washer fluid Ram 2500 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 2500, Model: Ram 2500 2020Pages: 553, PDF Size: 21.99 MB

Page 10 of 553

8

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS) ................................................................ 371

EVENT DATA RECORDER (EDR) ....................... 371

BULB REPLACEMENT ........................................ 372 Replacement Bulbs ...................................372

Replacing Exterior Bulbs ...........................374

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GAS ENGINE ....... 380Maintenance Plan — Gasoline Engine......380

Heavy Duty Use Of The Vehicle ................. 384

SCHEDULED SERVICING— DIESEL ENGINE .... 384

Oil Change Indicator System — Cummins

Diesel ..........................................................385 Perform Service Indicator — Cummins

Diesel ..........................................................385

Maintenance Plan — Cummins Diesel

Engine ........................................................ 386

ENGINE COMPARTMENT .................................. 391

6.4L Engine ...............................................391

6.7L Diesel Engine — Six-Speed 68RFE ..392

6.7L Diesel Engine — Six-Speed

AS69RC HD ................................................393 Checking Oil Level — Gas Engine .............394

Checking Oil Level — Diesel Engine ..........394

Adding Washer Fluid..................................394

Maintenance-Free Battery .......................395

Pressure Washing ......................................395 DEALER SERVICE ..............................................396

Engine Oil .................................................. 396

Engine Oil Filter .......................................... 398

Engine Air Cleaner Filter............................ 398

Air Conditioner Maintenance .................... 400

Accessory Drive Belt Inspection ............... 403

Draining Fuel/Water Separator Filter —

Diesel Engine ............................................ 403 Engine Mounted Fuel Filter Replacement —

Diesel Engine ............................................. 405 Underbody Mounted Fuel Filter

Replacement — Diesel Engine .................. 406 Priming If The Engine Has Run Out Of

Fuel — Diesel Engine ................................. 407 Intervention Regeneration Strategy —

Message Process Flow ............................. 407 Diesel Exhaust Fluid .................................. 408

Body Lubrication ........................................ 408

Windshield Wiper Blades .......................... 409

Exhaust System ........................................ 410

Cooling System ......................................... 411

Charge Air Cooler — Inter-Cooler .............. 415

Brake System ............................................ 415

Automatic Transmission............................ 416

Rear Axle And 4x4 Front Driving Axle Fluid

Level .......................................................... 418 Transfer Case ............................................ 419

Noise Control System Required

Maintenance & Warranty ......................... 419 HOISTING ........................................................... 422

TIRES ................................................................... 422

Tire Safety Information.............................. 422

Tires — General Information .................... 428

Tire Types ................................................... 432

Spare Tires — If Equipped ......................... 433

Wheel And Wheel Trim Care ..................... 434

Tire Chains And Traction Devices ............ 435

Tire Rotation Recommendations ............. 436

DEPARTMENT OF TRANSPORTATION UNIFORM

TIRE QUALITY GRADES .................................... 438

Treadwear .................................................. 438

Traction Grades ......................................... 438

Temperature Grades ................................. 438

STORING THE VEHICLE ..................................... 439

BODYWORK ........................................................ 439

Protection From Atmospheric Agents....... 439

Body And Underbody Maintenance .......... 439

Preserving The Bodywork.......................... 440

INTERIORS ......................................................... 442

Seats And Fabric Parts .............................. 442

Plastic And Coated Parts........................... 442

Leather Parts ............................................. 443

Glass Surfaces .......................................... 443

20_DJD2_OM_EN_USC_t.book Page 8

Page 58 of 553

56GETTING TO KNOW YOUR VEHICLE

Windshield Washers

To use the windshield washer, push the washer

knob, located on the end of the multifunction

lever, inward to the second detent. Washer fluid

will be sprayed and the wiper will operate for

two to three cycles after the washer knob is

released from this position.

If the washer knob is depressed while in the

delay range, the wiper will operate for several

seconds after the washer knob is released. It

will then resume the intermittent interval previ -

ously selected. If the washer knob is pushed

while in the off position, the wiper will turn on

and cycle approximately three times after the

wash knob is released.

To prevent freeze-up of your windshield washer

system in cold weather, select a solution or

mixture that meets or exceeds the temperature

range of your climate. This rating information

can be found on most washer fluid containers.

