ABS RAM 1500 2021 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 312 of 496

310 (Continued)

SAFETY

SAFETY FEATURES

ANTI-LOCK BRAKE SYSTEM (ABS)

The ABS provides increased vehicle stability

and brake performance under most braking

conditions. The system automatically prevents

wheel lock, and enhances vehicle control during

braking.

The ABS performs a self-check cycle to ensure

that the ABS is working properly each time the

vehicle is started and driven. During this

self-check, you may hear a slight clicking sound

as well as some related motor noises.

The ABS is activated during braking when the

system detects one or more wheels are

beginning to lock. Road conditions such as ice,

snow, gravel, bumps, railroad tracks, loose

debris, or panic stops may increase the

likelihood of ABS activation(s).You also may experience the following normal

characteristics when ABS activates:

ABS motor noise or clicking sounds (you may

continue to hear for a short time after the

stop)

Brake pedal pulsations

A slight drop of the brake pedal at the end of

the stop

The ABS is designed to function with the

Original Equipment Manufacturer (OEM) tires.

Modification may result in degraded ABS

performance.

WARNING!

The ABS contains sophisticated electronic

equipment that may be susceptible to inter -

ference caused by improperly installed or

high output radio transmitting equipment.

This interference can cause possible loss of

anti-lock braking capability. Installation of

such equipment should be performed by

qualified professionals.

Pumping of the Anti-Lock Brakes will

diminish their effectiveness and may lead

to a collision. Pumping makes the stopping

distance longer. Just press firmly on your

brake pedal when you need to slow down or

stop.

The ABS cannot prevent the natural laws of

physics from acting on the vehicle, nor can

it increase braking or steering efficiency

beyond that afforded by the condition of the

vehicle brakes and tires or the traction

afforded.

The ABS cannot prevent collisions,

including those resulting from excessive

speed in turns, following another vehicle

too closely, or hydroplaning.

The capabilities of an ABS equipped vehicle

must never be exploited in a reckless or

dangerous manner that could jeopardize

the user’s safety or the safety of others.

WARNING! (Continued)

21_DT_OM_EN_USC_t.book Page 310

Page 313 of 496

SAFETY311

Anti-Lock Brake System (ABS) Warning

Light

The yellow ABS Warning Light will turn on when

the ignition is placed in the ON/RUN mode and

may stay on for as long as four seconds.

If the ABS Warning Light remains on or comes

on while driving, it indicates that the anti-lock

portion of the brake system is not functioning

and that service is required. However, the

conventional brake system will continue to

operate normally if the ABS Warning Light is on.

If the ABS Warning Light is on, the brake system

should be serviced as soon as possible to

restore the benefits of anti-lock brakes. If the

ABS Warning Light does not come on when the

ignition is placed in the ON/RUN mode, have

the light repaired as soon as possible.

ELECTRONIC BRAKE CONTROL (EBC)

S

YSTEM

Your vehicle is equipped with an advanced

Electronic Brake Control (EBC) system. This

system includes Anti-Lock Brake System (ABS),

Brake Assist System (BAS), Electronic Brake

Force Distribution (EBD), Electronic Roll

Mitigation (ERM), Electronic Stability Control

(ESC), Hill Start Assist (HSA), and Traction Control System (TCS). These systems work

together to enhance both vehicle stability and

control in various driving conditions.

Your vehicle may also be equipped with Trailer

Sway Control (TSC) and Hill Descent Control

(HDC).

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s

braking capability during emergency braking

maneuvers. The system detects an emergency

braking situation by sensing the rate and

amount of brake application, and then applies

optimum pressure to the brakes. This can help

reduce braking distances. The BAS

complements the Anti-Lock Brake System

(ABS). Applying the brakes very quickly results

in the best BAS assistance. To receive the

benefit of the system, you must apply

continuous braking pressure during the

stopping sequence (do not “pump” the brakes).

Do not reduce brake pedal pressure unless

braking is no longer desired. Once the brake

pedal is released, the BAS is deactivated.

