maintenance RAM 1500 2021 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 315 of 496

SAFETY313

(Continued)

ESC Operating Modes

Depending upon model and mode of operation,

the ESC system may have multiple operating

modes. ESC On

This is the normal operating mode for the ESC.

Whenever the vehicle is started, the ESC system

will be in this mode. This mode should be used

for most driving conditions. Alternate ESC

modes should only be used for specific reasons

as noted in the following paragraphs.

Partial Off

This mode may be useful if the vehicle becomes

stuck. This mode may modify TCS and ESC

thresholds for activation, which allows for more

wheel spin than normally allowed.

To enter the “Partial Off” mode, momentarily

push the ESC OFF switch and the ESC OFF

Indicator Light will illuminate. To turn the ESC

on again, momentarily push the ESC OFF switch

and the ESC OFF Indicator Light will turn off.

NOTE:

For vehicles with multiple partial ESC modes,

the push and release of the button will toggle

the ESC modes. Multiple attempts may be

required to return to “ESC On”.

WARNING!

Electronic Stability Control (ESC) cannot

prevent the natural laws of physics from

acting on the vehicle, nor can it increase

the traction afforded by prevailing road

conditions. ESC cannot prevent accidents,

including those resulting from excessive

speed in turns, driving on very slippery

surfaces, or hydroplaning. ESC also cannot

prevent accidents resulting from loss of

vehicle control due to inappropriate driver

input for the conditions. Only a safe, atten

-

tive, and skillful driver can prevent acci -

dents. The capabilities of an ESC equipped

vehicle must never be exploited in a reck -

less or dangerous manner which could

jeopardize the user’s safety or the safety of

others.Vehicle modifications, or failure to properly

maintain your vehicle, may change the

handling characteristics of your vehicle,

and may negatively affect the performance

of the ESC system. Changes to the steering

system, suspension, braking system, tire

type and size or wheel size may adversely

affect ESC performance. Improperly

inflated and unevenly worn tires may also

degrade ESC performance. Any vehicle

modification or poor vehicle maintenance

that reduces the effectiveness of the ESC

system can increase the risk of loss of

vehicle control, vehicle rollover, personal

injury and death.

WARNING! (Continued)

6

21_DT_OM_EN_USC_t.book Page 313

Page 331 of 496

SAFETY329

NOTE:

The TPMS is not intended to replace normal

tire care and maintenance or to provide

warning of a tire failure or condition.

The TPMS should not be used as a tire pres -

sure gauge while adjusting your tire pressure,

unless your vehicle is equipped with a Tire Fill

Alert (TFA) system.

Driving on a significantly underinflated tire

causes the tire to overheat and can lead to

tire failure. Underinflation also reduces fuel

efficiency and tire tread life, and may affect

the vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsi -

bility to maintain correct tire pressure using

an accurate tire pressure gauge, even if

underinflation has not reached the level to

trigger illumination of the TPMS Warning

Light.

Seasonal temperature changes will affect

tire pressure, and the TPMS will monitor the

actual tire pressure in the tire.

