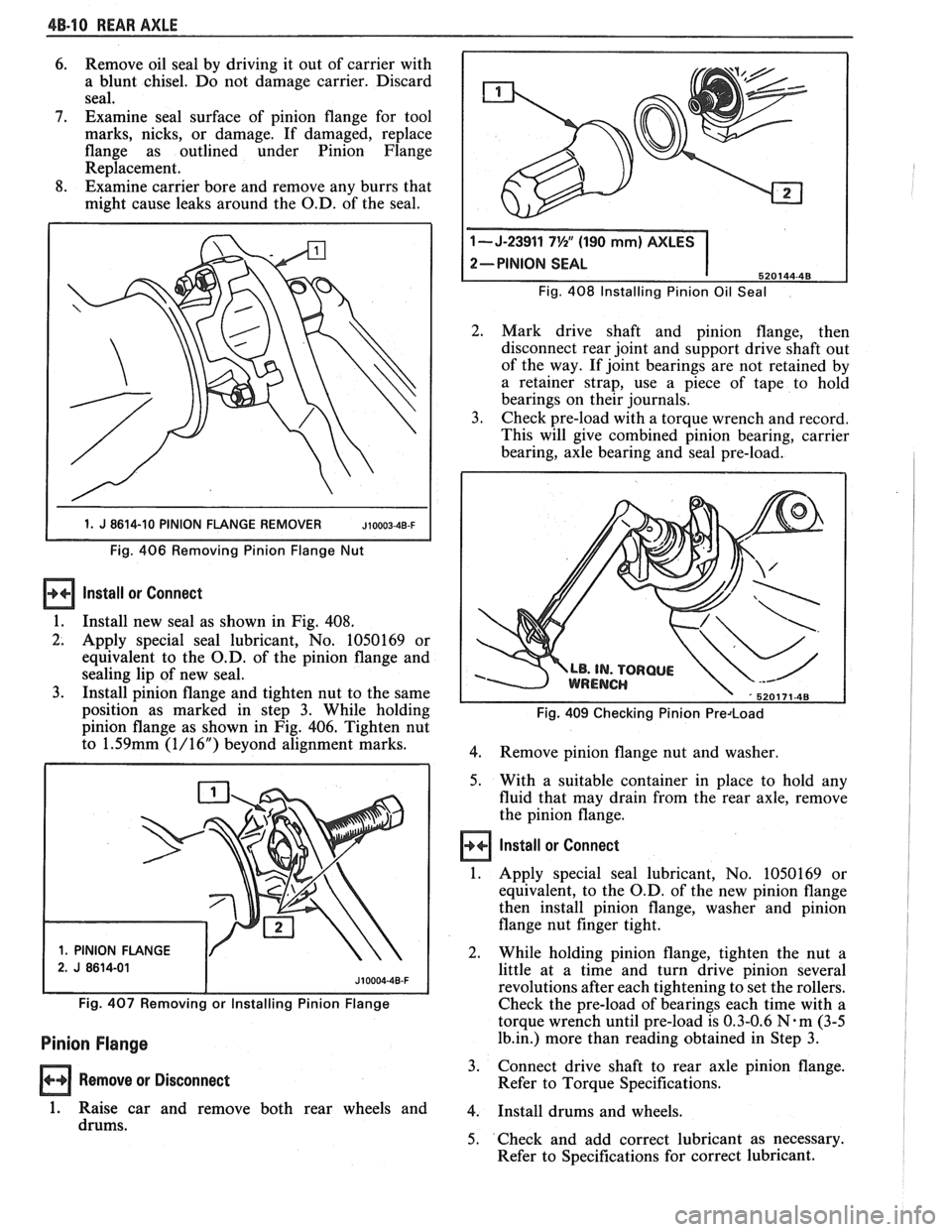

6. Remove oil seal by driving it out of carrier with

a blunt chisel. Do not damage carrier. Discard

seal,

7. Examine seal surface of pinion flange for tool

marks, nicks, or damage. If damaged, replace

flange as outlined under Pinion Flange

Replacement.

8. Examine carrier bore and remove any burrs that

might cause leaks around the O.D. of the seal.

