wipers PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 152 of 1825

STEERING WHEELS AND COLUMNS 385.1

SECTION 3B5

STEER NG WHEELS AND COLUMNS

NOTICE: All steering wheel and column fasteners are important attaching parts in that they could affect

the performance of vital parts and systems, and/or could result in major repair expense. They

must be replaced

with one of the same part number or with an equivalent part if

replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. 'Torque values must be used as specified during reassembly

to assure proper retention of all parts. There is to be no welding as

it may result in extensive damage and weakening

of the metal.

For prevailing torque

nut(s) and bolts(s), refer to the "Reuse of Prevailing Torque Nut(<) and Bolt(s) " chart

in Section OA.

CONTENTS

..................... ................................................................... GENERAL DESCRIPTION .. 3B5-1 ............................................. ........................ MAINTENANCE AND ADJUSTMENTS .. 3B5-1 ON-CAR SERVICE ........................................................................................................ 3B5-2

Steering Column ............................................................................................................ 3B5-2 ......................................................................................................... Intermediateshaft 3B5-3

Park Lock Cable .................................................................... 3B54 ......................................................................................... Checking For Accident Damage 3B5-5 ............................................................................ Unit Repair Intermediate Shaft Assembly 3B5-6

..................................................................................... Standard Column @lanual Trans) 3B5-7 ......................................................... ....................... Standard Column (Auto Trans) .. 3B5-13 Tilt Column (Manual Trans) ............................................................................................. 3B5-19

Tilt Column (Auto Trans). ................................................................................................ 3B5-27

................ .................... TORQUE SPECIFICATIONS .. .. 3B5-35

SPECIAL TOOLS .......................................................................................................... 3B5-35

GENERAL DESCRIPTION

STEERING COLUMN

The function locking energy absorbing steering

column includes three important features in addition

to the steering function:

1. 'The column is energy absorbing, designed to

compress in a front-end collision to minimize the

possibility of an injury to the driver of the car.

2. The ignition switch and lock are mounted

conveniently on this column.

3. With the column mounted lock, the ignition and

steering operations can be locked to inhibit theft

of the car.

The turn signal lever provides for control of

headlight beams, windshield washer and wipers.

The column may be easily

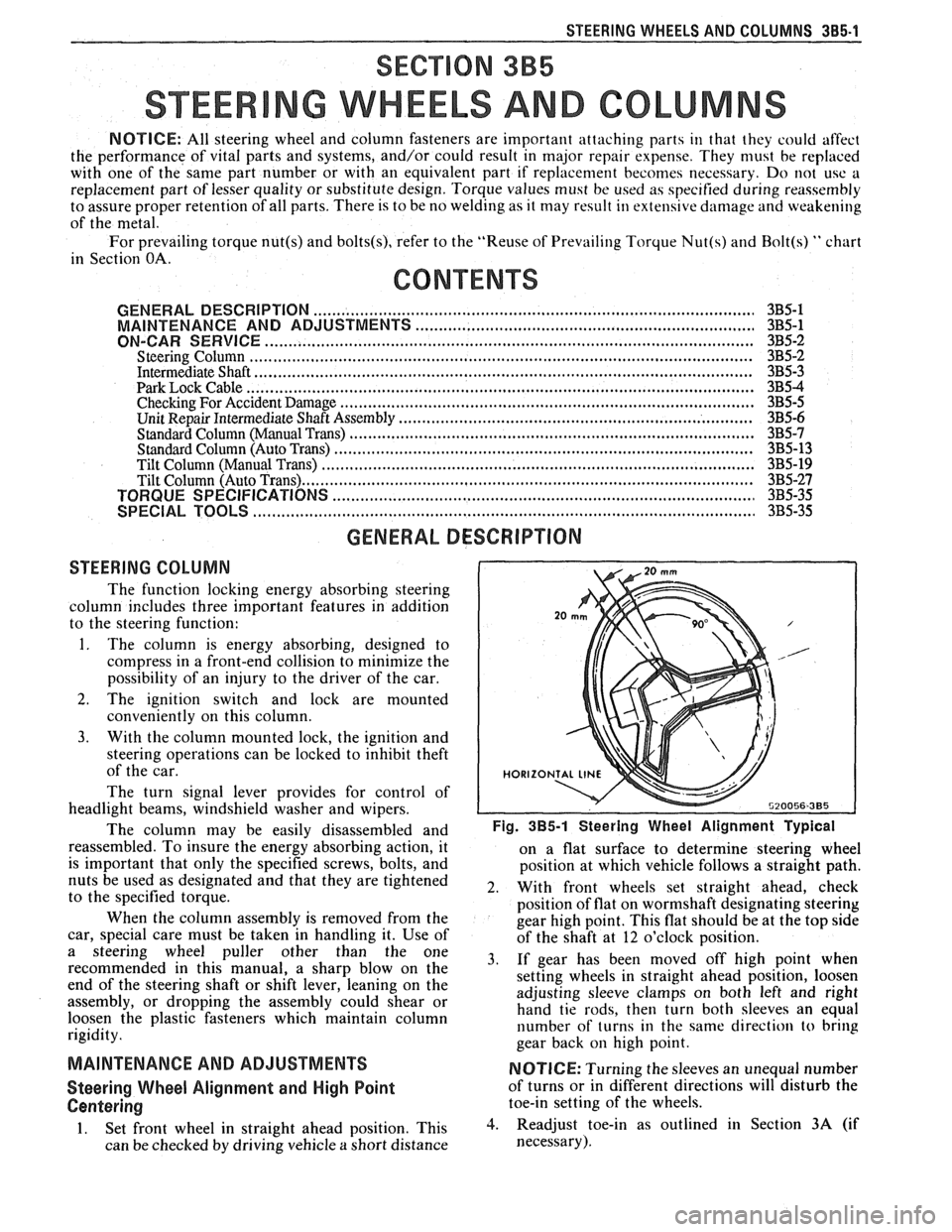

disassembled and Fig. 385-1 Steering Wheel Alignment ~ypical

reassembled. To insure the energy absorbing action, it

on a flat surface to determine steering wheel

is important that only the specified screws, bolts, and

position at which vehicle follows a straight path.

nuts be used as designated and that they are tightened

2. With front wheels set straight ahead, check to the specified torque.

position of flat on wormshaft designating steering

When the column assembly is removed from the

gear high point. This flat should be at the top side

car, special care must be taken in handling it. Use of

of the shaft at 12 o'clock position.

a steering puller other than the One 3, if gear has been moved off high when recommended in this manual, a sharp blow on the

setting wheels in straight ahead position, loosen

end of the steering shaft or shift lever, leaning on the

assembly, or dropping the assembly could shear or adjusting

sleeve clamps on both left and right

hand tie rods, then turn both sleeves an equal

loosen the plastic fasteners which maintain column

rigidity. number

of turns in the same direction

to bring

gear back

on high point.

