back Ram 1500 2015 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: 1500, Model: Ram 1500 2015Pages: 871, PDF Size: 24.83 MB

Page 729 of 871

Hub Caps/Wheel Covers — If Equipped

The hub caps must be removed before raising the vehicle

off the ground.

CAUTION!

Use extreme caution when removing the front and

rear center caps. Damage can occur to the center cap

and/or the wheel if screwdriver type tools are used. A

pulling motion, not a pry off motion, is recom-

mended to remove the caps.

For single rear wheel (SRW) models, use the flat blade on

the end of the lug wrench to pull the hub cap off. Insert

the blade end into the pull off notch and carefully pull the

hub cap off with a back and forth motion.

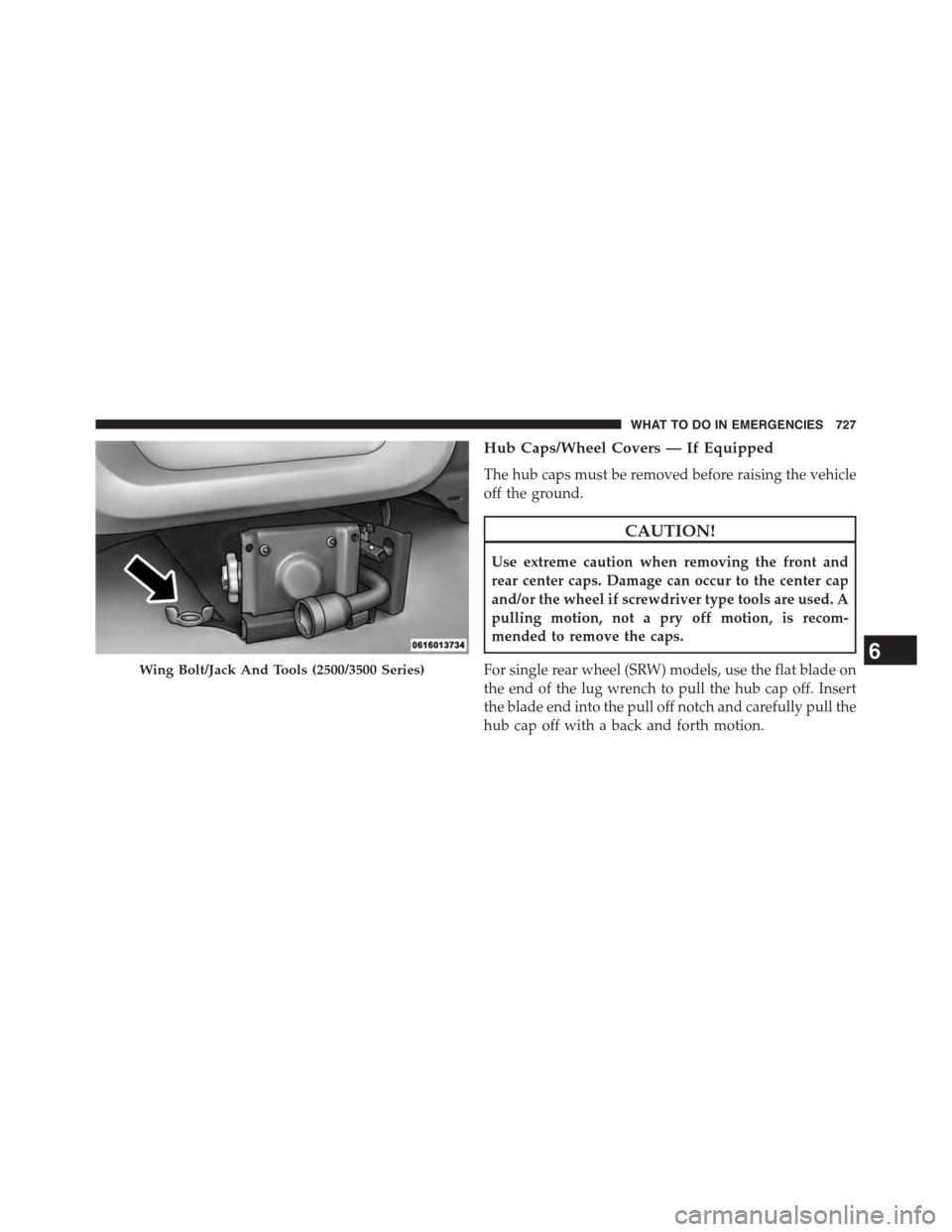

Wing Bolt/Jack And Tools (2500/3500 Series)6

WHAT TO DO IN EMERGENCIES 727

Page 730 of 871

On 3500 models with dual rear wheels (DRW), you must

first remove the hub caps. The jack handle driver has a

hook at one end that will fit in the pull off notch of the

rear hub caps. Position the hook and pull straight out on

the ratchet firmly. The hub cap should pop off. The wheel

skins can now be removed. For the front hub cap, use the

flat blade on the end of the lug wrench to pull the caps

off. The wheel skin can now be removed.