1 1. J 8614-10 PINION FLANGE REMOVER JIOOO~-~B-F I

Fig. 406 Removing Pinion Flange Nut

Install ar Connect

1.

Install new seal as shown in Fig. 408.

2. Apply special seal lubricant, No. 1050169 or

equivalent to the O.D. of the pinion flange and

sealing lip of new seal.

3. Install pinion flange and tighten nut to the same

position as marked in step 3. While holding

pinion flange as shown in Fig. 406. Tighten nut

to

1.59mm (1/16") beyond alignment marks.

1. PINION FLANGE Fig.

408 Installing Pinion

Oil Seal

2. Mark drive shaft and pinion flange, then

disconnect rear joint and support drive shaft out

of the way. If joint bearings are not retained by

a retainer strap, use a piece of tape to hold

bearings on their journals.

3. Check pre-load with a torque wrench and record.

This will give combined pinion bearing, carrier

bearing, axle bearing and seal pre-load.

Fig. 409 Checking Pinion Predoad

4.

Remove pinion flange nut and washer.

5. With a suitable container in place to hold any

fluid that may drain from the rear axle, remove

the pinion flange.

Install or Connect

1. Apply special seal lubricant, No. 1050169 or

equivalent, to the O.D. of the new pinion flange

then install pinion flange, washer and pinion

flange nut finger tight.

2. While holding pinion flange, tighten the nut a

little at a time and turn drive pinion several

revolutions after each tightening to set the rollers.

Fig. 407 Removing or Installing Pinion Flange Check the pre-load of bearings each time with a

torque wrench until pre-load is 0.3-0.6

N-m (3-5

Pinion Flange 1b.in.) more than reading obtained in Step 3.

Remove or Disconnect 3.

Connect drive shaft to rear axle pinion flange.

Refer to Torque Specifications.

1. Raise car and remove both rear wheels and 4. Install drums and wheels.

drums. 5. Check and add correct lubricant as necessary.

Refer to Specifications for correct lubricant.

Page 323 of 1825

586.2 DISC BRAKE CALIPER ASSEMBLY

GENERAL DESCRIPUON

This caliper has a single bore and is mounted to

the support bracket with two mounting bolts.

Hydraulic pressure, created by applying force to the

brake pedal, is converted by the caliper to a stopping

force. This force acts equally against the piston and the

bottom of the caliper bore to move the piston outward

and to move (slide) the caliper inward resulting in a

clamping action on the rotor. This clamping action

forces the linings against the rotor, creating friction to

stop the vehicle.

When the parking brake is applied, the lever turns

the actuator screw which is threaded into a nut in the

piston assembly. This causes the piston to move

outward and the caliper to slide inward mechanically,

forcing the linings against the rotor. The piston

assembly contains a self-adjusting mechanism to keep

the parking brake in proper adjustment.

NOTICE: Replace all components included in

repair kits used to service this caliper. Lubricate

rubber parts with clean brake fluid to ease

assembly. Do not

uhe lubricated shop air on brake

parts as damage to rubber components may result.

If any hydraulic

coniponent is removed or

disconnected,

it may he necessary to bleed all or

part of the brake system. Replace shoe and linings

in axle sets only. The torque values specified are

for dry,

unlubricated fasteners. Perform service

operations

011 a clean bench free from all mineral

oil materials.

