ECO mode RAM 1500 2023 Manual PDF

[x] Cancel search | Manufacturer: RAM, Model Year: 2023, Model line: 1500, Model: RAM 1500 2023Pages: 416, PDF Size: 20.59 MB

Page 282 of 416

280SAFETY

The system will be activated when a positive increase in

tire pressure is detected by the TPMS while inflating the

tire. The ignition must be in the RUN mode, with the

transmission in PARK.

NOTE:It is not required to have the engine running to enter Tire

Fill Alert mode.

The hazard lamps will come on to confirm the vehicle is in

Tire Fill Alert mode.

When Tire Fill Alert mode is entered, the tire pressure

display screen will be displayed in the instrument cluster.

If the hazard lamps do not come on while inflating the tire,

the TPMS sensor may be out of range preventing the TPMS

sensor signal from being received. In this case, the vehicle

may need to be moved either forward or backward slightly

to exit the null spot.

Operation:

The horn will sound once to let the user know when to

stop filling the tire, when it reaches recommended

pressure.

The horn will sound three times if the tire is overfilled

and will continue to sound every five seconds if the

user continues to inflate the tire.

The horn will sound once again when enough air is let

out to reach proper inflation level.

The horn will also sound three times if the tire is then

underinflated and will continue to sound every five

seconds if the user continues to deflate the tire.

Trailer Tire Pressure Monitoring System

(TTPMS) — If Equipped

The Trailer Tire Pressure Monitoring System (TTPMS) is a

feature that displays the trailer tire pressure values and

warns the driver of a low tire pressure event based on the

driver’s set target tire pressure value, through TTPMS

settings found in the radio.

The TTPMS monitors the pressure of each tire and warns

the driver through the instrument cluster, when either a

low tire pressure condition falls below 25% of the driver’s

set pressure or if a system malfunction occurs. The

instrument cluster will display the actual tire pressure or

dashes for each of the trailer tires in the correct trailer

position, based on trailer configuration. The TTPMS can

support up to 12 trailer tires per configured trailer on up to

four configurable trailers

Úpage 191.

Trailer Tire Pressure Monitoring System

Trailer Tire Pressure Sensor Pairing

In order use this feature, the provided tire pressure

sensors must be installed in the desired trailer tires and

the sensors must be paired to the truck. If the target trailer

requires more than the provided four sensors, additional

sensors can be purchased at an authorized Ram

dealership.

With the sensors installed and the trailer near or

connected to your Ram truck, initiate the pairing process

by entering the settings menu in the radio and selecting

trailer. Select the desired trailer profile to pair to, open the

“Tire Pressure” menu, and hit “Setup All Tires”

Úpage 191.

NOTE:The vehicle may not be driven until the pairing process is

complete.

Trailer Tire Pressure Settings

23_DT_OM_EN_USC_t.book Page 280

Page 296 of 416

294SAFETY

The Air Bag Warning Light in the instrument panel will

turn on whenever the OCS is unable to classify the front

passenger seat status. A malfunction in the OCS may

affect the operation of the air bag system.

If the Air Bag Warning Light does not come on, or stays

on after you start the vehicle, or it comes on as you drive,

take the vehicle to an authorized dealer for service

immediately.

The passenger seat assembly contains critical OCS

components that may affect the Passenger Advanced

Front Air Bag inflation. In order for the OCS to properly

classify the seated weight of a front seat passenger, the

OCS components must function as designed. Do not make

any modifications to the front passenger seat

components, assembly, or to the seat cover. If the seat,

trim cover, or cushion needs service for any reason, take

the vehicle to an authorized dealer. Only FCA US LLC

approved seat accessories may be used.

The following requirements must be strictly followed:

Do not modify the front passenger seat assembly or

components in any way.

Do not use prior or future model year seat covers or

cushions not designated by FCA US LLC for the specific

model being repaired. Always use the correct seat

cover and cushion specified for the vehicle.

Do not replace the seat cover or cushion with an after -

market seat cover or cushion.