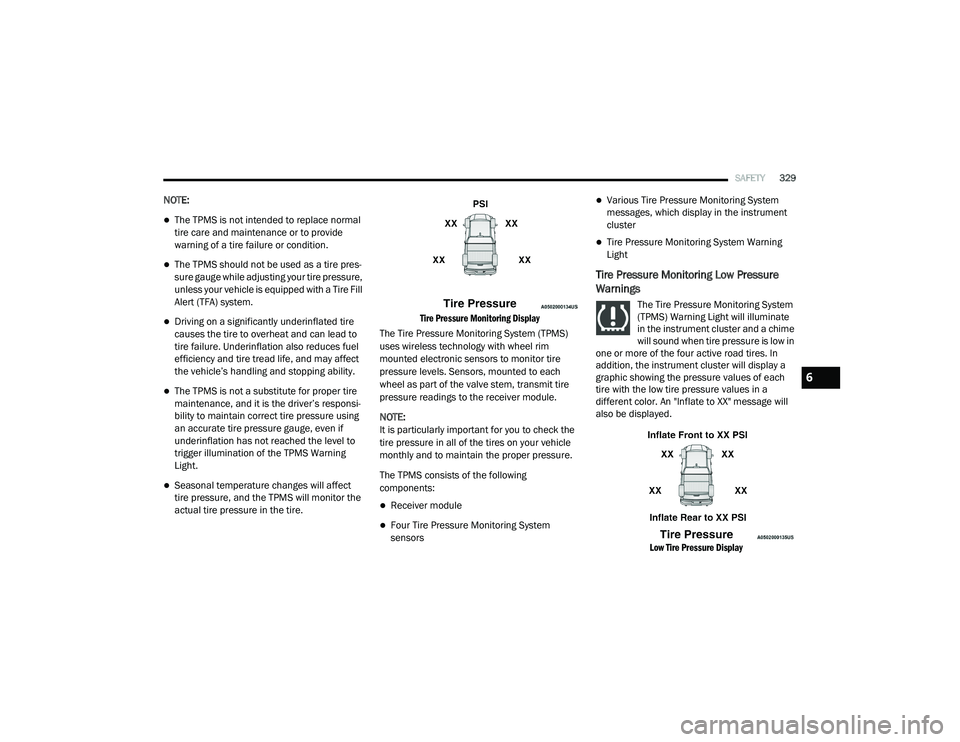

Tire Pressure Monitoring Display

The Tire Pressure Monitoring System (TPMS)

uses wireless technology with wheel rim

mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire

pressure readings to the receiver module.

NOTE:

It is particularly important for you to check the

tire pressure in all of the tires on your vehicle

monthly and to maintain the proper pressure.

The TPMS consists of the following

components:

Receiver module

Four Tire Pressure Monitoring System

sensors

Various Tire Pressure Monitoring System

messages, which display in the instrument

cluster

Tire Pressure Monitoring System Warning

Light

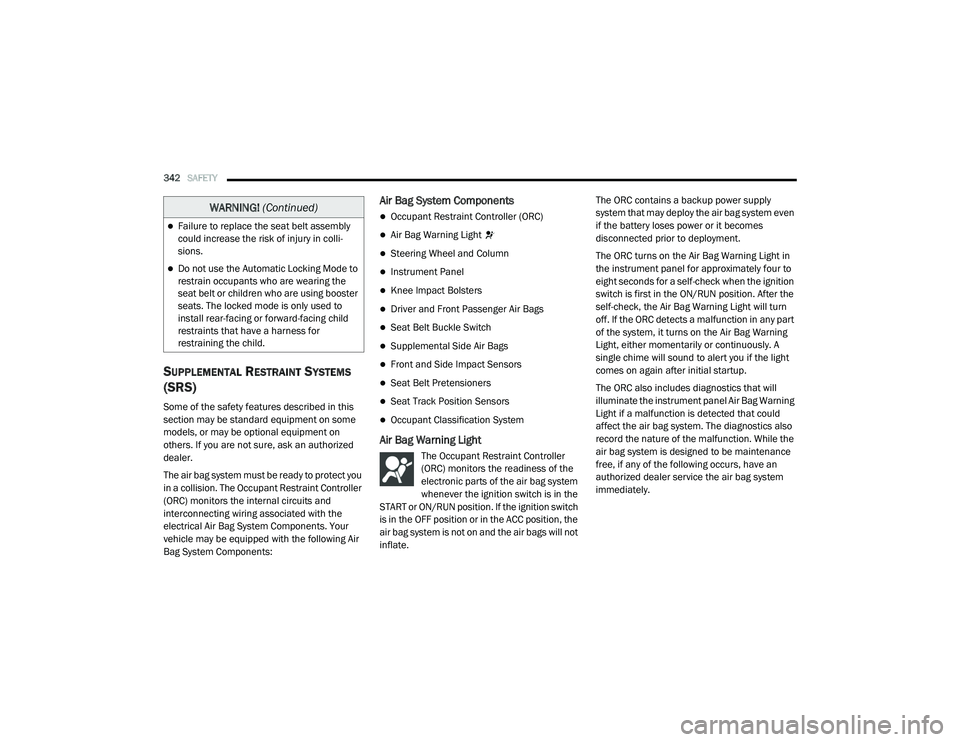

Tire Pressure Monitoring Low Pressure

Warnings

The Tire Pressure Monitoring System

(TPMS) Warning Light will illuminate

in the instrument cluster and a chime

will sound when tire pressure is low in

one or more of the four active road tires. In

addition, the instrument cluster will display a

graphic showing the pressure values of each

tire with the low tire pressure values in a

different color. An "Inflate to XX" message will

also be displayed.

Low Tire Pressure Display

6

21_DT_OM_EN_USC_t.book Page 329

Page 344 of 496

342SAFETY

SUPPLEMENTAL RESTRAINT SYSTEMS

(SRS)

Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on

others. If you are not sure, ask an authorized

dealer.

The air bag system must be ready to protect you

in a collision. The Occupant Restraint Controller

(ORC) monitors the internal circuits and

interconnecting wiring associated with the

electrical Air Bag System Components. Your

vehicle may be equipped with the following Air

Bag System Components:

Air Bag System Components

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Knee Impact Bolsters

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags

Front and Side Impact Sensors

Seat Belt Pretensioners

Seat Track Position Sensors

Occupant Classification System

Air Bag Warning Light

The Occupant Restraint Controller

(ORC) monitors the readiness of the

electronic parts of the air bag system

whenever the ignition switch is in the

START or ON/RUN position. If the ignition switch

is in the OFF position or in the ACC position, the

air bag system is not on and the air bags will not

inflate. The ORC contains a backup power supply

system that may deploy the air bag system even

if the battery loses power or it becomes

disconnected prior to deployment.

The ORC turns on the Air Bag Warning Light in

the instrument panel for approximately four to

eight seconds for a self-check when the ignition

switch is first in the ON/RUN position. After the

self-check, the Air Bag Warning Light will turn

off. If the ORC detects a malfunction in any part

of the system, it turns on the Air Bag Warning

Light, either momentarily or continuously. A

single chime will sound to alert you if the light

comes on again after initial startup.

The ORC also includes diagnostics that will

illuminate the instrument panel Air Bag Warning

Light if a malfunction is detected that could

affect the air bag system. The diagnostics also

record the nature of the malfunction. While the

air bag system is designed to be maintenance

free, if any of the following occurs, have an

authorized dealer service the air bag system

immediately.

Failure to replace the seat belt assembly

could increase the risk of injury in colli

-

sions.

Do not use the Automatic Locking Mode to

restrain occupants who are wearing the

seat belt or children who are using booster

seats. The locked mode is only used to

install rear-facing or forward-facing child

restraints that have a harness for

restraining the child.

WARNING! (Continued)

21_DT_OM_EN_USC_t.book Page 342

Page 374 of 496

372SAFETY

CARBON MONOXIDE WARNINGS

WARNING!

Carbon monoxide (CO) in exhaust gases is

deadly. Follow the precautions below to

prevent carbon monoxide poisoning:

Do not inhale exhaust gases. They contain

carbon monoxide, a colorless and odorless

gas, which can kill. Never run the engine in

a closed area, such as a garage, and never

sit in a parked vehicle with the engine

running for an extended period. If the

vehicle is stopped in an open area with the

engine running for more than a short

period, adjust the ventilation system to

force fresh, outside air into the vehicle.

Guard against carbon monoxide with

proper maintenance. Have the exhaust

system inspected every time the vehicle is

raised. Have any abnormal conditions

repaired promptly. Until repaired, drive with

all side windows fully open.

21_DT_OM_EN_USC_t.book Page 372

Page 397 of 496

395

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the

“Oil Change Required” message is displayed.

