tow RAM 1500 2021 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 383 of 496

IN CASE OF EMERGENCY381

(Continued)

6. Lift the spare tire with one hand to give clearance to tilt the retainer at the end of

the cable.

Tilting The Retainer Through The Center Of The Wheel

7. Pull the retainer through the center of the wheel.

Pulling The Retainer Through The Center Of The Wheel

NOTE:

The winch mechanism is designed for use with

the extension tubes only. Use of an air wrench

or other power tools is not recommended and

can damage the winch.

JACKING INSTRUCTIONS

Jack Warning Label

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the

wheel to be raised.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

WARNING!

(Continued)

7

21_DT_OM_EN_USC_t.book Page 381

Page 385 of 496

IN CASE OF EMERGENCY383

When changing a rear wheel, assemble the

extension with jack hook to the jack and

connect the extension tubes. Access the

rear jacking location from behind the rear

tire. Place the jack under the Jack Lifting

Point located on the rear axle lower control

arm bracket. Then locate the slot in the jack

lift plate onto the rear axle Jack Lifting Point.

Attach the extension with jack hook extend -

ing to the rear of the vehicle.

Rear Lifting Point Rear Jacking Location

Connect the long extensions to the lug

wrench.

5. By rotating the lug wrench clockwise, raise the vehicle until the wheel just clears the

ground surface. 6. Remove the lug nuts and pull the wheel off.

Install the spare wheel and lug nuts with the

cone shaped end of the lug nuts toward the

wheel. Hand tighten the lug nuts with the

vehicle lifted. To avoid the risk of forcing the

vehicle off the jack, do not fully tighten the

lug nuts until the vehicle has been

completely lowered.

7. Finish tightening the lug nuts. Push down on the wrench handle for increased leverage.

Tighten the lug nuts in a star pattern until

each lug nut has been tightened twice

Úpage 467. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

CAUTION!

Before raising the wheel off the ground, make

sure that the jack will not damage

surrounding truck parts and adjust the jack

position as required.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

7

21_DT_OM_EN_USC_t.book Page 383

Page 386 of 496

384IN CASE OF EMERGENCY

8. If your vehicle is equipped with a wheel

center cap, install the cap and remove the

wheel blocks. Do not install chrome or

aluminum wheel center caps on the spare

wheel. This may result in cap damage.

9. Lower the jack to its fully closed position. Stow the replaced tire, and secure the jack

and tools in the proper location.

10. Adjust the tire pressure when possible.

TO STOW THE FLAT OR SPARE

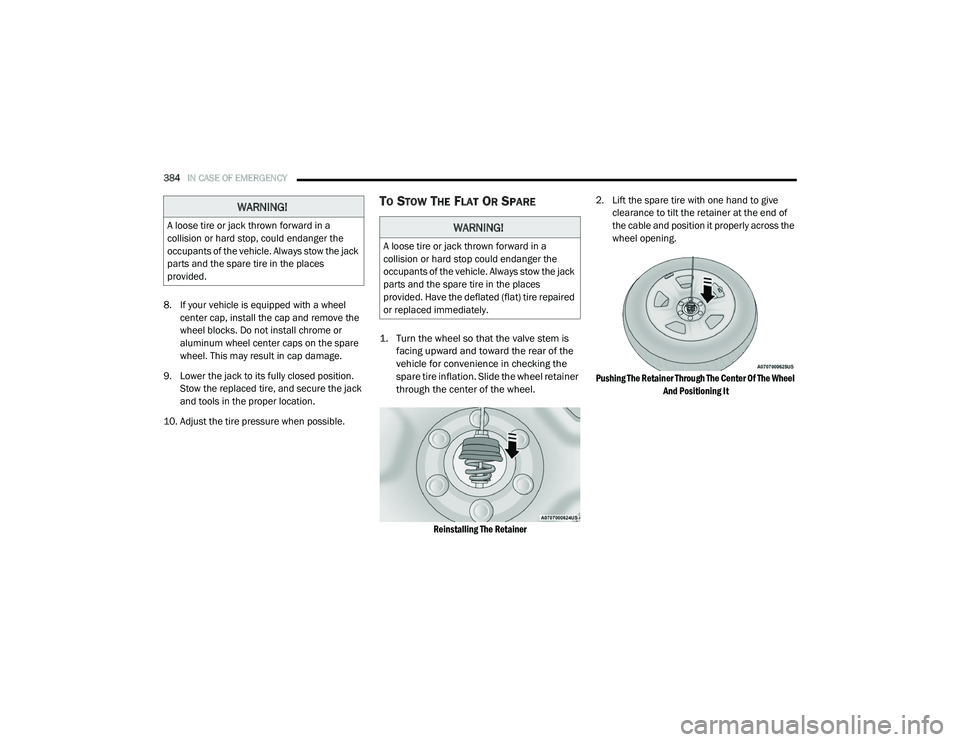

1. Turn the wheel so that the valve stem is facing upward and toward the rear of the

vehicle for convenience in checking the

spare tire inflation. Slide the wheel retainer

through the center of the wheel.