Do not add a secondary seat cover or mat.

At no time should any Supplemental Restraint System

(SRS) component or SRS related component or

fastener be modified or replaced with any part except

those which are approved by FCA US LLC.Knee Impact Bolsters

The Knee Impact Bolsters help protect the knees of the

driver and front passenger, and position the front

occupants for improved interaction with the front air bags.

Supplemental Side Air Bags

Supplemental Seat-Mounted Side Air Bags (SABs)

This vehicle is equipped with Supplemental Seat-Mounted

Side Air Bags (SABs).

Supplemental Seat-Mounted Side Air Bags (SABs) are

located in the outboard side of the front seats. The SABs

are marked with “SRS AIRBAG” or “AIRBAG” on a label or

on the seat trim on the outboard side of the seats.

The SABs may help to reduce the risk of occupant injury

during certain side impacts, in addition to the injury

reduction potential provided by the seat belts and body

structure.

WARNING!

Unapproved modifications or service procedures to

the passenger seat assembly, its related compo -

nents, seat cover or cushion may inadvertently

change the air bag deployment in case of a frontal

collision. This could result in death or serious injury

to the front passenger if the vehicle is involved in a

collision. A modified vehicle may not comply with

required Federal Motor Vehicle Safety Standards

(FMVSS) and/or Canadian Motor Vehicle Safety

Standards (CMVSS).

If it is necessary to modify the air bag system

for persons with disabilities, contact an authorized

dealer.

WARNING!

Do not drill, cut, or tamper with the knee impact

bolsters in any way.

Do not mount any accessories to the knee impact

bolsters such as alarm lights, stereos, citizen band

radios, etc.

23_DT_OM_EN_USC_t.book Page 294

Page 310 of 416

308SAFETY

Installing A Child Restraint With A

Switchable Automatic Locking Retractor

(ALR):

Child restraint systems are designed to be secured in

vehicle seats by lap belts or the lap belt portion of a lap/

shoulder belt.

1. Place the child seat in the center of the seating

position. If the second row seat can be reclined, you

may recline the seat and/or raise the head restraint

(if adjustable) to get a better fit. If the rear seat can

be moved forward and rearward in the vehicle, you

may wish to move it to its rear-most position to make

room for the child seat. You may also move the front

seat forward to allow more room for the child seat.

2. Pull enough of the seat belt webbing from the retractor to pass it through the belt path of the

child restraint. Do not twist the belt webbing in

the belt path. 3. Slide the latch plate into the buckle until you hear a

“click.”

4. Pull on the webbing to make the lap portion tight against the child seat.

5. To lock the seat belt, pull down on the shoulder part of the belt until you have pulled all the seat belt

webbing out of the retractor. Then, allow the webbing

to retract back into the retractor. As the webbing

retracts, you will hear a clicking sound. This means

the seat belt is now in the Automatic Locking mode.

6. Try to pull the webbing out of the retractor. If it is locked, you should not be able to pull out any

webbing. If the retractor is not

locked, repeat step 5.

7. Finally, pull up on any excess webbing to tighten the lap portion around the child restraint while you push

the child restraint rearward and downward into the

vehicle seat.

8. If the child restraint has a top tether strap and the seating position has a top tether anchorage, connect

the tether strap to the anchorage and tighten the

tether strap

Úpage 308.

9. Test that the child restraint is installed tightly by pulling back and forth on the child seat at the belt

path. It should not move more than 1 inch (25.4 mm) in any direction.

Any seat belt system will loosen with time, so check the

belt occasionally, and pull it tight if necessary.

Installing Child Restraints Using The Top

Tether Anchorage

WARNING!

Improper installation or failure to properly secure a

child restraint can lead to failure of the restraint.

The child could be badly injured or killed.

Follow the child restraint manufacturer’s directions

exactly when installing an infant or child restraint.

WARNING!

