parking brake PONTIAC G5 2010 Owner's Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 2010, Model line: G5, Model: PONTIAC G5 2010Pages: 422, PDF Size: 2.22 MB

Page 263 of 422

If parking the rig on a hill:1. Press the brake pedal, but do not shift into P (Park) yet for an automatic transmission, or into gear for a

manual transmission. Turn the wheels into the

curb if facing downhill or into traffic if facing uphill.

2. Have someone place chocks under the trailer wheels.

3. When the wheel chocks are in place, release the regular brakes until the chocks absorb the load.

4. Reapply the regular brakes. Then apply the parking brake, and then shift into P (Park) for an automatic

transmission or R (Reverse) for a manual

transmission.

5. Release the brake pedal.

Leaving After Parking on a Hill

1. Apply the regular brakes and hold the pedal down while you:

•Start the engine.

•Shift into a gear.

•Release the parking brake.

2. Let up on the brake pedal.

3. Drive slowly until the trailer is clear of the chocks.

4. Stop and have someone pick up and store the chocks.

Maintenance When Trailer Towing

The vehicle needs service more often when pulling a

trailer. See Scheduled Maintenance on page 7-3

for more on this. Things that are especially important in

trailer operation are automatic transmission fluid (do

not overfill), engine oil, drive belt, cooling system

and brake system.

Each of these is covered in this manual, and the Index

will help to find them quickly. When trailering, it is a good

idea to review this information before starting the trip.

Check periodically to see that all hitch nuts and bolts are

tight.

Engine Cooling When Trailer Towing

The cooling system may temporarily overheat during

severe operating conditions. See Engine Overheating on

page 6-27.

Towing a Trailer (Manual

Transmission)

Do not tow a trailer if the vehicle is equipped with a

manual transmission.

5-39

Page 265 of 422

Service........................................................... .6-3

Accessories and Modifications ..........................6-3

California Proposition 65 Warning .....................6-4

California Perchlorate Materials Requirements .....6-4

Doing Your Own Service Work .........................6-4

Adding Equipment to the Outside of the Vehicle ..................................................... .6-5

Fuel ............................................................... .6-5

Gasoline Octane ........................................... .6-6

Gasoline Specifications ................................... .6-6

California Fuel .............................................. .6-6

Additives ...................................................... .6-6

Fuels in Foreign Countries ...............................6-7

Filling the Tank ............................................. .6-8

Filling a Portable Fuel Container .....................6-10

Checking Things Under the Hood ....................6-10

Hood Release ............................................. .6-11

Engine Compartment Overview .......................6-12

Engine Oil .................................................. .6-13

Engine Oil Life System ................................. .6-16

Engine Air Cleaner/Filter ................................6-18

Automatic Transmission Fluid .........................6-19

Hydraulic Clutch .......................................... .6-19

Cooling System ........................................... .6-20

Engine Coolant ............................................ .6-24

Engine Overheating ...................................... .6-27Windshield Washer Fluid

................................6-28

Brakes ....................................................... .6-29

Battery ....................................................... .6-33

Jump Starting .............................................. .6-34

Headlamp Aiming .......................................... .6-38

Bulb Replacement ......................................... .6-41

Halogen Bulbs ............................................. .6-41

Headlamps, Front Turn Signal, Sidemarker, and Parking Lamps ................................... .6-42

Center High-Mounted Stoplamp (CHMSL) .........6-43

Taillamps

and Turn Signal Lamps (Coupe) .......6-44

Taillamps, Turn Signal, Stoplamps and Back-up Lamps (Sedan) .............................6-44

Back-Up Lamps (Coupe) ................................6-45

License Plate Lamp ..................................... .6-46

Replacement Bulbs ...................................... .6-47

Windshield Wiper Blade Replacement ..............6-47

Tires ............................................................. .6-48

Tire Sidewall Labeling .................................. .6-49

Tire Terminology and Definitions .....................6-52

Inflation - Tire Pressure .................................6-55

Tire Pressure Monitor System .........................6-56

Tire Pressure Monitor Operation .....................6-58

Tire Inspection and Rotation ...........................6-62

When It Is Time for New Tires .......................6-64

Section 6 Service and Appearance Care

6-1

Page 298 of 422

Jump Starting

If the vehicle’s battery has run down, you may want to

use another vehicle and some jumper cables to start the

vehicle. Be sure to use the following steps to do it

safely.