MAINTENANCE AND ADJUSTMENTS NOTICE: Turning the sleeves an unequal number

Steering Wheel Alignment and High Point of turns or in different directions will disturb the

Centering toe-in setting of the wheels.

1. Set front wheel in straight ahead position, This 3. Readjust toe-in as outlined in Section 3A (if

can be checked by driving vehicle

a short distance necessary).

Page 1440 of 1825

TROUBLESHOOTING HINTS

0 Try the following checks before doing the

System Check.

1. Check the WIPER Fuse by visual

inspection.

2. Check that the three Wiper Motor mount-

ing bolts are clean and tight.

3. Check that the Wiper/Washer Switch con-

nector C240 is correctly mated.

4. If the Washer does not operate, check that:

- Washer reservoir is filled.

- Hoses are not pinched or kinked.

- Hoses are correctly attached.

- Nozzles are not clogged.

r Go to System Check for a guide to, normal

operation.

0 Go to System Diagnosis for diagnostic tests.

SYSTEM C H EGK

Use the System Check Table as a guide to

normal operation.

Refer to System Diagnosis for a list of symp-

toms and diagnostic steps.

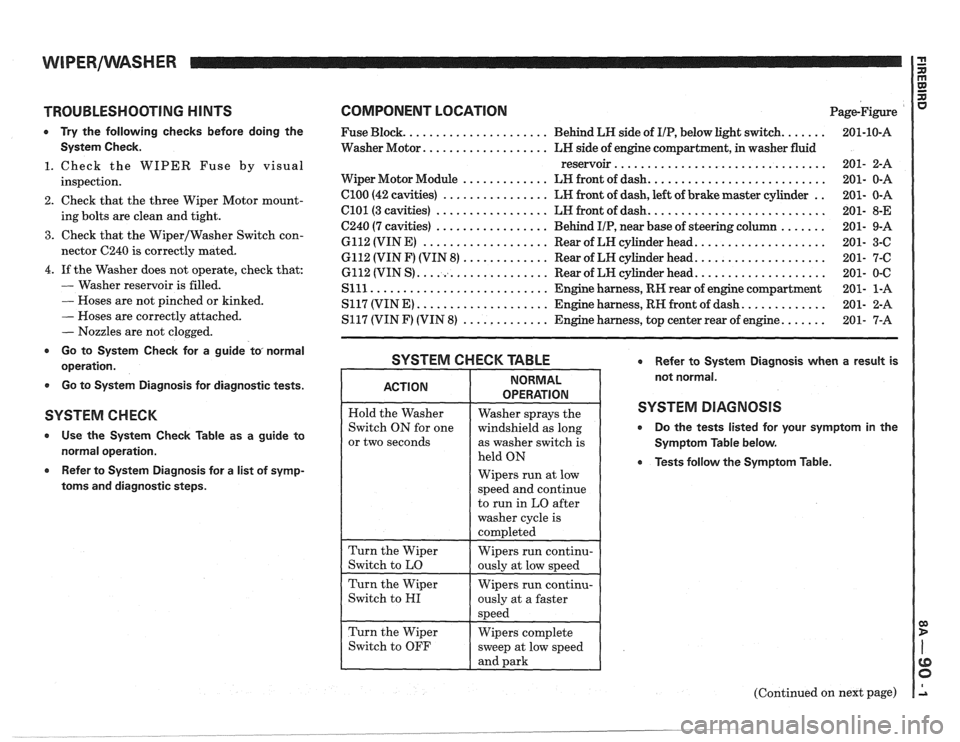

COMPONENT LOCATION Page-Figure

...... ..................... Fuse Block. Behind LH side of IIP, below light switch.

Washer Motor.

.................. LH side of engine compartment, in washer fluid

reservoir

................................

.......................... Wiper Motor Module ............. LH front of dash.

.. Cl00 (42 cavities) ................ LH front of dash, left of brake master cylinder

.......................... C101 (3 cavities) ................. LH front of dash.

....... C240 (7 cavities) ................. Behind IIP, near base of steering column

................... 6112 (VIN E) ................... Rear of LH cylinder head.

................... 6112 (VIN F) (VIN 8) ............. Rear of LH cylinder head.

................... 6112 (VIN S) .................... Rear of LW cylinder head.

Slll ........................... Engine harness, RH rear of engine compartment

............ S117 (VIN E) .................... Engine harness, RH front of dash.

...... S117 (VIN F) (VIN 8) ............. Engine harness, top center rear of engine.

SYSTEM CHECK TABLE Refer to System Diagnosis when a result is

not normal.

SYSTEM DIAGNOSIS

0 Do the tests listed for your symptom in the

Symptom Table below.

0 Tests follow the Symptom Table.

or two seconds

Wipers run at low

(Continued on next page)

. __- ______ --___ -..- .