Mist Feature

When a single wipe to clear off road mist or

spray from a passing vehicle is needed, push

the washer knob, located on the end of the

multifunction lever, inward to the first detent

and release. The wipers will cycle one time and

automatically shut off.

NOTE:

The mist feature does not activate the washer

pump; therefore, no washer fluid will be sprayed

on the windshield. The wash function must be

used in order to spray the windshield with

washer fluid.

Rain Sensing Wipers — If Equipped

This feature senses moisture on the windshield

and automatically activates the wipers for the

driver. The feature is especially useful for road

splash or overspray from the windshield

washers of the vehicle ahead. Rotate the end of

the multifunction lever to one of five settings to

activate this feature.

NOTE:

This feature can be programmed on/off through

the Uconnect system. Refer to “Uconnect

Settings” in “Multimedia” for further informa -

tion.

The sensitivity of the system can be adjusted

with the multifunction lever. Wiper delay posi -

tion 1 is the least sensitive, and wiper delay

position 5 is the most sensitive. Position 3

should be used for normal rain conditions. Posi -

tions 1 and 2 can be used if the driver desires

less wiper sensitivity. Positions 4 and 5 can be

used if the driver desires more sensitivity. Place

the wiper switch in the O (off) position when not

using the system.WARNING!

Sudden loss of visibility through the

windshield could lead to a collision. You might

not see other vehicles or other obstacles. To

avoid sudden icing of the windshield during

freezing weather, warm the windshield with

the defroster before and during windshield

washer use.

20_DJD2_OM_EN_USC_t.book Page 56

Page 137 of 553

GETTING TO KNOW YOUR INSTRUMENT PANEL135

Service LaneSense Warning Light — If

Equipped

This warning light will illuminate when

the LaneSense system is not oper-

ating and requires service. Please see

an authorized dealer.

Low Washer Fluid Warning Light

This warning light will illuminate when

the windshield washer fluid is low.

Refer to “Engine Compartment” in

“Servicing And Maintenance” for

further information.

Low Fuel Warning Light

When the fuel level reaches approxi -

mately 3.2 gal (12 L) this light will turn

on, and remain on until fuel is added.

A single warning chime will sound with

Low Fuel Warning.

Low Coolant Level Warning Light

This telltale will turn on to indicate the

vehicle coolant level is low.

Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.

Loose Fuel Filler Cap Warning Light — If

Equipped

This warning light will illuminate when

the fuel filler cap is loose. Properly

close the filler cap to disengage the

light. If the light does not turn off,

please see an authorized dealer.

Trailer Merge Assist Indicator Light — If

Equipped

This indicator light will illuminate to

indicate when Trailer Merge Assist

has been activated.

Refer to “Blind Spot Monitoring (BSM)” in

“Safety” for further information.

Tire Pressure Monitoring System (TPMS)

Warning Light

The warning light switches on and a

message is displayed to indicate that

the tire pressure is lower than the

recommended value and/or that slow

pressure loss is occurring. In these cases,

optimal tire duration and fuel consumption may

not be guaranteed.

Should one or more tires be in the condition

mentioned above, the display will show the indi -

cations corresponding to each tire. Each tire, including the spare (if provided),

should be checked monthly when cold and

inflated to the inflation pressure recommended

by the vehicle manufacturer on the vehicle

placard or tire inflation pressure label. If your

vehicle has tires of a different size than the size

indicated on the vehicle placard or tire inflation

pressure label, you should determine the

proper tire inflation pressure for those tires.

As an added safety feature, your vehicle has

been equipped with a Tire Pressure Monitoring

System (TPMS) that illuminates a low tire pres

-

sure telltale when one or more of your tires is

significantly under-inflated. Accordingly, when

the low tire pressure telltale illuminates, you

should stop and check your tires as soon as

possible, and inflate them to the proper pres -

sure. Driving on a significantly under-inflated

CAUTION!

Do not continue driving with one or more flat

tires as handling may be compromised. Stop

the vehicle, avoiding sharp braking and

steering. If a tire puncture occurs, repair

immediately using the dedicated tire repair

kit and contact an authorized dealer as soon

as possible.

3

20_DJD2_OM_EN_USC_t.book Page 135

Page 382 of 553

380

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GAS ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indi-

cator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will

influence when the “Oil Change Required”

message is displayed. Severe Operating Condi-

tions can cause the change oil message to illu -

minate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles

(805 km).

