maintenance Ram 2500 2020 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 220 of 553

218STARTING AND OPERATING

5. After engine start-up, check to see that

there is oil pressure.

6. Release the parking brake and drive.

NOTE:

Engine idle speed will automatically increase

to 1,000 RPM and engage the Variable

Geometry Turbocharger at low coolant

temperatures to improve engine warm-up.

The engine will not automatically crank after

the engine “Wait To Start” telltale goes off if

a door or the hood is ajar.

If the engine stalls, or if the ignition switch is

left ON for more than two minutes after the

“Wait To Start” telltale goes out, reset the

intake air heater by turning the ignition

switch to the OFF position for at least

5 seconds and then back ON. Repeat steps

1 through 7 of “Keyless Enter-N-Go Starting Procedure – Engine Manifold Air Tempera

-

ture Below 66° F (19° C).”

Extreme Cold Weather

The Cummins® Turbo Diesel engine is

equipped with several features designed to

assist cold weather starting and operation:

The engine block heater is a resistance

heater installed in the water jacket of the

engine just above and behind the oil filter. It

requires a 110–115 Volt AC electrical outlet

with a grounded, three-wire extension cord.

NOTE:

The engine block heater cord is a factory

installed option. If your vehicle is not equipped,

heater cords are available from an authorized

Mopar dealer.

A 12 Volt heater built into the fuel filter hous -

ings aid in preventing fuel gelling. It is

controlled by a built-in thermostat.

A intake air heater system both improves

engine starting and reduces the amount of

white smoke generated by a warming engine.

Normal Starting Procedure — Engine

Manifold Air Temperature Above 66° F

(19° C)

Observe the instrument panel cluster lights

when starting the engine.

1. Always apply the parking brake.

2. Shift into PARK for an automatic transmis -

sion.

3. Place the ignition switch in the ON position and watch the instrument panel cluster

lights.

4. Place the ignition switch in the START posi -

tion and crank the engine. Do not press the

accelerator during starting.

CAUTION!

Do not crank engine for more than 25 seconds

at a time or starter motor damage may result.

Turn the ignition switch to the OFF position and

wait at least two minutes for the starter to cool

before repeating start procedure.

CAUTION!

If the “Water in Fuel Indicator Light” remains

on, DO NOT START the engine before you

drain the water from the fuel filters to avoid

engine damage. Refer to “Draining Fuel/

Water Separator Filter” in “Servicing And

Maintenance” for further information.

20_DJD2_OM_EN_USC_t.book Page 218

Page 221 of 553

STARTING AND OPERATING219

5. Check that the oil pressure warning light

has turned off.

6. Release the parking brake.

Starting Procedure — Engine Manifold Air

Temperature 0°F To 66°F (–18°C to 19°C)

NOTE:

The temperature displayed in the instrument

cluster does not necessarily reflect the engine

manifold air temperature. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

When engine temperatures fall below 66°F

(19°C) the “Wait To Start Light” will remain on

indicating the intake air heater system is active.

Follow the steps in the “Normal Starting” proce -

dure except:

1. The “Wait To Start” telltale will remain on

for a period of time that varies depending

on the engine temperature.

2. While the “Wait To Start” telltale is on, the instrument cluster will additionally display a

gauge or bar whose initial length represents

the full “Wait To Start” time period. Its

length will decrease until it disappears

when the “Wait To Start” time has elapsed.

3. After the “Wait To Start” telltale goes off, place the ignition switch in the START posi -

tion. Do not press the accelerator during

starting. 4. After engine start-up, check that the oil

pressure warning light has turned off.

5. Release the parking brake and drive.

NOTE:

Engine idle speed will automatically increase

to 1,000 RPM and engage the Variable

Geometry Turbocharger at low coolant

temperatures to improve engine warm-up.

Automatic equipped vehicles with optional

Keyless Enter-N-Go – If the start button is

pushed once while in park with the ignition

off and driver’s foot on the brake pedal, the

vehicle will automatically crank and start

after the Wait to Start time has elapsed. If it

is desired to abort the start process before it

CAUTION!

