axle PONTIAC VIBE 2005 Workshop Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 2005, Model line: VIBE, Model: PONTIAC VIBE 2005Pages: 374, PDF Size: 2.49 MB

Page 338 of 374

At Least Twice a Year

Restraint System Check

Make sure the safety belt reminder light and all your belts,

buckles, latch plates, retractors and anchorages are

working properly. Look for any other loose or damaged

safety belt system parts. If you see anything that might

keep a safety belt system from doing its job, have it

repaired. Have any torn or frayed safety belts replaced.

Also look for any opened or broken air bag coverings,

and have them repaired or replaced. (The air bag

system does not need regular maintenance.)

Wiper Blade Check

Inspect wiper blades for wear or cracking. Replace

blade inserts that appear worn or damaged or that

streak or miss areas of the windshield. Also see

Windshield, Backglass, and Wiper Blades on page 5-91.

Weatherstrip Lubrication

Silicone grease on weatherstrips will make them last

longer, seal better, and not stick or squeak. Apply

silicone grease with a clean cloth. During very cold,

damp weather more frequent application may be

required. SeePart D: Recommended Fluids and

Lubricants on page 6-19.

Fluid Level Check

Check the power steering pump and automatic or manual

transaxle �uid levels and add as needed. SeePower

Steering Fluid on page 5-37andAutomatic Transaxle

Fluid on page 5-23orManual Transaxle Fluid on

page 5-26. Check for leaks. A �uid loss in these systems

could indicate a problem. Have the system inspected and

repaired at once.

At Least Once a Year

Key Lock Cylinders Service

Lubricate the key lock cylinders with the lubricant

speci�ed in Part D.

Seat Operation Check

Make sure the head restraints stay in position and all

seat latches lock. Check that the recliner holds by

pushing and pulling the seatback while it is reclined.

Body Lubrication Service

Lubricate all hood latch assembly, secondary latch,

pivots, spring anchor, release pawl, hood and body door

hinges, rear compartment and any folding seat

hardware. Part D tells you what to use. More frequent

lubrication may be required when exposed to a corrosive

environment.

6-14

Page 339 of 374

Starter Switch Check

{CAUTION:

When you are doing this inspection, the

vehicle could move suddenly. If the vehicle

moves, you or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. SeeParking Brake on page 2-28if necessary.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. On automatic transaxle vehicles, try to start the

engine in each gear. The starter should work only in

PARK (P) or NEUTRAL (N). If the starter works in

any other position, your vehicle needs service.

On manual transaxle vehicles, put the shift lever in

NEUTRAL (N), push the clutch down halfway and try

to start the engine. The starter should work only

when the clutch is pushed down all the way to the

�oor. If the starter works when the clutch is not

pushed all the way down, your vehicle needs service.

Automatic Transaxle Shift Lock Control

System Check

{CAUTION:

When you are doing this inspection, the

vehicle could move suddenly. If the vehicle

moves, you or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle. It should be parked on a level

surface.

2. Firmly apply the parking brake. SeeParking Brake

on page 2-28if necessary.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the ignition to ON, but do

not start the engine. Without applying the regular

brake, try to move the shift lever out of PARK (P)

with normal effort. If the shift lever moves out

of PARK (P), your vehicle needs service.

6-15

Page 340 of 374

Ignition Transaxle Lock Check

While parked, and with the parking brake set, try to turn

the ignition to LOCK in each shift lever position.

With an automatic transaxle, the ignition should turn

to LOCK only when the shift lever is in PARK (P).

With a manual transaxle, the ignition should turn to

LOCK only if you push the key in farther, while

turning it toward LOCK.

Parking Brake and Automatic Transaxle

Park (P) Mechanism Check

{CAUTION:

When you are doing this check, your vehicle

could begin to move. You or others could be

injured and property could be damaged. Make

sure there is room in front of your vehicle in

case it begins to roll. Be ready to apply the

regular brake at once should the vehicle begin

to move.Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake, set the

parking brake.

To check the parking brake’s holding ability: With

the engine running and transaxle in NEUTRAL (N),

slowly remove foot pressure from the regular

brake pedal. Do this until the vehicle is held by the

parking brake only.

To check the PARK (P) mechanism’s holding

ability: With the engine running, shift to PARK (P).

Then release the parking brake followed by the

regular brake.

Underbody Flushing Service

At least every spring, use plain water to �ush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other debris

can collect.

6-16

Page 341 of 374

Part C: Periodic Maintenance

Inspections

Listed in this part are inspections and services which

should be performed at least twice a year (for instance,

each spring and fall).You should let your dealer’s

service department do these jobs. Make sure any

necessary repairs are completed at once.

