fuel filter RAM 1500 2021 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 405 of 496

SERVICING AND MAINTENANCE403

ADDITIONAL MAINTENANCE — B6 TO

B20 B

IODIESEL

NOTE:

Under no circumstances should oil change

intervals exceed 8,000 miles (12,875 km) or

six months, whichever comes first when

using biodiesel blends greater than 5% (B5).

The owner is required to monitor mileage for

B6-B20 biodiesel, the automatic oil change

indicator system does not reflect the use of

biofuels.

Fuel filter change interval is maintained at

every second oil change. This is especially

important with biodiesel usage.

For more information on using biodiesel

Ú page 472.

WARNING!

You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge and

the right equipment. If you have any doubt

about your ability to perform a service job,

take your vehicle to a competent mechanic.

Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an acci -

dent.

8

21_DT_OM_EN_USC_t.book Page 403

Page 410 of 496

408SERVICING AND MAINTENANCE

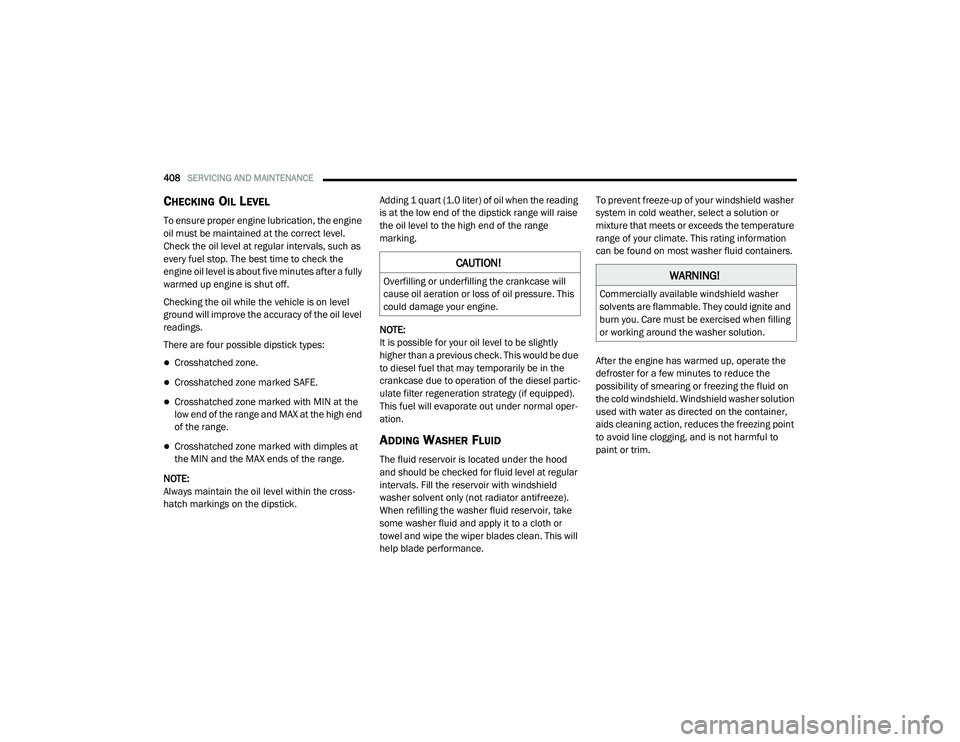

CHECKING OIL LEVEL

To ensure proper engine lubrication, the engine

oil must be maintained at the correct level.

Check the oil level at regular intervals, such as

every fuel stop. The best time to check the

engine oil level is about five minutes after a fully

warmed up engine is shut off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings.

There are four possible dipstick types:

Crosshatched zone.

Crosshatched zone marked SAFE.

Crosshatched zone marked with MIN at the

low end of the range and MAX at the high end

of the range.

Crosshatched zone marked with dimples at

the MIN and the MAX ends of the range.

NOTE:

Always maintain the oil level within the cross -

hatch markings on the dipstick. Adding 1 quart (1.0 liter) of oil when the reading

is at the low end of the dipstick range will raise

the oil level to the high end of the range

marking.

NOTE:

It is possible for your oil level to be slightly

higher than a previous check. This would be due

to diesel fuel that may temporarily be in the

crankcase due to operation of the diesel partic

-

ulate filter regeneration strategy (if equipped).