{WARNING:

Batteries can hurt you. They can be dangerous

because:

•They contain acid that can burn you.

•They contain gas that can explode or ignite.

•They contain enough electricity to burn you.

If you do not follow these steps exactly, some or

all of these things can hurt you. Notice:

Ignoring these steps could result in costly

damage to the vehicle that would not be covered

by the warranty.

Trying to start the vehicle by pushing or pulling it

will not work, and it could damage the vehicle.

1. Check the other vehicle. It must have a 12-volt battery with a negative ground system.

Notice: If the other vehicle’s system is not a 12-volt

system with a negative ground, both vehicles can

be damaged. Only use vehicles with 12-volt systems

with negative grounds to jump start your vehicle.

2. Get the vehicles close enough so the jumper cables can reach, but be sure the vehicles are not touching

each other. If they are, it could cause a ground

connection you do not want. You would not be able

to start the vehicle, and the bad grounding could

damage the electrical systems.

To avoid the possibility of the vehicles rolling, set

the parking brake firmly on both vehicles involved in

the jump start procedure. Put an automatic

transmission in P (Park) or a manual transmission

in N (Neutral) before setting the parking brake.

6-34

Page 324 of 422

TPMS Sensor Matching Process

Each TPMS sensor has a unique identification code.

Any time you replace one or more of the TPMS sensors

or rotate the vehicle’s tires, the identification codes need

to be matched to the new tire/wheel location. The sensors

are matched, to the tire/wheel locations, in the following

order: driver side front tire, passenger side front tire,

passenger side rear tire, and driver side rear tire using a

TPMS diagnostic tool. See your dealer/retailer for

service.

The TPMS sensors can also be matched to each

tire/wheel position by increasing or decreasing the tire’s

air pressure. When increasing the tire’s pressure, do

not exceed the maximum inflation pressure indicated on

the tire’s sidewall. To decrease the tire’s air-pressure

use the pointed end of the valve cap, a pencil-style

air pressure gage, or a key.

You have two minutes to match each tire and wheel

position. If it takes longer than two minutes to match any

tire and wheel position, the matching process stops

and you need to start over.

TPMS Matching Process for Vehicles

with Remote Keyless Entry (RKE)

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with theengine off.

3. Press and hold the Remote Keyless Entry (RKE) transmitter’s lock and unlock buttons, at the same

time, for about five seconds to start the TPMS learn

mode. The horn sounds twice indicating the

TPMS receiver is ready and in learn mode.

4. Start with the driver side front tire. The driver side front turn signal also comes on to indicate that

corner’s sensor is ready to be learned.

5. Remove the valve cap from the tire’s valve stem. Activate the TPMS sensor by increasing or

decreasing the tire’s air pressure for about

eight seconds. The horn chirp, can take up to

30 seconds to sound. It chirps one time and then all

the turn signals flash one time to confirm the sensor

identification code has been matched to the tire/

wheel position.

6. The passenger side front turn signal comes on to indicate that corner sensor is ready to be learned.

Proceed to the passenger side front tire and

repeat the procedure in Step 5.

6-60

Page 325 of 422

7. The passenger side rear turn signal comes on toindicate that corner sensor is ready to be learned.

Proceed to the passenger side rear tire and

repeat the procedure in Step 5.

8. The driver side rear turn signal comes on to indicate that corner sensor is ready to be learned.

Proceed to the driver side rear tire, and repeat

the procedure in Step 5.

9. After hearing the single horn chirp for the driver side rear tire, two additional horn chirps sound to

indicate the tire learning process is done. Turn

the ignition switch to LOCK/OFF.

If no tires are learned after entering the TPMS learn

mode, or if communication with the receiver

stops, or if the time limit has expired, turn the

ignition switch to LOCK/OFF and start over

beginning with Step 2.

10. Set all four tires to the recommended air pressure level as indicated on the Tire and Loading

Information label.

11. Put the valve caps back on the valve stems.TPMS Matching Process for Vehicles

without Remote Keyless Entry (RKE)

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the engine off.