Do not attach a tether strap for a rear-facing car seat to

any location in front of the car seat, including the seat

frame or a tether anchorage. Only attach the tether

strap of a rear-facing car seat to the tether anchorage

that is approved for that seating position, located

behind the top of the vehicle seat. For the location of

approved tether anchorages in your vehicle, see

Úpage 302.

WARNING!

Never place a rear-facing child restraint in front of an air

bag. A deploying Passenger Front Air Bag can cause

death or serious injury to a child 12 years or younger,

including a child in a rear-facing child restraint.

23_DT_OM_EN_USC_t.book Page 308

Page 313 of 416

SAFETY311

SAFETY TIPS

TRANSPORTING PASSENGERS

NEVER TRANSPORT PASSENGERS IN THE CARGO AREA.

TRANSPORTING PETS

Air Bags deploying in the front seat could harm your pet.

An unrestrained pet will be thrown about and possibly

injured, or injure a passenger during panic braking or in a

collision.

Pets should be restrained in the rear seat (if equipped)

in pet harnesses or pet carriers that are secured by

seat belts.

CONNECTED VEHICLES

Privacy of any wireless and wired communications cannot

be assured. Third parties may unlawfully intercept

information and private communications without your

consent. For further information, refer to “Data Collection

& Privacy” in your Uconnect Radio Instruction Manual or

“Onboard Diagnostic System (OBD II) Cybersecurity”

Úpage 116.

SAFETY CHECKS YOU SHOULD MAKE

I

NSIDE THE VEHICLE

Seat Belts

Inspect the seat belt system periodically, checking for

cuts, frays, and loose parts. Damaged parts must be

replaced immediately. Do not disassemble or modify the

system. If your vehicle is involved in a collision, or if you have

questions regarding the seat belt or retractor conditions,

take your vehicle to an authorized FCA dealer or

authorized FCA Certified Collision Care Program facility for

inspection.

Air Bag Warning Light

The Air Bag Warning Light will turn on for four to

eight seconds as a bulb check when the

ignition switch is first placed in the ON/RUN

position. If the light is either not on during

starting, stays on, or turns on while driving, have the

system inspected at an authorized dealer as soon as

possible. After the bulb check, this light will illuminate with

a single chime when a fault with the Air Bag System has

been detected. It will stay on until the fault is removed.

If the light comes on intermittently or remains on while

driving, have an authorized dealer service the vehicle

immediately.

See

Úpage 282 for further information.

Defroster

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to

feel the air directed against the windshield. See an

authorized dealer for service if your defroster is

inoperable.

WARNING!

Do not leave children or animals inside parked vehi -

cles in hot weather. Interior heat buildup may cause

serious injury or death.

It is extremely dangerous to ride in a cargo area,

inside or outside of a vehicle. In a collision, people

riding in these areas are more likely to be seriously

injured or killed.

Do not allow people to ride in any area of your vehicle

that is not equipped with seats and seat belts.

Be sure everyone in your vehicle is in a seat and

using a seat belt properly.

WARNING!

It is not possible to know or to predict all of the possible

outcomes if your vehicle’s systems are breached. It may

be possible that vehicle systems, including safety

related systems, could be impaired or a loss of vehicle

control could occur that may result in an accident

involving serious injury or death.

6

23_DT_OM_EN_USC_t.book Page 311

Page 314 of 416

312SAFETY

(Continued)

(Continued)

Floor Mat Safety Information

Always use floor mats designed to fit your vehicle. Only use

a floor mat that does not interfere with the operation of the

accelerator, brake or clutch pedals. Only use a floor mat

that is securely attached using the floor mat fasteners so

it cannot slip out of position and interfere with the

accelerator, brake or clutch pedals or impair safe

operation of your vehicle in other ways.

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks, and bulges.

Check the lug nut/bolt torque for tightness. Check the

tires (including spare) for proper cold inflation pressure.

WARNING!

An improperly attached, damaged, folded, or stacked

floor mat, or damaged floor mat fasteners may cause

your floor mat to interfere with the accelerator, brake, or

clutch pedals and cause a loss of vehicle control.