This fuel will evaporate out under normal oper -

ation.ADDING WASHER FLUID

The fluid reservoir is located under the hood

and should be checked for fluid level at regular

intervals. Fill the reservoir with windshield

washer solvent only (not radiator antifreeze).

When refilling the washer fluid reservoir, take

some washer fluid and apply it to a cloth or

towel and wipe the wiper blades clean. This will

help blade performance. To prevent freeze-up of your windshield washer

system in cold weather, select a solution or

mixture that meets or exceeds the temperature

range of your climate. This rating information

can be found on most washer fluid containers.

After the engine has warmed up, operate the

defroster for a few minutes to reduce the

possibility of smearing or freezing the fluid on

the cold windshield. Windshield washer solution

used with water as directed on the container,

aids cleaning action, reduces the freezing point

to avoid line clogging, and is not harmful to

paint or trim.

CAUTION!

Overfilling or underfilling the crankcase will

cause oil aeration or loss of oil pressure. This

could damage your engine.WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling

or working around the washer solution.

21_DT_OM_EN_USC_t.book Page 408

Page 414 of 496

412SERVICING AND MAINTENANCE

(Continued)

Engine Air Cleaner Filter Installation

NOTE:

Inspect and clean the housing if dirt or debris is

present before replacing the engine air cleaner

filter.

1. Install the engine air cleaner filter into the housing assembly with the engine air

cleaner filter inspection surface facing

downward.

2. Install the engine air cleaner filter cover onto the housing assembly.

3. Tighten the fasteners (six) on the engine air cleaner filter assembly.

DRAINING FUEL/WATER SEPARATOR

F

ILTER — DIESEL ENGINE

The fuel/water separator filter housing is

located inside the frame rail, behind the left

front wheel. The best access to this water drain

valve is from under the vehicle. If water is detected in the water separator while

the engine is running, or while the ignition

switch is in the ON/RUN position, the “Water In

Fuel Indicator Light” will illuminate and an

audible chime will be heard. At this point, you

should stop the engine and drain the water from

the filter housing.

Fuel Filter Assembly

If the “Water In Fuel Indicator Light” comes on

and a single chime is heard while you are

driving, or with the ignition in the ON position,

there may be a problem with your water

separator wiring or sensor. See an authorized

dealer for service.

Upon proper draining of the water from the fuel

filter, the “Water In Fuel Indicator Light” will

remain illuminated for approximately 10

seconds. If the water was drained while the

engine was running, the “Water In Fuel Indicator

Light” may remain on for approximately three

minutes.

NOTE:

Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately

discarded, can present a problem to the envi

-

ronment. Contact an authorized dealer, service

station, or government agency for advice on

recycling programs and for where used fluids

and filters can be properly disposed of in your

area.

CAUTION!

Do not drain the fuel/water separator filter

when the engine is running.

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

1 — Water In Fuel Drain Valve

CAUTION! (Continued)CAUTION!

If the “Water In Fuel Indicator Light” remains

on, DO NOT START the engine before you

drain water from the fuel filter to avoid engine

damage.

21_DT_OM_EN_USC_t.book Page 412

Page 415 of 496

SERVICING AND MAINTENANCE413

Drain the fuel/water separator filter when the

“Water In Fuel Indicator Light” is ON. Within

10 minutes of vehicle shutdown, turn the filter

drain valve (located on the bottom of the filter

housing) counterclockwise to drain fuel/water,

then turn the ignition switch to the ON position,

and allow any accumulated water to drain.

Leave the drain valve open until all water and

contaminants have been removed. When clean

fuel is visible, close the drain valve by turning it

clockwise, and turn the ignition switch to OFF.

If more than two ounces or 60 milliliters of fuel

have been drained Úpage 414.

UNDERBODY MOUNTED FUEL FILTER

R

EPLACEMENT — DIESEL ENGINE

NOTE:

Using a fuel filter that does not meet FCA’s filtra-

tion and water separating requirements can

severely impact fuel system life and reliability.