Your authorized dealer will reset the oil change

indicator message after completing the sched -

uled oil change.

If a scheduled oil change is performed by

someone other than your authorized dealer, the

message can be reset by referring to the steps described under “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel”.

NOTE:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

NOTE:

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominantly at idle, or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, power steering and

automatic transmission (six-speed only) and

fill as needed

Check function of all interior and exterior

lights

Maintenance Plan — Gasoline Engine

Required Maintenance

Refer to the Maintenance Plan on the following

pages for required maintenance. More frequent

maintenance may be needed in severe condi

-

tions, such as dusty areas and very short trip

driving. In some extreme conditions, additional

maintenance not specified in the maintenance

schedule may be required.

20_DJD2_OM_EN_USC_t.book Page 380

Page 393 of 553

SERVICING AND MAINTENANCE391

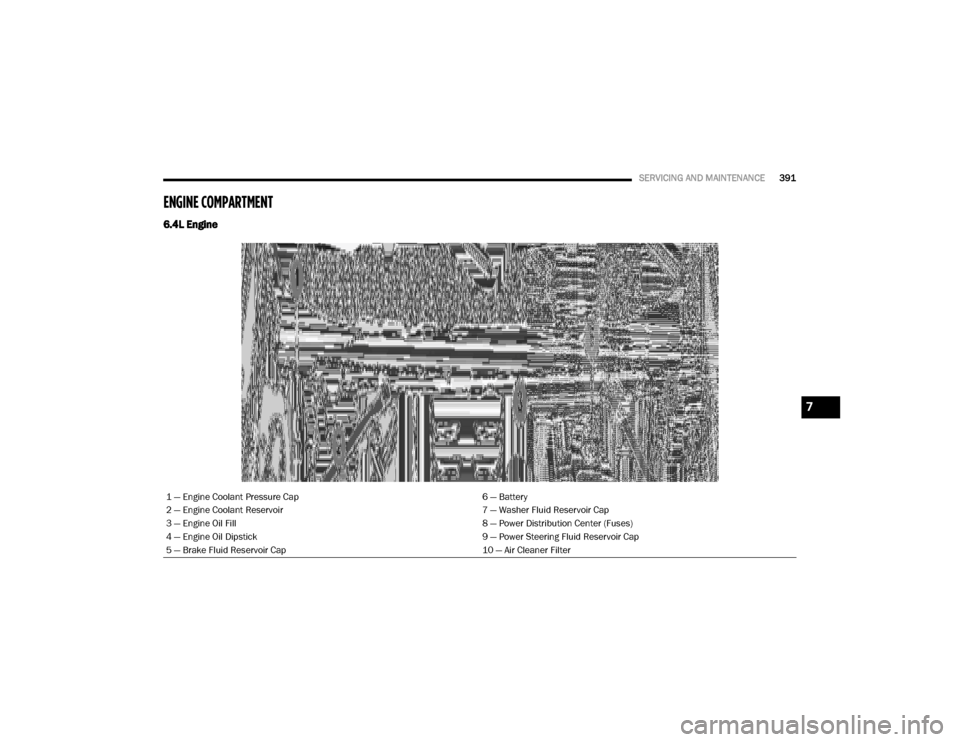

ENGINE COMPARTMENT

6.4L Engine

1 — Engine Coolant Pressure Cap 6 — Battery

2 — Engine Coolant Reservoir 7 — Washer Fluid Reservoir Cap

3 — Engine Oil Fill 8 — Power Distribution Center (Fuses)