Reinstalling The Retainer

2. Lift the spare tire with one hand to give

clearance to tilt the retainer at the end of

the cable and position it properly across the

wheel opening.

Pushing The Retainer Through The Center Of The Wheel And Positioning It

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided.WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

21_DT_OM_EN_USC_t.book Page 384

Page 392 of 496

390IN CASE OF EMERGENCY

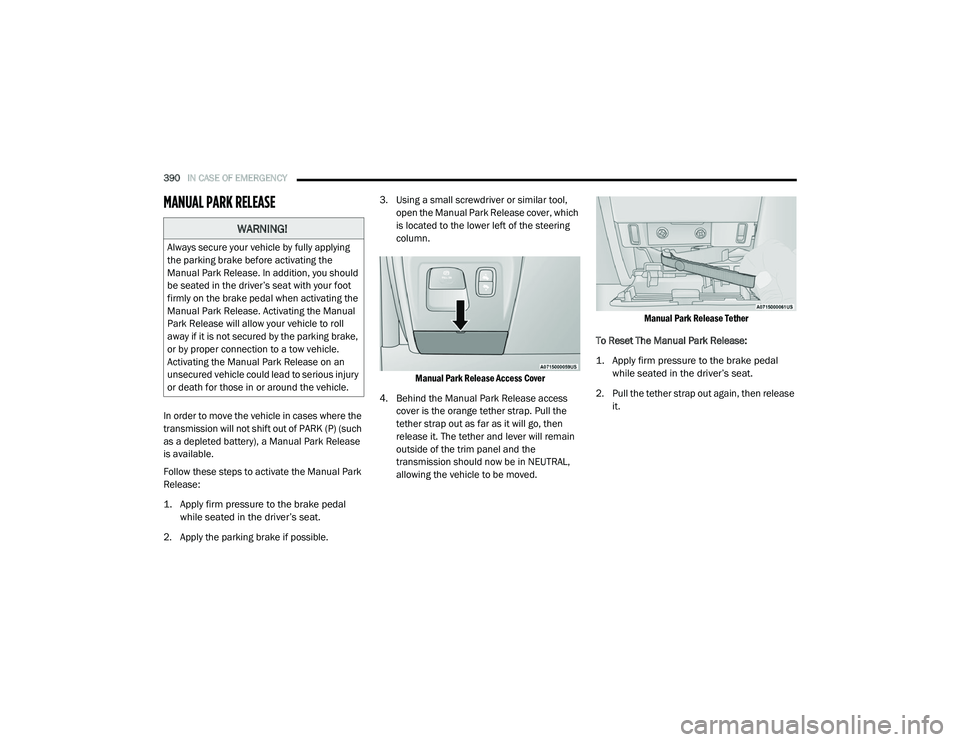

MANUAL PARK RELEASE

In order to move the vehicle in cases where the

transmission will not shift out of PARK (P) (such

as a depleted battery), a Manual Park Release

is available.

Follow these steps to activate the Manual Park

Release:

1. Apply firm pressure to the brake pedal

while seated in the driver’s seat.

2. Apply the parking brake if possible. 3. Using a small screwdriver or similar tool,

open the Manual Park Release cover, which

is located to the lower left of the steering

column.

Manual Park Release Access Cover

4. Behind the Manual Park Release access cover is the orange tether strap. Pull the

tether strap out as far as it will go, then

release it. The tether and lever will remain

outside of the trim panel and the

transmission should now be in NEUTRAL,

allowing the vehicle to be moved.

Manual Park Release Tether

To Reset The Manual Park Release:

1. Apply firm pressure to the brake pedal while seated in the driver’s seat.

2. Pull the tether strap out again, then release it.

WARNING!

