floor Ram 1500 2013 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2013, Model line: 1500, Model: Ram 1500 2013Pages: 734, PDF Size: 5.47 MB

Page 348 of 734

WARNING!(Continued)

•If the vehicle has a discharged battery, booster

cables may be used to obtain a start from a booster

battery or the battery in another vehicle. This type

of start can be dangerous if done improperly. Refer

to “Jump Starting” in “What To Do In Emergen-

cies” for further information.

If the engine has been flooded, it may start to run, but not

have enough power to continue running when the key

fob is released. If this occurs, continue cranking with the

accelerator pedal pushed all the way to the floor. Release

the accelerator pedal and the key fob once the engine is

running smoothly.

If the engine shows no sign of starting after two 15-

second periods of cranking with the accelerator pedal

held to the floor, the “Normal Starting” procedure should

be repeated.

After Starting

The idle speed is controlled automatically and it will

decrease as the engine warms up.

STOP/START SYSTEM — IF EQUIPPED

The Stop/Start function is developed to save fuel and

reduce emissions. The system will stop the engine auto-

matically during a vehicle stop if the required conditions

are met. Releasing the brake pedal will automatically

re-start the vehicle.

Automatic Mode

The Stop/Start feature is enabled after every normal

customer engine start. It will remain in STOP/START

NOT READY until you drive forward with a vehicle

speed greater than 5 mph (8 km/h). At that time, the

system will go into STOP/START READY and if all other

conditions are met, can go into an STOP/START AUTO

STOP ACTIVE “Autostop” mode.

346 STARTING AND OPERATING

Page 440 of 734

recover the vehicle, there is a high risk of environmen-

tal or vehicle damage, or where nothing else seems to

work. A winch can deliver a high pulling force with a

great deal of control. It allows you to walk the vehicle

out of the situation in a slow controlled manner. This

control works well for avoiding further vehicle dam-

age. Once you decide it is time to use the winch look

for a good anchor point. It needs to be strong enough

to hold more than the vehicle’s weight and provide a

direction of pull as straight as possible. Use block and

tackle if necessary to improve the angle of pull or

increase the winch’s pulling force. If the anchor point

is a tree use a strap around its base and hook the cable

to the strap. If it is another vehicle, then place that

vehicle in PARK and block the front tires. If you cannot

find an anchor point within reach try using your spare

tire by burying it. Once you have determined an

anchor point hook up the cable, ensuring there are a

least five wraps of cable left on the drum, and place a

floor mat or something else over the strung out cable.Placing something over the strung out cable helps

keep the cable on the ground if it breaks. Next, place

the vehicle in first gear and apply a very light throttle

as you power the winch in. Be careful not to allow

slack in the cable as you recover the vehicle. Do not try

to guide the cable into the drum. If it starts to bunch up

on one end, let it. You can re-spool the cable after-

wards. Never use a winch cable as a tow strap and

always stand back while winching.

WARNING!

Winch cables are under high tension when in use and

can become a projectile if they fail. Never stand over

or straddle the winch cable. Never jerk or overload

the winch cable. Never stand in front of the vehicle

while winching. Failure to follow these instructions

can result in serious or fatal injury.

438 STARTING AND OPERATING

Page 573 of 734

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located on the

upper switch bank just below the radio.Press the switch to turn on the Hazard Warning

flasher. When the switch is activated, all direc-

tional turn signals will flash on and off to warn oncoming

traffic of an emergency. Press the switch a second time to

turn off the Hazard Warning flashers.

This is an emergency warning system and it should not

be used when the vehicle is in motion. Use it when your

vehicle is disabled and it is creating a safety hazard for

other motorists.

When you must leave the vehicle to seek assistance, the

Hazard Warning flashers will continue to operate even

though the ignition is placed in the OFF position.

NOTE: With extended use the Hazard Warning flashers

may wear down your battery.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can reduce the

potential for overheating by taking the appropriate ac-

tion.

• On the highways — slow down.

• In city traffic — while stopped, place the transmission

in NEUTRAL, but do not increase the engine idle

speed.

NOTE: There are steps that you can take to slow down

an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off. The A/C

system adds heat to the engine cooling system and

turning the A/C off can help remove this heat.

• You can also turn the temperature control to maximum

heat, the mode control to floor and the blower control

to high. This allows the heater core to act as a

6

WHAT TO DO IN EMERGENCIES 571

Page 590 of 734

Reinstalling The Jack And Tools (1500 Series)

1. Tighten the jack all the way down by turning the jackturn-screw counterclockwise until the jack is snug.

2. Position the jack and tool bag. Make sure the lug wrench is under the jack near the jack turn-screw. 3. Secure the tool bag straps to the jack.

