Trailer towing Ram 2500 2020 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 287 of 553

STARTING AND OPERATING285

NOTE:

Aftermarket add-ons such as snow plows, lift

kits, and brush/grille bars can hinder module

performance. Ensure the radar/camera has

no obstructions in the field of view.

Height modifications can limit module perfor -

mance and functionality.

Do not put stickers or easy passes over the

camera/radar field of view.

Any modifications to the vehicle that may

obstruct the field of view of the radar/camera

are not recommended.

Cleaning Instructions

Dust and dirt can accumulate on the cover and

block the camera lens. Clean the camera lens

with a soft microfiber cloth, being careful not to

damage or scratch the module.

Towing A Trailer

ACC while towing a trailer is recommended only

with an Integrated Trailer Brake Controller.

Aftermarket trailer brake controllers will not

activate the trailer brakes when ACC is braking.

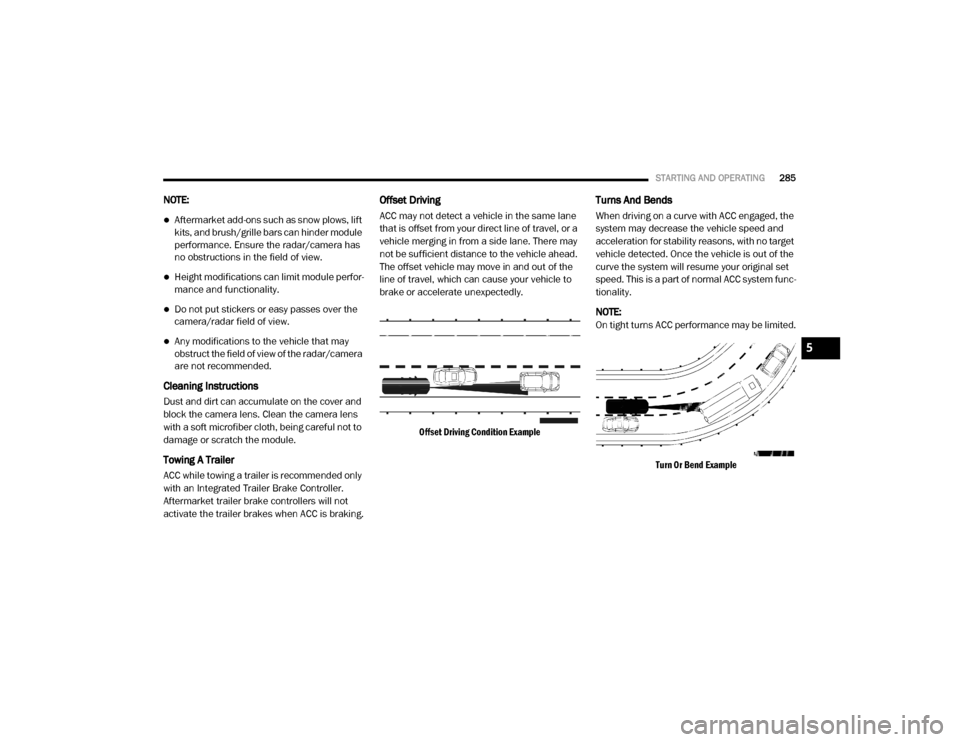

Offset Driving

ACC may not detect a vehicle in the same lane

that is offset from your direct line of travel, or a

vehicle merging in from a side lane. There may

not be sufficient distance to the vehicle ahead.

The offset vehicle may move in and out of the

line of travel, which can cause your vehicle to

brake or accelerate unexpectedly.