Always secure your vehicle by fully applying

the parking brake before activating the

Manual Park Release. In addition, you should

be seated in the driver’s seat with your foot

firmly on the brake pedal when activating the

Manual Park Release. Activating the Manual

Park Release will allow your vehicle to roll

away if it is not secured by the parking brake,

or by proper connection to a tow vehicle.

Activating the Manual Park Release on an

unsecured vehicle could lead to serious injury

or death for those in or around the vehicle.

21_DT_OM_EN_USC_t.book Page 390

Page 394 of 496

392IN CASE OF EMERGENCY

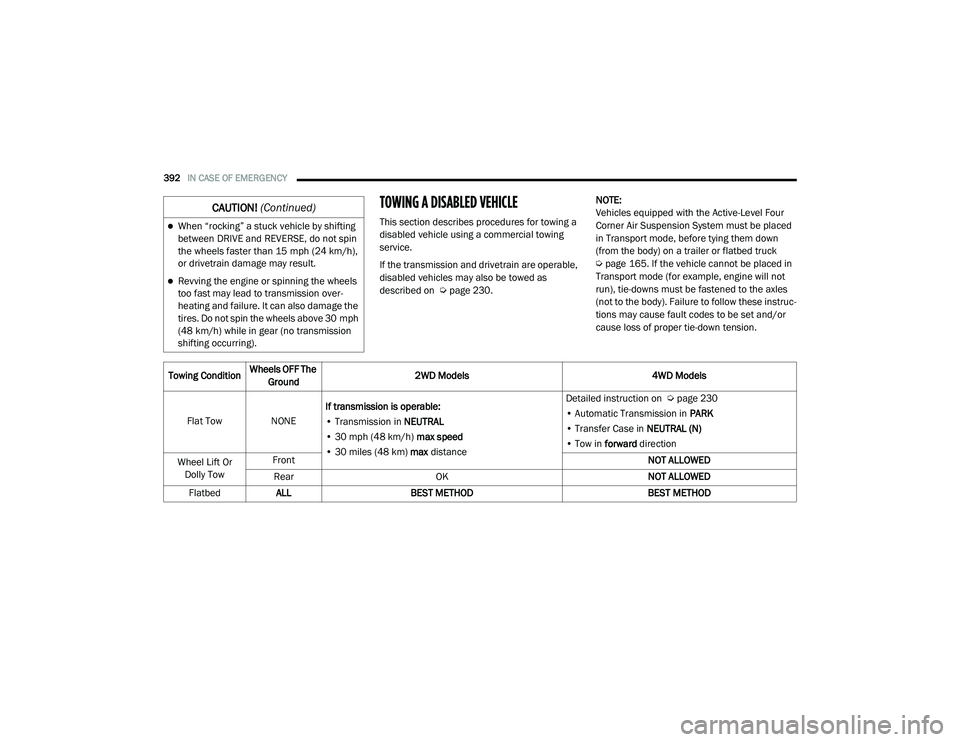

TOWING A DISABLED VEHICLE

This section describes procedures for towing a

disabled vehicle using a commercial towing

service.

If the transmission and drivetrain are operable,

disabled vehicles may also be towed as

described on Úpage 230. NOTE:

Vehicles equipped with the Active-Level Four

Corner Air Suspension System must be placed

in Transport mode, before tying them down

(from the body) on a trailer or flatbed truck

Ú

page 165. If the vehicle cannot be placed in

Transport mode (for example, engine will not

run), tie-downs must be fastened to the axles

(not to the body). Failure to follow these instruc -

tions may cause fault codes to be set and/or

cause loss of proper tie-down tension.When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin

the wheels faster than 15 mph (24 km/h), or drivetrain damage may result.

Revving the engine or spinning the wheels

too fast may lead to transmission over -

heating and failure. It can also damage the

tires. Do not spin the wheels above 30 mph

(48 km/h) while in gear (no transmission

shifting occurring).

CAUTION! (Continued)

Towing Condition Wheels OFF The

Ground 2WD Models

4WD Models

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max speed

• 30 miles (48 km) max distance Detailed instruction on

Ú page 230

• Automatic Transmission in PARK

• Transfer Case in NEUTRAL (N)

• Tow in forward direction

Wheel Lift Or Dolly Tow Front

NOT ALLOWED

Rear OK NOT ALLOWED

Flatbed ALL BEST METHOD BEST METHOD

21_DT_OM_EN_USC_t.book Page 392

Page 395 of 496

IN CASE OF EMERGENCY393

(Continued)

Proper towing or lifting equipment is required to

prevent damage to your vehicle. Use only tow

bars and other equipment designed for this

purpose, following equipment FCA’s

instructions. Use of safety chains is mandatory.