Page 1442 of 1825

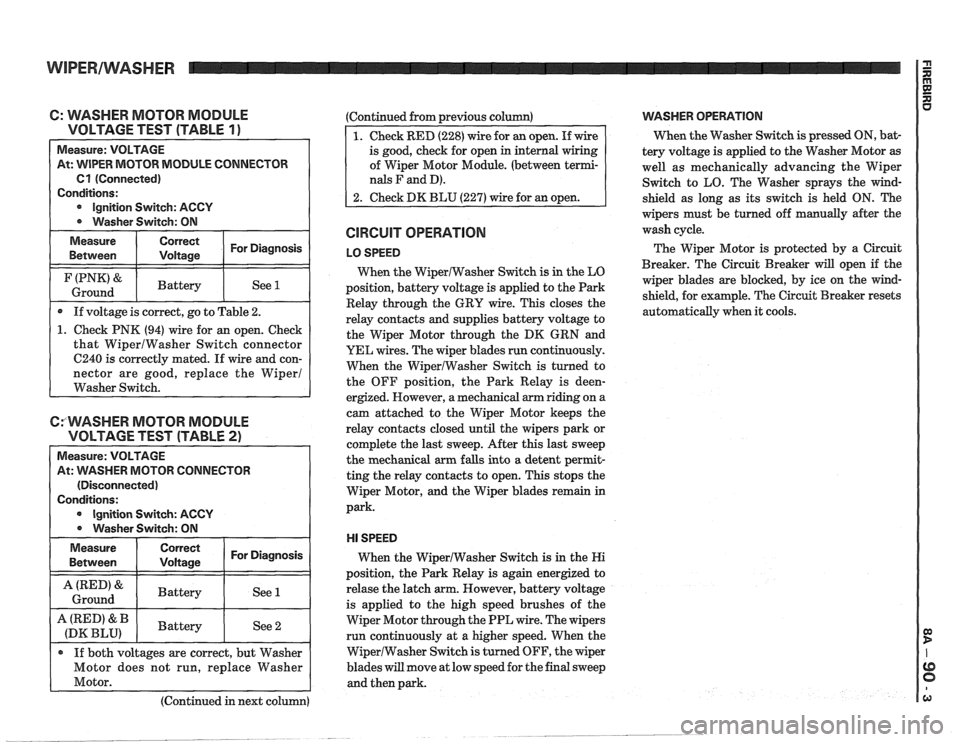

C: WASHER MOTOR MODULE

VOLTAGE TEST (TABLE

1 ) -

Measure: VOLTAGE

At: WIPER MOTOR MODULE CONNECTOR

Cl (Connected)

Conditions:

Ignition Switch: ACCY

Washer Switch: ON

Measure Correct For Diagnosis

Between Voltage

I (PNK'& I Battery I See 1 I Ground

If voltage is correct, go to Table 2.

1. Check PNK (94) wire for an open. Check

that WiperlWasher Switch connector

6240 is correctly mated. If wire and con-

nector are good, replace the Wiper1

Washer Switch.

CfWASHER MOTOR MODULE

VOLTAGE TEST (TABLE

2)

Measure: VOLTAGE

At:

VVASHER MOTOR CONNECTOR

(Disconnected)

Conditions:

Ignition Switch: ACCY

0 Washer Switch: ON

Measure

Between

I ::::ii 1 For Diagnosis I

I A(RED'& I Battery I See 1 I Ground

A (RED' & Battery

(DK BLU) See 2

If both voltages are correct, but Washer

Motor does not run, replace Washer

Motor.

(Continued in next column) (Continued

from previous column)

of Wiper Motor Module. (between

terrni-

nals F and D).

CIRCUIT OPERATION

LO SPEED

When the WiperlWasher Switch is in the LO

position, battery voltage is applied to the Park

Relay through the GRY wire. This closes the

relay contacts and supplies battery voltage to

the Wiper Motor through the DK GRN and

YEL wires. The wiper blades run continuously.

When the WiperIWasher Switch is turned to

the OFF position, the Park Relay is

deen-

ergized. However, a mechanical arm riding on a

cam attached to the Wiper Motor keeps the

relay contacts closed until the wipers park or

complete the last sweep. After this last sweep

the mechanical arm falls into a detent

perrnit-

ting the relay contacts to open. This stops the

Wiper Motor, and the Wiper blades remain in

park.

HI SPEED

When the WiperIWasher Switch is in the Hi

position, the Park Relay is again energized to

relase the latch arm. However, battery voltage

is applied to the high speed brushes of the

Wiper Motor through the PPL wire. The wipers

run continuously at a higher speed. When the

WiperlWasher Switch is turned OFF, the wiper

blades

will move at low speed for the final sweep

and then park.

VVASHER OPERATION

When the Washer Switch is pressed ON, bat-

tery voltage is applied to the Washer Motor

as

well as mechanically advancing the Wiper

Switch to LO. The Washer sprays the wind-

shield as long as its switch is held ON. The

wipers must be turned off manually after the

wash cycle.

The Wiper Motor is protected by a Circuit

Breaker. The Circuit Breaker

will open if the

wiper blades are blocked, by ice on the wind-

shield, for example. The Circuit Breaker resets

automatically when it cools.

Page 1444 of 1825

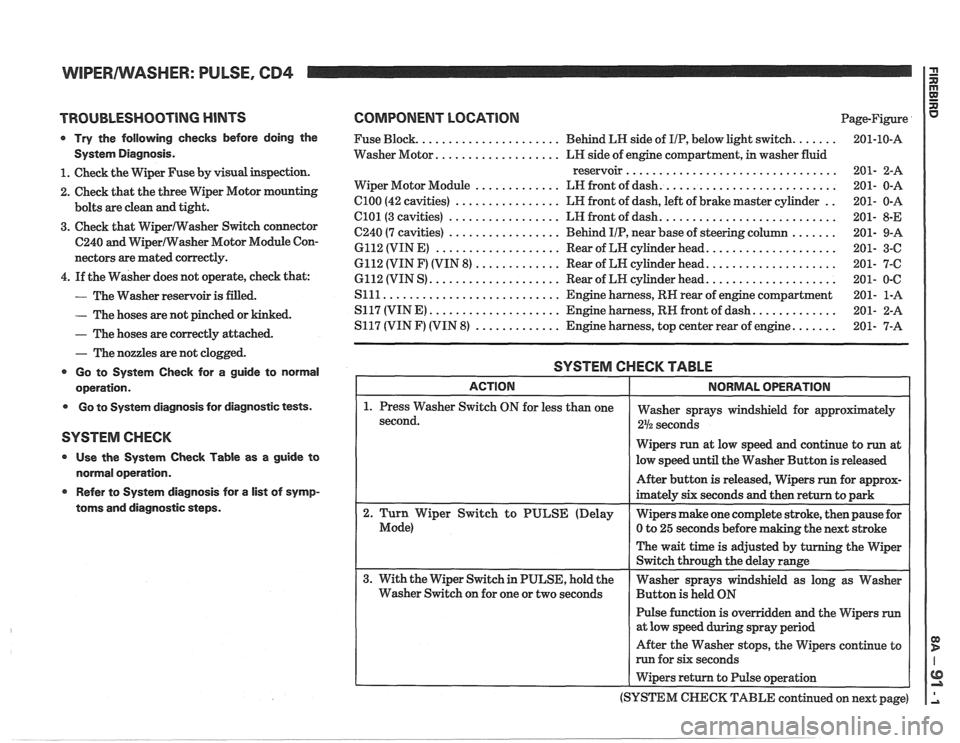

WIPERIWASHER: PULSE, CD4 I G n

TROUBLESHOOTING HINTS

Try the following checks before doing the

System Diagnosis.