Offset Driving Condition Example

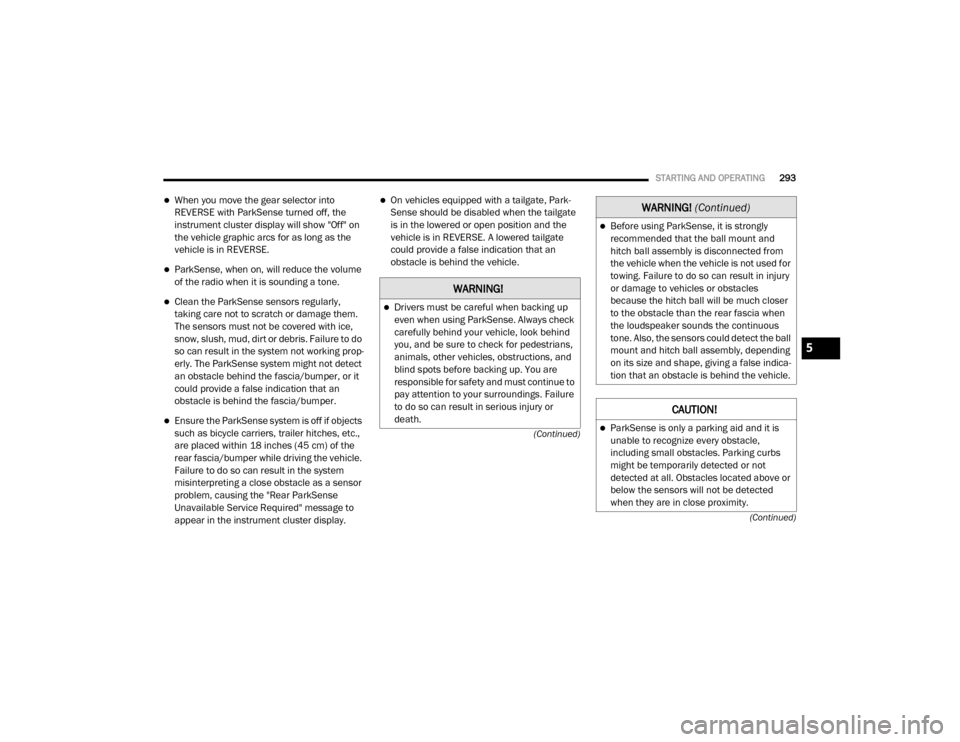

Turns And Bends

When driving on a curve with ACC engaged, the

system may decrease the vehicle speed and

acceleration for stability reasons, with no target

vehicle detected. Once the vehicle is out of the

curve the system will resume your original set

speed. This is a part of normal ACC system func -

tionality.

NOTE:

On tight turns ACC performance may be limited.

Turn Or Bend Example

5

20_DJD2_OM_EN_USC_t.book Page 285

Page 295 of 553

STARTING AND OPERATING293

(Continued)

(Continued)

When you move the gear selector into

REVERSE with ParkSense turned off, the

instrument cluster display will show "Off" on

the vehicle graphic arcs for as long as the

vehicle is in REVERSE.

ParkSense, when on, will reduce the volume

of the radio when it is sounding a tone.

Clean the ParkSense sensors regularly,

taking care not to scratch or damage them.

The sensors must not be covered with ice,

snow, slush, mud, dirt or debris. Failure to do

so can result in the system not working prop

-

erly. The ParkSense system might not detect

an obstacle behind the fascia/bumper, or it

could provide a false indication that an

obstacle is behind the fascia/bumper.

Ensure the ParkSense system is off if objects

such as bicycle carriers, trailer hitches, etc.,

are placed within 18 inches (45 cm) of the

rear fascia/bumper while driving the vehicle.

Failure to do so can result in the system

misinterpreting a close obstacle as a sensor

problem, causing the "Rear ParkSense

Unavailable Service Required" message to

appear in the instrument cluster display.

On vehicles equipped with a tailgate, Park -

Sense should be disabled when the tailgate

is in the lowered or open position and the

vehicle is in REVERSE. A lowered tailgate

could provide a false indication that an

obstacle is behind the vehicle.

WARNING!

Drivers must be careful when backing up

even when using ParkSense. Always check

carefully behind your vehicle, look behind

you, and be sure to check for pedestrians,

animals, other vehicles, obstructions, and

blind spots before backing up. You are

responsible for safety and must continue to

pay attention to your surroundings. Failure

to do so can result in serious injury or

death.