Brake System Warning Light

The red Brake System Warning Light will turn on

when the ignition is placed in the ON/RUN

mode and may stay on for as long as four

seconds.

If the Brake System Warning Light remains on or

comes on while driving, it indicates that the

brake system is not functioning properly and

that immediate service is required. If the Brake

System Warning Light does not come on when

the ignition is placed in the ON/RUN mode,

have the light repaired as soon as possible.

WARNING!

The Brake Assist System (BAS) cannot

prevent the natural laws of physics from

acting on the vehicle, nor can it increase the

traction afforded by prevailing road

conditions. BAS cannot prevent collisions,

including those resulting from excessive

speed in turns, driving on very slippery

surfaces, or hydroplaning. The capabilities of

a BAS-equipped vehicle must never be

exploited in a reckless or dangerous manner,

which could jeopardize the user's safety or

the safety of others.

6

21_DT_OM_EN_USC_t.book Page 311

Page 314 of 496

312SAFETY

Electronic Brake Force Distribution (EBD)

EBD manages the distribution of the braking

torque between the front and rear axles by

limiting braking pressure to the rear axle. This is

done to prevent overslip of the rear wheels to

avoid vehicle instability, and to prevent the rear

axle from entering the Anti-Lock Brake System

(ABS) before the front axle.

Electronic Roll Mitigation (ERM)

The ERM system anticipates the potential for

wheel lift by monitoring the driver’s steering

wheel input and the speed of the vehicle. When

ERM determines that the rate of change of the

steering wheel angle and vehicle’s speed are

sufficient to potentially cause wheel lift, it then

applies the appropriate brake and may also

reduce engine power to lessen the chance that

wheel lift will occur. ERM can only reduce the

chance of wheel lift occurring during severe or

evasive driving maneuvers; it cannot prevent

wheel lift due to other factors, such as road

conditions, leaving the roadway, striking objects

or other vehicles.

Electronic Stability Control (ESC)

ESC enhances directional control and stability

of the vehicle under various driving conditions.

ESC corrects for oversteering or understeering

of the vehicle by applying the brake of the

appropriate wheel(s) to counteract the above

conditions. Engine power may also be reduced

to help the vehicle maintain the desired path.

Oversteer — when the vehicle is turning more

than appropriate for the steering wheel posi -

tion.

Understeer — when the vehicle is turning less

than appropriate for the steering wheel posi -

tion.

ESC uses sensors in the vehicle to determine

the vehicle path intended by the driver and

compares it to the actual path of the vehicle.

When the actual path does not match the

intended path, ESC applies the brake of the

appropriate wheel to assist in counteracting the

oversteer or understeer condition.

The ESC Activation/Malfunction Indicator Light

located in the instrument cluster will start to

flash as soon as the ESC system becomes

active. The ESC Activation/Malfunction

Indicator Light also flashes when the TCS is

active. If the ESC Activation/Malfunction

Indicator Light begins to flash during

acceleration, ease up on the accelerator and

apply as little throttle as possible. Be sure to

adapt your speed and driving to the prevailing

road conditions.

WARNING!

Many factors, such as vehicle loading, road

conditions and driving conditions, influence

the chance that wheel lift or rollover may

occur. ERM cannot prevent all wheel lift or roll

overs, especially those that involve leaving

the roadway or striking objects or other

vehicles. The capabilities of an

ERM-equipped vehicle must never be

exploited in a reckless or dangerous manner

which could jeopardize the user's safety or

the safety of others.

21_DT_OM_EN_USC_t.book Page 312

Page 351 of 496

SAFETY349

for any reason, take the vehicle to an authorized

dealer. Only FCA US LLC approved seat

accessories may be used.

The following requirements must be strictly

followed:

Do not modify the front passenger seat

assembly or components in any way.

Do not use prior or future model year seat

covers or cushions not designated by FCA US

LLC for the specific model being repaired.