4 — Engine Oil Dipstick 9 — Power Steering Fluid Reservoir Cap

5 — Brake Fluid Reservoir Cap 10 — Air Cleaner Filter

7

20_DJD2_OM_EN_USC_t.book Page 391

Page 394 of 553

392SERVICING AND MAINTENANCE

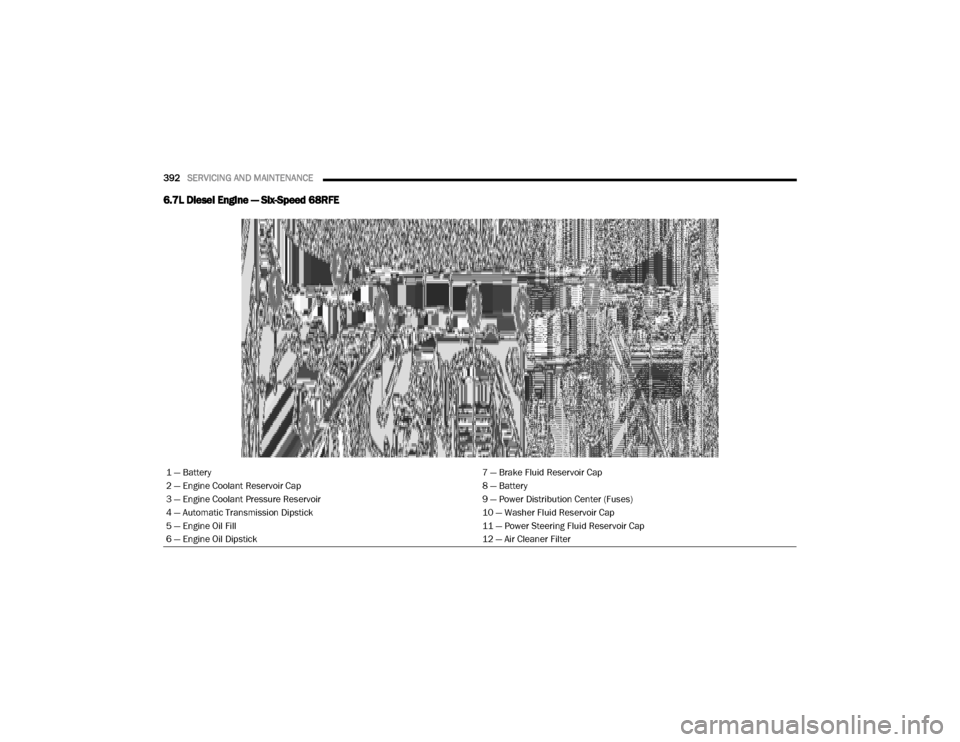

6.7L Diesel Engine — Six-Speed 68RFE

1 — Battery 7 — Brake Fluid Reservoir Cap

2 — Engine Coolant Reservoir Cap 8 — Battery

3 — Engine Coolant Pressure Reservoir 9 — Power Distribution Center (Fuses)

4 — Automatic Transmission Dipstick 10 — Washer Fluid Reservoir Cap

5 — Engine Oil Fill 11 — Power Steering Fluid Reservoir Cap

6 — Engine Oil Dipstick 12 — Air Cleaner Filter

20_DJD2_OM_EN_USC_t.book Page 392

Page 395 of 553

SERVICING AND MAINTENANCE393

6.7L Diesel Engine — Six-Speed AS69RC HD

1 — Battery 7 — Brake Fluid Reservoir Cap

2 — Engine Coolant Reservoir Cap 8 — Battery

3 — Engine Coolant Pressure Reservoir 9 — Power Distribution Center (Fuses)

4 — Engine Oil Fill 10 — Washer Fluid Reservoir Cap

5 — Engine Oil Dipstick 11 — Power Steering Fluid Reservoir Cap

6 — Automatic Transmission Dipstick 12 — Air Cleaner Filter

7

20_DJD2_OM_EN_USC_t.book Page 393

Page 396 of 553

394SERVICING AND MAINTENANCE

Checking Oil Level — Gas Engine

To ensure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals, such as every fuel stop. The best time

to check the engine oil level is about five

minutes after a fully warmed up engine is shut

off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings. Always maintain the oil level within

the SAFE zone on the dipstick. Adding one quart

of oil when the reading is at the bottom of the

SAFE zone will result in a reading at the top of

the safe zone on these engines.

Checking Oil Level — Diesel Engine

To ensure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals. The best time to check the oil level is

before starting the engine after it has been parked overnight. When checking oil after oper

-

ating the engine, first ensure the engine is at full

operating temperature, then wait for

30 minutes after engine shutdown to check the

oil.

Engine Oil Dipstick

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings. Add oil only when the level on the

dipstick is below the “ADD” mark. The total

capacity from the ADD mark to the Full mark is

2 qts (1.9L). Never operate the engine with oil level below

the “ADD” mark or above the upper “SAFE”

mark.