To prevent SERIOUS INJURY or DEATH:

ALWAYS securely attach your floor mat

using the floor mat fasteners. DO NOT

install your floor mat upside down or turn

your floor mat over. Lightly pull to confirm

mat is secured using the floor mat fasteners on a

regular basis.

ALWAYS REMOVE THE EXISTING FLOOR

MAT FROM THE VEHICLE before installing

any other floor mat. NEVER install or stack

an additional floor mat on top of an

existing floor mat.

ONLY install floor mats designed to fit your vehicle.

NEVER install a floor mat that cannot be properly

attached and secured to your vehicle. If a floor mat

needs to be replaced, only use a FCA approved floor

mat for the specific make, model, and year of your

vehicle.

ONLY use the driver’s side floor mat on the driver’s

side floor area. To check for interference, with the

vehicle properly parked with the engine off, fully

depress the accelerator, the brake, and the clutch

pedal (if present) to check for interference. If your

floor mat interferes with the operation of any pedal,

or is not secure to the floor, remove the floor mat

from the vehicle and place the floor mat in your

trunk.

ONLY use the passenger’s side floor mat on the

passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide into

the driver’s side floor area when the vehicle is

moving. Objects can become trapped under acceler -

ator, brake, or clutch pedals and could cause a loss

of vehicle control.

NEVER place any objects under the floor mat (e.g.,

towels, keys, etc.). These objects could change the

position of the floor mat and may cause interference

with the accelerator, brake, or clutch pedals.

WARNING!

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to the floor

and check the floor mat fasteners are secure to the

vehicle carpet. Fully depress each pedal to check for

interference with the accelerator, brake, or clutch

pedals then re-install the floor mats.

It is recommended to only use mild soap and water

to clean your floor mats. After cleaning, always check

your floor mat has been properly installed and is

secured to your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

23_DT_OM_EN_USC_t.book Page 312

Page 331 of 416

IN CASE OF EMERGENCY329

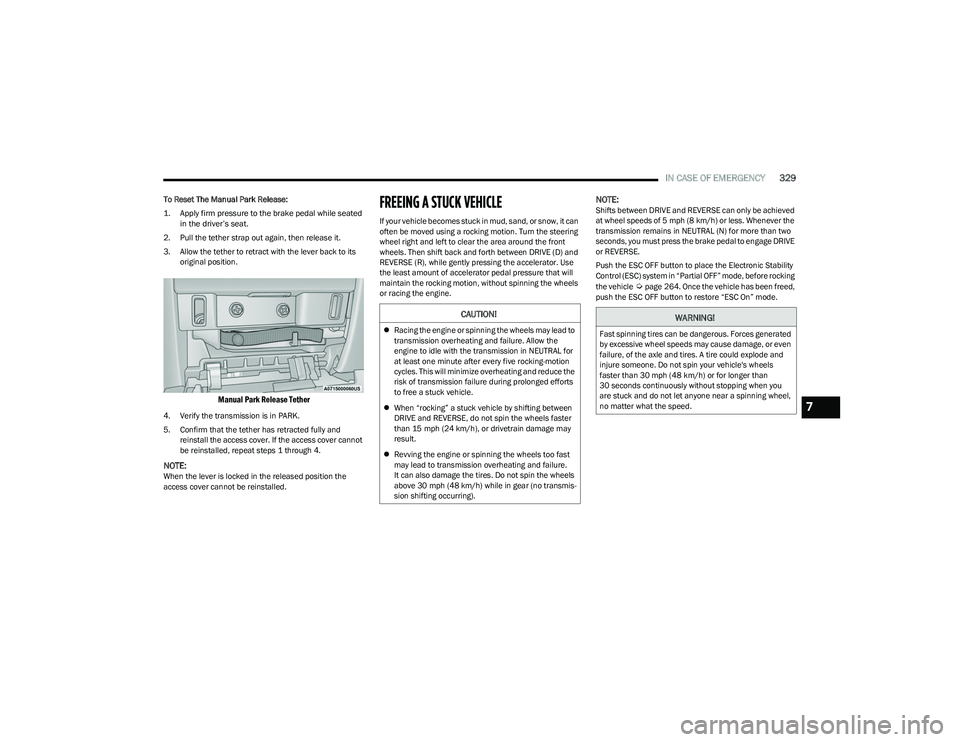

To Reset The Manual Park Release:

1. Apply firm pressure to the brake pedal while seated

in the driver’s seat.