Under normal conditions the diesel fuel filter

should be replaced every 20,000 miles (every

other oil change). If the vehicle is being used in

severe operating conditions, or In certain

geographical areas of the country (Pennsyl -

vania, New York, Ohio, Maryland, West Virginia,

Arkansas, Oklahoma, Kansas, Iowa, Missouri and Nebraska) due to fuel cleanliness’ issues,

it’s recommended to replace the fuel filter every

10,000 miles.

Fuel Filter Assembly

1. Turn engine off.

2. Place a drain pan under the fuel filter

assembly.

3. Open the water drain valve, and let any accumulated water drain.

4. Close the water drain valve.

5. Remove bottom cover using a strap wrench. Rotate counterclockwise for removal.

Remove the used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of it according to your

local regulations.

7. Wipe the sealing surfaces of the lid and housing clean.

8. Install a new o-ring into the ring groove on the filter housing and lubricate with clean

engine oil.

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter

during this action. It is best to install the

filter dry and allow the in-tank lift pump to

prime the fuel system.

1 — Water In Fuel Drain Valve

2 — Fuel Filter Access

8

21_DT_OM_EN_USC_t.book Page 413

Page 416 of 496

414SERVICING AND MAINTENANCE

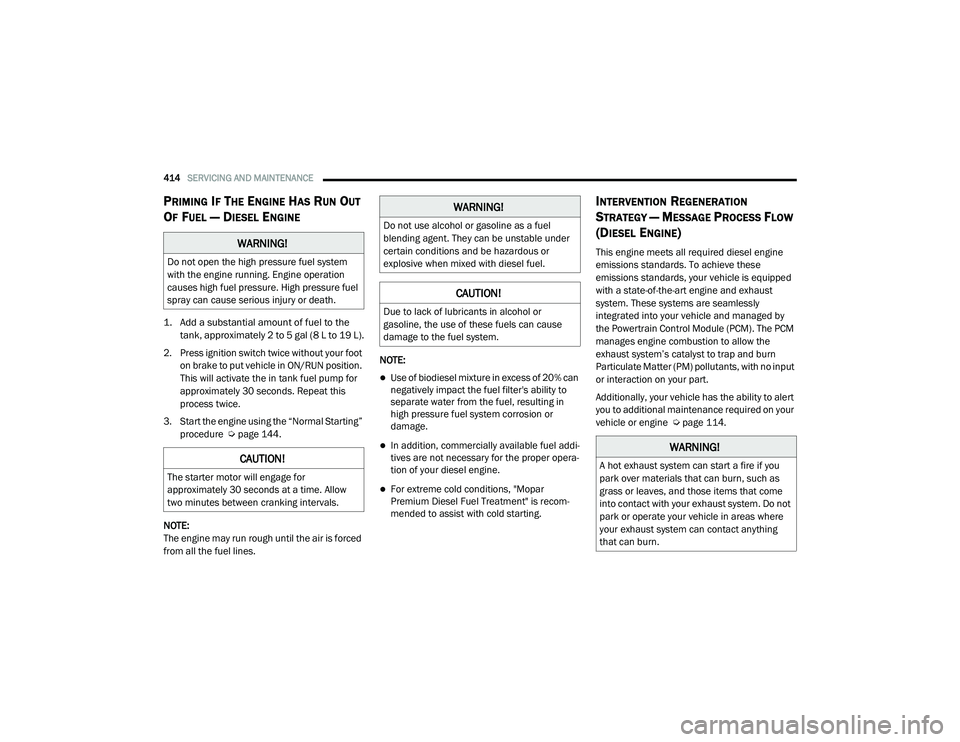

PRIMING IF THE ENGINE HAS RUN OUT

O

F FUEL — DIESEL ENGINE

1. Add a substantial amount of fuel to the

tank, approximately 2 to 5 gal (8 L to 19 L).

2. Press ignition switch twice without your foot on brake to put vehicle in ON/RUN position.

This will activate the in tank fuel pump for

approximately 30 seconds. Repeat this

process twice.

3. Start the engine using the “Normal Starting” procedure Ú page 144.

NOTE:

The engine may run rough until the air is forced

from all the fuel lines. NOTE:

Use of biodiesel mixture in excess of 20% can

negatively impact the fuel filter's ability to

separate water from the fuel, resulting in

high pressure fuel system corrosion or

damage.