Adding Washer Fluid

The fluid reservoir is located under the hood

and should be checked for fluid level at regular

intervals. Fill the reservoir with windshield

washer solvent only (not radiator antifreeze).

When refilling the washer fluid reservoir, take

some washer fluid and apply it to a cloth or

towel and wipe the wiper blades clean. This will

help blade performance.

To prevent freeze-up of your windshield washer

system in cold weather, select a solution or

mixture that meets or exceeds the temperature

range of your climate. This rating information

can be found on most washer fluid containers.

CAUTION!

Overfilling or underfilling will cause oil

aeration or loss of oil pressure. This could

damage your engine.

1 — ADD Range

2 — Full Mark

3 — SAFE Range

CAUTION!

Overfilling or underfilling the crankcase will

cause oil aeration or loss of oil pressure. This

could damage your engine.

20_DJD2_OM_EN_USC_t.book Page 394

Page 397 of 553

SERVICING AND MAINTENANCE395

After the engine has warmed up, operate the

defroster for a few minutes to reduce the possi -

bility of smearing or freezing the fluid on the

cold windshield. Windshield washer solution

used with water as directed on the container,

aids cleaning action, reduces the freezing point

to avoid line clogging, and is not harmful to

paint or trim.

Maintenance-Free Battery

Your vehicle is equipped with a mainte-

nance-free battery. You will never have to add

water, nor is periodic maintenance required.

Pressure Washing

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling

or working around the washer solution.

WARNING!

Battery fluid is a corrosive acid solution and

can burn or even blind you. Do not allow

battery fluid to contact your eyes, skin, or

clothing. Do not lean over a battery when

attaching clamps. If acid splashes in eyes

or on skin, flush the area immediately with

large amounts of water. Refer to “Jump

Starting Procedure” in “In Case Of Emer -

gency” for further information.

Battery gas is flammable and explosive.

Keep flame or sparks away from the

battery. Do not use a booster battery or any

other booster source with an output greater

than 12 Volts. Do not allow cable clamps to

touch each other.

Battery posts, terminals, and related acces -

sories contain lead and lead compounds.

Wash hands after handling.

CAUTION!

It is essential when replacing the cables on

the battery that the positive cable is

attached to the positive post and the nega -

tive cable is attached to the negative post.

Battery posts are marked positive (+) and

negative (-) and are identified on the battery

case. Cable clamps should be tight on the

terminal posts and free of corrosion.

If a “fast charger” is used while the battery

is in the vehicle, disconnect both vehicle

battery cables before connecting the

charger to the battery. Do not use a “fast

charger” to provide starting voltage.

CAUTION!

Cleaning the engine compartment with a high

pressure washer is not recommended.

Precautions have been taken to safeguard all

parts and connections however, the

pressures generated by these machines is

such that complete protection against water

ingress cannot be guaranteed.

7

20_DJD2_OM_EN_USC_t.book Page 395

Page 411 of 553

SERVICING AND MAINTENANCE409

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and

the windshield periodically with a sponge or soft

cloth and a mild nonabrasive cleaner. This will

remove accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry wind -

shield.

Avoid using the wiper blades to remove frost or

ice from the windshield. Keep the blade rubber

out of contact with petroleum products such as

engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies

depending on geographical area and frequency

of use. Poor performance of blades may be

present with chattering, marks, water lines or

wet spots. If any of these conditions are

present, clean the wiper blades or replace as

necessary. The wiper blades and wiper arms should be

inspected periodically, not just when wiper

performance problems are experienced. This

inspection should include the following points:

Wear or uneven edges

Foreign material

Hardening or cracking

Deformation or fatigue

If a wiper blade or wiper arm is damaged,

replace the affected wiper arm or blade with a

new unit. Do not attempt to repair a wiper arm

or blade that is damaged.

Wiper Blade Removal/Installation

1. Lift the wiper arm to raise the wiper blade off of the glass, until the wiper arm is in the

full up position.

2. To disengage the wiper blade from the wiper arm, flip up the locking tab.

Wiper Locking Assembly

CAUTION!

Do not allow the wiper arm to spring back

against the glass without the wiper blade in

place or the glass may be damaged.

1 — Wiper

2 — Locking Tab7

20_DJD2_OM_EN_USC_t.book Page 409