Do not crank engine for more than 25 seconds

at a time or starter motor damage may result.

Turn the ignition switch to the OFF position and

wait at least two minutes for the starter to cool

before repeating start procedure.

CAUTION!

If the “Water in Fuel Indicator Light” remains

on, DO NOT START the engine before you

drain the water from the fuel filters to avoid

engine damage. Refer to “Draining Fuel/

Water Separator Filter” in “Servicing And

Maintenance” for further information.

CAUTION!

Do not crank engine for more than 25 seconds

at a time or starter motor damage may result.

Turn the ignition switch to the OFF position and

wait at least two minutes for the starter to cool

before repeating start procedure.

5

20_DJD2_OM_EN_USC_t.book Page 219

Page 222 of 553

220STARTING AND OPERATING

completes, the driver’s foot should be fully

removed from the brake pedal prior to

pushing the start button again in order for the

ignition to move directly to off.

If the engine stalls, or if the ignition switch is

left ON for more than two minutes after the

“Wait To Start” telltale goes out, reset the

intake air heater by turning the ignition

switch to the OFF position for at least five

seconds and then back ON. Repeat steps

1 through 5 of “Starting Procedure – Engine

Manifold Air Temperature Below 66°F

(19°C).”

Starting Procedure — Engine Manifold Air

Temperature Below 0°F (-18°C)

In extremely cold weather below 0°F (-18°C) it

may be beneficial to cycle the intake air heater

twice before attempting to start the engine. This

can be accomplished by turning the ignition OFF

for at least 5 seconds and then back ON after

the “Wait To Start” telltale has turned off, but

before the engine is started. However, exces -

sive cycling of the intake air heater will result in

damage to the heater elements or reduced

battery voltage. NOTE:

If multiple pre-heat cycles are used before

starting, additional engine run time may be

required to maintain battery state of charge at a

satisfactory level.

1. If the engine stalls after the initial start, the

ignition must be turned to the OFF position

for at least five seconds and then to the ON

position to recycle the intake air heater.

NOTE:

Excessive white smoke and poor engine perfor -

mance will result if intake air heater are not

recycled.

2. Heat generated by the intake air heater dissipates rapidly in a cold engine. If more

than two minutes pass between the time

the “Wait To Start” telltale turns off and the

engine is started, recycle the intake air

heater by turning the ignition switch to the

OFF position for at least five seconds and

then back ON.

3. If the vehicle is driven and vehicle speed exceeds 19 mph (31 km/h) before the

intake air heater post-heat (after start) cycle

is complete, the intake air heater will shut

off. 4. If the engine is cranked for more than

10 seconds, the post-heat cycle will turn off.

NOTE:

Engine idle speed will automatically increase

to 1,000 RPM and engage the Variable

Geometry Turbocharger at low coolant

temperatures to improve engine warm-up.

When a diesel engine is allowed to run out of

fuel or the fuel gels at low temperatures, air

is pulled into the fuel system. If your engine

has run out of fuel, refer to “Dealer Service/

Priming If The Engine Has Run Out Of Fuel” in

“Servicing And Maintenance” for further

information.

If the engine stalls, or if the ignition switch is

left ON for more than two minutes after the

“Wait To Start” telltale goes out, reset the

intake air heater by turning the ignition

switch to the OFF position for at least 5

seconds and then back ON. Repeat steps

1 through 5 of “Starting Procedure – Engine

Manifold Air Temperature Below 66°F

(19°C).”

20_DJD2_OM_EN_USC_t.book Page 220

Page 225 of 553

STARTING AND OPERATING223

NOTE:

Use of Climatized Ultra Low Sulfur Diesel Fuel

or Number 1 Ultra Low Sulfur Diesel Fuel

results in a noticeable decrease in fuel

economy.