Before using ParkSense, it is strongly

recommended that the ball mount and

hitch ball assembly is disconnected from

the vehicle when the vehicle is not used for

towing. Failure to do so can result in injury

or damage to vehicles or obstacles

because the hitch ball will be much closer

to the obstacle than the rear fascia when

the loudspeaker sounds the continuous

tone. Also, the sensors could detect the ball

mount and hitch ball assembly, depending

on its size and shape, giving a false indica -

tion that an obstacle is behind the vehicle.

CAUTION!

ParkSense is only a parking aid and it is

unable to recognize every obstacle,

including small obstacles. Parking curbs

might be temporarily detected or not

detected at all. Obstacles located above or

below the sensors will not be detected

when they are in close proximity.

WARNING! (Continued)

5

20_DJD2_OM_EN_USC_t.book Page 293

Page 320 of 553

318STARTING AND OPERATING

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full

GAWR.

Curb Weight

The curb weight of a vehicle is defined as the

total weight of the vehicle with all fluids,

including vehicle fuel, at full capacity condi -

tions, and with no occupants or cargo loaded

into the vehicle. The front and rear curb weight

values are determined by weighing your vehicle

on a commercial scale before any occupants or

cargo are added.

Loading

The actual total weight and the weight of the

front and rear of your vehicle at the ground can

best be determined by weighing it when it is

loaded and ready for operation.

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has

not been exceeded. The weight on the front and

rear of the vehicle should then be determined separately to be sure that the load is properly

distributed over the front and rear axles.

Weighing the vehicle may show that the GAWR

of either the front or rear axle has been

exceeded but the total load is within the speci

-

fied GVWR. If so, weight must be shifted from

front to rear or rear to front as appropriate until

the specified weight limitations are met. Store

the heavier items down low and be sure that the

weight is distributed equally. Stow all loose

items securely before driving.

Improper weight distributions can have an

adverse effect on the way your vehicle steers

and handles and the way the brakes operate.

TRAILER TOWING

In this section you will find safety tips and infor -

mation on limits to the type of towing you can reasonably do with your vehicle. Before towing a

trailer, carefully review this information to tow

your load as efficiently and safely as possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and recom

-

mendations in this manual concerning vehicles

used for trailer towing.

Common Towing Definitions

The following trailer towing-related definitions

will assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your

vehicle. This includes driver, passengers, cargo

and tongue weight. The total load must be

limited so that you do not exceed the GVWR.

Refer to “Vehicle Loading/Vehicle Certification

Label” in “Starting And Operating” for further

information.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the

weight of all cargo, consumables and equip -

ment (permanent or temporary) loaded in or on

the trailer in its "loaded and ready for operation"

condition.

CAUTION!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR.

If you do, parts on your vehicle can break, or

it can change the way your vehicle handles.

This could cause you to lose control. Also

overloading can shorten the life of your

vehicle.

20_DJD2_OM_EN_USC_t.book Page 318

Page 321 of 553

STARTING AND OPERATING319

The recommended way to measure GTW is to

put your fully loaded trailer on a vehicle scale.

The entire weight of the trailer must be

supported by the scale.

Gross Combination Weight Rating (GCWR)

The GCWR is the total allowable weight of your

vehicle and trailer when weighed in combina -

tion.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do

not exceed either front or rear GAWR. Refer to

“Vehicle Loading/Vehicle Certification Label” in

“Starting And Operating” for further informa -

tion.

Tongue Weight (TW)

The tongue weight is the downward force

exerted on the hitch ball by the trailer. You must

consider this as part of the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height multi -

plied by the maximum width of the front of a

trailer.

Trailer Sway Control

The trailer sway control can be a mechanical

telescoping link that can be installed between

the hitch receiver and the trailer tongue that

typically provides adjustable friction associated

with the telescoping motion to dampen any

unwanted trailer swaying motions while trav -

eling. If equipped, the electronic Trailer Sway Control

(TSC) recognizes a swaying trailer and automat

-

ically applies individual wheel brakes and/or

reduces engine power to attempt to eliminate

the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer

tongue weight, just as if it were luggage located

at a hitch ball or some other connecting point of

the vehicle. These kinds of hitches are the most

popular on the market today and they are

commonly used to tow small and medium sized

trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute

trailer tongue weight to the tow vehicle's front

axle and the trailer axle(s). When used in accor -

dance with the manufacturer's directions, it

provides for a more level ride, offering more

consistent steering and brake control, thereby

enhancing towing safety. The addition of a fric -

tion/hydraulic sway control also dampens sway

caused by traffic and crosswinds and contrib -

utes positively to tow vehicle and trailer

stability. Trailer Sway Control (TSC) and a weight

WARNING!