Attach a tow bar or other towing device to main

structural members of the vehicle, not to

fascia/bumpers or associated brackets. State

and local laws regarding vehicles under tow

must be observed.

If you must use the accessories (wipers,

defrosters, etc.) while being towed, the ignition

must be in the ON/RUN mode, not the ACC

mode.

If the key fob is unavailable or the vehicle's

battery is discharged, find Instructions on

shifting the transmission out of PARK

Ú page 390.TWO-WHEEL DRIVE MODELS

FCA recommends towing your vehicle with all

four wheels OFF the ground using a flatbed.

If flatbed equipment is not available, and the

transmission is operable, the vehicle may be

towed (with rear wheels on the ground) under

the following conditions:

The transmission must be in NEUTRAL (N).

Instructions on shifting the transmission to

NEUTRAL (N) when the engine is off

Ú page 390.

The towing speed must not exceed 30 mph

(48 km/h).

The towing distance must not exceed

30 miles (48 km).

If the transmission is not operable, or the

vehicle must be towed faster than 30 mph

(48 km/h) and farther than 30 miles (48 km), tow with the rear wheels OFF the ground.

Acceptable methods to tow the vehicle on a

flatbed are as follows:

The front wheels raised and the rear wheels

on a towing dolly

Using a suitable steering wheel stabilizer to

hold the front wheels in the straight position

with the rear wheels raised when and the

front wheels ON the ground.

FOUR-WHEEL DRIVE MODELS

FCA recommends towing with all wheels OFF

the ground. Acceptable methods are to tow the

vehicle on a flatbed or with one end of vehicle

raised and the opposite end on a towing dolly.

CAUTION!

Do not use sling type equipment when

towing. Vehicle damage may occur.

When securing the vehicle to a flat bed

truck, do not attach to front or rear suspen -

sion components. Damage to your vehicle

may result from improper towing.

CAUTION!

Towing this vehicle in violation of the above

requirements can cause severe transmission

damage. Damage from improper towing is not

covered under the New Vehicle Limited

Warranty.

CAUTION!

Front or rear wheel lifts must not be used (if

the remaining wheels are on the ground).

Internal damage to the transmission or

transfer case will occur if a front or rear

wheel lift is used when towing.

7

21_DT_OM_EN_USC_t.book Page 393

Page 396 of 496

394IN CASE OF EMERGENCY

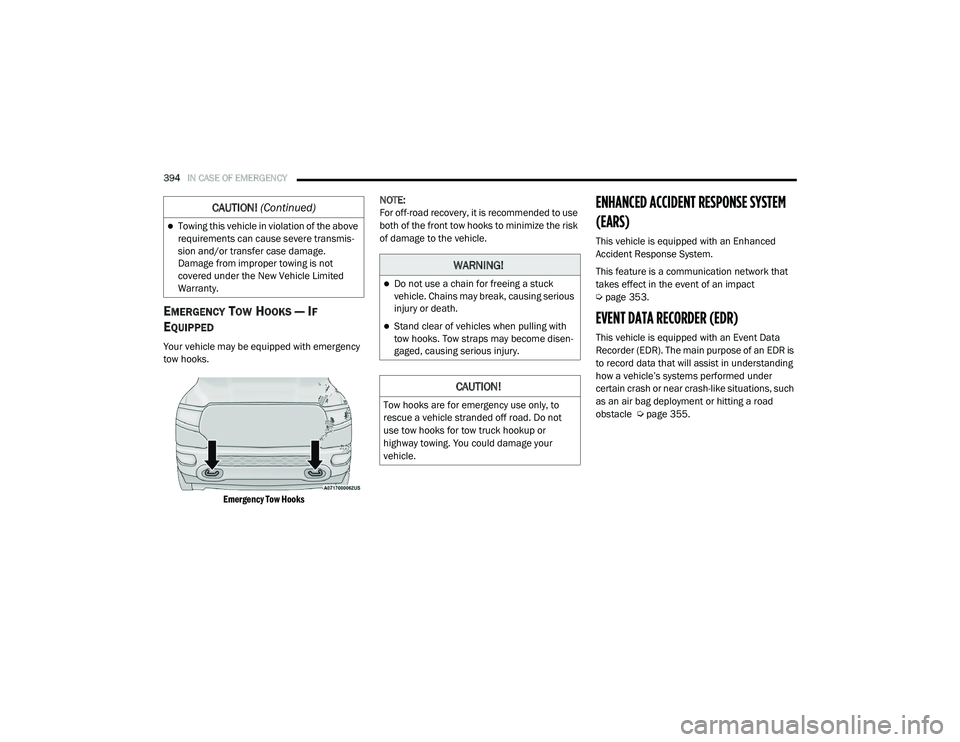

EMERGENCY TOW HOOKS — IF

E

QUIPPED

Your vehicle may be equipped with emergency

tow hooks.