Always use the correct seat cover and

cushion specified for the vehicle.

Do not replace the seat cover or cushion with

an aftermarket seat cover or cushion.

Do not add a secondary seat cover or mat.

At no time should any Supplemental

Restraint System (SRS) component or SRS

related component or fastener be modified

or replaced with any part except those which

are approved by FCA US LLC.Knee Impact Bolsters

The Knee Impact Bolsters help protect the

knees of the driver and front passenger, and

position the front occupants for improved

interaction with the front air bags.

Supplemental Side Air Bags

Supplemental Seat-Mounted Side Air Bags

(SABs)

This vehicle is equipped with Supplemental

Seat-Mounted Side Air Bags (SABs).

Supplemental Seat-Mounted Side Air Bags

(SABs) are located in the outboard side of the

front seats. The SABs are marked with “SRS

AIRBAG” or “AIRBAG” on a label or on the seat

trim on the outboard side of the seats.

The SABs may help to reduce the risk of

occupant injury during certain side impacts, in

addition to the injury reduction potential

provided by the seat belts and body structure.

WARNING!

Unapproved modifications or service proce -

dures to the passenger seat assembly, its

related components, seat cover or cushion

may inadvertently change the air bag

deployment in case of a frontal collision.

This could result in death or serious injury

to the front passenger if the vehicle is

involved in a collision. A modified vehicle

may not comply with required Federal

Motor Vehicle Safety Standards (FMVSS)

and/or Canadian Motor Vehicle Safety

Standards (CMVSS).

If it is necessary to modify the air bag

system for persons with disabilities,

contact an authorized dealer.

WARNING!

Do not drill, cut, or tamper with the knee

impact bolsters in any way.

Do not mount any accessories to the knee

impact bolsters such as alarm lights,

stereos, citizen band radios, etc.

6

21_DT_OM_EN_USC_t.book Page 349

Page 364 of 496

362SAFETY

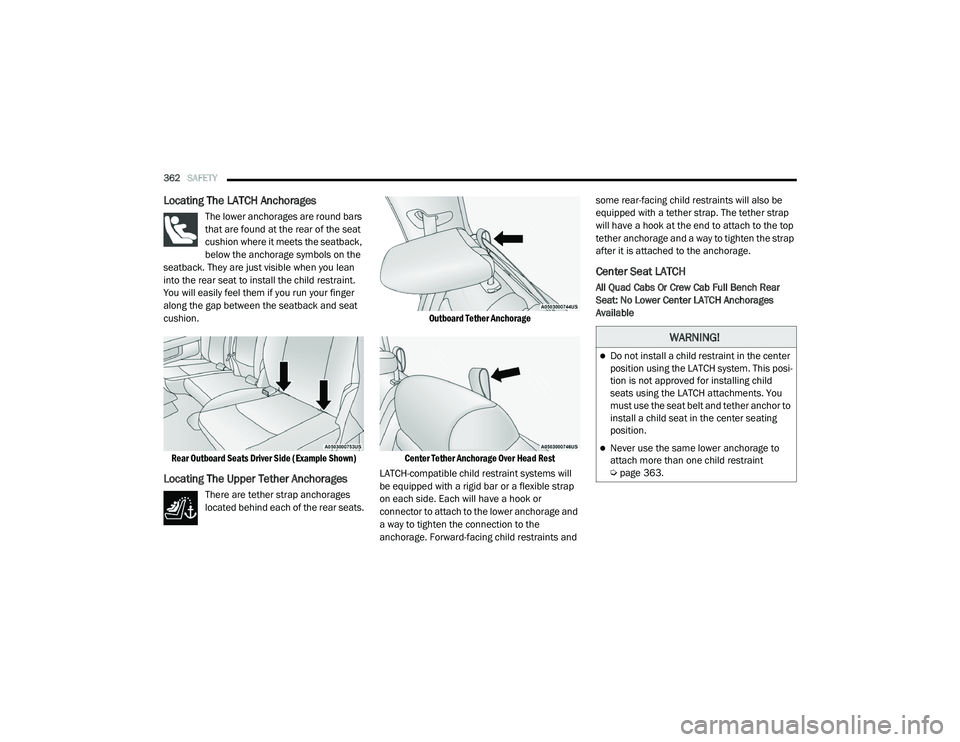

Locating The LATCH Anchorages

The lower anchorages are round bars

that are found at the rear of the seat

cushion where it meets the seatback,

below the anchorage symbols on the

seatback. They are just visible when you lean

into the rear seat to install the child restraint.