4. Place the jack and tools in the storage position holding

the jack by the jack turn-screw, slip the jack and tools

under the seat so that the bottom slot engages into the

fastener on the floor.

Jack And Tool Bag

Jack And Tools Tied

588 WHAT TO DO IN EMERGENCIES

Page 591 of 734

NOTE:Ensure that the jack slides into the front hold

down location.

5. Turn the wing bolt clockwise to secure to the floor pan. Reinstall the plastic cover.WARNING!

After using the jack and tools, always reinstall them

in the original carrier and location. While driving

(Continued)

Jack Hold Down FastenerJack And Tools (1500 Series)6

WHAT TO DO IN EMERGENCIES 589

Page 608 of 734

Reinstalling The Jack And Tools (2500 And 3500

Series)

1. Tighten the jack all the way down by turning the jackturn-screw counterclockwise until the jack is snug.

2. Position the jack and tools into bracket assembly. Make sure the lug wrench is under the jack near the

jack turn-screw. Snap tools into bracket assembly clips.

Install the jack into bracket assembly and turn the

jack-turn-screw clockwise until jack is snug into

bracket assembly.

3. Place the jack and tool bracket assembly in the storageposition holding the jack by the jack turn-screw, slip

the jack and tools under the seat so that the bottom slot

engages into the fastener on the floor.

Jack And Tools Bracket Assembly

606 WHAT TO DO IN EMERGENCIES

Page 609 of 734

NOTE:Ensure that the jack and tool bracket assembly

slides into the front hold down location.

4. Turn the wing bolt clockwise to secure to the floor pan. Reinstall the plastic cover.Hub Caps/Wheel Covers — If Equipped

The hub caps must be removed before raising the vehicle

off the ground.

Jack Hold Down FastenerJack And Tools (2500/3500 Series)6

WHAT TO DO IN EMERGENCIES 607

Page 613 of 734

These dual rear wheels should be tightened as follows:

1. Tighten the wheel nuts in the numbered sequence to asnug fit.

2. Retighten the wheel nuts in the same sequence to the torques listed in the table. Go through the sequence a second time to verify that specific torque has been

achieved. Retighten to specifications at 100 miles

(160 km) and after 500 miles (800 km).

It is recommended that wheel stud nuts be kept torqued

to specifications at all times. Torque wheel stud nuts to

specifications at each lubrication interval.

HOISTING

A conventional floor jack may be used at the jacking

locations. Refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts of the underbody.

CAUTION!

Never use a floor jack directly under the differential

housing of a loaded truck or damage to your vehicle

may result.

Tightening Pattern

6

WHAT TO DO IN EMERGENCIES 611

Page 670 of 734

Spray-On Bedliners are chemically-resistant to many

different types of chemicals (including gasoline, oil,

hydraulic fluids) for short periods of time. If a spill

occurs on your Spray-On Bedliner, rinse the truck out as

soon as possible to avoid permanent damage.

Repairing The Spray-On Bedliner

While extremely tough, it is possible to damage a

Spray-On Bedliner. One common condition is when

loading a heavy pallet and dragging that pallet across the

floor of the bed. If a nail or sharp point is exposed under

the weight of the pallet a scratch or tear is possible. While

not covered by your new vehicle warranty, a cosmetic fix

to cover the metal exposed by the scratch is required. To

repair a tear or gouge, follow the directions provided in

the MOPAR® Quick Repair Kit.FUSES

POWER DISTRIBUTION CENTER

The Power Distribution Center is located in the engine

compartment near the battery. This center contains car-

tridge fuses, micro fuses, relays, and circuit breakers. A

description of each fuse and component may be stamped

on the inside cover, otherwise the cavity number of each

fuse is stamped on the inside cover that corresponds to

the following chart.