Proper procedures to perform these services may be

found in a service manual. SeeService Publications

Ordering Information on page 7-11.

Steering, Suspension and Front

Drive Axle Boot and Seal Inspection

Inspect the front and rear suspension and steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

lines and hoses for proper hook-up, binding, leaks,

cracks, cha�ng, etc. Clean and then inspect the drive

axle boot seals for damage, tears or leakage. Replace

seals if necessary.

Exhaust System Inspection

Inspect the complete exhaust system. Inspect the body

near the exhaust system. Look for broken, damaged,

missing or out-of-position parts as well as open seams,

holes, loose connections or other conditions which

could cause a heat build-up in the �oor pan or could let

exhaust fumes into the vehicle. SeeEngine Exhaust

on page 2-32.

Fuel System Inspection

Inspect the complete fuel system for damage or leaks.

6-17

Page 343 of 374

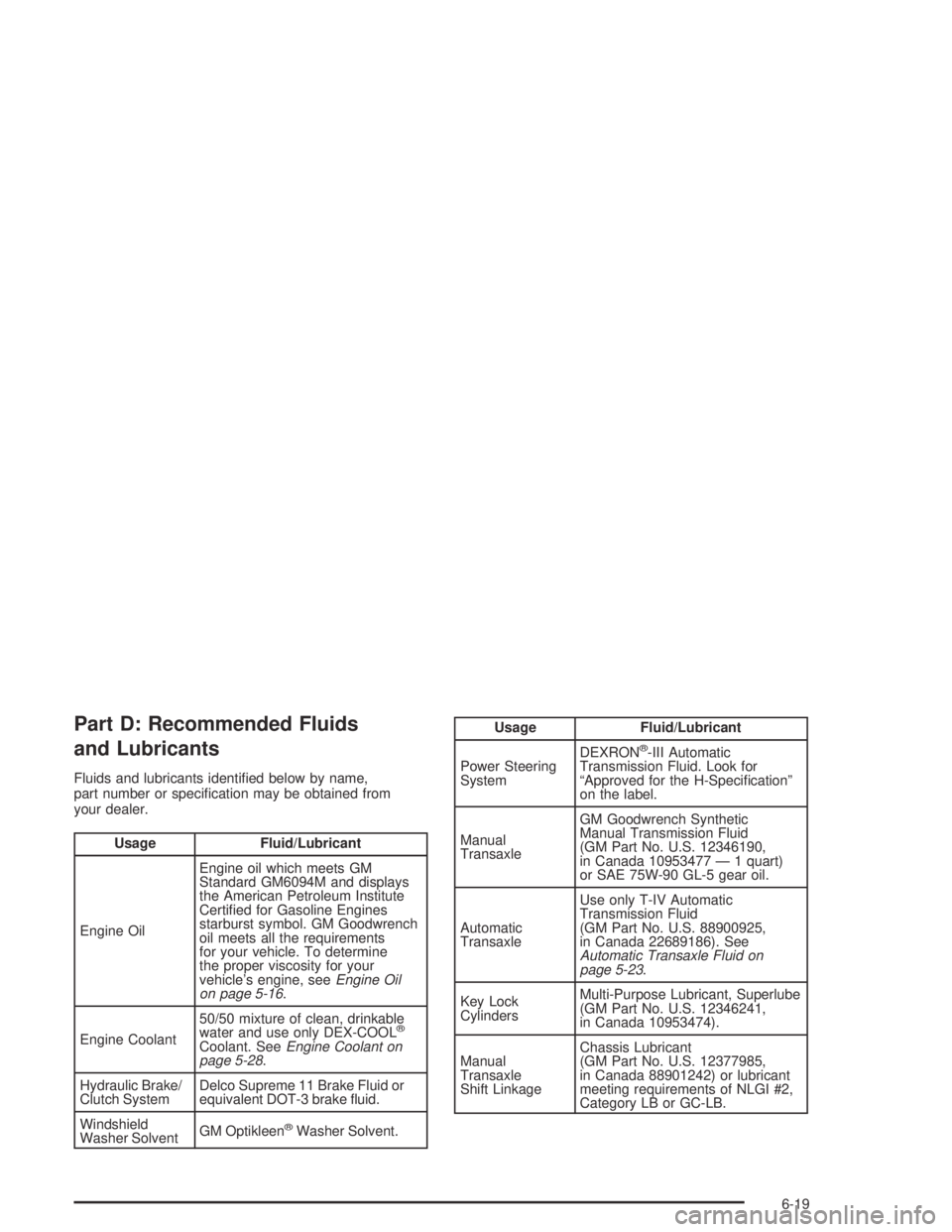

Part D: Recommended Fluids

and Lubricants

Fluids and lubricants identi�ed below by name,

part number or speci�cation may be obtained from

your dealer.