Climatized Ultra Low Sulfur Diesel Fuel is a

blend of Number 2 Ultra Low Sulfur and

Number 1 Ultra Low Sulfur Diesel Fuels

which reduces the temperature at which wax

crystals form in fuel.

The fuel grade should be clearly marked on

the pump at the fuel station.

The engine requires the use of “Ultra Low

Sulfur Diesel Fuel”. Use of incorrect fuel

could result in engine and exhaust system

damage. Refer to “Fuel Requirements” in

“Technical Specifications” for further infor -

mation.

If climatized or diesel Number 1 ULSD fuel is

not available, and you are operating below

(20°F/-6°C), in sustained arctic conditions,

Mopar Premium Diesel Fuel Treatment (or

equivalent) is recommended to avoid gelling

(see Fuel Operating Range Chart).

Under some circumstances increased

engine noise may be audible in the seconds

following a cold start. This is most likely to

occur when using fuel that isn't blended for

the ambient temperature present. This may

occur on an unseasonably cold day or when

a truck is fueled in a warmer climate and

driven to a colder climate. The noise can

typically be prevented by using Mopar

Premium Diesel Fuel Treatment as recom-

mended (see Fuel Operating Range Chart).

Engine Oil Usage

Refer to “Dealer Service” in “Servicing And

Maintenance” for the correct engine oil

viscosity.

Winter Front Cover Usage

A Winter front or cold weather cover is to be

used in ambient temperatures below 32°F

(0°C), especially during extended idle condi -

tions. This cover is equipped with four flaps for

managing total grille opening in varying ambient

temperatures. If a Winter front or cold weather

cover is to be used the flaps should be left in the

full open position to allow air flow to the charge

air cooler and automatic transmission oil

cooler. When ambient temperatures drop below

0°F (-17°C) the four flaps need to be closed. A suitable cold weather cover is available from

your Mopar dealer.

Battery Blanket Usage

A battery loses 60% of its cranking power as the

battery temperature decreases to 0°F (-18°C).

For the same decrease in temperature, the

engine requires twice as much power to crank

at the same RPM. The use of 120 VAC powered

battery blankets will greatly increase starting

capability at low temperatures. Suitable battery

blankets are available from your authorized

Mopar dealer.

Engine Warm-Up

Avoid full throttle operation when the engine is

cold. When starting a cold engine, bring the

engine up to operating speed slowly to allow the

oil pressure to stabilize as the engine warms up.

NOTE:

High-speed, no-load running of a cold engine

can result in excessive white smoke and poor

engine performance. No-load engine speeds

should be kept under 1,000 RPM during the

warm-up period, especially in cold ambient

temperature conditions.

5

20_DJD2_OM_EN_USC_t.book Page 223

Page 285 of 553

STARTING AND OPERATING283

Push the Adaptive Cruise Control (ACC) on/off

button (located on the steering wheel) until one

of the following appears in the instrument

cluster display:

Adaptive Cruise Control Off

When ACC is deactivated, the display will read

“Adaptive Cruise Control Off.”

Adaptive Cruise Control Ready

When ACC is activated, but the vehicle speed

setting has not been selected, the display will

read “Adaptive Cruise Control Ready.”

Adaptive Cruise Control Set

When the RES (+) or the SET(-) button (located

on the steering wheel) is pushed, the display will

read “ACC SET.”

When ACC is set, the set speed will show in the

instrument cluster display.

The ACC screen may display once again if any

ACC activity occurs, which may include any of

the following:

System Cancel

Driver Override

System Off

ACC Proximity Warning

ACC Unavailable Warning

The instrument cluster display will return to

the last display selected after five seconds of

no ACC display activity

Display Warnings And Maintenance

“Wipe Front Radar Sensor In Front Of

Vehicle” Warning

The “ACC/FCW Unavailable Wipe Front Radar

Sensor” warning will display and also a chime

will indicate when conditions temporarily limit

system performance.