1. Check the Wiper Fuse by visual inspection.

2. Check that the three

VViper Motor mounting

bolts are clean and tight.

3. Check that Wipermasher Switch connector

C240 and WiperIWasher Motor Module Con-

nectors are mated correctly.

4. If the Washer does not operate, check that:

- The Washer reservoir is filled.

- The hoses are not pinched or kinked.

- The hoses are correctly attached.

- The nozzles are not clogged.

Go to System Check for a guide to normal

operation.

Go to System diagnosis for diagnostic tests.

SYSTEM CHECK

Use the System Check Table as a guide to

normal operation.

e Refer to System diagnosis for a list of symp-

toms and diagnostic steps.

COMPONENT LOCATION Page-Figure

...... ..................... Fuse Block. Behind LR side of IIP, below light switch.

.................. Washer Motor. LH side of engine compartment, in washer fluid

reservoir

................................

.......................... ............. Wiper Motor Module LN front of dash.

.. C100 (42 cavities) ................ LR front of dash, left of brake master cylinder

.......................... C101(3 cavities) ................. LH front of dash.

....... C240 (7 cavities) ................. Behind IIP, near base of steering column

................... 6112 (VIN E) ................... Rear of LN cylinder head.

................... 6112 (VIN F) (VIN 8) ............. Rear of LN cylinder head.

................... 6112 (VIN S) .................... Rear of LH cylinder head.

S111 ........................... Engine harness, RN rear of engine compartment

............ S117 (VINE) .................... Engine harness, RN front of dash.

...... S117 (VIN F) (VIN 8) ............. Engine harness, top center rear of engine.

SYSTEM CHECK TABLE

Wipers run at low speed and continue to run at

low speed until the Washer Button is released

Pulse function is overridden and the Wipers

run

After the Washer stops, the Wipers continue to

run for six seconds

I Wipers return to Pulse operation

(SYSTEM

CHECK TABLE continued on next page)

Page 1445 of 1825

WIPERIWASHER: PULSE, CD4 1 g

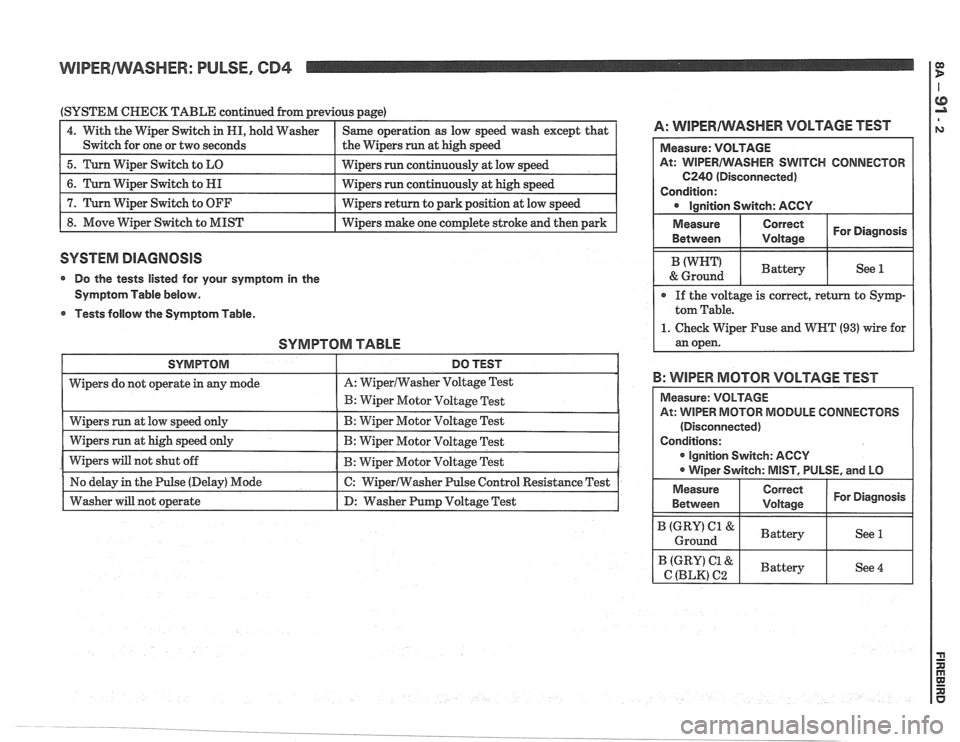

(SYSTEM CHECK TABLE continued from previous page)

1 4. With the Wiper Switch in HI, hold Washer I Same operation as low speed wash except that I A: WlPERAlVASHER VOLTAGE TEST

I Switch for one or two seconds I the Wipers run at high speed I

1 5. Turn Wiper Switch to LO I wipers run continuously at low speed I

1 8. Move Wiper Switch to MIST I Wipers make one complete stroke and then park I

6. Turn Wiper Switch to HI

7. Turn Wiper Switch to OFF

SYSTEM DIAGNOSIS

Wipers run continuously at high speed

Wipers return to park position at low speed

@ Do the tests listed for your symptom in the

Symptom Table below.

Tests

dollovv the Symptom Table.

SYMPTOM TABLE

SWITCH CONNECTOR

B: WIPER MOTOR VOLTAGE TEST

ODULE CONNECTORS

(Disconnected)

r ignition Switch: AGCY

Page 1447 of 1825

WIPERIWASHER: PULSE, CB4

(Continued from previous page)