Usage Fluid/Lubricant

Engine OilEngine oil which meets GM

Standard GM6094M and displays

the American Petroleum Institute

Certi�ed for Gasoline Engines

starburst symbol. GM Goodwrench

oil meets all the requirements

for your vehicle. To determine

the proper viscosity for your

vehicle’s engine, seeEngine Oil

on page 5-16.

Engine Coolant50/50 mixture of clean, drinkable

water and use only DEX-COOL

®

Coolant. SeeEngine Coolant on

page 5-28.

Hydraulic Brake/

Clutch SystemDelco Supreme 11 Brake Fluid or

equivalent DOT-3 brake �uid.

Windshield

Washer SolventGM Optikleen

®Washer Solvent.

Usage Fluid/Lubricant

Power Steering

SystemDEXRON

®-III Automatic

Transmission Fluid. Look for

“Approved for the H-Speci�cation”

on the label.

Manual

TransaxleGM Goodwrench Synthetic

Manual Transmission Fluid

(GM Part No. U.S. 12346190,

in Canada 10953477 — 1 quart)

or SAE 75W-90 GL-5 gear oil.

Automatic

TransaxleUse only T-IV Automatic

Transmission Fluid

(GM Part No. U.S. 88900925,

in Canada 22689186). See

Automatic Transaxle Fluid on

page 5-23.