If the gross trailer weight is 5,000 lbs (2,267 kg)

or more, it is recommended to use a

weight-distributing hitch to ensure stable

handling of your vehicle. If you use a standard

weight-carrying hitch, you could lose control of

your vehicle and cause a collision.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the

vehicle and have a collision.

5

20_DJD2_OM_EN_USC_t.book Page 319

Page 322 of 553

320STARTING AND OPERATING

distributing (load equalizing) hitch are recom -

mended for heavier Tongue Weights (TW) and

may be required depending on vehicle and

trailer configuration/loading to comply with

GAWR requirements.

With Weight-Distributing Hitch (Correct) Without Weight-Distributing Hitch (Incorrect)

Improper Adjustment Of Weight-Distributing Hitch (Incorrect)

Recommended Distribution Hitch Adjustment

Towing With 2500/3500 Air Suspension

1. Position the truck to be ready to connect to

the trailer (do not connect the trailer).

NOTE:

Normal Ride Height (NRH) or Alternate Trailer

Height (ATH) can be used. The vehicle must

remain in the engine running position while

attaching a trailer for proper leveling of the air

suspension system. It may not be possible to

enter Alternate Trailer Height (ATH) while lightly

loaded.

2. Measure the height of the top of the front wheel opening on the fender to ground, this

is height H1.

3. Attach the trailer to the vehicle without the weight distribution bars connected.

4. Measure the height of the top of the front wheel opening on the fender to ground, this

is height H2.

WARNING!

An improperly adjusted weight distributing

hitch system may reduce handling, stability

and braking performance and could result

in a collision.

Weight distributing systems may not be

compatible with surge brake couplers.

Consult with your hitch and trailer manufac -

turer or a reputable Recreational Vehicle

dealer for additional information.

