PONTIAC FIREBIRD 1994 Owners Manual

Manufacturer: PONTIAC, Model Year: 1994, Model line: FIREBIRD, Model: PONTIAC FIREBIRD 1994Pages: 290, PDF Size: 14.84 MB

Page 251 of 290

Maintenance Schedule

Section B: Owner Checks and Services (Cont.)

At least Once a Year (CONK)

CHECK

OR SERVICE

Steering Column Lock

Parking Brake and

Automatic Transmission “P” (Park) Mechanism

Check

Underbody Flushing

WHAT TO DO

While parked, and with the parking brake set, try to turn the key to “LOCK” in each shift lever

position.

With an automatic transmission, the key should turn to “LOCK” only when the shift lever is

0 With a manual transmission, the key should turn to “LOCK” only when the shift lever is in

On vehicles with a key release button, try to turn the key to “LOCK” without pressing the

button. The key should turn to “LOCK” only with the key button depressed. On all vehicles,

the kev should come out only in “LOCK.”

in

“P” (Park).

“R” (Reverse).

brake, set the parking brake.

0 To check the parhng brake: With the engine running and transmission in “N” (Neutral),

slowly remove foot pressure from the regular brake pedal.

Do this until the vehicle is held by

the parking brake only.

brakes.

0 To check the “P” (Park) mechanism’s holding ability: Shift to “P” (Park). Then release all

~~ ~

At least every spring, use plain water to flush any corrosive materials from the underbody. Take

care to clean thoroughly any areas where mud and other debris can collect.

. . .250

ProCarManuals.com

Page 252 of 290

Section C: Periodic Maintenance Inspections

Listed below are inspections and services which should be performed at least twi\

ce a year (for instance, each spring and fall).

You should let your

GM dealer’s service department or other qualified service center do these jobs. Make sure any necessary

repairs are completed at once.

INSPECTION

I OR SERVICE

Restraint Systems

~ ~~~~

Steering and

Suspension Inspection

Exhaust System

Inspection

Inspection

WHAT SHOULD BE DONE

Now and then, make sure all your belts, buckles, latch plates, retractors, anchorages and

reminder systems are working properly. Look for any loose parts or damage. If you see anything

that might keep a restraint system from doing its job, have it repaired.

Inspect the front and rear suspension and steering system for damaged, loose or missing parts,

signs of wear, or lack of lubrication. Inspect the power steering lines and hoses for proper

hookup, binding, leaks, cracks, chafing, etc.

Inspect the complete exhaust system. Inspect the body near the \

exhaust system. Look for broken,

damaged, missing

or out-of-position parts as well as open seams, holes, loose connections or , ’;;

other conditions which could cause a heat build-up in the floor pan or could let exhaust fumes :~

into the vehicle. See “Engine Exhaust’’ in the Index.

Inspect the throttle linkage for interference or binding, and for damaged or missing parts.

Replace parts as needed.

251 . . .

ProCarManuals.com

Page 253 of 290

Maintenance Schedule

Section C: Periodic Maintenance Inspections (Cont.)

I INSPECTION

F Manual Transmission

I

Rear Axle Service

Brake System

Inspection

WHAT SHOULD BE DONE

Check the transmission fluid level; add if needed. See “Manual Transmission” in the Index.

A fluid

loss may indicate a problem. Check the system and repair if needed.

Check the gear lubricant level in the rear axle and add if needed. See “Rear Axle” in the Index.

A fluid loss may indicate a problem. Check the axle and repai\

r it if needed.

If your vehicle

is used to pull a trailer, have the rear axle gear lubricant changed every

7,500 miles

(12 500 km).

Inspect the complete system. Inspect brake lines and hoses for \

proper hookup, binding, leaks,

cracks, chafing, etc. Inspect disc brake pads for wear and rotors for surface condition. Also

inspect drum brake linings for wear and cracks. Inspect other \

brake parts, including drums,

wheel cylinders, calipers, parking brake, etc. The parking brake\

is self-adjusting and no manual

adjustment is required. You may need to have your brakes inspected more often if your driving

habits or conditions result in frequent braking.

NOTE: A low brake fluid level can indicate worn disc brake pads which may need to be serv-

iced. Also, if the brake system warning light stays on or comes on, something may be wrong

with the brake system.

See “Brake System Warning Light” in the Index. If your anti-lock brake \

system warning light stays on, comes on or flashes, something may be wrong with the anti-lock

brake system. See “Anti-Lock Brake System Warning Light’’ in the Index.

~~

. . .252

ProCarManuals.com

Page 254 of 290

Section D: Recommended Fluids & Lubricants

JOTE: Fluids and lubricants identified below by name, part number or specification may be obtained from your GM Dealer.