You will easily feel them if you run your finger

along the gap between the seatback and seat

cushion.

Rear Outboard Seats Driver Side (Example Shown)

Locating The Upper Tether Anchorages

There are tether strap anchorages

located behind each of the rear seats.

Outboard Tether Anchorage

Center Tether Anchorage Over Head Rest

LATCH-compatible child restraint systems will

be equipped with a rigid bar or a flexible strap

on each side. Each will have a hook or

connector to attach to the lower anchorage and

a way to tighten the connection to the

anchorage. Forward-facing child restraints and some rear-facing child restraints will also be

equipped with a tether strap. The tether strap

will have a hook at the end to attach to the top

tether anchorage and a way to tighten the strap

after it is attached to the anchorage.

Center Seat LATCH

All Quad Cabs Or Crew Cab Full Bench Rear

Seat: No Lower Center LATCH Anchorages

Available

WARNING!

Do not install a child restraint in the center

position using the LATCH system. This posi

-

tion is not approved for installing child

seats using the LATCH attachments. You

must use the seat belt and tether anchor to

install a child seat in the center seating

position.

Never use the same lower anchorage to

attach more than one child restraint

Ú page 363.

21_DT_OM_EN_USC_t.book Page 362

Page 418 of 496

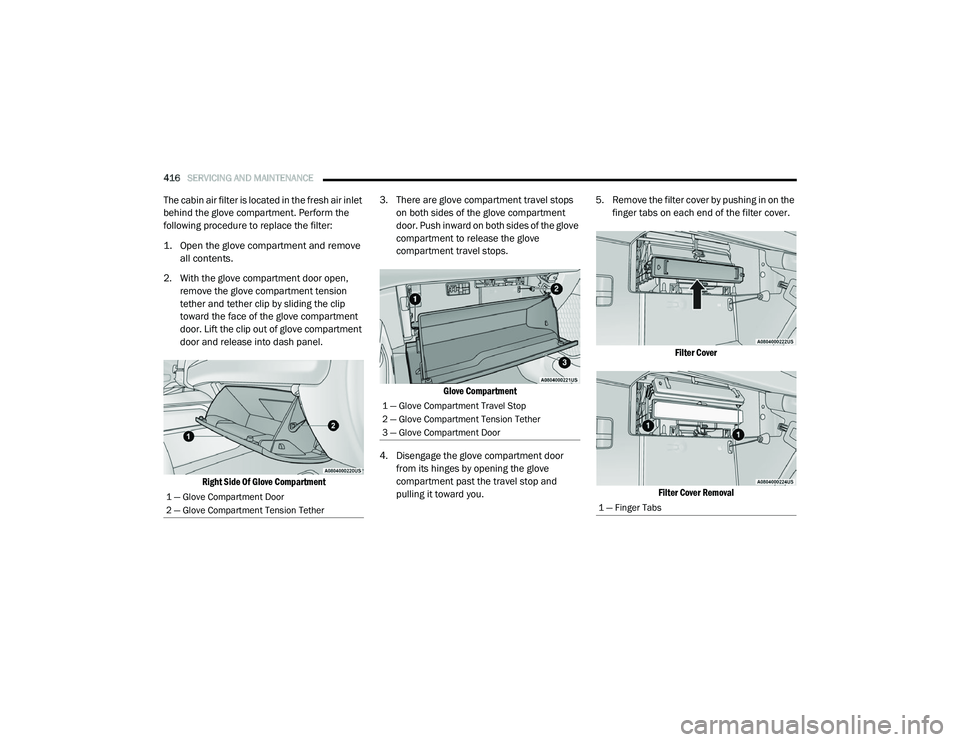

416SERVICING AND MAINTENANCE

The cabin air filter is located in the fresh air inlet

behind the glove compartment. Perform the

following procedure to replace the filter:

1. Open the glove compartment and remove

all contents.