ON-CAR SERVICE

CALIPER ASSEMBLY

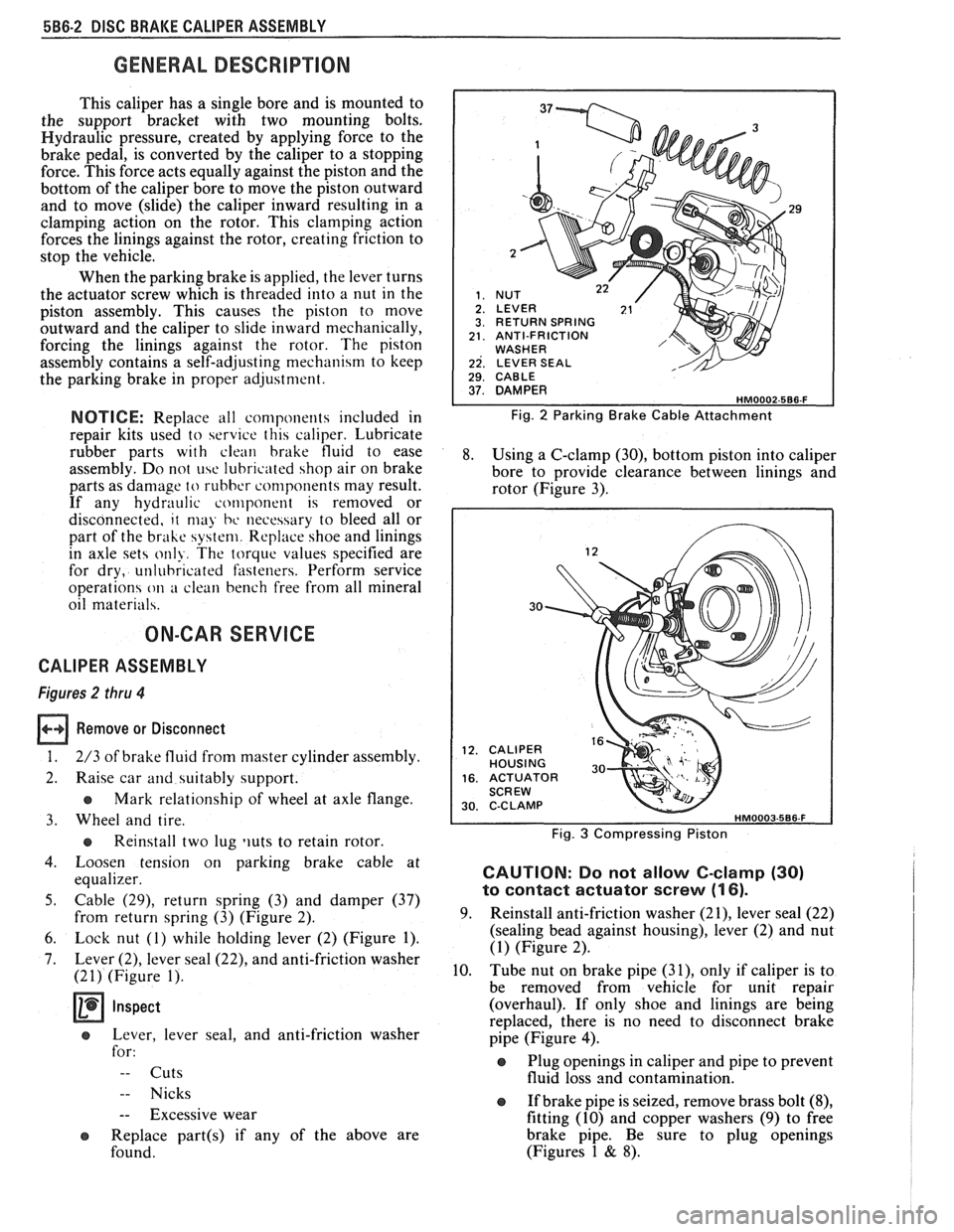

Figures 2 thru 4

Remove or Disconnect

1. 2/3 of brake fluid from master cylinder assembly.

2. Raise car and suitably support.

e Mark relationship of wheel at axle flange.

3. Wheel and tire.

e Reinstall two lug liuts to retain rotor.

4. Loosen tension on parking brake cable at

equalizer.

5. Cable (29), return spring (3) and damper (37)

from return spring (3) (Figure 2).

6. Lock nut (1) while holding lever (2) (Figure 1).

7. Lever (2), lever seal (22), and anti-friction washer

(21) (Figure 1).

Inspect

e Lever, lever seal, and anti-friction washer

for:

-- Cuts

-- Nicks

-- Excessive wear

e Replace part(s) if any of the above are

found.

29

RETURN SPRING ANTI-FRICTION WASHER LEVER SEAL 1 29. CABLE I

Fig. 2 Parking Brake Cable Attachment

8. Using a C-clamp (30), bottom piston into caliper

bore to provide clearance between linings and

rotor (Figure 3).