Severe operating conditions can cause the

change oil message to illuminate as early as

3,500 miles (5,600 km) since last reset. Have

your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an authorized dealer, the message can be reset by

referring to the steps described under

Instrument Cluster Display Ú

page 114.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

NOTE:

Vehicles that are operated in a dusty and

off-road environment, or predominately at idle

or very low engine RPM are known as Severe

Duty vehicles. It is recommended that you

change the engine oil at 4,000 miles

(6,500 km) or 350 hours of engine run time.

Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and fill as needed.

Check function of all interior and exterior

lights.

MAINTENANCE PLAN

Refer to the Maintenance Plan for required

maintenance. More frequent maintenance may

be needed in severe conditions, such as dusty

areas and very short trip driving. In some

extreme conditions, additional maintenance

not specified in the maintenance schedule may

be required.

8

21_DT_OM_EN_USC_t.book Page 395

Page 398 of 496

396SERVICING AND MAINTENANCE

NOTE:

Using white lithium grease, lubricate the door hinge roller pivot joints twice a year to prevent premature wear.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change the oil and filter.

Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect the battery and clean and tighten terminals as required.

Inspect the CV/Universal joints.

Inspect the brake pads, shoes, rotors, drums, and hoses.

Inspect the engine cooling system protection and hoses.

Inspect the exhaust system.

Inspect the engine air cleaner if using in dusty or off-road conditions, replace the engine air cleaner, as necessary.

Inspect and replace the Evaporative System Fresh Air Filter as necessary; replacement may be more frequent if vehicle is operated in extreme dusty

conditions.