2. With the glove compartment door open, remove the glove compartment tension

tether and tether clip by sliding the clip

toward the face of the glove compartment

door. Lift the clip out of glove compartment

door and release into dash panel.

Right Side Of Glove Compartment

3. There are glove compartment travel stops

on both sides of the glove compartment

door. Push inward on both sides of the glove

compartment to release the glove

compartment travel stops.

Glove Compartment

4. Disengage the glove compartment door from its hinges by opening the glove

compartment past the travel stop and

pulling it toward you. 5. Remove the filter cover by pushing in on the

finger tabs on each end of the filter cover.

Filter Cover

Filter Cover Removal

1 — Glove Compartment Door

2 — Glove Compartment Tension Tether

1 — Glove Compartment Travel Stop

2 — Glove Compartment Tension Tether

3 — Glove Compartment Door

1 — Finger Tabs

21_DT_OM_EN_USC_t.book Page 416

Page 427 of 496

SERVICING AND MAINTENANCE425

(Continued)

and through another hose to the intake

manifold of the engine. This cooling process

enables more efficient burning of fuel resulting

in fewer emissions.

To guarantee optimum performance of the

system, keep the surfaces of the charge air

cooler, condenser and radiator clean and free

of debris. Periodically check the hoses leading

to and from the charge air cooler for cracks or

loose clamps resulting in loss of pressure and

reduced engine performance.

BRAKE SYSTEM

In order to ensure brake system performance,

all brake system components should be

inspected periodically Ú page 395.

Fluid Level Check — Brake Master Cylinder

The fluid level of the brake master cylinder

should be checked whenever the vehicle is

serviced, or immediately if the brake system

warning light is on. If necessary, add fluid to

bring level within the designated marks on the

side of the reservoir of the brake master

cylinder. Be sure to clean the top of the master

cylinder area before removing cap. With disc

brakes, fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be

checked when pads are replaced. If the brake

fluid is abnormally low, check the system for

leaks Úpage 478.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.

WARNING!

Use only manufacturer's recommended

brake fluid Ú page 478. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its perfor -

mance. The proper type of brake fluid for

your vehicle is also identified on the original

factory installed hydraulic master cylinder

reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

8

21_DT_OM_EN_USC_t.book Page 425

Page 445 of 496

SERVICING AND MAINTENANCE443

3. Turn the desired bulb socket a quarter turn

counterclockwise and remove the socket

and bulb from housing.

4. Pull the desired bulb straight from the socket.

Outside Bulbs: Cargo Lamps

Inside Bulb: Center High Mounted Stop

Lamp

5. Reverse the procedure for installation of bulbs and housing.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on

US design standards. P-Metric tires have the

letter “P” molded into the sidewall preceding

the size designation. Example: P215/65R15

95H.

European — Metric tire sizing is based on

European design standards. Tires designed

to this standard have the tire size molded

into the sidewall beginning with the section

width. The letter "P" is absent from this tire

size designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based

on US design standards. The size designation

for LT-Metric tires is the same as for P-Metric

tires except for the letters “LT” that are

molded into the sidewall preceding the size

designation. Example: LT235/85R16.

Temporary spare tires are designed for

temporary emergency use only. Temporary

high pressure compact spare tires have the

letter “T” or “S” molded into the sidewall

preceding the size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on US

design standards and it begins with the tire

diameter molded into the sidewall. Example:

31x10.5 R15 LT.

CAUTION!