In addition, commercially available fuel addi

-

tives are not necessary for the proper opera -

tion of your diesel engine.

For extreme cold conditions, "Mopar

Premium Diesel Fuel Treatment" is recom -

mended to assist with cold starting.

INTERVENTION REGENERATION

S

TRATEGY — MESSAGE PROCESS FLOW

(D

IESEL ENGINE)

This engine meets all required diesel engine

emissions standards. To achieve these

emissions standards, your vehicle is equipped

with a state-of-the-art engine and exhaust

system. These systems are seamlessly

integrated into your vehicle and managed by

the Powertrain Control Module (PCM). The PCM

manages engine combustion to allow the

exhaust system’s catalyst to trap and burn

Particulate Matter (PM) pollutants, with no input

or interaction on your part.

Additionally, your vehicle has the ability to alert

you to additional maintenance required on your

vehicle or engine Ú page 114.WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure fuel

spray can cause serious injury or death.

CAUTION!

The starter motor will engage for

approximately 30 seconds at a time. Allow

two minutes between cranking intervals.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under

certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system.

WARNING!

A hot exhaust system can start a fire if you

park over materials that can burn, such as

grass or leaves, and those items that come

into contact with your exhaust system. Do not

park or operate your vehicle in areas where

your exhaust system can contact anything

that can burn.

21_DT_OM_EN_USC_t.book Page 414

Page 473 of 496

TECHNICAL SPECIFICATIONS471

FUEL REQUIREMENTS – DIESEL ENGINE

Federal law requires that you must fuel this

vehicle with Ultra Low Sulfur Highway Diesel

fuel (15 ppm Sulfur maximum) and prohibits

the use of Low Sulfur Highway Diesel fuel

(500 ppm Sulfur maximum) to avoid damage to

the emissions control system.

Use good quality diesel fuel from a reputable

supplier in your vehicle. For most year-round

service, No. 2 diesel fuel meeting ASTM

(formerly known as the American Society for

Testing and Materials) specification D-975

Grade S15 will provide good performance. If the

vehicle is exposed to extreme cold (below 20°F

or -7°C), or is required to operate at

colder-than-normal conditions for prolonged

periods, use Climatized Number 2 diesel fuel or

dilute the Number 2 diesel fuel with 50%

Number 1 diesel fuel. This will provide better

protection from fuel gelling or wax-plugging of

the fuel filters. Diesel fuel is seldom completely free of water.

To prevent fuel system trouble, drain the

accumulated water from the fuel/water

separator filter using the fuel/water separator

drain provided on the fuel filter housing. If you

buy good quality fuel and follow the cold

weather advice above, fuel conditioners should

not be required in your vehicle. If available in

your area, a high cetane “premium” diesel fuel

may offer improved cold-starting and warm-up

performance.

DIESEL FUEL SPECIFICATIONS

This diesel engine has been developed to take

advantage of the high energy content and

generally lower cost Number 2 Ultra Low Sulfur

diesel fuel or Number 2 Ultra Low Sulfur

Climatized diesel fuels.

NOTE:

If you accidentally fill the fuel tank with gaso

-

line on your diesel vehicle, do not start the

engine. Damage to the engine and fuel

system could occur. Please call an autho -

rized dealer for service.

A maximum blend of 5% biodiesel meeting

ASTM specification D-975 may be used with

your diesel engine without any adjustments

to regular service schedules.

Commercially available fuel additives are not

necessary for the proper operation of your

diesel engine.

Number 1 Ultra Low Sulfur diesel fuel should

only be used where extended arctic condi -

tions (-10°F or -23°C) exist.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under

certain conditions and hazardous or

explosive when mixed with diesel fuel.

CAUTION!

If the “Water in Fuel Indicator Light” remains

on, DO NOT START engine before you drain

the water from the fuel filter(s) to avoid

engine damage Ú page 412.9

21_DT_OM_EN_USC_t.book Page 471

Page 474 of 496

472TECHNICAL SPECIFICATIONS

BIODIESEL FUEL REQUIREMENTS

A maximum blend of 5% biodiesel meeting

ASTM specification D975 is recommended for

use with your diesel engine. If frequent

operation with Biodiesel blends that are

between 6% and 20% (B6–B20) is desired, the

maintenance schedule is subject to shorter

intervals.