30

CALIPER HOUSING ACTUATOR SCREW C-C LAMP

Fig. 3 Compressing Piston

CAUTION: Do not allow C-clamp (30)

to contact actuator screw (1 6).

9. Reinstall anti-friction washer (21), lever seal (22)

(sealing bead against housing), lever (2) and nut

(1) (Figure 2).

10. Tube nut on brake pipe

(31), only if caliper is to

be removed from vehicle for unit repair

(overhaul). If only shoe and linings are being

replaced, there is no need to disconnect brake

pipe (Figure

4).

Plug openings in caliper and pipe to prevent

fluid loss and contamination.

If brake pipe is seized, remove brass bolt

(8),

fitting (10) and copper washers (9) to free

brake pipe. Be sure to plug openings

(Figures 1

& 8).

Page 324 of 1825

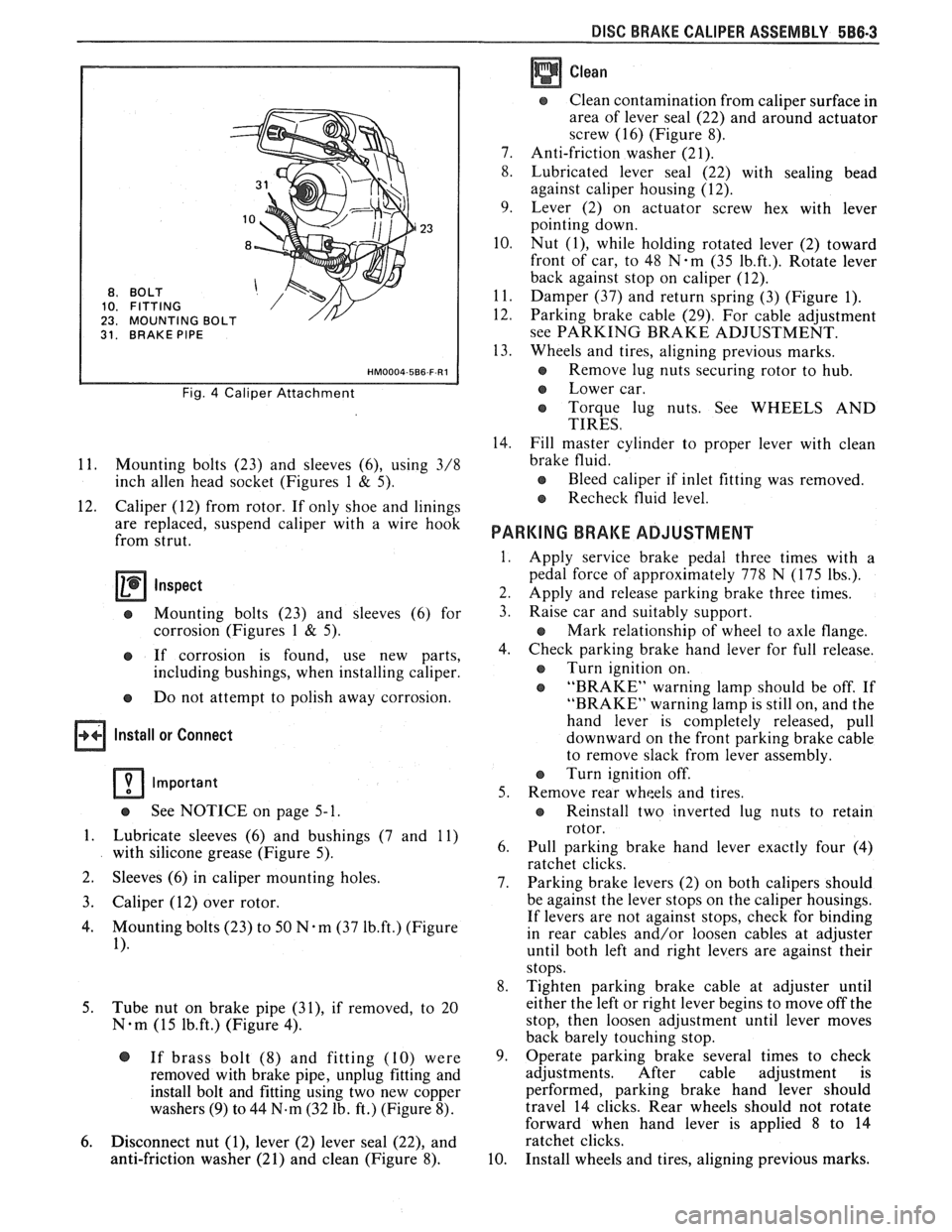

DISC BRAKE CALIPER ASSEMBLY 588-3

BO LT

FITTING

MOUNTING

31. BRAKE PIPE

Fig. 4 Caliper Attachment

11. Mounting bolts (23) and sleeves (6), using 3/8

inch

allen head socket (Figures 1 & 5).

12. Caliper (12) from rotor. If only shoe and linings

are replaced, suspend caliper with a wire hook

from strut.

Inspect

e Mounting bolts (23) and sleeves (6) for

corrosion (Figures

1 & 5).

e If corrosion is found, use new parts,

including bushings, when installing caliper.

e Do not attempt to polish away corrosion.

Install or Connect

Important

See NOTICE on page 5- 1.

1. Lubricate sleeves (6) and bushings (7 and 11)

with silicone grease (Figure 5).

2. Sleeves

(6) in caliper mounting holes.

3. Caliper (12) over rotor.

4. Mounting bolts (23) to 50 N-m (37 1b.ft.) (Figure

1).

5.

Tube nut on brake pipe (31), if removed, to 20

N-m (15 1b.ft.) (Figure 4).

@ If brass bolt (8) and fitting (10) were

removed with brake pipe, unplug fitting and

install bolt and fitting using two new copper

washers

(9) to 44 N.m (32 lb. ft.) (Figure 8).

6. Disconnect nut (I), lever (2) lever seal (22), and

anti-friction washer (21) and clean (Figure 8).

Clean

Clean contamination from caliper surface in

area of lever seal (22) and around actuator

screw (16) (Figure 8).

7. Anti-friction washer (21).