2. Pull the tether strap out again, then release it.

3. Allow the tether to retract with the lever back to its original position.

Manual Park Release Tether

4. Verify the transmission is in PARK.

5. Confirm that the tether has retracted fully and reinstall the access cover. If the access cover cannot

be reinstalled, repeat steps 1 through 4.

NOTE:When the lever is locked in the released position the

access cover cannot be reinstalled.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or snow, it can

often be moved using a rocking motion. Turn the steering

wheel right and left to clear the area around the front

wheels. Then shift back and forth between DRIVE (D) and

REVERSE (R), while gently pressing the accelerator. Use

the least amount of accelerator pedal pressure that will

maintain the rocking motion, without spinning the wheels

or racing the engine.

NOTE:Shifts between DRIVE and REVERSE can only be achieved

at wheel speeds of 5 mph (8 km/h) or less. Whenever the

transmission remains in NEUTRAL (N) for more than two

seconds, you must press the brake pedal to engage DRIVE

or REVERSE.

Push the ESC OFF button to place the Electronic Stability

Control (ESC) system in “Partial OFF” mode, before rocking

the vehicle

Úpage 264. Once the vehicle has been freed,

push the ESC OFF button to restore “ESC On” mode.

CAUTION!

Racing the engine or spinning the wheels may lead to

transmission overheating and failure. Allow the

engine to idle with the transmission in NEUTRAL for

at least one minute after every five rocking-motion

cycles. This will minimize overheating and reduce the

risk of transmission failure during prolonged efforts

to free a stuck vehicle.

When “rocking” a stuck vehicle by shifting between

DRIVE and REVERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain damage may

result.

Revving the engine or spinning the wheels too fast

may lead to transmission overheating and failure.

It can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmis -

sion shifting occurring).

WARNING!

Fast spinning tires can be dangerous. Forces generated

by excessive wheel speeds may cause damage, or even

failure, of the axle and tires. A tire could explode and

injure someone. Do not spin your vehicle's wheels

faster than 30 mph (48 km/h) or for longer than

30 seconds continuously without stopping when you

are stuck and do not let anyone near a spinning wheel,

no matter what the speed.

7

23_DT_OM_EN_USC_t.book Page 329

Page 333 of 416

IN CASE OF EMERGENCY331

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use only tow bars and other

equipment designed for this purpose, following equipment

per FCA US LLC instructions. Use of safety chains is

mandatory. Attach a tow bar or other towing device to

main structural members of the vehicle, not to fascia/

bumpers or associated brackets. State and local laws

regarding vehicles under tow must be observed.

If you must use the accessories (wipers, defrosters, etc.)

while being towed, the ignition must be in the ON/RUN

mode, not the ACC mode.

If the key fob is unavailable or the vehicle's battery is

discharged, find Instructions on shifting the transmission

out of PARK in order to move the vehicle

Úpage 328.

TWO-WHEEL DRIVE MODELS

FCA US LLC recommends towing your vehicle with all four

wheels OFF the ground using a flatbed.

If flatbed equipment is not available, and the transmission

is operable, the vehicle may be towed (with front wheels

on the ground) under the following conditions:

The transmission must be in NEUTRAL (N). Instructions

on shifting the transmission to NEUTRAL (N) when the

engine is OFF

Úpage 328.

The towing speed must not exceed 30 mph (48 km/h).

The towing distance must not exceed 30 miles

(48 km).