21_DT_OM_EN_USC_t.book Page 396

Page 399 of 496

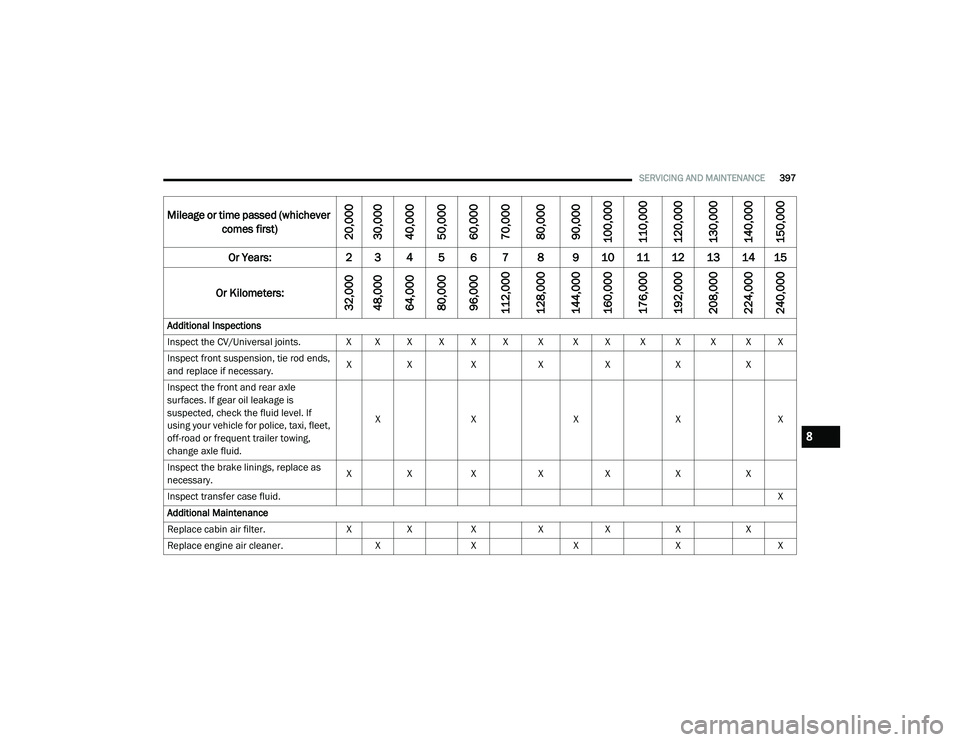

SERVICING AND MAINTENANCE397

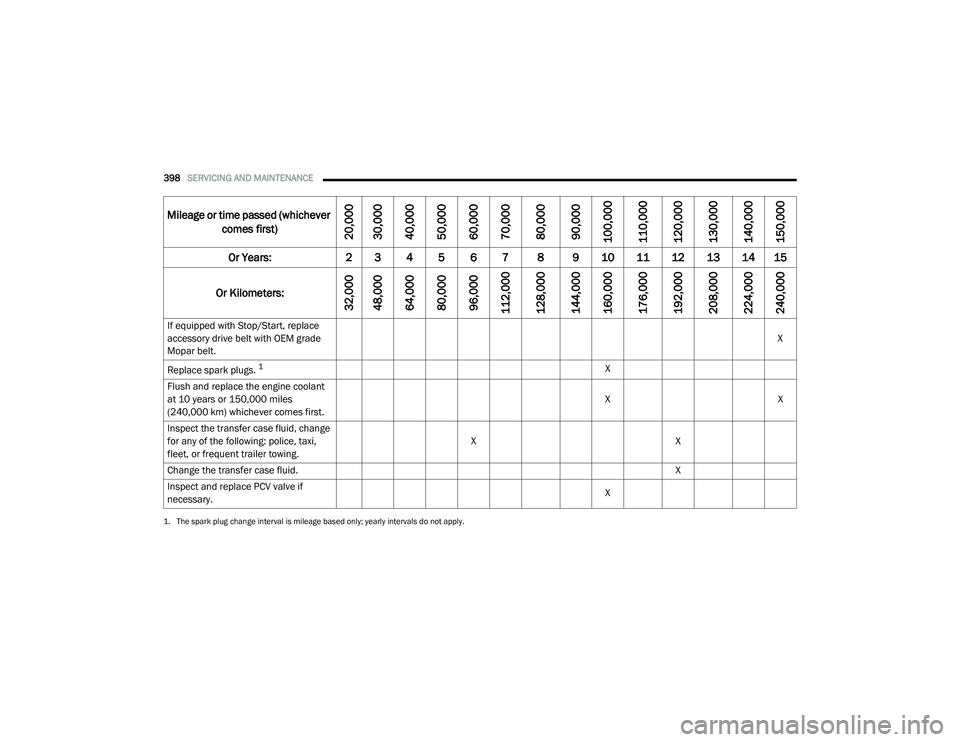

Mileage or time passed (whichever

comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X X X X X X X X Inspect front suspension, tie rod ends,

and replace if necessary. X

X X XX XX

Inspect the front and rear axle

surfaces. If gear oil leakage is

suspected, check the fluid level. If

using your vehicle for police, taxi, fleet,

off-road or frequent trailer towing,

change axle fluid. X

X XXX

Inspect the brake linings, replace as

necessary. X

X X XX XX

Inspect transfer case fluid. X

Additional Maintenance

Replace cabin air filter. XX X XX XX

Replace engine air cleaner. XX XXX

8

21_DT_OM_EN_USC_t.book Page 397

Page 400 of 496

398SERVICING AND MAINTENANCE

If equipped with Stop/Start, replace

accessory drive belt with OEM grade

Mopar belt. X

Replace spark plugs.

1X

Flush and replace the engine coolant

at 10 years or 150,000 miles

(240,000 km) whichever comes first. X

X

Inspect the transfer case fluid, change

for any of the following: police, taxi,

fleet, or frequent trailer towing. X

X

Change the transfer case fluid. X

Inspect and replace PCV valve if

necessary. X

1. The spark plug change interval is mileage based only; yearly intervals do not apply.

Mileage or time passed (whichever

comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

21_DT_OM_EN_USC_t.book Page 398

Page 401 of 496

SERVICING AND MAINTENANCE399

SCHEDULED SERVICING — DIESEL ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance. Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures will influence when the

“Oil Change Required” message is displayed.