20_DJD2_OM_EN_USC_t.book Page 320

Page 323 of 553

STARTING AND OPERATING321

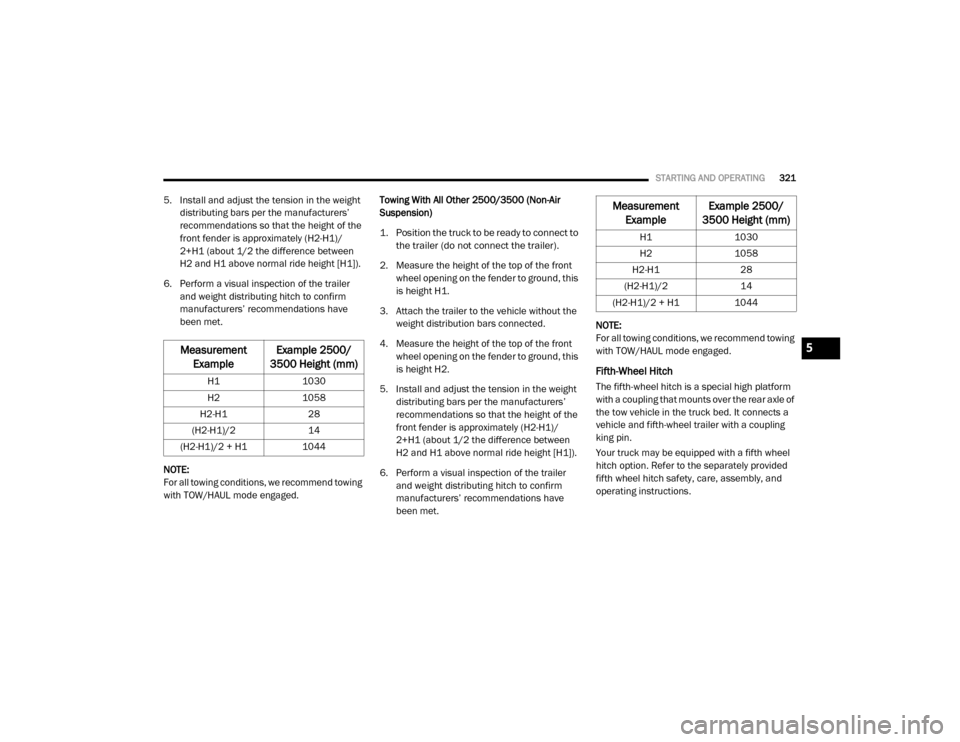

5. Install and adjust the tension in the weight

distributing bars per the manufacturers’

recommendations so that the height of the

front fender is approximately (H2-H1)/

2+H1 (about 1/2 the difference between

H2 and H1 above normal ride height [H1]).

6. Perform a visual inspection of the trailer and weight distributing hitch to confirm

manufacturers’ recommendations have

been met.

NOTE:

For all towing conditions, we recommend towing

with TOW/HAUL mode engaged. Towing With All Other 2500/3500 (Non-Air

Suspension)

1. Position the truck to be ready to connect to

the trailer (do not connect the trailer).

2. Measure the height of the top of the front wheel opening on the fender to ground, this

is height H1.

3. Attach the trailer to the vehicle without the weight distribution bars connected.

4. Measure the height of the top of the front wheel opening on the fender to ground, this

is height H2.

5. Install and adjust the tension in the weight distributing bars per the manufacturers’

recommendations so that the height of the

front fender is approximately (H2-H1)/

2+H1 (about 1/2 the difference between

H2 and H1 above normal ride height [H1]).

6. Perform a visual inspection of the trailer and weight distributing hitch to confirm

manufacturers’ recommendations have

been met. NOTE:

For all towing conditions, we recommend towing

with TOW/HAUL mode engaged.

Fifth-Wheel Hitch

The fifth-wheel hitch is a special high platform

with a coupling that mounts over the rear axle of

the tow vehicle in the truck bed. It connects a

vehicle and fifth-wheel trailer with a coupling

king pin.

Your truck may be equipped with a fifth wheel

hitch option. Refer to the separately provided

fifth wheel hitch safety, care, assembly, and

operating instructions.

Measurement

Example Example 2500/

3500 Height (mm)

H1 1030

H2 1058

H2-H1 28

(H2-H1)/2 14

(H2-H1)/2 + H1 1044

Measurement

Example Example 2500/

3500 Height (mm)

H1 1030

H2 1058

H2-H1 28

(H2-H1)/2 14

(H2-H1)/2 + H1 1044

5

20_DJD2_OM_EN_USC_t.book Page 321

Page 324 of 553

322STARTING AND OPERATING

Gooseneck Hitch

The gooseneck hitch employs a pivoted

coupling arm which attaches to a ball mounted

in the bed of a pickup truck. The coupling arm

connects to the hitch mounted over the rear

axle in the truck bed.

Trailer Hitch Type and Maximum Trailer

Weight

The following chart provides the maximum

trailer weight a given factory equipped trailer

hitch type can tow and should be used to assist you in selecting the correct trailer hitch for your

intended towing condition.

All trailer hitches should be professionally installed on your vehicle.

Trailer Hitch Type and Maximum Trailer Weight

Hitch Type Max. Trailer Weight / Max. Tongue Weight

Class V - 2500 Models 20,000 lbs (9,071 kg) / 2,000 lbs (907 kg)

Class V - 3500 Models 23,000 lbs (10,432 kg) / 2,300 lbs (1,043 kg)

Fifth Wheel - 2500 Models 25,000 lbs (11,339 kg) / 3,750 lbs (1,700 kg)

Fifth Wheel - 3500 Models 30,000 lbs (13,607 kg) / 4,500 lbs (2,041 kg)

Gooseneck - 2500 Models 20,000 lbs (9,071 kg) / 3,000 lbs (1,360 kg)

Gooseneck - 3500 Models 35,250 lbs (15,989 kg) / 5,287 lbs (2,398 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” for the Maximum Gross Trailer Weight (GTW) towable for your given drivetrain.