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Manual

Transaxle

Shift LinkageChassis Lubricant

(GM Part No. U.S. 12377985,

in Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

6-19

Page 344 of 374

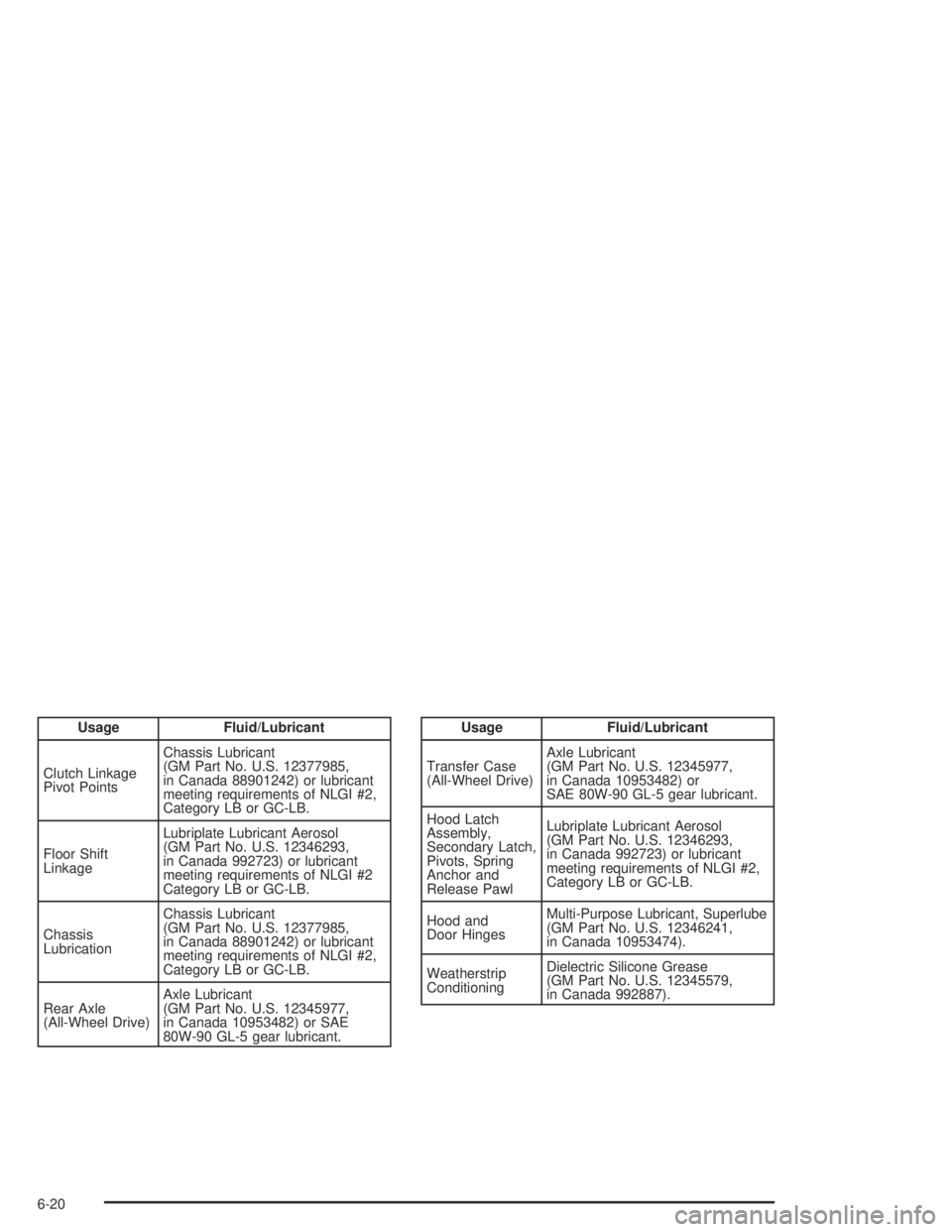

Usage Fluid/Lubricant

Clutch Linkage

Pivot PointsChassis Lubricant

(GM Part No. U.S. 12377985,

in Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Floor Shift

LinkageLubriplate Lubricant Aerosol

(GM Part No. U.S. 12346293,

in Canada 992723) or lubricant

meeting requirements of NLGI #2

Category LB or GC-LB.

Chassis

LubricationChassis Lubricant

(GM Part No. U.S. 12377985,

in Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Rear Axle

(All-Wheel Drive)Axle Lubricant

(GM Part No. U.S. 12345977,

in Canada 10953482) or SAE

80W-90 GL-5 gear lubricant.Usage Fluid/Lubricant

Transfer Case

(All-Wheel Drive)Axle Lubricant

(GM Part No. U.S. 12345977,

in Canada 10953482) or

SAE 80W-90 GL-5 gear lubricant.

Hood Latch

Assembly,

Secondary Latch,

Pivots, Spring

Anchor and

Release PawlLubriplate Lubricant Aerosol

(GM Part No. U.S. 12346293,

in Canada 992723) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Hood and

Door HingesMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Weatherstrip

ConditioningDielectric Silicone Grease

(GM Part No. U.S. 12345579,

in Canada 992887).

6-20

Page 359 of 374

Reporting Safety Defects to the

Canadian Government

If you live in Canada, and you believe that your vehicle

has a safety defect, you should immediately notify

Transport Canada, in addition to notifying General

Motors of Canada Limited. You may write to:

Transport Canada

330 Sparks Street

Tower C

Ottawa, Ontario K1A 0N5

Reporting Safety Defects to

General Motors

In addition to notifying NHTSA (or Transport Canada) in

a situation like this, we certainly hope you’ll notify us.

Please call us at 1-800-762-2737, or write:

Pontiac Customer Assistance Center

P.O. Box 33172

Detroit, MI 48232-5172

In Canada, please call us at 1-800-263-3777 (English)

or 1-800-263-7854 (French). Or, write:

General Motors of Canada Limited

Customer Communication Centre, 163-005

1908 Colonel Sam Drive

Oshawa, Ontario L1H 8P7

Service Publications Ordering

Information

Service Manuals

Service Manuals have the diagnosis and repair

information on engines, transmission, axle, suspension,

brakes, electrical, steering, body, etc.

RETAIL SELL PRICE: $120.00

Transmission, Transaxle, Transfer

Case Unit Repair Manual

This manual provides information on unit repair service

procedures, adjustments, and speci�cations for GM

transmissions, transaxles, and transfer cases.

RETAIL SELL PRICE: $50.00

Service Bulletins

Service Bulletins give technical service information

needed to knowledgeably service General Motors cars

and trucks. Each bulletin contains instructions to

assist in the diagnosis and service of your vehicle.

In Canada, information pertaining to Product Service

Bulletins can be obtained by contacting your General

Motors dealer or by calling 1-800-GM-DRIVE

(1-800-463-7483).