The oil and filter change along with fuel filter

replacement is subject to shorter intervals

when operating your engine on biodiesel

greater than 5%. Do not use biodiesel greater

than 20%.

For regular use of biodiesel blends between 6%

and 20% (B6–B20) it is important that you

understand and comply with these

requirements. For further direction

Úpage 403. Biodiesel is a fuel produced from renewable

resources typically derived from animal fat,

rapeseed oil (Rapeseed Methyl Ester (RME)

base), or soybean oil (Soy Methyl Ester (SME or

SOME) base).

Biodiesel fuel has inherent limitations which

require that you understand and adhere to the

following requirements if you use blends of

Biodiesel between 6% and 20% (B6–B20).

There are no unique restrictions for the use of

B5.

Biodiesel Fuel Properties — Low Ambient

Temperatures

Biodiesel fuel may gel or solidify at low ambient

temperatures, which may pose problems for

both storage and operation. Precautions can be

necessary at low ambient temperatures, such

as storing the fuel in a heated building or a

heated storage tank, or using cold temperature

additives.

CAUTION!

Failure to comply with Oil Change

requirements for vehicles operating on

biodiesel blends between 6% and 20%

(B6–B20) will result in premature engine

wear. Such wear is not covered by the New

Vehicle Limited Warranty.

CAUTION!

Use of blends greater than 20% is not

approved. Use of blends greater than 20%

can result in engine damage. Such damage is

not covered by the New Vehicle Limited

Warranty.

CAUTION!

In the event that the vehicle is filled with

biodiesel and not used for more than a

month, the fuel should either be used up by

driving (up to quarter tank) and filled with

standard diesel blends with less than 5% that

is normally available. This will help prevent

the fuel filter clogging and potential damage

to the fuel injection system due to degraded

biodiesel, which is not covered by the New

Vehicle Limited Warranty.

21_DT_OM_EN_USC_t.book Page 472

Page 475 of 496

TECHNICAL SPECIFICATIONS473

Fuel Quality — Must Comply With ASTM

Standards

The quality of Biodiesel fuel may vary widely.

Only fuel produced by a BQ9000 supplier to the

following specifications may be blended to

meet Biodiesel blend B6 – B20 fuel meeting

ASTM specification D-7467:

Petrodiesel fuel meeting ASTM specification

D-975 and Biodiesel fuel (B100) meeting ASTM

specification D-6751

Fuel Oxidation Stability — Must Use Fuel

Within Six Months Of Manufacture

Biodiesel fuel has poor oxidation stability which

can result in long term storage problems. Fuel

produced to approved ASTM standards, if

stored properly, provides for protection against

fuel oxidation for up to six months.

Fuel Water Separation — Must Use Mopar

Approved Fuel Filter Elements

Biodiesel fuel has a natural affinity to water and

water accelerates microbial growth. Your Mopar

filtration system is designed to provide

adequate fuel water separation capabilities.

Fuel In Oil Dilution — Must Adhere To

Required Oil Change Interval

Fuel dilution of lubricating oil has been

observed with the use of Biodiesel fuel. Fuel in

oil must not exceed 5%. To ensure this limit is

met your oil change interval must be

maintained with in the suggested schedule. The

regular use of biodiesel between 6% and 20%

requires intervals shorter than the outlined

10,000 miles (16,100 km) and must not

exceed the suggested schedule. When routinely

operating on biodiesel between 6% and 20%, oil

and filter replacement intervals must not

exceed 8,000 Miles (12,900 km) or six months,

which ever comes first.

Biodiesel Fuel Filter Change Intervals

The use of biodiesel requires more frequent fuel

filter change intervals. When operating on

biodiesel between 6% and 20%, fuel filter

replacement intervals should be every second

oil change, and must not exceed 16,000 miles

(25,750 km).

