fuel cap Ram 2500 2020 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 360 of 553

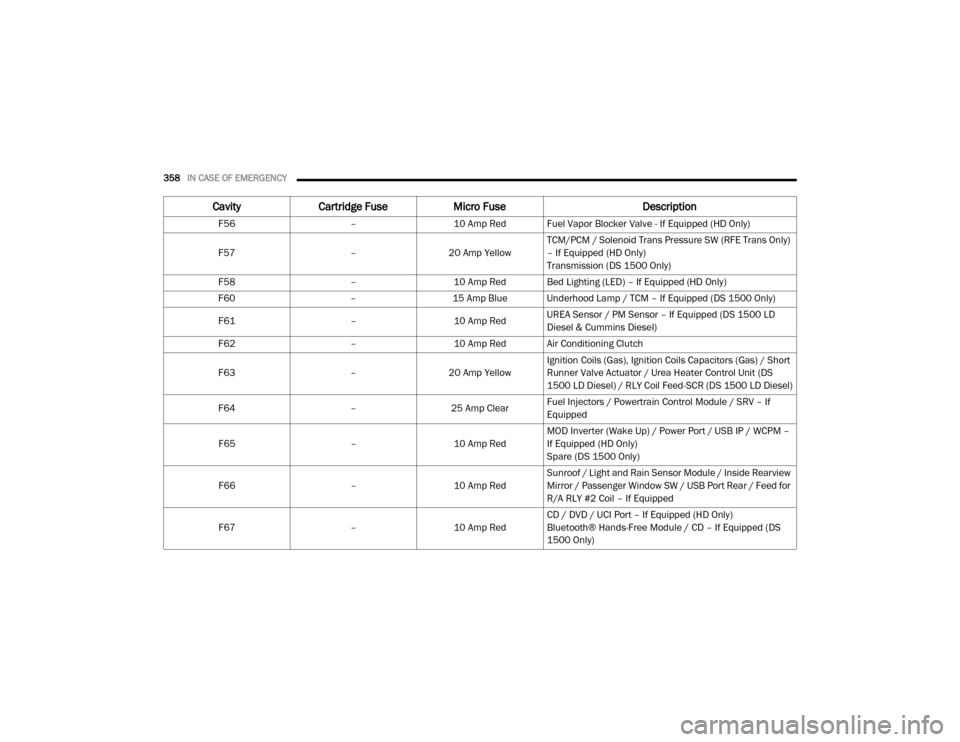

358IN CASE OF EMERGENCY

F56 –10 Amp Red Fuel Vapor Blocker Valve - If Equipped (HD Only)

F57 –20 Amp Yellow TCM/PCM / Solenoid Trans Pressure SW (RFE Trans Only)

– If Equipped (HD Only)

Transmission (DS 1500 Only)

F58 –10 Amp Red Bed Lighting (LED) – If Equipped (HD Only)

F60 –15 Amp Blue Underhood Lamp / TCM – If Equipped (DS 1500 Only)

F61 –10 Amp RedUREA Sensor / PM Sensor – If Equipped (DS 1500 LD

Diesel & Cummins Diesel)

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils (Gas), Ignition Coils Capacitors (Gas) / Short

Runner Valve Actuator / Urea Heater Control Unit (DS

1500 LD Diesel) / RLY Coil Feed-SCR (DS 1500 LD Diesel)

F64 –25 Amp ClearFuel Injectors / Powertrain Control Module / SRV – If

Equipped

F65 –10 Amp RedMOD Inverter (Wake Up) / Power Port / USB IP / WCPM –

If Equipped (HD Only)

Spare (DS 1500 Only)

F66 –10 Amp RedSunroof / Light and Rain Sensor Module / Inside Rearview

Mirror / Passenger Window SW / USB Port Rear / Feed for

R/A RLY #2 Coil – If Equipped

F67 –10 Amp RedCD / DVD / UCI Port – If Equipped (HD Only)

Bluetooth® Hands-Free Module / CD – If Equipped (DS

1500 Only)

Cavity

Cartridge Fuse Micro Fuse Description

20_DJD2_OM_EN_USC_t.book Page 358

Page 387 of 553

SERVICING AND MAINTENANCE385

Inspection and service should also be

performed anytime a malfunction is observed or

suspected. Retain all receipts.

NOTE:

Using white lithium grease, lubricate the door

hinge pivot joints twice a year to prevent prema-

ture wear.