8. Lubricated lever seal (22) with sealing bead

against caliper housing (12).

9. Lever (2) on actuator screw hex with lever

pointing down.

10. Nut

(I), while holding rotated lever (2) toward

front of car, to 48

N-m (35 1b.ft.). Rotate lever

back against stop on caliper (12).

11. Damper (37) and return spring (3) (Figure 1).

12. Parking brake cable (29). For cable adjustment

see PARKING BRAKE ADJUSTMENT.

13. Wheels and tires, aligning previous marks.

s Remove lug nuts securing rotor to hub.

e Lower car.

e Torque lug nuts. See WHEELS AND

TIRES.

14. Fill master cylinder to proper lever with clean

brake fluid.

e Bleed caliper if inlet fitting was removed.

Recheck fluid level.

PARKING BRAKE ADJUSTMENT

Apply service brake pedal three times with a

pedal force of approximately 778 N (175 lbs.).

Apply and release parking brake three times.

Raise car and suitably support.

e Mark relationship of wheel to axle flange.

Check parking brake hand lever for full release.

e Turn ignition on.

e "BRAKE" warning lamp should be off. If

"BRAKE" warning lamp is still on, and the

hand lever is completely released, pull

downward on the front parking brake cable

to remove slack from lever assembly.

Turn ignition off.

Remove rear wheels and tires.

e Reinstall two inverted lug nuts to retain

rotor.

Pull parking brake hand lever exactly four (4)

ratchet clicks.

Parking brake levers (2) on both calipers should

be against the lever stops on the caliper housings.

If levers are not against stops, check for binding

in rear cables and/or loosen cables at adjuster

until both left and right levers are against their

stops.

Tighten parking brake cable at adjuster until

either the left or right lever begins to move off the

stop, then loosen adjustment until lever moves

back barely touching stop.

Operate parking brake several times to check

adjustments. After cable adjustment is

performed, parking brake hand lever should

travel 14 clicks. Rear wheels should not rotate

forward when hand lever is applied

8 to 14

ratchet clicks.

Install wheels and tires, aligning previous marks.