7-11

Page 362 of 374

Audio System(s).............................................3-42

Care of Your CD Player...............................3-65

Care of Your CDs........................................3-64

Fixed Mast Antenna.....................................3-65

Navigation/Radio System..............................3-64

Radio with CD............................................3-43

Radio with Six-Disc CD................................3-53

Setting the Time..........................................3-42

Understanding Radio Reception.....................3-64

XM™ Satellite Radio Antenna System............3-65

Automatic Headlamp System............................3-15

Automatic Transaxle

Fluid..........................................................5-23

Operation...................................................2-22

B

Battery..........................................................5-42

Before Leaving on a Long Trip.........................4-23

Brake

Anti-Lock Brake System (ABS)........................ 4-7

Emergencies................................................ 4-9

Panic Assist................................................4-11

Parking......................................................2-28

System Inspection.......................................6-18

System Warning Light..................................3-32Brakes..........................................................5-39

Braking........................................................... 4-6

Braking in Emergencies..................................... 4-9

Break-In, New Vehicle.....................................2-17

Bulb Replacement...........................................5-49

Back-Up Lamps...........................................5-54

Center High-Mounted Stoplamp (CHMSL)........5-51

Halogen Bulbs............................................5-49

Headlamps, Front Turn Signal, and

Parking Lamps.........................................5-49

Replacement Bulbs......................................5-55

Taillamps, Turn Signal, and Stoplamps............5-53

Buying New Tires...........................................5-70

C

California Fuel.................................................. 5-6

Canadian Owners................................................ ii

Capacities and Speci�cations..........................5-100

Carbon Monoxide...................2-11, 2-32, 4-26, 4-40

Care of

Safety Belts................................................5-90

Your CD Player...........................................3-65

Your CDs ...................................................3-64

Cargo Cover..................................................2-39

2

Page 365 of 374

E

Electrical System

Add-On Equipment......................................5-95

Engine Compartment Fuse Block...................5-98

Fuses and Circuit Breakers...........................5-96

Headlamp Wiring.........................................5-96

Instrument Panel Fuse Block.........................5-97

Power Windows and Other Power Options......5-96

Windshield Wiper Fuses...............................5-96

Engine

Air Cleaner/Filter.........................................5-21

Battery.......................................................5-42

Check and Service Engine Soon Light............3-35

Coolant......................................................5-28

Coolant Heater............................................2-21

Coolant Temperature Gage...........................3-35

Cooling System Inspection............................6-18

Engine Compartment Overview......................5-12

Exhaust.....................................................2-32

Oil .............................................................5-16

Overheating................................................5-30

Starting......................................................2-19

Entry Lighting.................................................3-16

Event Data Recorders (EDR)............................. 7-9

Extender, Safety Belt.......................................1-25

Exterior Lamps...............................................3-13

F

Filter

Engine Air Cleaner......................................5-21

Finish Damage...............................................5-93

Fixed Mast Antenna........................................3-65

Flash-to-Pass................................................... 3-8

Flat Tire........................................................5-74

Flat Tire, Changing.........................................5-75

Flat Tire, Storing.............................................5-84

Floor Mats.....................................................2-38

Fluid

Automatic Transaxle.....................................5-23

Manual Transaxle........................................5-26

Power Steering...........................................5-37

Windshield Washer......................................5-38

Fog Lamps....................................................3-15

Folding Seatback, Passenger............................. 1-5

Fuel............................................................... 5-5

Additives...................................................... 5-6

California Fuel.............................................. 5-6

Filling a Portable Fuel Container..................... 5-9

Filling Your Tank........................................... 5-7

Fuels in Foreign Countries.............................. 5-7

Gage.........................................................3-41

Gasoline Octane........................................... 5-5

5

Page 367 of 374

I

Ignition Positions.............................................2-18

Infants and Young Children, Restraints...............1-28

In�ation -- Tire Pressure..................................5-64

Inspection

Brake System.............................................6-18

Engine Cooling System................................6-18

Exhaust System..........................................6-17

Fuel System...............................................6-17

Part C - Periodic Maintenance.......................6-17

Steering, Suspension and Front Drive Axle

Boot and Seal.........................................6-17

Throttle System...........................................6-18

Instrument Panel

Brightness..................................................3-15

Cluster.......................................................3-26

Overview..................................................... 3-4

Storage Area..............................................2-37

Interior Lamps Control.....................................3-16

J

Jump Starting.................................................5-43

K

Keyless Entry System....................................... 2-4

Keys............................................................... 2-2

L

Labelling, Tire Sidewall....................................5-58

Lamps

Exterior......................................................3-13

Fog ...........................................................3-15

Interior Control............................................3-16

Reading.....................................................3-17

LATCH System

Child Restraints...........................................1-38

Securing a Child Restraint Designed for

the LATCH System...................................1-39

Liftgate/Liftglass..............................................2-11

Liftglass/Liftgate..............................................2-11

Light

Airbag Readiness........................................3-29

Anti-Lock Brake System Warning...................3-33

Brake System Warning.................................3-32

Charging System.........................................3-31

Cruise Control.............................................3-39

Door Ajar...................................................3-40

7