Oil Change Indicator System — Cummins

Diesel

Your vehicle is equipped with an engine oil

change indicator system. This system will alert

you when it is time to change your engine oil by

displaying the words “Oil Change Due” in your

instrument cluster display. The oil change

reminder will remind the owner to change the

engine oil every 15,000 miles (24,000 km) or

500 hours, whichever comes first, except for the

Chassis Cab models configured with optional

B20 capability that are using greater than 5%

levels of biodiesel, which are 12,500 miles

(20,000 km) or 400 hours, whichever comes

first. Failure to change the engine oil per the

maintenance schedule can result in internal

engine damage. Your authorized dealer will reset the oil change

indicator message after completing the sched

-

uled oil change. If a scheduled oil change is

performed by someone other than your autho -

rized dealer, the message can be reset by refer -

ring to the steps described under “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

Replace the engine oil and oil filter every

15,000 miles (24,000 km) or 12 months, or

sooner if prompted by the oil change indicator

system. Under no circumstances should oil

change intervals exceed 15,000 miles

(24,000 km) or 12 months, whichever comes

first.

NOTE:

Under no circumstances should oil change

intervals exceed 15,000 miles (24,000 km)

or 12 months or 500 hours, whichever

comes first.

Replace the engine oil and oil filter every

12,500 miles (20,000 km) or 400 hours,

whichever comes first when running greater

than 5% levels of biodiesel (Chassis Cab

models configured with optional B20 capa -

bility). If Chassis Cab models configured with optional

B20 capability are operated with greater than

5% levels of biodiesel, the oil change interval

must not exceed 12,500 miles (20,000 km) or

400 hours, whichever comes first under any

circumstances. See the Fuel Requirements

section for more information regarding opera

-

tion with biodiesel blend (B6-B20) fuel meeting

ASTM specification D-7467.

Perform Service Indicator — Cummins

Diesel

Your vehicle will require emissions mainte -

nance at a set interval. To help remind you

when this maintenance is due, the instrument

cluster will display “Perform Service”. When the

“Perform Service” message is displayed on the

instrument cluster it is necessary to have the

emissions maintenance performed. Emissions

maintenance may include replacing the Closed

Crankcase Ventilation (CCV) filter element. The

procedure for clearing and resetting the

“Perform Service” indicator message is located

in the appropriate Service Information.

7

20_DJD2_OM_EN_USC_t.book Page 385

Page 396 of 553

394SERVICING AND MAINTENANCE

Checking Oil Level — Gas Engine

To ensure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals, such as every fuel stop. The best time

to check the engine oil level is about five

minutes after a fully warmed up engine is shut

off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings. Always maintain the oil level within

the SAFE zone on the dipstick. Adding one quart

of oil when the reading is at the bottom of the

SAFE zone will result in a reading at the top of

the safe zone on these engines.

Checking Oil Level — Diesel Engine

To ensure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals. The best time to check the oil level is

before starting the engine after it has been parked overnight. When checking oil after oper

-

ating the engine, first ensure the engine is at full

operating temperature, then wait for

30 minutes after engine shutdown to check the

oil.

Engine Oil Dipstick

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings. Add oil only when the level on the

dipstick is below the “ADD” mark. The total

capacity from the ADD mark to the Full mark is

2 qts (1.9L). Never operate the engine with oil level below

the “ADD” mark or above the upper “SAFE”

mark.

Adding Washer Fluid

The fluid reservoir is located under the hood

and should be checked for fluid level at regular

intervals. Fill the reservoir with windshield

washer solvent only (not radiator antifreeze).

When refilling the washer fluid reservoir, take

some washer fluid and apply it to a cloth or

towel and wipe the wiper blades clean. This will

help blade performance.

To prevent freeze-up of your windshield washer

system in cold weather, select a solution or

mixture that meets or exceeds the temperature

range of your climate. This rating information

can be found on most washer fluid containers.

CAUTION!

Overfilling or underfilling will cause oil

aeration or loss of oil pressure. This could

damage your engine.

1 — ADD Range

2 — Full Mark

3 — SAFE Range

CAUTION!

Overfilling or underfilling the crankcase will

cause oil aeration or loss of oil pressure. This

could damage your engine.

20_DJD2_OM_EN_USC_t.book Page 394

Page 409 of 553

SERVICING AND MAINTENANCE407

Priming If The Engine Has Run Out Of Fuel —

Diesel Engine

1. Add a substantial amount of fuel to the

tank, approximately 2 to 5 gal (8L to 19L).

2. Three priming cycles must be completed. Turn ignition to the RUN position and wait

approximately 30 seconds. This will activate

the in tank fuel pump. Turn the ignition

switch to the off position, and leave off for at

least 30 seconds. Repeat this procedure

three times before cranking the engine.