Emergency Tow Hooks

NOTE:

For off-road recovery, it is recommended to use

both of the front tow hooks to minimize the risk

of damage to the vehicle.

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS)

This vehicle is equipped with an Enhanced

Accident Response System.

This feature is a communication network that

takes effect in the event of an impact

Ú

page 353.

EVENT DATA RECORDER (EDR)

This vehicle is equipped with an Event Data

Recorder (EDR). The main purpose of an EDR is

to record data that will assist in understanding

how a vehicle’s systems performed under

certain crash or near crash-like situations, such

as an air bag deployment or hitting a road

obstacle Ú page 355.

Towing this vehicle in violation of the above

requirements can cause severe transmis -

sion and/or transfer case damage.

Damage from improper towing is not

covered under the New Vehicle Limited

Warranty.

CAUTION! (Continued)

WARNING!

Do not use a chain for freeing a stuck

vehicle. Chains may break, causing serious

injury or death.

Stand clear of vehicles when pulling with

tow hooks. Tow straps may become disen -

gaged, causing serious injury.

CAUTION!

Tow hooks are for emergency use only, to

rescue a vehicle stranded off road. Do not

use tow hooks for tow truck hookup or

highway towing. You could damage your

vehicle.

21_DT_OM_EN_USC_t.book Page 394

Page 397 of 496

395

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the

“Oil Change Required” message is displayed.

Severe operating conditions can cause the

change oil message to illuminate as early as

3,500 miles (5,600 km) since last reset. Have

your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an authorized dealer, the message can be reset by

referring to the steps described under

Instrument Cluster Display Ú

page 114.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

NOTE:

Vehicles that are operated in a dusty and

off-road environment, or predominately at idle

or very low engine RPM are known as Severe

Duty vehicles. It is recommended that you

change the engine oil at 4,000 miles

(6,500 km) or 350 hours of engine run time.

Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and fill as needed.

Check function of all interior and exterior

lights.

MAINTENANCE PLAN

Refer to the Maintenance Plan for required

maintenance. More frequent maintenance may

be needed in severe conditions, such as dusty

areas and very short trip driving. In some

extreme conditions, additional maintenance

not specified in the maintenance schedule may

be required.