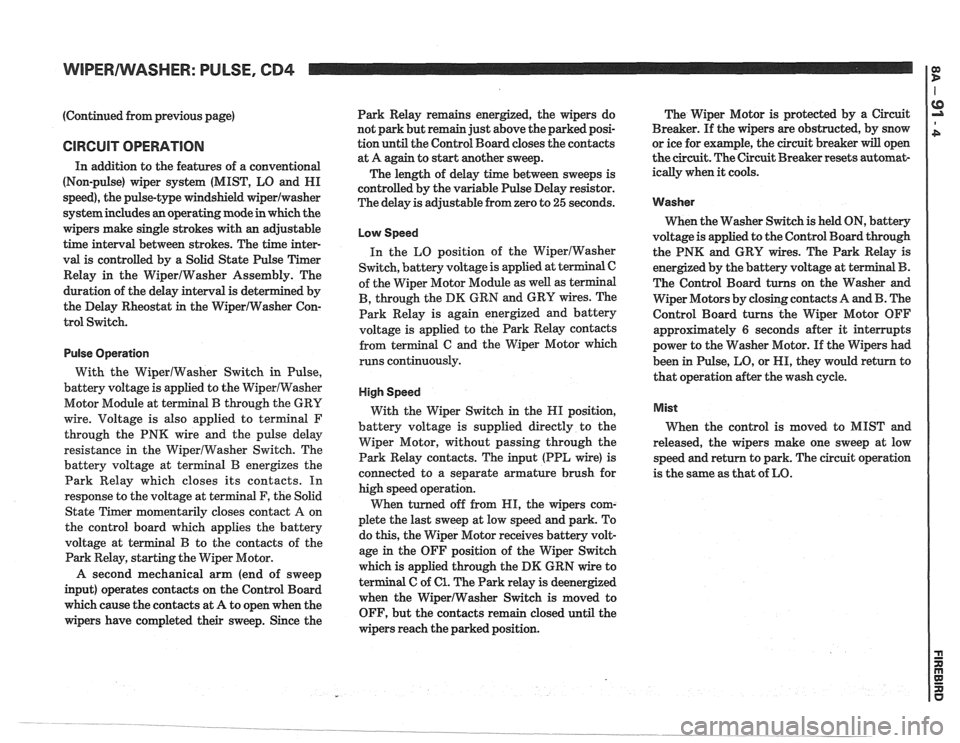

CIRCUIT OPERATION

In addition to the features of a conventional

(Non-pulse) wiper system (MIST, LO and HI

speed), the pulse-type windshield

wiperlwasher

system includes an operating mode in which the

wipers make single strokes with an adjustable

time interval between strokes. The time inter-

val is controlled by a Solid State Pulse Timer

Relay in the WiperIWasher Assembly. The

duration of the delay interval is determined by

the Delay Rheostat

in the WiperIWasher Con-

trol Switch.

Pulse Operation

With the WiperlWasher Switch in Pulse,

battery voltage is applied to the WiperlWasher

Motor Module at terminal

B through the GRY

wire. Voltage is also applied to

terminal F

through the PNK wire and the pulse delay

resistance in the WiperlWasher Switch. The

battery voltage at terminal

B energizes the

Park Relay which closes its contacts. In

response to the voltage at terminal F, the Solid

State Timer momentarily closes contact

A on

the control board which applies the battery

voltage at terminal

B to the contacts of the

Park Relay, starting the Wiper Motor.

A second mechanical arm (end of sweep

input) operates contacts on the Control Board

which cause the contacts at A to open when the

wipers have completed their sweep. Since the Park

Relay remains energized, the wipers do

not park but remain just above the parked posi-

tion until the Control Board closes the contacts

at A again to start

another sweep.

The length of delay time between sweeps is

controlled by the variable Pulse Delay resistor.

The delay is adjustable from zero to

25 seconds.

Low Speed

In the LO position of the WiperIWasher

Switch, battery voltage is applied at terminal C

of the Wiper Motor Module as well as terminal

B, through the DK GRN and GRY wires. The

Park Relay is again energized and battery

voltage is applied to the Park Relay contacts

from terminal

G and the Wiper Motor which

runs continuously.

High Speed

With the Wiper Switch in the HI position,

battery voltage is supplied directly to the

Wiper Motor, without passing through the

Park Relay contacts. The input (PPL wire) is

connected to a separate armature brush for

high speed operation.

When turned off from HI, the wipers com-

plete the last sweep at low speed and park. To

do this, the Wiper Motor receives battery volt-

age

in the OFF position of the Wiper Switch

which is applied through the

DM GRN wire to

terminal C of

61. The Park relay is deenergized

when the WiperlWasher Switch

is moved to

OFF, but the contacts remain closed until the

wipers reach the parked position. The

Wiper Motor is protected by a Circuit

Breaker. If the wipers are obstructed, by snow

or ice for example, the circuit breaker

will open

the circuit. The Circuit Breaker resets automat-

ically when

it cools.

Washer

When the Washer Switch is held ON, battery

voltage is applied to the Control Board through

the PNK and GRY wires. The Park Relay is

energized by the battery voltage at ter

The Control Board turns on the Washer and

Wiper Motors by closing contacts A and

B. The

Control Board turns the Wiper Motor OFF

approximately

6 seconds after it interrupts

power to the Washer Motor. If the Wipers had

been in Pulse, LO, or HI, they would return to

that operation after the wash cycle.

Mist

When the control is moved to MIST and

released, the wipers make one sweep at low

speed and return to park. The circuit operation

is the same as that of LO.

Page 1600 of 1825

LIGHTING SYSTEMS AND HORNS 8B-I

SECTION 8B

NG SYSTEMS AND HORNS

CONTENTS

........................... GENERAL DESCRIPTION 8B-1

Exterior Lights

....................... ................... Back-up Lights .. 8B- 1

Center High-Mounted Stoplight .................... 8B-1

Exterior Light Monitor .................................. 8B-1

............................ .................... Fog Lights .. 8B-1

Front Parking/Turn Signal Lights ................ 8B-2

............................... Hazard Flashers .. ........ 8B-2 .................................................... Headlights 8B-2

License Plate Lights ..................................... 8B-2

Light Switch ............................................... 8B-2

............... Rear Tail/Stop/Turn Signal Lights 8B-2

Sidemarker Lights ........................................ 8B-2

Turn Signals .......................................... 8B-2

......................... Underhood Light ... ........ 8B-2

Horns .......................................................... 8B-3

....................................... ON-CAR SERVICE 8B-3

Exterior Lights

............................................. Back-up Lights 8B-3

Center High-Mounted Stoplight .................... 8B-3

Fog Lights .................................................... 8B-4

Front Parking/Turn Signal Lights ................ 8B-4

Hazard Flasher .............................................. 8B-5

....................................................... Headlights 8B-5

License Plate Lights ..................................... 8B-7

............... Rear Tail/Stop/Turn Signal Lights 8B-8

.......................................... Sidemarker Lights 8B-8

................... ............... Turn Signal Flasher .. 8B-9

......................................... Underhood Light 8B-9

Horns ................................................................. 8B-9

REPLACEMENT BULB

.................................... SPECIFICATIONS 8B- 10

The following information, previously shown in this section,

has been moved to the sections shown.