3. Start the engine using the “Normal Starting” procedure. Refer to “Starting Procedures”

in “Starting and Operating” for further infor -

mation.

4. Once the engine starts, allow the engine to idle for a minimum of 30 seconds. NOTE:

The engine may run rough until the air is forced

from all the fuel lines.

NOTE:

A maximum blend of 5% biodiesel, meeting

ASTM specification D-975 may be used with

your Cummins diesel engine. (Chassis Cab

models not configured with B20 capability.)

A maximum blend of 20% biodiesel, meeting

ASTM specification D-7467 may be used with

your Cummins diesel engine. (Pickup models

and Chassis Cab models configured with B20

capability.)

Use of biodiesel mixture in excess of 20% can

negatively impact the fuel filter's ability to

separate water from the fuel, resulting in

high pressure fuel system corrosion or

damage.

Ethanol blends are not recommended or

approved for use with your Cummins diesel

engine.

In addition, commercially available fuel addi

-

tives are not necessary for the proper opera -

tion of your Cummins diesel engine.

Intervention Regeneration Strategy —

Message Process Flow

The Cummins diesel engine meets all Environ -

mental Protection Agency (EPA) Heavy Duty

Diesel Engine Emissions Standards, resulting in

one of the lowest emitting diesel engines ever

produced.

To achieve these emissions standards, your

vehicle is equipped with a state-of-the-art

engine and exhaust system. The engine and

WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure fuel

spray can cause serious injury or death.

CAUTION!

Do not engage the starter motor for more

than 15 seconds at a time. Allow two minutes

between the cranking intervals.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under

certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system.

7

20_DJD2_OM_EN_USC_t.book Page 407

Page 413 of 553

SERVICING AND MAINTENANCE411

(Continued)

(Continued)

exhaust system inspected each time the vehicle

is raised for lubrication or oil change. Replace

as required.

Under normal operating conditions, the cata-

lytic converter will not require maintenance.

However, it is important to keep the engine

properly tuned to ensure proper catalyst opera-

tion and prevent possible catalyst damage.

NOTE:

Intentional tampering with emissions control

systems can result in civil penalties being

assessed against you.

In unusual situations involving grossly malfunc -

tioning engine operation, a scorching odor may

suggest severe and abnormal catalyst over -

heating. If this occurs, stop the vehicle, turn off the engine and allow it to cool. Service,

including a tune-up to manufacturer's specifica-

tions, should be obtained immediately.

To minimize the possibility of catalytic converter

damage:

Do not interrupt the ignition when the transmis

-

sion is in gear and the vehicle is in motion.

Do not try to start the vehicle by pushing or

towing the vehicle.

Do not idle the engine with any ignition

components disconnected or removed, such

as when diagnostic testing, or for prolonged

periods during very rough idle or malfunc -

tioning operating conditions.

Cooling System

WARNING!

Exhaust gases can injure or kill. They contain

carbon monoxide (CO), which is colorless

and odorless. Breathing it can make you

unconscious and can eventually poison you.

To avoid breathing CO, refer to “Safety Tips”

in “Safety” for further information.

A hot exhaust system can start a fire if you

park over materials that can burn. Such

materials might be grass or leaves coming

into contact with your exhaust system. Do

not park or operate your vehicle in areas

where your exhaust system can contact

anything that can burn.

CAUTION!

The catalytic converter requires the use of

unleaded fuel only. Leaded gasoline will

destroy the effectiveness of the catalyst as

an emissions control device and may seri-

ously reduce engine performance and

cause serious damage to the engine.

Damage to the catalytic converter can

result if your vehicle is not kept in proper

operating condition. In the event of engine

malfunction, particularly involving engine

misfire or other apparent loss of perfor -

mance, have your vehicle serviced

promptly. Continued operation of your

vehicle with a severe malfunction could

cause the converter to overheat, resulting

in possible damage to the converter and

vehicle.

CAUTION! (Continued)

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from your

radiator. If you see or hear steam coming from

under the hood, do not open the hood until the

radiator has had time to cool. Never open a

cooling system pressure cap when the radiator

or coolant bottle is hot.

7

20_DJD2_OM_EN_USC_t.book Page 411

Page 417 of 553

SERVICING AND MAINTENANCE415

(Continued)

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning,

keep the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever

necessary, install ONLY the correct type ther -

mostat. Other designs may result in unsatis -

factory engine coolant (antifreeze)

performance, poor gas mileage, and

increased emissions.