CAUTION!

•Use a pulling motion to remove the hub cap. Do not

use a twisting motion when removing the hub cap,

damage to the hub cap; finish may occur.

•The rear hub caps on the dual rear wheel has two

pull off notches. Make sure that the hook of the

jack handle driver is located squarely in the cap

notch before attempting to pull off.

You must use the flat end of the lug wrench to pull off the

wheel skins. Locate the hub cap pull notches (2 notches

on each cap). Insert the flat tip completely and using a

back and forth motion, loosen the wheel skin. Repeat this

procedure around the tire until the skin pops off.

Replace the wheel skins first using a rubber mallet. When

replacing the hub caps, tilt the cap retainer over the lug

nut bolt circle and strike the high side down with a

rubber mallet. Be sure that the hub caps and wheel skins

are firmly seated around the wheel.

HOISTING

A conventional floor jack may be used at the jacking

locations. Refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts of the underbody.

728 WHAT TO DO IN EMERGENCIES

Page 736 of 871

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or snow, it

can often be moved using a rocking motion. Turn the

steering wheel right and left to clear the area around the

front wheels. Then shift back and forth between DRIVE

and REVERSE (with automatic transmission) or 2nd gear

and REVERSE (with manual transmission), while gently

pressing the accelerator. Use the least amount of accel-

erator pedal pressure that will maintain the rocking

motion, without spinning the wheels or racing the en-

gine.

NOTE:For trucks equipped with 8-speed automatic

transmission: Shifts between DRIVE and REVERSE can

only be achieved at wheel speeds of 5 mph (8 km/h) or

less. Whenever the transmission remains in NEUTRAL

for more than two seconds, you must press the brake

pedal to engage DRIVE or REVERSE.

CAUTION!

Racing the engine or spinning the wheels may lead to

transmission overheating and failure. Allow the en-

gine to idle with the transmission in NEUTRAL for at

least one minute after every five rocking-motion

cycles. This will minimize overheating and reduce

the risk of transmission failure during prolonged

efforts to free a stuck vehicle.

NOTE:Press the#ESC Off#switch, to place the Electronic

Stability Control (ESC) system in#Partial Off#mode,

before rocking the vehicle. Refer to “Electronic Brake

Control” in “Starting And Operating” for further infor-

mation. Once the vehicle has been freed, press the#ESC

Off#switch again to restore#ESC On#mode.

734 WHAT TO DO IN EMERGENCIES

Page 748 of 871

▫Adding Washer Fluid..................771

▫Exhaust System......................772

▫Cooling System......................774

▫Brake System........................782

▫Rear Axle And 4x4 Front Driving Axle Fluid

Level..............................784

▫Transfer Case........................785

▫Automatic Transmission................786

▫Appearance Care And Protection From

Corrosion...........................790

!FUSES..............................797

▫Power Distribution Center...............798

!VEHICLE STORAGE....................807

!REPLACEMENT BULBS.................808

!BULB REPLACEMENT..................809

▫Base Quad / Premium Bi-Halogen: Low Beam

Headlamp, High Beam Headlamp, Front Park

And Turn — If Equipped...............810

▫Fog Lamps — If Equipped..............812

▫Rear Tail/Stop, Turn Signal And Backup Lamps

..................................812

▫Center High-Mounted Stoplamp (CHMSL) With

Cargo Lamp.........................814

▫Cab Top Clearance Lamps — If Equipped . . . .816

▫Rear Lamp Bar ID Marker (Dual Rear Wheels) —

If Equipped..........................817

▫Side Marker Lamps (Dual Rear Wheels) —

If Equipped.........................818

746 MAINTAINING YOUR VEHICLE

Page 761 of 871

Engine Air Cleaner Filter

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

WARNING!

The air induction system (air cleaner, hoses, etc.) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

cleaner, hoses, etc.) unless such removal is necessary

for repair or maintenance. Make sure that no one is

near the engine compartment before starting the

vehicle with the air induction system (air cleaner,

hoses, etc.) removed. Failure to do so can result in

serious personal injury.