Back-up Lights Switch

............................. ... ............................................................................ 7

................................................................................................................................. Fuse Block 8A

Ignition Switch ........................................................................................................................... 3B

Interior Lights

................................................................................................................... 8A, 8C

Neutral Start Switch ..................................................................................................................... 7

Parking Brake Warning Switch

......................... ... .................................................................... 5

........................................................................ Seat Belt, Key and Headlight Warning Alarm 8A

Stoplight Switch .......................... .. ............................................................................................... 5

Windshield

Wipers/Washers .................................................................................................... 8E

GENERAL DESCRIPTION

The exterior lighting system includes the

headlights (and headlight motors to raise or lower the

headlights), front

parkinghurn signal lights, front

cornering lights, fog lights, rear

tail/stop/turn signal

lights, back-up lights, license plate lights, center

high-mounted stoplight, and the underhood light; it

also includes all associated wiring, controls and related

hardware for these lights.

BACK-UP LIGHTS - The back-up lights are

next to the rear license plate. They will come on when

the transmission is shifted to Reverse. On cars with an

automatic transmission, the back-up lights are

activated by the neutral start switch. On cars with a

manual transmission, they are activated by a separate

back-up light switch on the transmission. For more

information, see Section 7.

CENTER HIGH-MOUNTED STOPLIGHT-

The center high-mounted stoplight, in the center of the

rear spoiler, will come on whenever the brake pedal is

pushed down. The light is powered separately from the rear

tail/stop/turn signal

lights through a separate

circuit in the stoplight switch (see Section

8A).

EXTERIOR LIGHT MONITOR - The Driver

Information Center, on cars so equipped, also monitors

certain front and rear lights. When a bulb burns out,

the message

"FRONT LAMP" or "REAR LAMP"

will appear in the DIC display, and a light will come

on to indicate which bulb has burned out. For more

information, see Section

8A.

FOG LIGHTS -The fog light switches are to the

left of the steering column on the edge of the

instrument panel. To use the fog lights, first turn on the

headlights or parking lights. Then, push the middle

switch (with the fog light symbol) to turn on the fog

lights. Push the left

("OFF") switch to turn off the fog

lights.

The fog lights should not be used as a substitute

for the headlights.

Switching to high-beam headlights will turn off

the fog lights; switching back to low-beams will turn

the fog lights on again.

Page 1628 of 1825

WINDSI4IELD WIPER SYSTEMS - F CARLINE 8E -1

SECTION 8E

F CARL

ELD W PER-WASHER SYSTEM

PULSE & STANDARD

CONTENTS

General Description ....................... 8E -1 Park Switch Replacement ............... .8E -3

Wiper and Washer Operation

............ 8E -1

Wiper Motor Replacement .............. 8E -1 1

Pulse Windshield Wiper System

........... 8E -1

Wiper Transmission .................... 8E -1 1

Diagnosis Wiper Arm

........................... 8E -12

Diagnostic Procedures

................... 8E -2 Wiper Blade ........................... 8E -13

Wiper Motor

........................... 8E -2 Wiper Blade Insert ..................... 8E -14

Washer Pump

.......................... 8E -2 Windshield Washer ..................... 8E -15

........................ Diagnostic Chart 8E -3 Unit Repair

On-Car Service Gear Replacement

..................... 8E - 15

Washer Pump Replacement .............. 8E -3 Wiper-Washer Nozzle and Container

Wiper Cover Replacement

............... 8E -3 Mounting ........................... 8E -1 8

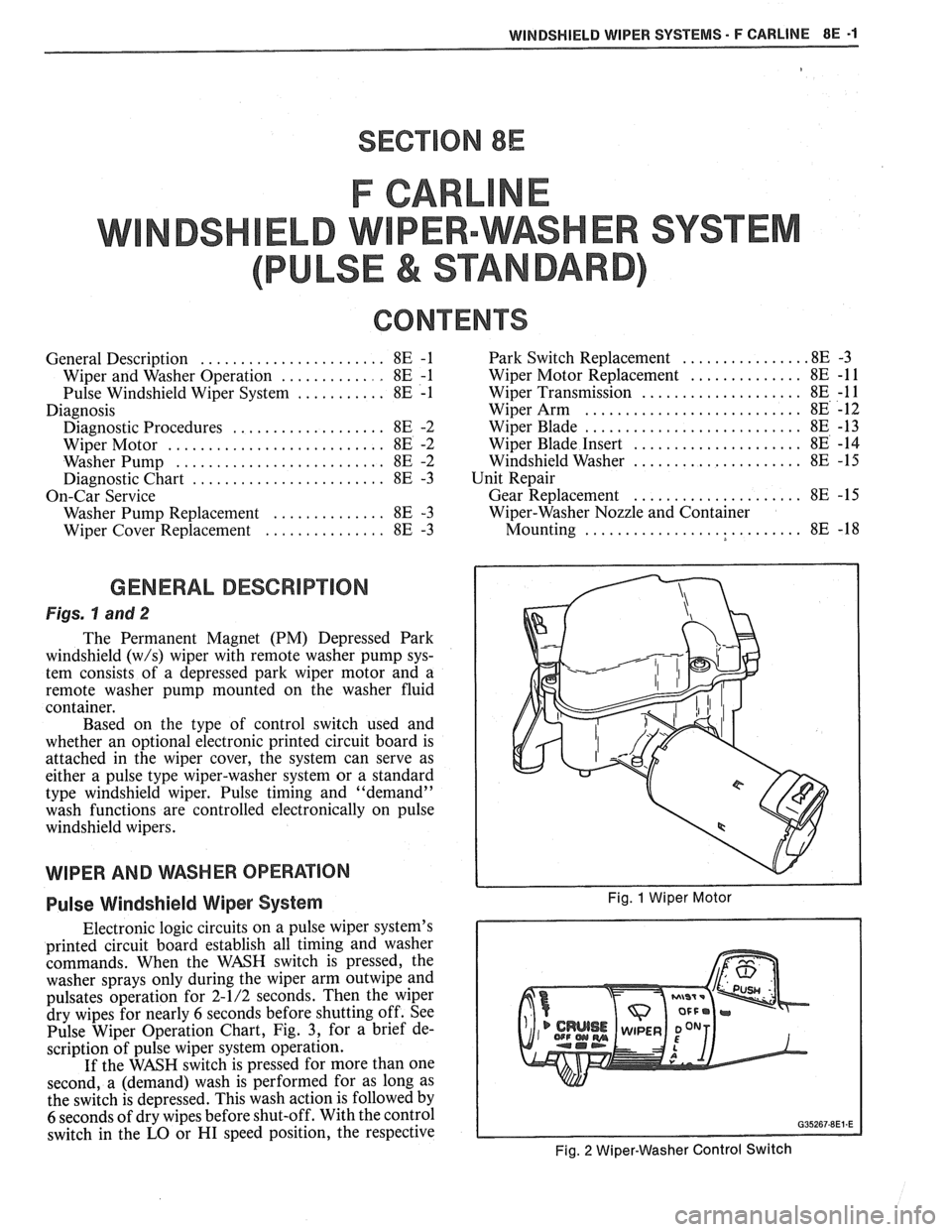

GENERAL DESCRIPTION

Figs. hand 2

The Permanent Magnet (PM) Depressed Park

windshield

(w/s) wiper with remote washer pump sys-

tem consists of a depressed park wiper motor and a

remote washer pump mounted on the washer fluid

container.