Do not contaminate the bulb glass by

touching it with your fingers or by allowing it

to contract other oily surfaces. Shortened

bulb life will result.

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera -

ture Grades

8

21_DT_OM_EN_USC_t.book Page 443

Page 447 of 496

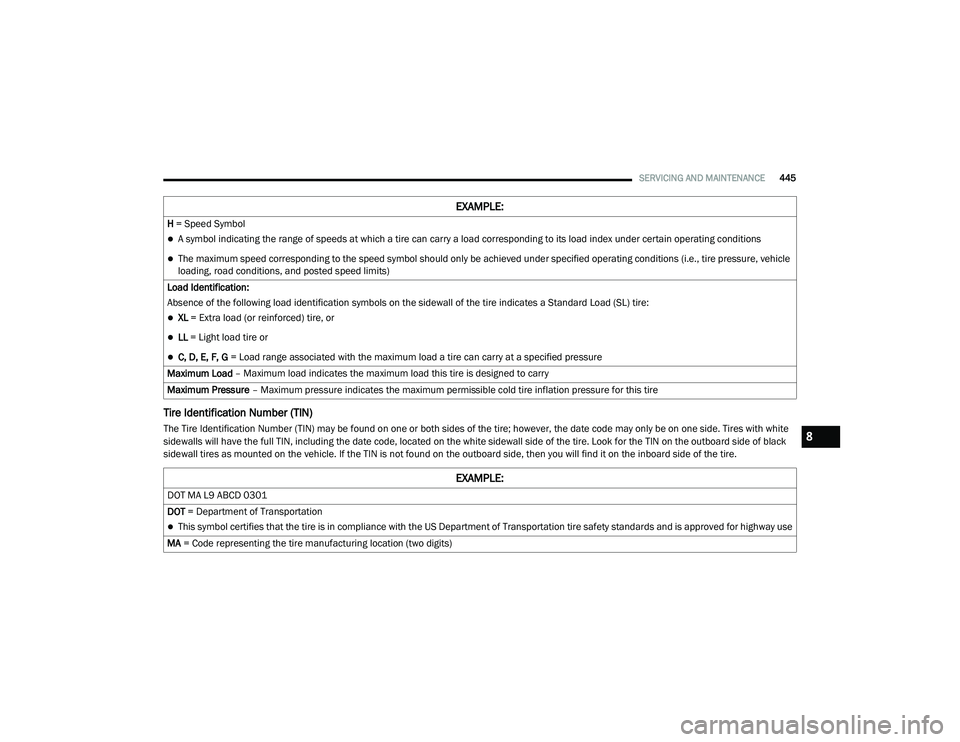

SERVICING AND MAINTENANCE445

Tire Identification Number (TIN)

The Tire Identification Number (TIN) may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white

sidewalls will have the full TIN, including the date code, located on the white sidewall side of the tire. Look for the TIN on the outboard side of black

sidewall tires as mounted on the vehicle. If the TIN is not found on the outboard side, then you will find it on the inboard side of the tire.H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle

loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

8

21_DT_OM_EN_USC_t.book Page 445

Page 469 of 496

467

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER

The Vehicle Identification Number (VIN) is found

on the left front corner of the instrument panel,

visible through the windshield.

Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for

example, repeated brake applications with the

engine off), the brakes will still function.

However, you will experience a substantial

increase in braking effort to stop the vehicle.

If either the front or rear hydraulic system loses

normal braking capability, the remaining

system will still function with some loss of

overall braking effectiveness. This will be

evident by increased pedal travel during

application, greater pedal force required to slow

or stop, and the “Brake Warning Light” and the

“ABS Warning Light” will activate during brake

use.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a six sided (hex)

deep wall socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Lug Nut/ Bolt

Torque Lug Nut/

Bolt Type **Lug

Nut/Bolt Size Lug Nut/

Bolt

Socket Size

130

Ft-Lbs

(176 N·m) Cone

M14 x

1.50 22 mm

9

21_DT_OM_EN_USC_t.book Page 467