Engine Air Cleaner Filter Selection

The quality of replacement engine air cleaner filters

varies considerably. Only high quality filters should be

used to assure most efficient service. MOPAR® engine air

cleaner filters are a high quality filter and are recom-

mended.

Engine Air Cleaner Filter Inspection and

Replacement

Inspect engine air cleaner filter for dirt and or debris, if

you find evidence of either dirt or debris you should

change your air cleaner filter.

7

MAINTAINING YOUR VEHICLE 759

Page 770 of 871

The wiper blades and wiper arms should be inspected

periodically, not just when wiper performance problems

are experienced. This inspection should include the fol-

lowing points:

•Wear Or Uneven Edges

•Foreign Material

•Hardening Or Cracking

•Deformation Or Fatigue

If a wiper blade or wiper arm is damaged, replace the

affected wiper arm or blade with a new unit. Do not

attempt to repair a wiper arm or blade that is damaged.

Wiper Blade Removal/Installation

CAUTION!

Do not allow the wiper arm to spring back against

the glass without the wiper blade in place or the glass

may be damaged.

1. Lift the wiper arm to raise the wiper blade off of the

glass, until the wiper arm is in the full up position.

768 MAINTAINING YOUR VEHICLE

Page 777 of 871

Engine Coolant Checks

Check the engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If the engine coolant (antifreeze) is dirty or

rusty in appearance, the system should be drained,

flushed and refilled with fresh coolant. Check the front of

the A/C condenser (if equipped) or radiator for any

accumulation of bugs, leaves, etc. If dirty, clean by gently

spraying water from a garden hose vertically down the

face of the A/C condenser (if equipped) or the back of the

radiator core.

Check the engine cooling system hoses for brittle rubber,

cracking, tears, cuts and tightness of the connection at the

coolant recovery bottle and radiator. Inspect the entire

system for leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

engine coolant (antifreeze) from the radiator drain cock.

The radiator drain cock is located in the lower radiator

tank. If the cap is sealing properly, the engine coolant

(antifreeze) will begin to drain from the coolant expan-

sion bottle. DO NOT REMOVE THE COOLANT PRES-

SURE CAP WHEN THE COOLING SYSTEM IS HOT.

Cooling System — Drain Flush And Refill

If the engine coolant (antifreeze) is dirty or contains a

considerable amount of sediment, clean and flush with a

reliable cooling system cleaner. Follow with a thorough

rinsing to remove all deposits and chemicals. Properly

dispose of old engine coolant (antifreeze).

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

7

MAINTAINING YOUR VEHICLE 775

Page 791 of 871

NOTE:If it is necessary to check the transmissionbelow

the operating temperature, the fluid level should be

between the two “COLD” (lower) holes on the dipstick

with the fluid at 60-70°F / 16-21°C. Only use the COLD

region of the dipstick as a rough reference when setting

the fluid level after a transmission service or fluid

change. Re-check the fluid level, and adjust as required,

once the transmission reaches normal operating tempera-

ture.

CAUTION!

If the fluid temperature is below 50°F (10°C) it may

not register on the dipstick. Do not add fluid until

the temperature is elevated enough to produce an

accurate reading. Run the engine at idle, in PARK, to

warm the fluid.

8. Reinsert the dipstick. Check for leaks. Release the

parking brake.

NOTE:To prevent dirt and water from entering the

transmission after checking or replenishing fluid, make

sure that the dipstick cap is properly reseated. It is

normal for the dipstick cap to spring back slightly from

its fully seated position, as long as its seal remains

engaged in the dipstick tube.

Fluid And Filter Changes — Eight-Speed

Transmission

Under normal operating conditions, the fluid installed at

the factory will provide satisfactory lubrication for the

life of the vehicle.

Routine fluid and filter changes are not required. How-

ever, change the fluid and filter if the fluid becomes

contaminated (with water, etc.), or if the transmission is

disassembled for any reason.