NOTE:

Under no circumstances should oil change

intervals exceed 8,000 miles (12,875 km) or

six months, if regular operation occurs with 6%

- 20% biodiesel blends. Under no circumstances

should fuel filter replacement intervals exceed

every second oil change and must not exceed

16,000 miles (25,750 km), if regular operation

occurs with 6% - 20% biodiesel blends. Failure

to comply with these oil change and fuel filter

requirements for vehicles operating on

biodiesel blends up to B20 may result in prema -

ture engine wear. Such wear is not covered by

the New Vehicle Limited Warranty. The engine

may suffer severe damage if operated with

concentrations of biodiesel higher than 20%.

9

21_DT_OM_EN_USC_t.book Page 473

Page 476 of 496

474TECHNICAL SPECIFICATIONS

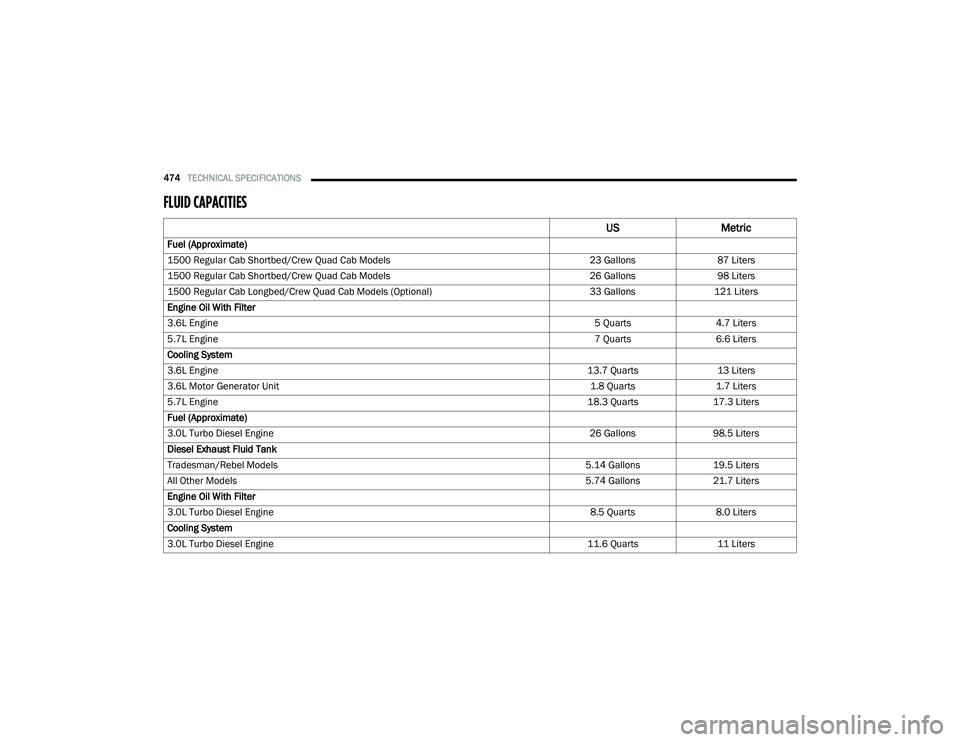

FLUID CAPACITIES

USMetric

Fuel (Approximate)

1500 Regular Cab Shortbed/Crew Quad Cab Models 23 Gallons87 Liters

1500 Regular Cab Shortbed/Crew Quad Cab Models 26 Gallons98 Liters

1500 Regular Cab Longbed/Crew Quad Cab Models (Optional) 33 Gallons121 Liters

Engine Oil With Filter

3.6L Engine 5 Quarts4.7 Liters

5.7L Engine 7 Quarts6.6 Liters

Cooling System

3.6L Engine 13.7 Quarts13 Liters

3.6L Motor Generator Unit 1.8 Quarts1.7 Liters

5.7L Engine 18.3 Quarts17.3 Liters

Fuel (Approximate)