Severe Operating Conditions will cause the

change oil message to illuminate more

frequently. Have your vehicle serviced as soon

as possible, within the next 500 miles

(805 km).

An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an

authorized dealer, the message can be reset by

referring to the steps described under

Instrument Cluster Display Ú

page 114.NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km) or

12 months, whichever comes first.

Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check the tire inflation pressures and look

for unusual wear or damage

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering,

and fill as needed

Check function of all interior and exterior

lights

WARNING!

You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge and

the right equipment. If you have any doubt

about your ability to perform a service job,

take your vehicle to a competent mechanic.

Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an acci

-

dent.

8

21_DT_OM_EN_USC_t.book Page 399

Page 402 of 496

400SERVICING AND MAINTENANCE

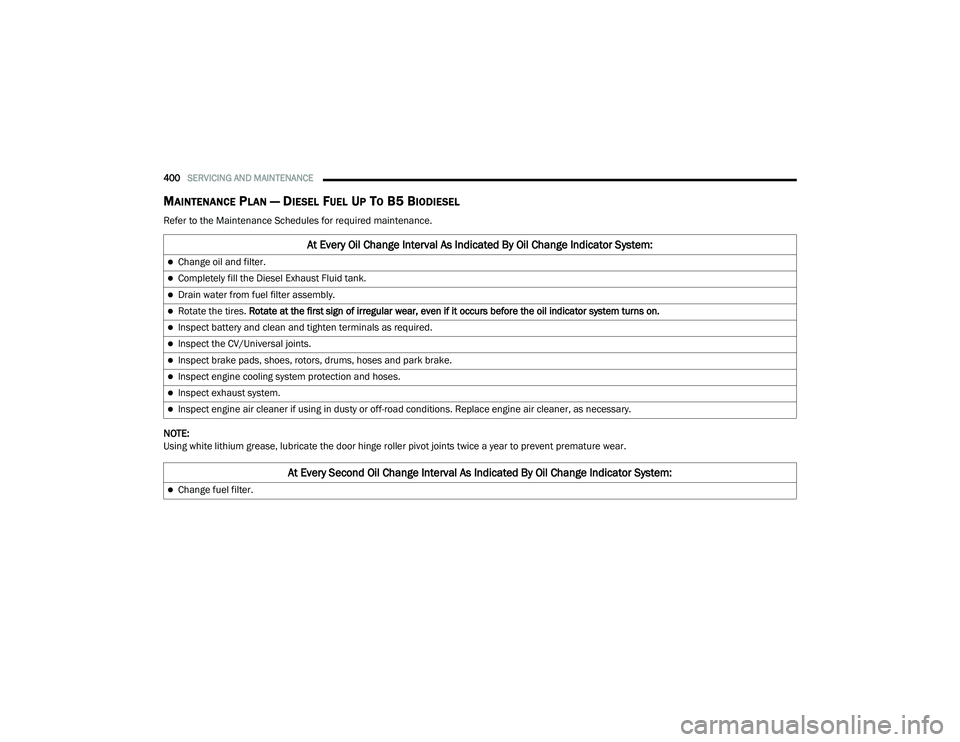

MAINTENANCE PLAN — DIESEL FUEL UP TO B5 BIODIESEL

Refer to the Maintenance Schedules for required maintenance.

NOTE:

Using white lithium grease, lubricate the door hinge roller pivot joints twice a year to prevent premature wear.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter.

Completely fill the Diesel Exhaust Fluid tank.

Drain water from fuel filter assembly.

Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect battery and clean and tighten terminals as required.

Inspect the CV/Universal joints.

Inspect brake pads, shoes, rotors, drums, hoses and park brake.

Inspect engine cooling system protection and hoses.

Inspect exhaust system.

Inspect engine air cleaner if using in dusty or off-road conditions. Replace engine air cleaner, as necessary.

At Every Second Oil Change Interval As Indicated By Oil Change Indicator System:

Change fuel filter.

21_DT_OM_EN_USC_t.book Page 400