20_DJD2_OM_EN_USC_t.book Page 322

Page 325 of 553

STARTING AND OPERATING323

(Continued)

Trailer Towing Weights (Maximum Trailer

Weight Ratings)

NOTE:

For trailer towing information (maximum trailer

weight ratings) refer to the following website

addresses:

ramtrucks.com/en/towing_guide/

ramtruck.ca (Canada)

rambodybuilder.com

Trailer And Tongue Weight

Weight Distribution

Consider the following items when computing

the weight on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or

equipment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:

Remember that everything put into or on the

trailer adds to the load on your vehicle. Also,

additional factory-installed options or

dealer-installed options must be considered as

part of the total load on your vehicle. Refer to

the “Tire And Loading Information” placard for

the maximum combined weight of occupants

and cargo for your vehicle.

Towing Requirements

To promote proper break-in of your new vehicle

drivetrain components, the following guidelines

are recommended. Perform the maintenance listed in the “Sched

-

uled Servicing”. Refer to “Scheduled Servicing”

in “Servicing And Maintenance” for the proper

maintenance intervals. When towing a trailer,

never exceed the GAWR or GCWR ratings.

CAUTION!

Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is

driven. The engine, axle or other parts could

be damaged.

Then, during the first 500 miles (805 km)

that a trailer is towed, do not drive over

50 mph (80 km/h) and do not make starts

at full throttle. This helps the engine and

other parts of the vehicle wear in at the

heavier loads.

WARNING!

Make certain that the load is secured in the

trailer and will not shift during travel. When

trailering cargo that is not fully secured,

dynamic load shifts can occur that may be

difficult for the driver to control. You could

lose control of your vehicle and have a colli -

sion.

5

20_DJD2_OM_EN_USC_t.book Page 323

Page 326 of 553

324STARTING AND OPERATING

(Continued)

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h) when towing while using a full size spare tire.

Proper tire inflation pressures are essential

to the safe and satisfactory operation of your

vehicle. Refer to “Tires” in “Servicing And

Maintenance” for proper tire inflation proce -

dures.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer. Refer to

“Tires” in “Servicing And Maintenance” for

the proper inspection procedure.

When replacing tires, refer to “Tires” in

“Servicing And Maintenance” for the proper

tire replacement procedures. Replacing tires

with a higher load carrying capacity will not

increase the vehicle's GVWR and GAWR

limits.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake

system or vacuum system of your vehicle

with that of the trailer. This could cause inad -

equate braking and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer

with electronically actuated brakes. When

towing a trailer equipped with a hydraulic

surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers

over 1,000 lbs (453 kg) and required for

trailers in excess of 2,000 lbs (907 kg).

When hauling cargo or towing a trailer, do

not overload your vehicle or trailer. Over -

loading can cause a loss of control, poor

performance or damage to brakes, axle,

engine, transmission, steering, suspension,

chassis structure or tires.

Safety chains must always be used

between your vehicle and trailer. Always

connect the chains to the hook retainers of

the vehicle hitch. Cross the chains under

the trailer tongue and allow enough slack

for turning corners.

Vehicles with trailers should not be parked

on a grade. When parking, apply the

parking brake on the tow vehicle. Put the

tow vehicle transmission in PARK. For

four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL. Always,

block or "chock" the trailer wheels.

GCWR must not be exceeded.

WARNING! (Continued)

Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer

hitch utilized.