This most often occurs at times of poor visibility,

such as in snow or heavy rain. The ACC system

may also become temporarily blinded due to

obstructions, such as mud, dirt or ice. In these

cases, the instrument cluster display will display

“ACC/FCW Unavailable Wipe Front Radar

Sensor” and the system will deactivate.

The “ACC/FCW Unavailable Wipe Front Radar

Sensor” message can sometimes be displayed

while driving in highly reflective areas (i.e.

tunnels with reflective tiles, or ice and snow).

The ACC system will recover after the vehicle has left these areas. Under rare conditions,

when the radar is not tracking any vehicles or

objects in its path this warning may temporarily

occur.

NOTE:

If the “ACC/FCW Unavailable Wipe Front Radar

Sensor” warning is active Normal (Fixed Speed)

Cruise Control is still available. For additional

information refer to “Normal (Fixed Speed)

Cruise Control Mode” in this section.

If weather conditions are not a factor, the driver

should examine the sensor. It may require

cleaning or removal of an obstruction. The

sensor is located in the camera in the center of

the windshield, on the forward side of the rear

-

view mirror.

To keep the ACC System operating properly, it is

important to note the following maintenance

items:

Always keep the sensor clean. Carefully clear

the windshield.

Do not remove any screws from the sensor.

Doing so could cause an ACC system

5

20_DJD2_OM_EN_USC_t.book Page 283

Page 325 of 553

STARTING AND OPERATING323

(Continued)

Trailer Towing Weights (Maximum Trailer

Weight Ratings)

NOTE:

For trailer towing information (maximum trailer

weight ratings) refer to the following website

addresses:

ramtrucks.com/en/towing_guide/

ramtruck.ca (Canada)

rambodybuilder.com

Trailer And Tongue Weight

Weight Distribution

Consider the following items when computing

the weight on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or

equipment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:

Remember that everything put into or on the

trailer adds to the load on your vehicle. Also,

additional factory-installed options or

dealer-installed options must be considered as

part of the total load on your vehicle. Refer to

the “Tire And Loading Information” placard for

the maximum combined weight of occupants

and cargo for your vehicle.

Towing Requirements

To promote proper break-in of your new vehicle

drivetrain components, the following guidelines

are recommended. Perform the maintenance listed in the “Sched

-

uled Servicing”. Refer to “Scheduled Servicing”

in “Servicing And Maintenance” for the proper

maintenance intervals. When towing a trailer,

never exceed the GAWR or GCWR ratings.

CAUTION!

Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is

driven. The engine, axle or other parts could

be damaged.

Then, during the first 500 miles (805 km)

that a trailer is towed, do not drive over

50 mph (80 km/h) and do not make starts

at full throttle. This helps the engine and

other parts of the vehicle wear in at the

heavier loads.

WARNING!

Make certain that the load is secured in the

trailer and will not shift during travel. When

trailering cargo that is not fully secured,

dynamic load shifts can occur that may be

difficult for the driver to control. You could

lose control of your vehicle and have a colli -

sion.

5

20_DJD2_OM_EN_USC_t.book Page 323

Page 326 of 553

324STARTING AND OPERATING

(Continued)

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h) when towing while using a full size spare tire.

Proper tire inflation pressures are essential

to the safe and satisfactory operation of your

vehicle. Refer to “Tires” in “Servicing And

Maintenance” for proper tire inflation proce -

dures.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer. Refer to

“Tires” in “Servicing And Maintenance” for

the proper inspection procedure.

When replacing tires, refer to “Tires” in

“Servicing And Maintenance” for the proper

tire replacement procedures. Replacing tires

with a higher load carrying capacity will not

increase the vehicle's GVWR and GAWR

limits.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake

system or vacuum system of your vehicle

with that of the trailer. This could cause inad -

equate braking and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer

with electronically actuated brakes. When

towing a trailer equipped with a hydraulic

surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers

over 1,000 lbs (453 kg) and required for

trailers in excess of 2,000 lbs (907 kg).