Based on the type of control switch used and

whether an optional electronic printed circuit board is

attached in the wiper cover, the system can serve as

either a pulse type wiper-washer system or a standard

type windshield wiper. Pulse timing and "demand"

wash functions are controlled electronically on pulse

windshield wipers.

WIPER AND WSHER OPERAflON

Pulse Windshield Wiper System Fig. 1 Wiper Motor

Electronic logic circuits on a pulse wiper system's

printed circuit board establish all timing and washer

commands. When the WASH switch is pressed, the

washer sprays only during the wiper arm

outwipe and

pulsates operation for 2-1/2 seconds. Then the wiper

dry wipes for nearly

6 seconds before shutting off. See

Pulse Wiper Operation Chart, Fig.

3, for a brief de-

scription of pulse wiper system operation.

If the WASH switch is pressed for more than one

second, a (demand) wash is performed for as long as

the switch is depressed. This wash action is followed by

6 seconds of dry wipes before shut-off. With the control

switch in the

LO or HI speed position, the respective

Fig. 2 Wiper-Washer Control Switch

Page 1639 of 1825

8E -12 WINDSHIELD WIPER SYSTEMS. F CAWLINE

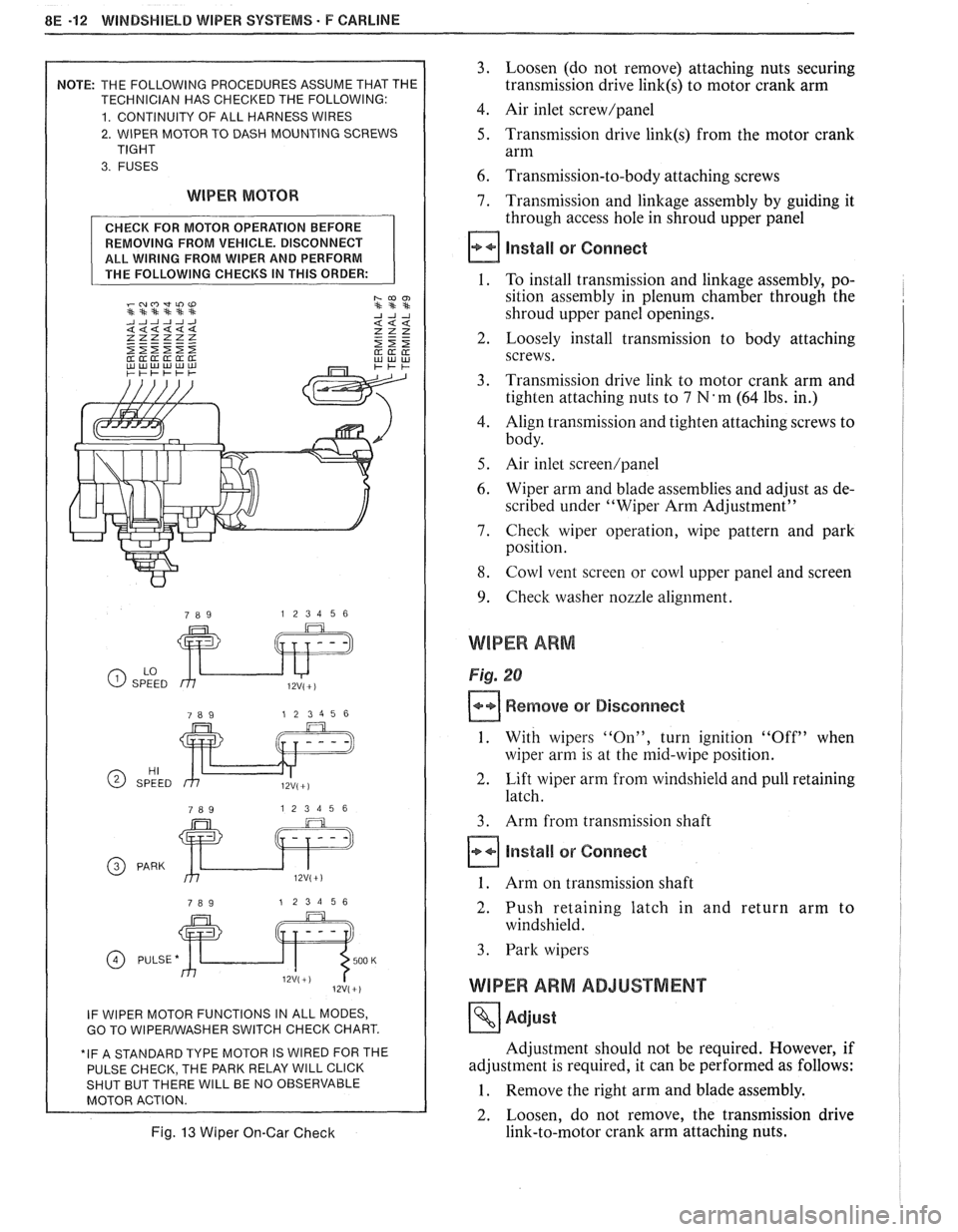

2. WIPER MOTOR TO DASH MOUNTING SCREWS

WIPER MOTOR

REMOVING FROM VEHICLE. DISCONNECT

ALL WIRING FROM WIPER AND PERFORM

GO TO WlPERlWASHER SWITCH CHECK CHART.

E PARK RELAY

WlLL CLICK WlLL BE NO OBSERVABLE

Fig. 13 Wiper On-Gar Check

3. Loosen (do not remove) attaching nuts securing

transmission drive

link(s) to motor crank arm

4. Air inlet screw/panel

5. Transmission drive link(s) from the motor crank

arm

6. Transmission-to-body attaching screws

7. Transmission and linkage assembly by guiding it

through access hole in shroud upper panel

install or Connect

1. To install transmission and linkage assembly, po-

sition assembly in plenum chamber through the

shroud upper panel openings.