If the transmission is not operable, or the vehicle must be

towed faster than 30 mph (48 km/h) and farther than 30 miles (48 km), tow with the rear wheels OFF the

ground. An acceptable method to tow the vehicle on a

flatbed are as follows:

Using a suitable steering wheel stabilizer to hold the

front wheels in the straight position with the rear

wheels raised and the front wheels ON the ground.

FOUR-WHEEL DRIVE MODELS

FCA US LLC recommends towing with all wheels OFF the

ground.

CAUTION!

Do not use sling type equipment when towing.

Vehicle damage may occur.

When securing the vehicle to a flatbed truck, do not

attach to front or rear suspension components.

Damage to your vehicle may result from improper

towing.

CAUTION!

Towing this vehicle in violation of the approved

requirements can cause severe transmission damage.

Damage from improper towing is not covered under the

New Vehicle Limited Warranty.

CAUTION!

Front or rear wheel lifts must not be used (if the

remaining wheels are on the ground). Internal

damage to the transmission or transfer case will

occur if a front or rear wheel lift is used when towing.

Towing this vehicle in violation of the approved

requirements can cause severe transmission and/or

transfer case damage. Damage from improper

towing is not covered under the New Vehicle

Limited Warranty.

7

23_DT_OM_EN_USC_t.book Page 331

Page 344 of 416

342SERVICING AND MAINTENANCE

Synthetic Engine Oils

Your engine was designed for synthetic engine oils, only

use synthetic API approved engine oils.

Synthetic engine oils which do not have both the correct

API trademark and the correct SAE viscosity grade

numbers should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against the

addition of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered product and

its performance may be impaired by supplemental

additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service

station or governmental agency for advice on how and

where used oil and oil filters can be safely discarded in

your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new filter at

every engine oil change. Engine Oil Filter Selection

A full-flow type disposable oil filter should be used for

replacement. The quality of replacement filters varies

considerably. Only high quality Mopar® certified filters

should be used. If a Mopar® Engine Oil Filter is

unavailable, only use filters that meet or exceed

SAE/USCAR-36 Filter Performance Requirements.

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 334.

Engine Air Cleaner Filter Selection

The quality of replacement filters varies considerably.

Only high quality Mopar® certified filters should be used.

Engine Air Cleaner Filter Inspection And

Replacement — Except G/T Model

Engine Air Cleaner Filter Removal

1. With suitable tool fully loosen (six) fasteners on the engine air cleaner filter cover.

Engine Air Cleaner Filter

2. Lift the engine air cleaner filter cover to access the engine air cleaner filter.

WARNING!

The air induction system (air cleaner, hoses, etc.) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system

(air cleaner, hoses, etc.) unless such removal is

necessary for repair or maintenance. Make sure that no

one is near the engine compartment before starting the

vehicle with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in serious

personal injury.

1 — Fasteners

2 — Engine Air Cleaner Filter Cover

23_DT_OM_EN_USC_t.book Page 342

Page 346 of 416

344SERVICING AND MAINTENANCE

Engine Air Cleaner Filter Installation

NOTE:Inspect and clean the housing if dirt or debris is present

before replacing the engine air cleaner filter.

1. Install the engine air cleaner filter onto the engine

air cleaner filter assembly.

2. Install the engine air cleaner filter cover onto the engine air cleaner filter assembly.

3. Tighten the fasteners (four) on the engine air cleaner filter assembly.

4. Install the engine cover.

G/T AIR FILTER MAINTENANCE

Clean Engine Air Filter

The G/T air filter comes equipped with a unique filter

media which is washable. See the following cleaning

procedure to prolong the life of the air filter component.

For recommended cleaning/replacement intervals

Úpage 334.

1. Spray the air filter with the recommended Mopar® air filter cleaner or apply mild dishwashing detergent

and water and let sit for at least 10 minutes to

loosen dirt before rinsing.

NOTE:Never use strong detergents, high pressure, or gasoline on

the air filter.