When hauling cargo or towing a trailer, do

not overload your vehicle or trailer. Over -

loading can cause a loss of control, poor

performance or damage to brakes, axle,

engine, transmission, steering, suspension,

chassis structure or tires.

Safety chains must always be used

between your vehicle and trailer. Always

connect the chains to the hook retainers of

the vehicle hitch. Cross the chains under

the trailer tongue and allow enough slack

for turning corners.

Vehicles with trailers should not be parked

on a grade. When parking, apply the

parking brake on the tow vehicle. Put the

tow vehicle transmission in PARK. For

four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL. Always,

block or "chock" the trailer wheels.

GCWR must not be exceeded.

WARNING! (Continued)

Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer

hitch utilized.

WARNING! (Continued)

20_DJD2_OM_EN_USC_t.book Page 324

Page 332 of 553

330STARTING AND OPERATING

Snowplow Prep Package Model Availability

For Information about snowplow applications

visit www.ramtrucks.com or refer to the current

Body Builders Guide.

1. The maximum number of occupants in the

truck should not exceed two.

2. The total GVWR or the Front GAWR or the Rear GAWR should never be exceeded.

3. Cargo capacity will be reduced by the addi -

tion of options or passengers, etc.

The loaded vehicle weight, including the snow -

plow system, all aftermarket accessories,

driver, passengers, options, and cargo, must

not exceed either the Gross Vehicle Weight

(GVWR) or Gross Axle Weight (GAWR) ratings.

These weights are specified on the Safety

Compliance Certification Label on the driver's

side door opening.

NOTE:

Detach the snowplow when transporting

passengers.

Vehicle front end wheel alignment was set to

specifications at the factory without consider -

ation for the weight of the plow. Front end toe-in should be checked and reset if necessary at the

beginning and end of the snowplow season.

This will help prevent uneven tire wear.

The blade should be lowered whenever the

vehicle is parked.

Maintain and operate your vehicle and snow

-

plow equipment following the recommenda -

tions provided by the specific snowplow

manufacturer.

Over The Road Operation With Snowplow

Attached

The blade restricts air flow to the radiator and

causes the engine to operate at higher than

normal temperatures. Therefore, when trans -

porting the plow, angle the blade completely

and position it as low as road or surface condi -

tions permit. Do not exceed 40 mph (64 km/h).

The operator should always maintain a safe

stopping distance and allow adequate passing

clearance.

Operating Tips

Under ideal snow plowing conditions, 20 mph

(32 km/h) should be maximum operating

speed. The operator should be familiar with the

area and surface to be cleaned. Reduce speed and use extreme caution when plowing unfa

-

miliar areas or under poor visibility.

General Maintenance

Snowplows should be maintained in accor -

dance with the plow manufacturer's instruc -

tions.

Keep all snowplow electrical connections and

battery terminals clean and free of corrosion.

When plowing snow, to avoid transmission and

drivetrain damage, the following precautions

should be observed.

Operate with transfer case in 4LO when

plowing small or congested areas where

speeds are not likely to exceed 15 mph

(24 km/h). At higher speeds operate in 4HI.

Vehicles with automatic transmissions

should use 4LO range when plowing deep or

heavy snow for extended periods of time to

avoid transmission overheating.

Do not shift the transmission unless the

engine has returned to idle and wheels have

stopped. Make a practice of stepping on the

brake pedal while shifting the transmission.

20_DJD2_OM_EN_USC_t.book Page 330

Page 382 of 553

380

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GAS ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indi-

cator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will

influence when the “Oil Change Required”

message is displayed. Severe Operating Condi-

tions can cause the change oil message to illu -

minate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles

(805 km).

Your authorized dealer will reset the oil change

indicator message after completing the sched -

uled oil change.

If a scheduled oil change is performed by

someone other than your authorized dealer, the

message can be reset by referring to the steps described under “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel”.