7

MAINTAINING YOUR VEHICLE 789

Page 803 of 871

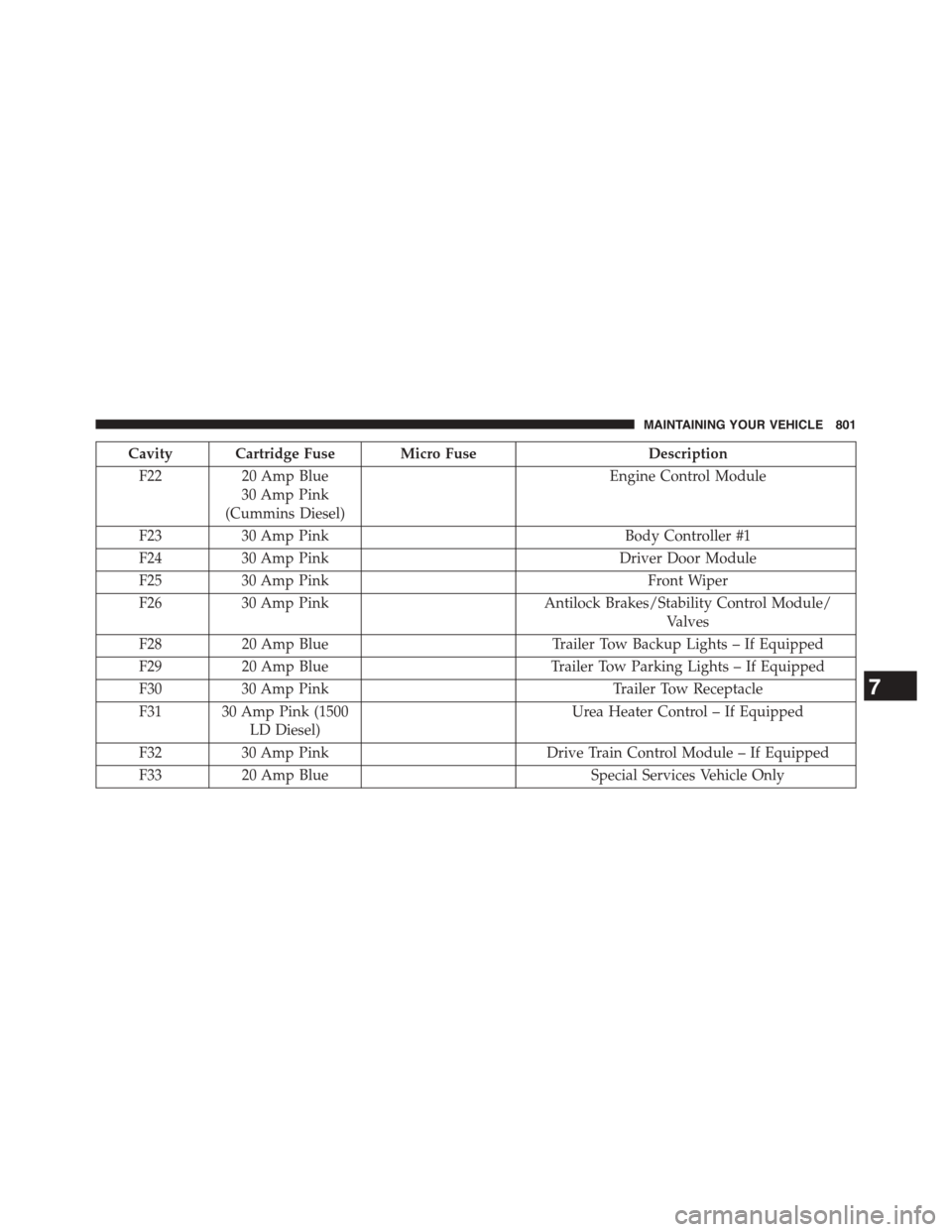

Cavity Cartridge Fuse Micro FuseDescription

F2220 Amp Blue

30 Amp Pink

(Cummins Diesel)

Engine Control Module

F2330 Amp PinkBody Controller #1

F2430 Amp PinkDriver Door Module

F2530 Amp PinkFront Wiper

F2630 Amp PinkAntilock Brakes/Stability Control Module/

Valves

F2820 Amp BlueTrailer Tow Backup Lights – If Equipped

F2920 Amp BlueTrailer Tow Parking Lights – If Equipped

F3030 Amp PinkTrailer Tow Receptacle

F31 30 Amp Pink (1500

LD Diesel)