USAGE

Engine Oil

Engine Coolant

Hydraulic Brake System

FLUID/LUBRICANT

API service SH or SG Energy Conserving I1 oils of the proper viscosity. The “SH” designation

may be shown alone or in combination with others, such as “SH/CD,”

“SH, SG, CD,”

“SG/CD,” etc. To determine the preferred viscosity for your vehicle’s engine, see “Engine

Oil”

in the Index.

50/50 mixture of water (preferably distilled) and good quality ethylene glycol base antifreeze

(GM Part No. 1052753 or equivalent) conforming to GM Specification 1825M or approved

recycled coolant conforming to

GM Specification 1825M.

Delco-Supreme

ll@ Brake Fluid (GM Part No. 1052535 or equivalent DOT-3 Brake Fluid).

Hydraulic Clutch Hydraulic Clutch Fluid (GM Part.

No. 12345347 or equivalent).

System

Power Steering System

~~

GM Hydraulic Power Steering Fluid (GM Part No. 1052884 or equivalent).

Manual Transmission DEXRON@-IIE Automatic Transmission Fluid.

Automatic DEXR0N’-III or DEXRON@-IIE Automatic Transmission Fluid.

Transmission

I

Key Lock Cylinders I Lubricate with Multi-Purpose Lubricant (GM Part No. 12345120) or synthetic SAE 5W-30

253. . .

ProCarManuals.com

Page 255 of 290

Maintenance Schedule

Section D: Recommended Fluids & Lubricants (Cont.)

Floor Shift Linkage

Chassis Lubrication

Rear Axle

(Standard Differential)

Rear Axle (Limited-

Slip Differential)

Windshield Washer Solvent

Hood Latch Assembly

a. Pivots and Spring

b. Release Pawl Anchor

Hood and Door

Hinges, Headlight

Door Assemblies,

Rear Folding Seat,

Fuel Door Hinge,

Rear Compartment

Lid Hinges

Weatherstrips

I

FLUlDlLUBRlCANT

Engine oil.

Chassis lubricant (GM Part

No. 1052497 or equivalent) or lubricant meeting requirements of

NLGI Grade 2, Category LB or GC-LB.

Axle Lubricant (GM Part No. 1052271) or SAE 80W-90 GL-5 Gear Lubricant.

Axle Lubricant (GM Part

No. 12345977) or SAE 8OW-90 GL-5 Gear Lubricant, and Limited-

Slip Differential Lubricant Additive (GM Part

No. 1052358 or equivalent) where required. See

“Rear Axle” in the Index.

GM Optikleen@ Washer Solvent (GM Part No. 105

15 15 or equivalent).

a. Engine oil.

b. Chassis lubricant (GM Part

No. 1052497 or equivalent) or lubricant meeting requirements of

NLGI Grade 2, Category LB

or GC-LB.

Engine oil or Lubriplate Lubricant (GM Part

No. 1050109).

Dielectric Silicone Grease (GM Part

No. 12345579 or equivalent).

I See “Replacement Parts” in the Index for recommended replacement filters, valves and spark plugs.