2. Rinse the air filter with cool low-pressure water applied from the inside (clean side) out in order to

flush the dirt out of the filter. Continue to rinse the

filter until all traces of the cleaner have been

removed.

NOTE:It may be necessary to repeat steps 1 and 2 if the air filter

is not completely clean.

3. After rinsing the air filter, gently shake off the excess water and allow air filter to dry naturally.

NOTE:Do not use forced air pressure as it may damage the

filtering capabilities of the filter’s microfibers and also void

its warranty.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner should

be checked and serviced by an authorized dealer at the

start of each warm season. This service should include

cleaning of the condenser fins and a performance test.

Drive belt tension should also be checked at this time.

Refrigerant Recovery And Recycling —

R–1234yf

R–1234yf Air Conditioning Refrigerant is a

Hydrofluoroolefin (HFO) that is endorsed by the

Environmental Protection Agency and is an ozone-friendly

substance with a low global-warming potential. It is

recommended that air conditioning service be performed

by an authorized dealer using recovery and recycling

equipment.

NOTE:Use only the manufacturer approved A/C system PAG

compressor oil, and refrigerants.

Cabin Air Filter Replacement

For the proper maintenance intervals Úpage 334.

WARNING!

Use only refrigerants and compressor lubricants

approved by the manufacturer for your air condi -

tioning system. Some unapproved refrigerants are

flammable and can explode, injuring you. Other

unapproved refrigerants or lubricants can cause the

system to fail, requiring costly repairs. Refer to

Warranty Information Book, for further warranty

information.

The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal injury

or damage to the system, adding refrigerant or any

repair requiring lines to be disconnected should be

done by an experienced technician.

CAUTION!

Do not use chemical flushes in your air conditioning

system as the chemicals can damage your air

conditioning components. Such damage is not covered

by the New Vehicle Limited Warranty.

WARNING!

Do not remove the cabin air filter while the vehicle is

running, or while the ignition is in the ACC or ON/RUN

mode. With the cabin air filter removed and the blower

operating, the blower can contact hands and may

propel dirt and debris into your eyes, resulting in

personal injury.

23_DT_OM_EN_USC_t.book Page 344

Page 349 of 416

SERVICING AND MAINTENANCE347

Any belt with cracks running along a rib must be replaced.

Also have the belt replaced if it has excessive wear, frayed

cords or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated from

belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between two ribs)

Belt slips

Groove jumping (belt does not maintain correct posi -

tion on pulley)

Belt broken

Noise (objectionable squeal, squeak, or rumble is

heard or felt while drive belt is in operation)

NOTE:Identify and correct problem before new belt is installed.

NOTE:If your vehicle is equipped with a Stop/Start, belt must be

replaced with an OEM grade Mopar® belt.

Some conditions can be caused by a faulty component

such as a belt pulley. Belt pulleys should be carefully

inspected for damage and proper alignment.

Belt replacement on some models requires the use of

special tools, we recommend having your vehicle serviced

at an authorized dealer.

BODY LUBRICATION

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should be

lubricated periodically. Use a lithium-based grease, such

as Mopar® Spray White Lube to assure quiet, easy

operation and to protect against rust and wear. Prior to the

application of any lubricant, the parts concerned should

be wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching

components to ensure proper function. When performing

other underhood services, the hood latch release

mechanism, and safety catch should be cleaned and

lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Autumn and Spring. Apply a small

amount of a high quality lubricant, such as Mopar® Lock

Cylinder Lubricant directly into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending on

geographical area and frequency of use. If chattering,

marks, water lines or wet spots are present, clean the

wiper blades or replace as necessary.

The wiper blades and wiper arms should be inspected

periodically, not just when wiper performance problems

are experienced. This inspection should include the

following points:

Wear or uneven edges

Foreign material

Hardening or cracking

Deformation or fatigue

If a wiper blade or wiper arm is damaged, replace the

affected wiper arm or blade with a new unit. Do not

attempt to repair a wiper arm or blade that is damaged.

8

23_DT_OM_EN_USC_t.book Page 347