WARNING! (Continued)

20_DJD2_OM_EN_USC_t.book Page 324

Page 327 of 553

STARTING AND OPERATING325

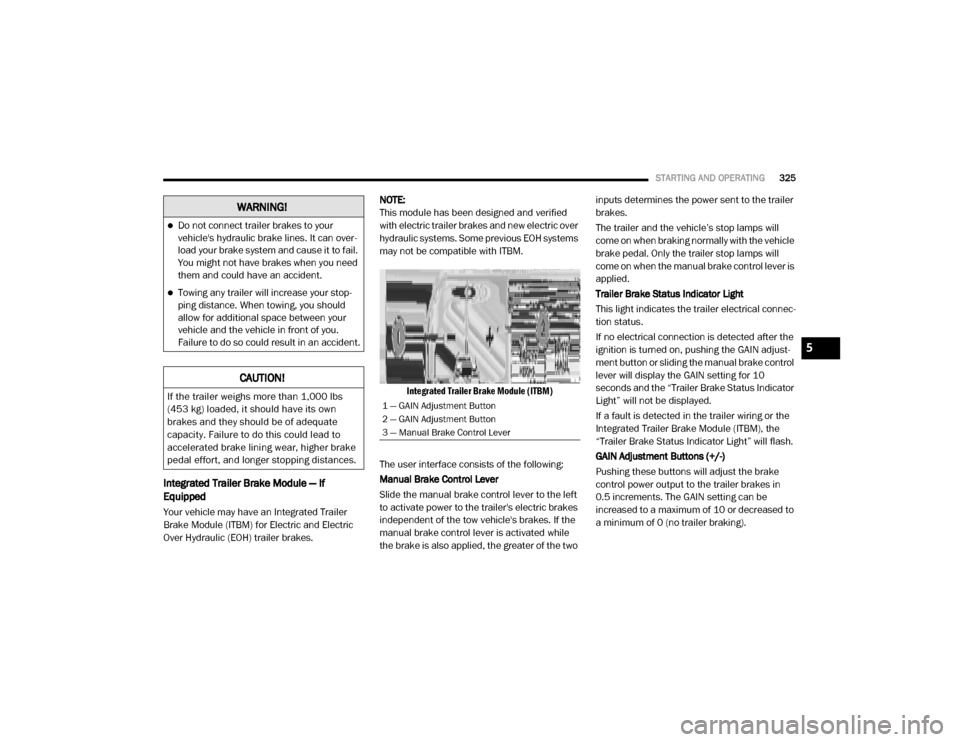

Integrated Trailer Brake Module — If

Equipped

Your vehicle may have an Integrated Trailer

Brake Module (ITBM) for Electric and Electric

Over Hydraulic (EOH) trailer brakes. NOTE:

This module has been designed and verified

with electric trailer brakes and new electric over

hydraulic systems. Some previous EOH systems

may not be compatible with ITBM.

Integrated Trailer Brake Module (ITBM)

The user interface consists of the following:

Manual Brake Control Lever

Slide the manual brake control lever to the left

to activate power to the trailer's electric brakes

independent of the tow vehicle's brakes. If the

manual brake control lever is activated while

the brake is also applied, the greater of the two inputs determines the power sent to the trailer

brakes.

The trailer and the vehicle’s stop lamps will

come on when braking normally with the vehicle

brake pedal. Only the trailer stop lamps will

come on when the manual brake control lever is

applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical connec

-

tion status.

If no electrical connection is detected after the

ignition is turned on, pushing the GAIN adjust -

ment button or sliding the manual brake control

lever will display the GAIN setting for 10

seconds and the “Trailer Brake Status Indicator

Light” will not be displayed.

If a fault is detected in the trailer wiring or the

Integrated Trailer Brake Module (ITBM), the

“Trailer Brake Status Indicator Light” will flash.

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake

control power output to the trailer brakes in

0.5 increments. The GAIN setting can be

increased to a maximum of 10 or decreased to

a minimum of 0 (no trailer braking).

WARNING!

Do not connect trailer brakes to your

vehicle's hydraulic brake lines. It can over -

load your brake system and cause it to fail.

You might not have brakes when you need

them and could have an accident.

Towing any trailer will increase your stop -

ping distance. When towing, you should

allow for additional space between your

vehicle and the vehicle in front of you.

Failure to do so could result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lbs

(453 kg) loaded, it should have its own

brakes and they should be of adequate

capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake

pedal effort, and longer stopping distances.1 — GAIN Adjustment Button

2 — GAIN Adjustment Button

3 — Manual Brake Control Lever

5

20_DJD2_OM_EN_USC_t.book Page 325