668 MAINTAINING YOUR VEHICLE

Page 721 of 734

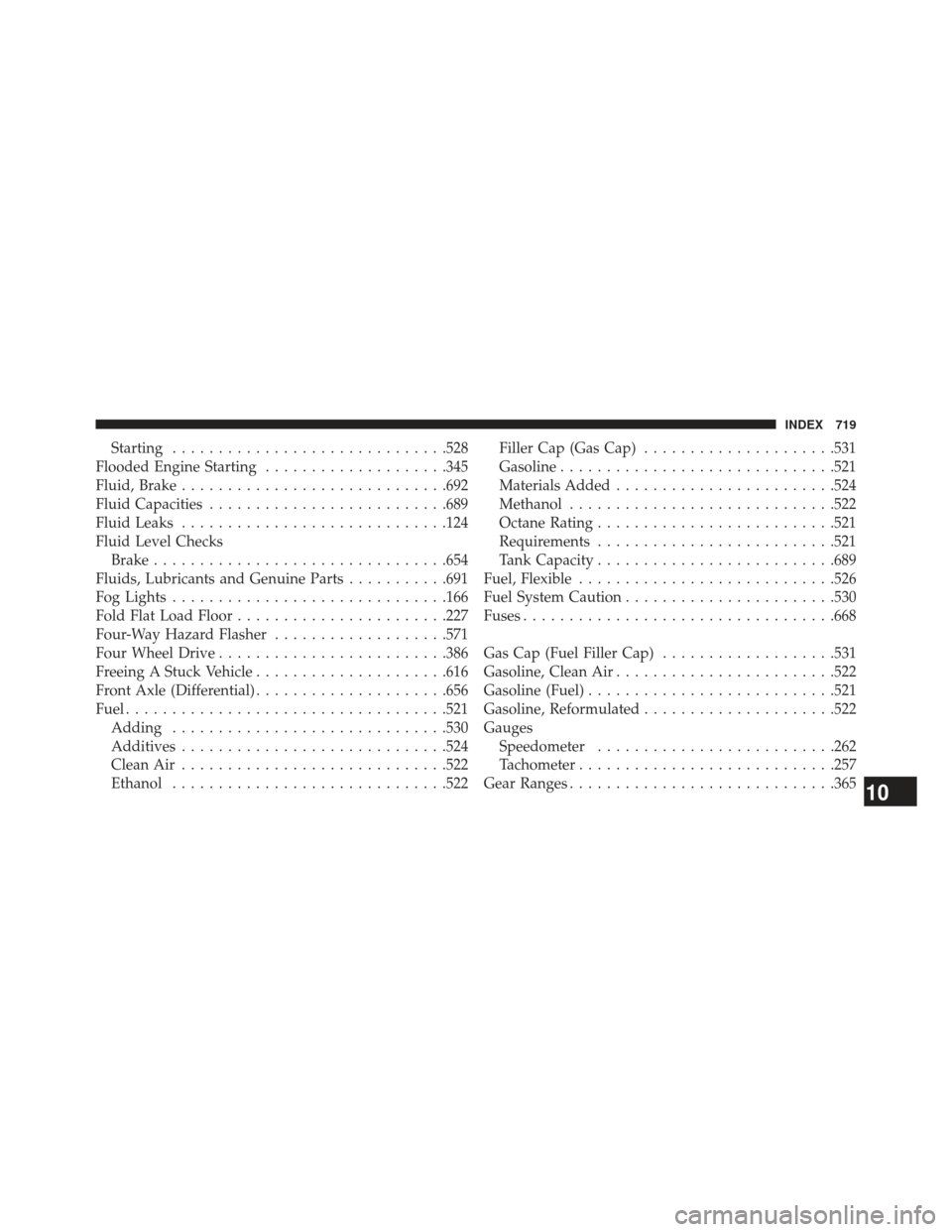

Starting............................. .528

Flooded Engine Starting ....................345

Fluid, Brake ............................ .692

Fluid Capacities ......................... .689

Fluid Leaks ............................ .124

Fluid Level Checks Brake ............................... .654

Fluids, Lubricants and Genuine Parts ...........691

Fog Lights ............................. .166

Fold Flat Load Floor ...................... .227

Four-Way Hazard Flasher ...................571

Four Wheel Drive ........................ .386

Freeing A Stuck Vehicle .....................616

Front Axle (Differential) .....................656

Fuel .................................. .521

Adding ............................. .530

Additives ............................ .524

Clean Air ............................ .522

Ethanol ............................. .522Filler Cap (Gas Cap)

.....................531

Gasoline ............................. .521

Materials Added ....................... .524

Methanol ............................ .522

Octane Rating ......................... .521

Requirements ......................... .521

Tank Capacity ......................... .689

Fuel, Flexible ........................... .526

Fuel System Caution ...................... .530

Fuses ................................. .668

Gas Cap (Fuel Filler Cap) ...................531

Gasoline, Clean Air ....................... .522

Gasoline (Fuel) .......................... .521

Gasoline, Reformulated .....................522

Gauges Speedometer ......................... .262

Tachometer ........................... .257

Gear

Ranges ............................ .365

10

INDEX 719