3. Using the Driver Information Center (DIC), press the INFO and Set/Reset buttons at the same time

for about one second. Then press and release

the INFO button until the TIRE LEARN? message

displays.

4. Press and hold the Set/Reset DIC button for approximately three seconds to start the TPMS

learn mode. The horn sounds twice to indicate the

TPMS receiver is ready and the TIRE LEARN

ON message displays. The driver side front turn

signal also comes on to indicate that corner sensor

is ready to be learned.

5. Start with the driver side front tire.

6. Remove the valve cap from the tire’s valve stem. Activate the TPMS sensor by increasing or

decreasing the tire’s air pressure for about

eight seconds. The horn chirp, can take up to

30 seconds to sound. It chirps one time and then all

the turn signals flash one time to confirm the sensor

identification code has been matched to the tire/

wheel position.

6-61

Page 335 of 422

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you would

use in a skid. In any rear blowout, remove your foot from

the accelerator pedal. Get the vehicle under control

by steering the way you want the vehicle to go. It may

be very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place and stopping.1. Turn on the hazard warning flashers. See Hazard

Warning Flashers on page 4-3 .

2. Park the vehicle. Set the parking brake firmly and put the shift lever in P (Park).

3. Turn off the engine.

4. Inspect the flat tire.

{WARNING:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without the

appropriate safety equipment and training. If a jack

is provided with the vehicle, it is designed only for

changing a flat tire. If it is used for anything else,

you or others could be badly injured or killed if the

vehicle slips off the jack. If a jack is provided with

the vehicle, only use it for changing a flat tire.

This vehicle may come with a jack and spare tire or a

tire sealant and compressor kit. To use the jack and

spare tire, see Changing a Flat Tire on page 6-80 .To

use the tire sealant and compressor kit, see Tire Sealant

and Compressor Kit on page 6-72 .

6-71

Page 344 of 422

3. Remove the retainer that holds the tire sealant andcompressor kit.

4. Remove the kit from the foam container.

To store the tire sealant and compressor kit, reverse the

steps.

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on the hazard

warning flashers. See Hazard Warning Flashers

on page 4-3.

{WARNING:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you or

other people. You and they could be badly injured

or even killed. Find a level place to change your

tire. To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put an automatic transmission shift lever in P (Park), or shift a manual transmission to

1 (First) or R (Reverse).

3. Turn off the engine and do not restart while the vehicle is raised.

4. Do not allow passengers to remain in the vehicle.

To be even more certain the vehicle will not move,

you should put blocks at the front and rear of the

tire farthest away from the one being changed.

That would be the tire on the other side, at the

opposite end of the vehicle.