8

21_DT_OM_EN_USC_t.book Page 395

Page 399 of 496

SERVICING AND MAINTENANCE397

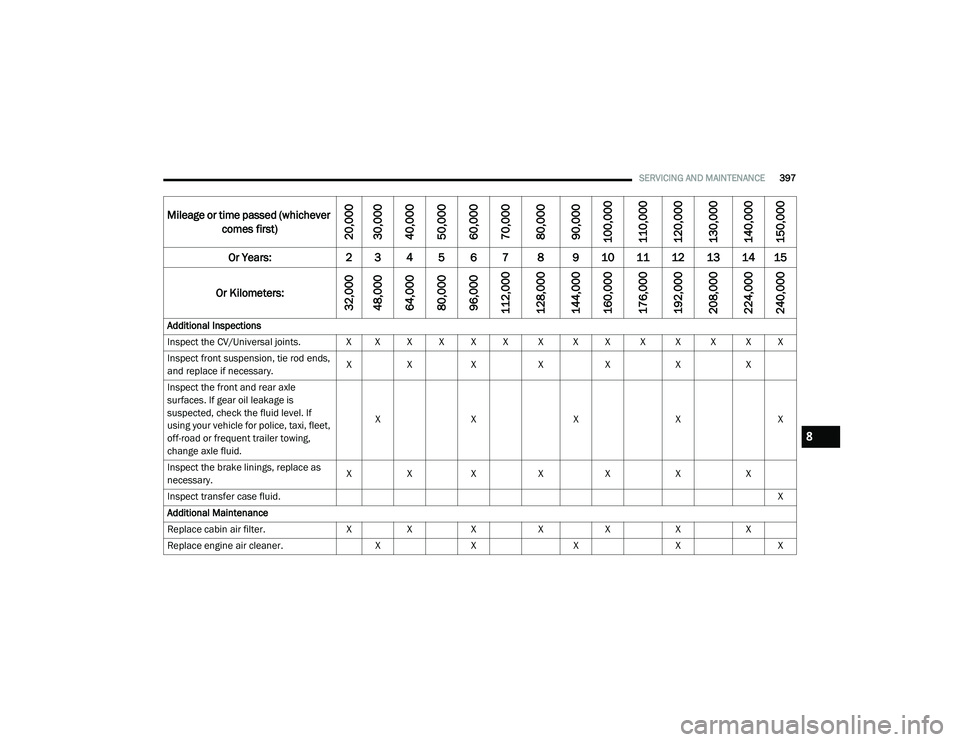

Mileage or time passed (whichever

comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X X X X X X X X Inspect front suspension, tie rod ends,

and replace if necessary. X

X X XX XX

Inspect the front and rear axle

surfaces. If gear oil leakage is

suspected, check the fluid level. If

using your vehicle for police, taxi, fleet,

off-road or frequent trailer towing,

change axle fluid. X

X XXX

Inspect the brake linings, replace as

necessary. X

X X XX XX

Inspect transfer case fluid. X

Additional Maintenance

Replace cabin air filter. XX X XX XX

Replace engine air cleaner. XX XXX

8

21_DT_OM_EN_USC_t.book Page 397

Page 400 of 496

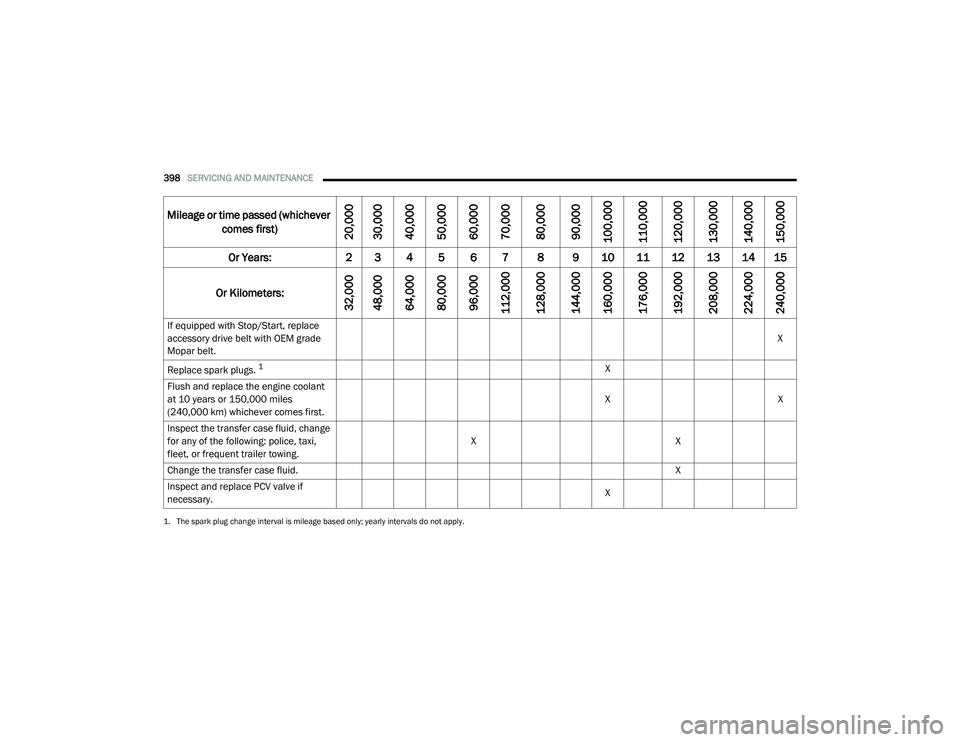

398SERVICING AND MAINTENANCE

If equipped with Stop/Start, replace

accessory drive belt with OEM grade

Mopar belt. X

Replace spark plugs.

1X

Flush and replace the engine coolant

at 10 years or 150,000 miles

(240,000 km) whichever comes first. X

X

Inspect the transfer case fluid, change

for any of the following: police, taxi,

fleet, or frequent trailer towing. X

X

Change the transfer case fluid. X

Inspect and replace PCV valve if

necessary. X

1. The spark plug change interval is mileage based only; yearly intervals do not apply.

Mileage or time passed (whichever

comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

21_DT_OM_EN_USC_t.book Page 398