. . .254

ProCarManuals.com

Page 256 of 290

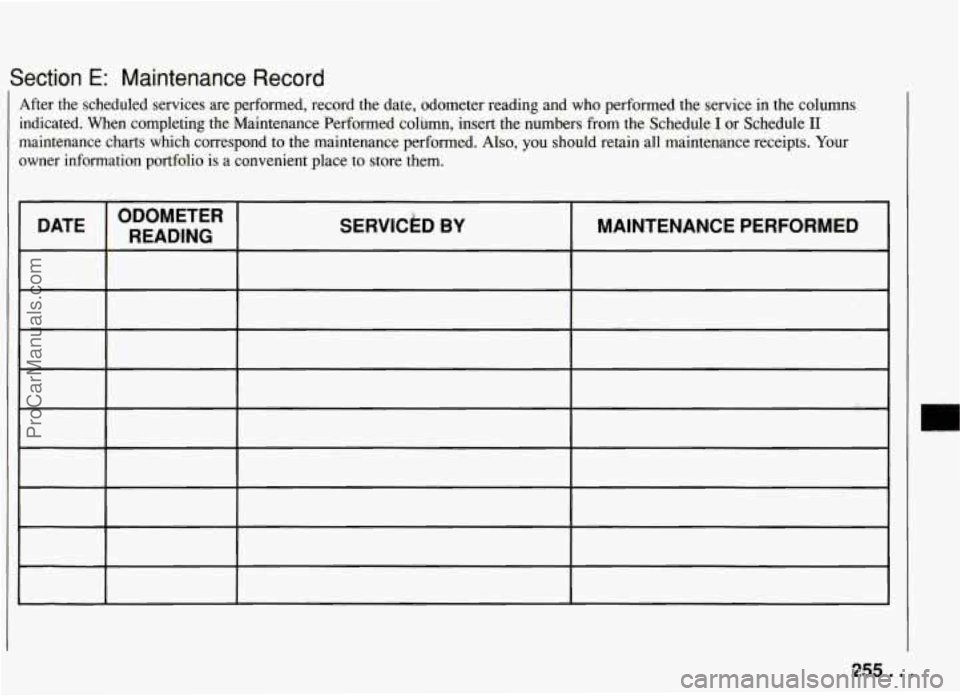

Section E: Maintenance Record

After the scheduled services are performed, record the date, odometer reading and who performed the service in the columns

indicated. When completing the Maintenance Performed column, inse\

rt the numbers from the Schedule

I or Schedule I1

maintenance charts which correspond to the maintenance performed. Also, you should retain all maintenance receipts. Your

owner information portfolio is a convenient place to store them.

DATE READING

ODOMETER SERVIC~D BY MAINTENANCE PERFORMED

255.. .

ProCarManuals.com

Page 257 of 290

Maintenance Schedule

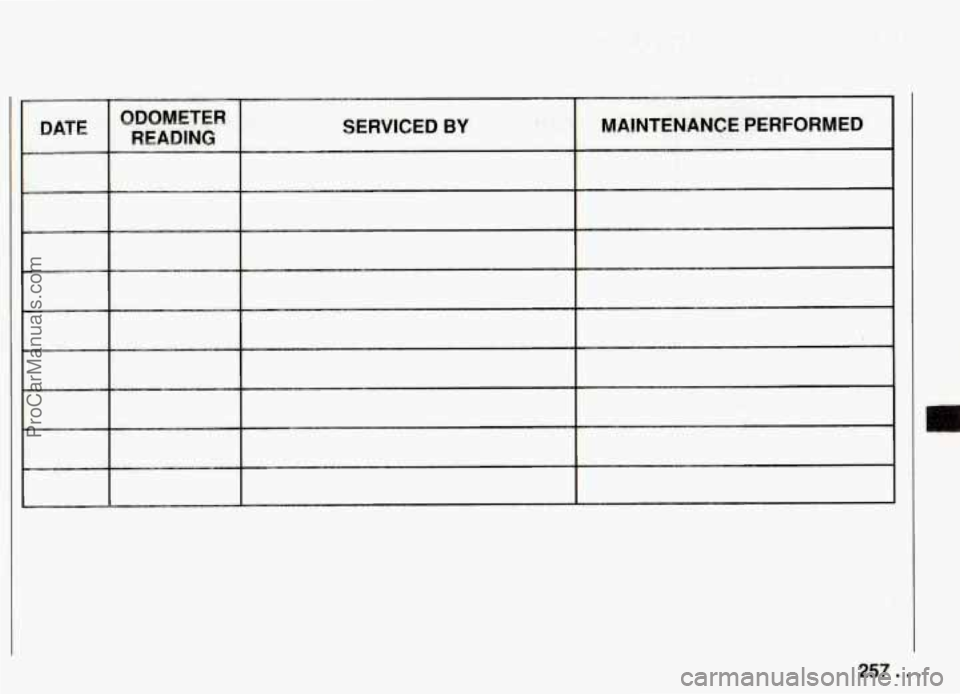

Section E: Maintenance Record (Cont.) V

. . .256

ProCarManuals.com

Page 258 of 290

ODOMETER READING

I SERVICED BY MAINTENANCE PERFORMED

I

257. . .

ProCarManuals.com

Page 259 of 290

Maintenance Schedule

Section E: Maintenance Record (Cont.)

DATE MAINTENANCE PERFORMED

. . .258

ProCarManuals.com

Page 260 of 290

Part 8

Customer Assistance Information

Here you will find out how to

contact Pontiac

if you need

assistance.

This part also tells

you

how to obtain service

publications and

how to report

any safety defects.

Customer Satisfaction Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

GM Participation in BBB AUTO LINE-Alternative Dispute

Resolution Program

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 261

Reporting Safety Defects to the United States Government

. . . . . . . . . . . . . . . . 262

Reporting Safety Defects to the Canadian Government

. . . . . . . . . . . . . . . . . . . 262

Reporting Safety Defects to General Motors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Pontiac Roadside Assistance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . 263

Canadian Roadside Assistance

. . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . ':'. 263

Pontiac Courtesy Transportation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Service Publications.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

. .,

259. - .

ProCarManuals.com