6-80

Page 371 of 422

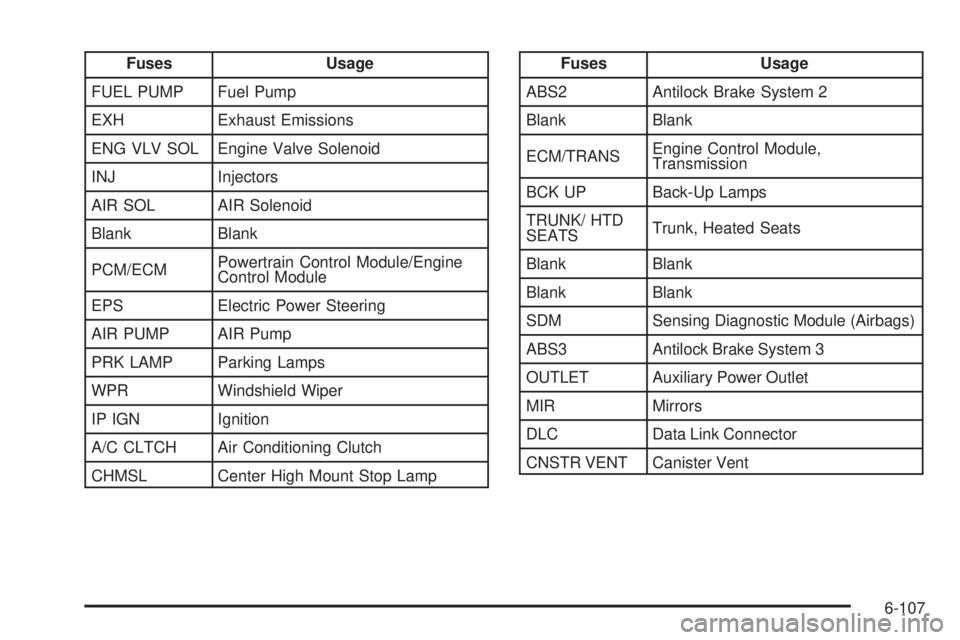

FusesUsage

FUEL PUMP Fuel Pump

EXH Exhaust Emissions

ENG VLV SOL Engine Valve Solenoid

INJ Injectors

AIR SOL AIR Solenoid

Blank Blank

PCM/ECM Powertrain Control Module/Engine

Control Module

EPS Electric Power Steering

AIR PUMP AIR Pump

PRK LAMP Parking Lamps

WPR Windshield Wiper

IP IGN Ignition

A/C CLTCH Air Conditioning Clutch

CHMSL Center High Mount Stop LampFuses Usage

ABS2 Antilock Brake System 2

Blank Blank

ECM/TRANS Engine Control Module,

Transmission

BCK UP Back-Up Lamps

TRUNK/ HTD

SEATS Trunk, Heated Seats

Blank Blank

Blank Blank

SDM Sensing Diagnostic Module (Airbags)

ABS3 Antilock Brake System 3

OUTLET Auxiliary Power Outlet

MIR Mirrors

DLC Data Link Connector

CNSTR VENT Canister Vent

6-107

Page 379 of 422

Additional Required Services

At Each Fuel Stop•

Engine oil level check. See Engine Oil on page 6-13.

•Engine coolant level check. See Engine Coolant on

page 6-24.

•Windshield washer fluid level check. See Windshield

Washer Fluid on page 6-28 .

Once a Month

•

Tire inflation check. See In�ation - Tire Pressure on

page 6-55.

•Tire wear inspection. See Tire Inspection and

Rotation on page 6-62 .

Once a Year

•

Starter switch check. See Owner Checks and

Services on page 7-8 .

•Parking brake and automatic transmission P (Park)

mechanism check. See Owner Checks and

Services on page 7-8 .

•Automatic transmission shiftlock control system

check. SeeOwner Checks and Services on

page 7-8.

•Ignition transmission lock check. See Owner

Checks and Services on page 7-8 .

•Engine cooling system and pressure cap pressure

check. Radiator and air conditioning condenser

outside cleaning. SeeCooling System on

page 6-20.

•Exhaust system and nearby heat shields inspection

for loose or damaged components.

•Throttle system inspection for interference, binding

or for damaged or missing parts. Replace parts as

needed. Replace any components that have

high effort or excessive wear. Do not lubricate

accelerator or cruise control cables.

•If the vehicle has a Tire Sealant and Compressor

Kit, check the sealant expiration date printed on

the instruction label of the kit. See Tire Sealant and

Compressor Kit on page 6-72 .

First Engine Oil Change After Every

40 000 km/25,000 Miles

•

Fuel system inspection for damage or leaks.

7-5

Page 382 of 422

Owner Checks and Services

Starter Switch Check

{WARNING:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough room around the vehicle.

2. Firmly apply both the parking brake and the regular brake. See Parking Brake on page 3-29 .

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. For automatic transmission vehicles, try to start the engine in each gear. The starter should work only

in P (Park) or N (Neutral). If the starter works in any

other position, your vehicle needs service.

For manual transmission vehicles, put the shift lever

in Neutral, push the clutch pedal down halfway, and

try to start the engine. The starter should work only

when the clutch pedal is pushed down all the way to

the floor. If the starter works when the clutch pedal is

not pushed all the way down, your vehicle needs

service.

Automatic Transmission Shift Lock

Control System Check

{WARNING:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough room around the vehicle. It should be parked on a

level surface.

2. Firmly apply the parking brake. See Parking Brake

on page 3-29.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the ignition to ON/RUN, but do not start the engine. Without applying the

regular brake, try to move the shift lever out

of P (Park) with normal effort. If the shift lever

moves out of P (Park), contact your dealer/retailer

for service.

7-8