NOTE:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

NOTE:

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominantly at idle, or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, power steering and

automatic transmission (six-speed only) and

fill as needed

Check function of all interior and exterior

lights

Maintenance Plan — Gasoline Engine

Required Maintenance

Refer to the Maintenance Plan on the following

pages for required maintenance. More frequent

maintenance may be needed in severe condi

-

tions, such as dusty areas and very short trip

driving. In some extreme conditions, additional

maintenance not specified in the maintenance

schedule may be required.

20_DJD2_OM_EN_USC_t.book Page 380

Page 383 of 553

SERVICING AND MAINTENANCE381

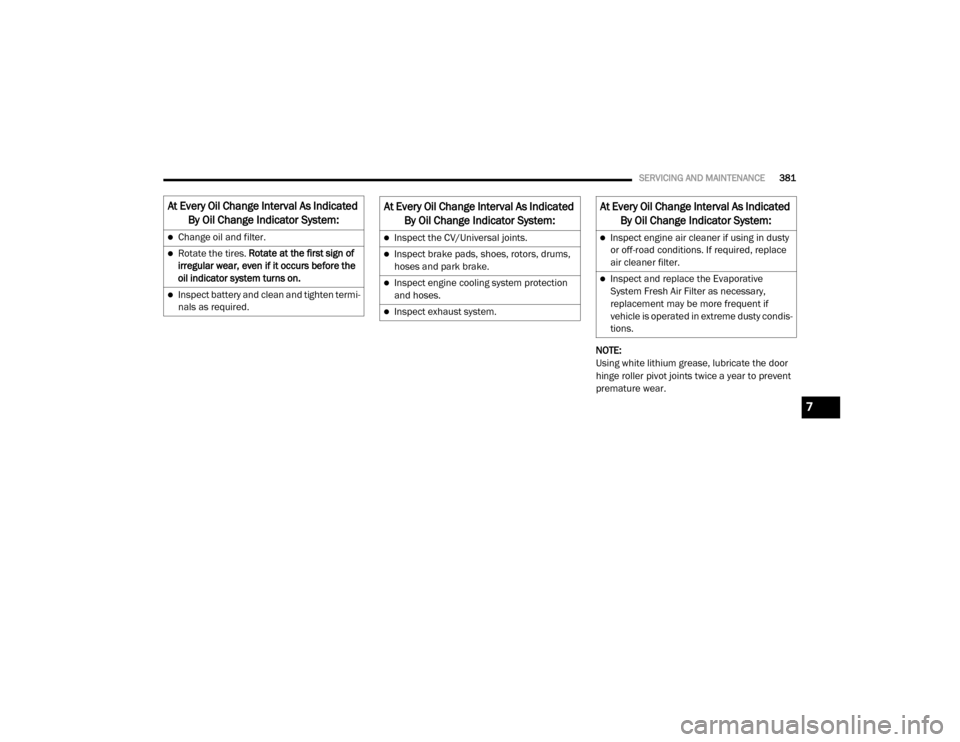

NOTE:

Using white lithium grease, lubricate the door

hinge roller pivot joints twice a year to prevent

premature wear.

At Every Oil Change Interval As Indicated

By Oil Change Indicator System:

Change oil and filter.

Rotate the tires. Rotate at the first sign of

irregular wear, even if it occurs before the

oil indicator system turns on.

Inspect battery and clean and tighten termi -

nals as required.

Inspect the CV/Universal joints.

Inspect brake pads, shoes, rotors, drums,

hoses and park brake.

Inspect engine cooling system protection

and hoses.

Inspect exhaust system.

At Every Oil Change Interval As Indicated

By Oil Change Indicator System:

Inspect engine air cleaner if using in dusty

or off-road conditions. If required, replace

air cleaner filter.

Inspect and replace the Evaporative

System Fresh Air Filter as necessary,

replacement may be more frequent if

vehicle is operated in extreme dusty condis -

tions.

At Every Oil Change Interval As Indicated

By Oil Change Indicator System:

7

20_DJD2_OM_EN_USC_t.book Page 381