Urea Heater Control – If Equipped

F3230 Amp PinkDrive Train Control Module – If Equipped

F3320 Amp BlueSpecial Services Vehicle Only

7

MAINTAINING YOUR VEHICLE 801

Page 811 of 871

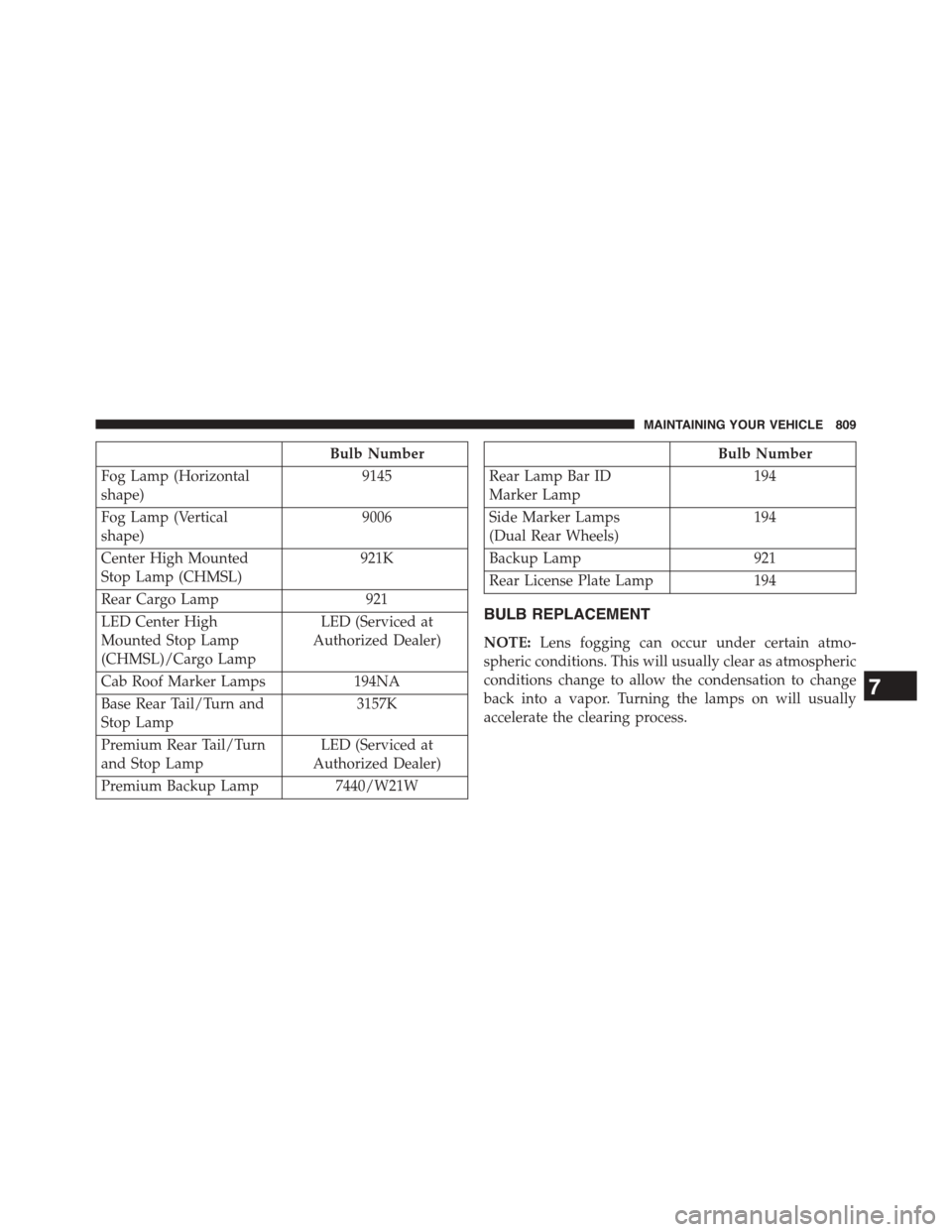

Bulb Number

Fog Lamp (Horizontal

shape)

9145

Fog Lamp (Vertical

shape)

9006

Center High Mounted

Stop Lamp (CHMSL)

921K

Rear Cargo Lamp 921

LED Center High

Mounted Stop Lamp

(CHMSL)/Cargo Lamp

LED (Serviced at

Authorized Dealer)

Cab Roof Marker Lamps194NA

Base Rear Tail/Turn and

Stop Lamp

3157K

Premium Rear Tail/Turn

and Stop Lamp

LED (Serviced at

Authorized Dealer)

Premium Backup Lamp7440/W21W

Bulb Number

Rear Lamp Bar ID

Marker Lamp

194

Side Marker Lamps

(Dual Rear Wheels)

194

Backup Lamp 921

Rear License Plate Lamp 194

BULB REPLACEMENT

NOTE:Lens fogging can occur under certain atmo-

spheric conditions. This will usually clear as atmospheric

conditions change to allow the condensation to change

back into a vapor. Turning the lamps on will usually

accelerate the clearing process.

7

MAINTAINING YOUR VEHICLE 809