Charge Air Cooler — Inter-Cooler

The charge air cooler is positioned below the

radiator and the air conditioner condenser. Air

enters the engine through the air cleaner and

passes through the turbocharger, where it is

pressurized. This pressurized air rapidly

reaches high temperature. The air is then

directed through a hose to the charge air cooler

and through another hose to the intake mani -

fold of the engine. The air entering the engine

has been cooled by about 50° to 100°F (10° to

38°C). This cooling process enables more effi -

cient burning of fuel resulting in fewer emis -

sions.

To guarantee optimum performance of the

system, keep the surfaces of the charge air

cooler, condenser and radiator clean and free of debris. Periodically check the hoses leading

to and from the charge air cooler for cracks or

loose clamps resulting in loss of pressure and

reduced engine performance.

Brake System

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the “Mainte

-

nance Plan” in this section for the proper main -

tenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood

service or immediately if the brake system

warning lamp indicates system failure. If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the

top of the master cylinder area before removing

cap.

With disc brakes the fluid level can be expected

to fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by

a leak and a system check should be

conducted.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder reser -

voir.

7

20_DJD2_OM_EN_USC_t.book Page 415

Page 430 of 553

428SERVICING AND MAINTENANCE

is for illustration purposes only and may not

be accurate for the seating and load carry

capacity of your vehicle.

For the following example, the combined

weight of occupants and cargo should never

exceed 865 lbs (392 kg).

Tires — General Information

Tire Pressure

Proper tire inflation pressure is essential to the

safe and satisfactory operation of your vehicle.

Four primary areas are affected by improper tire

pressure:

Safety

Fuel Economy

Tread Wear

Ride Comfort and Vehicle Stability Safety

Both underinflation and overinflation affect the

stability of the vehicle and can produce a feeling

of sluggish response or over responsiveness in

the steering.

NOTE:

Unequal tire pressures from side to side may

cause erratic and unpredictable steering

response.

Unequal tire pressure from side to side may

cause the vehicle to drift left or right.

Fuel Economy

Underinflated tires will increase tire rolling

resistance resulting in higher fuel consumption.

Tread Wear

Improper cold tire inflation pressures can cause

abnormal wear patterns and reduced tread life,

resulting in the need for earlier tire replace -

ment.

Ride Comfort And Vehicle Stability

Proper tire inflation contributes to a comfort -

able ride. Overinflation produces a jarring and

uncomfortable ride.

WARNING!

Overloading of your tires is dangerous.

Overloading can cause tire failure, affect vehicle

handling, and increase your stopping distance.

Use tires of the recommended load capacity for

your vehicle. Never overload them.

WARNING!

Improperly inflated tires are dangerous and

can cause collisions.

Underinflation increases tire flexing and

can result in overheating and tire failure.

Overinflation reduces a tire's ability to

cushion shock. Objects on the road and

chuckholes can cause damage that result

in tire failure.

Overinflated or underinflated tires can

affect vehicle handling and can fail

suddenly, resulting in loss of vehicle

control.

Unequal tire pressures can cause steering

problems. You could lose control of your

vehicle.

Unequal tire pressures from one side of the

vehicle to the other can cause the vehicle

to drift to the right or left.

Always drive with each tire inflated to the

recommended cold tire inflation pressure.

20_DJD2_OM_EN_USC_t.book Page 428

Page 451 of 553

TECHNICAL SPECIFICATIONS449

NOTE:

If you accidentally fill the fuel tank with gaso -

line on your diesel vehicle, do not start the

vehicle. If you restart your vehicle you risk

damaging the engine and fuel system. Please

call an authorized dealer for service.

A maximum blend of 5% biodiesel meeting

ASTM specification D-975 may be used with

your Cummins diesel engine. (Chassis Cab

models not configured with B20 capability.)

A maximum blend of 20% biodiesel meeting

ASTM specification D-7467 may be used with

your Cummins diesel engine. (Pickup models

and Chassis Cab models configured with

B20 Capability.)

In addition, commercially available fuel addi -

tives are not necessary for the proper opera -

tion of your Cummins diesel engine.

However, if seasonably adjusted fuel is not

available and you are operating below 20°F

(-6°C), Mopar Premium Diesel Fuel Treat -

ment (or equivalent) may be beneficial to

avoid fuel gelling.

No. 1 Ultra Low Sulfur diesel fuel should only

be used where extended arctic conditions

(0°F or -18°C) exist.

Biodiesel Fuel Requirements

Pickup Models And Chassis Cab Models

Ordered With B20 Option

Your vehicle has been validated and approved

for the use of biodiesel in blends up to 20%

(B20) provided that you comply with the require -

ments outlined below. It is important that you

understand and comply with these require -

ments. Failure to comply with Oil Change

requirements for vehicles operating on

biodiesel blends up to B20 will result in prema -

ture engine wear. Such wear is not covered by

the New Vehicle Limited Warranty.