3.0L Turbo Diesel Engine 26 Gallons98.5 Liters

Diesel Exhaust Fluid Tank

Tradesman/Rebel Models 5.14 Gallons19.5 Liters

All Other Models 5.74 Gallons21.7 Liters

Engine Oil With Filter

3.0L Turbo Diesel Engine 8.5 Quarts8.0 Liters

Cooling System

3.0L Turbo Diesel Engine 11.6 Quarts11 Liters

21_DT_OM_EN_USC_t.book Page 474

Page 477 of 496

TECHNICAL SPECIFICATIONS475

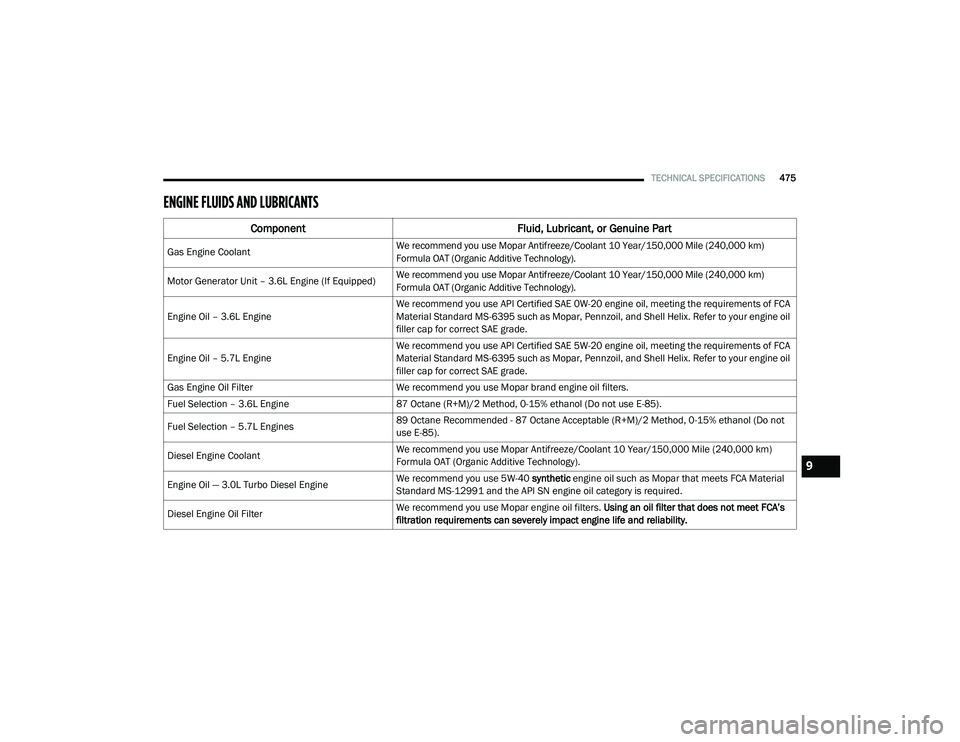

ENGINE FLUIDS AND LUBRICANTS

Component Fluid, Lubricant, or Genuine Part

Gas Engine CoolantWe recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile (240,000 km)

Formula OAT (Organic Additive Technology).

Motor Generator Unit – 3.6L Engine (If Equipped) We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile (240,000 km)

Formula OAT (Organic Additive Technology).

Engine Oil – 3.6L Engine We recommend you use API Certified SAE 0W-20 engine oil, meeting the requirements of FCA

Material Standard MS-6395 such as Mopar, Pennzoil, and Shell Helix. Refer to your engine oil

filler cap for correct SAE grade.

Engine Oil – 5.7L Engine We recommend you use API Certified SAE 5W-20 engine oil, meeting the requirements of FCA

Material Standard MS-6395 such as Mopar, Pennzoil, and Shell Helix. Refer to your engine oil

filler cap for correct SAE grade.

Gas Engine Oil Filter We recommend you use Mopar brand engine oil filters.

Fuel Selection – 3.6L Engine 87 Octane (R+M)/2 Method, 0-15% ethanol (Do not use E-85).

Fuel Selection – 5.7L Engines 89 Octane Recommended - 87 Octane Acceptable (R+M)/2 Method, 0-15% ethanol (Do not

use E-85).

Diesel Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile (240,000 km)

Formula OAT (Organic Additive Technology).

Engine Oil — 3.0L Turbo Diesel Engine We recommend you use 5W-40

synthetic engine oil such as Mopar that meets FCA Material

Standard MS-12991 and the API SN engine oil category is required.

Diesel Engine Oil Filter We recommend you use Mopar engine oil filters.

Using an oil filter that does not meet FCA’s

filtration requirements can severely impact engine life and reliability.

9

21_DT_OM_EN_USC_t.book Page 475