2. Loosely install transmission to body attaching

screws.

3. Transmission drive link to motor crank arm and

tighten attaching nuts to

7 N'm (64 lbs. in.)

4. Align transmission and tighten attaching screws to

body.

5. Air inlet screen/panel

6. Wiper arm and blade assemblies and adjust as de-

scribed under "Wiper Arm Adjustment"

7. Check wiper operation, wipe pattern and park

position.

8. Cowl vent screen or cowl upper panel and screen

9. Check washer nozzle alignment.

WIPER ARM

Fig. 20

Remove or Disconnect

1. With wipers "On", turn ignition "Off" when

wiper arm is at the mid-wipe position.

2. Lift wiper arm from windshield and pull retaining

latch.

3. Arm from transmission shaft

Install or Connect

1. Arm on transmission shaft

2. Push retaining latch in and return arm to

windshield.

3. Park wipers

WIPER ARM ADJUSTMENT

Adjust

Adjustment should not be required. However, if

adjustment is required, it can be performed as follows:

1. Remove the right arm and blade assembly.

2. Loosen, do not remove, the transmission drive

link-to-motor crank arm attaching nuts.

Page 1640 of 1825

WINDSHIELD WIPER SYSTEMS - F CARLINE 8E -13

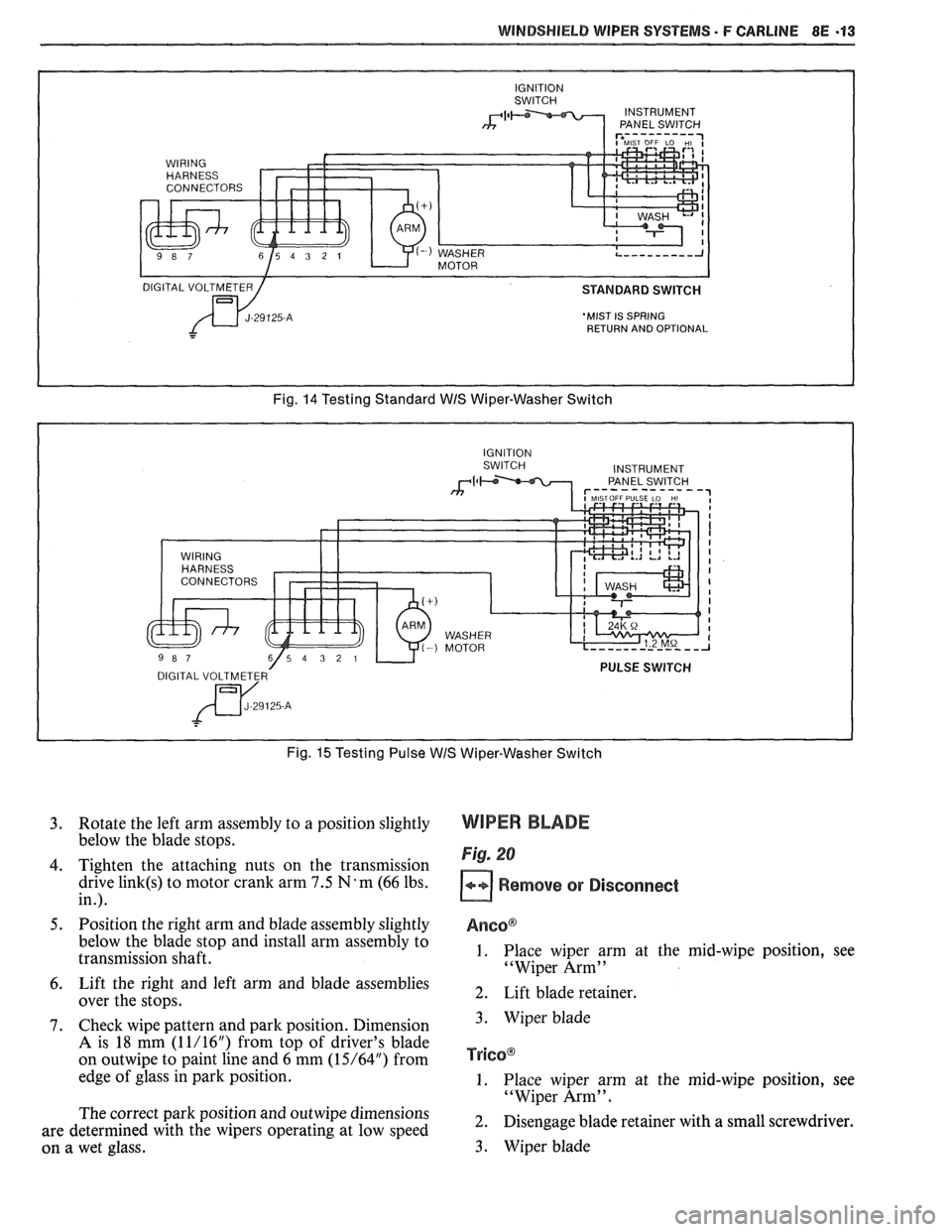

'MIST IS SPRING

RETURN AND OPTIONAL

Fig. 14 Testing Standard WIS Wiper-Washer Switch

Fig.

15 Testing Pulse WIS Wiper-Washer Switch

3. Rotate the left arm assembly to a position slightly

below the blade stops.

4. Tighten the attaching nuts on the transmission

drive

link(s) to motor crank arm 7.5 N'm (66 lbs.

in.).

5. Position the right arm and blade assembly slightly

below the blade stop and install arm assembly to

transmission shaft.

6. Lift the right and left arm and blade assemblies

over the stops.

7. Check wipe pattern and park position. Dimension

A is 18 mm (1 1/16") from top of driver's blade

on

outwipe to paint line and 6 mm (15/64") from

edge of glass in park position.

The correct park position and

outwipe dimensions

are determined with the wipers operating at low speed

on a wet glass.

WIPER BLADE

Fig. 20

Remove or Disconnect

Anso@

1. Place wiper arm at the mid-wipe position, see

"Wiper Arm"

2. Lift blade retainer.

3. Wiper blade

TY~GO@

1. Place wiper arm at the mid-wipe position, see

"Wiper Arm".

2. Disengage blade retainer with a small screwdriver.

3. Wiper blade