Biodiesel is a fuel produced from renewable

resources typically derived from animal fat,

rapeseed oil (Rapeseed Methyl Ester (RME)

base), or soybean oil (Soy Methyl Ester (SME or

SOME) base). Biodiesel fuel has inherent limita-

tions which require that you understand and

adhere to the following requirements if you use

blends of biodiesel greater then 5% but not

greater than 20% (B6-B20). There are no

unique restrictions for the use of B5. Use of

blends greater than 20% is not approved. Use of

blends greater than 20% can result in engine

damage. Such damage is not covered by the

New Vehicle Limited Warranty.

Fuel Quality — Must Comply With ASTM

Standards

The quality of biodiesel fuel may vary widely.

Only fuel produced by a BQ9000 supplier to the

following specifications may be blended to

meet biodiesel blend (B6–B20) fuel meeting

ASTM specification D-7467:

Pretrodiesel fuel meeting ASTM specification

D-975 and biodiesel fuel (B100) meeting

ASTM specification D-6751.

Fuel Oxidation Stability — Must Use Fuel

Within Six Months Of Manufacture

Biodiesel fuel has poor oxidation stability which

can result in long term storage problems. Fuel

produced to approved ASTM standards, if

stored properly, provides for protection against

fuel oxidation for up to six months.

Fuel Water Separation — Must Use Mopar/

Cummins Approved Fuel Filter Elements

You must use Mopar/Cummins approved fuel

filter elements in both your engine mounted

filter and frame mounted filter.

Biodiesel fuel has a natural affinity to water and

water accelerates microbial growth. Your

Mopar/Cummins filtration system is designed

to provide adequate fuel water separation capa-

bilities.

8

20_DJD2_OM_EN_USC_t.book Page 449

Page 452 of 553

450TECHNICAL SPECIFICATIONS

Bio-Diesel Fuel Properties — Low Ambient

Temperatures

Biodiesel fuel may gel or solidify at low ambient

temperatures, which may pose problems for

both storage and operation. Precautions can be

necessary at low ambient temperatures, such

as storing the fuel in a heated building or a

heated storage tank, or using cold temperature

additives.

Fuel In Oil Dilution — Must Adhere To

Required Oil Change Interval

Fuel dilution of lubricating oil has been

observed with the use of biodiesel fuel. Fuel in

oil must not exceed 5%. To ensure this limit is

met your oil change interval must be main -

tained to the following schedule:

Ram PickUp 2500/3500 Only — 15,000 Miles*

(*unless otherwise notified with a oil service

message)

CAUTION!

Under no circumstances should oil change

intervals exceed 15,000 miles (24 000 km)

pickup or 12,500 miles (20 000 km)

chassis cab if operation occurs with greater

than 5% biodiesel blends. Oil change inter -

vals should not exceed 6 months in either

case. Failure to comply with these Oil

Change requirements for vehicles operating

on biodiesel blends up to B20 may result in

premature engine wear. Such wear is not

covered by the New Vehicle Limited

Warranty.

B20 Biodiesel capable: The engine may

suffer severe damage if operated with

concentrations of Biodiesel higher than

20%.

20_DJD2_OM_EN_USC_t.book Page 450

Page 453 of 553

TECHNICAL SPECIFICATIONS451

FLUID CAPACITIES — GAS ENGINE

FLUID CAPACITIES — DIESEL ENGINE

USMetric

Fuel (Approximate)

2500/3500 Shortbed Models 31 Gallons117 Liters

2500/3500 Longbed Models 32 Gallons121 Liters

2500/3500 Crew Cab Longbed Models — If Equipped 50 Gallons189 Liters

Engine Oil With Filter

6.4L Engine (We recommend you use SAE 0W-40 engine oil meeting the requirements of

FCA Material Standard MS-12633 for use in all operating temperatures.) 7 Quarts

6.6 Liters

Cooling System

6.4L Engine – (We recommend you use Mopar® Antifreeze/Coolant 10 Year/

150,000 Mile Formula that meets the requirements of FCA Material Standard

MS.90032.) 16.6 Quarts

15.7 Liters

USMetric

Fuel (Approximate)

2500/3500 Standard Cab Longbed Models 28 Gallons106 Liters

2500/3500 Crew/Mega Cab Shortbed Models 31 Gallons117 Liters

2500/3500 Crew Cab Longbed Models 32 Gallons121 Liters

2500/3500 Crew Cab Longbed Models — If Equipped 50 Gallons189 Liters

8

20_DJD2_OM_EN_USC_t.book Page 451