check oil Ram 3500 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 3500, Model: Ram 3500 2018Pages: 372, PDF Size: 7.1 MB

Page 79 of 372

Vehicles equipped with the Anti-Lock Brake

System (ABS) are also equipped with Elec-

tronic Brake Force Distribution (EBD). In the

event of an EBD failure, the Brake Warning

Light will turn on along with the ABS Light.

Immediate repair to the ABS system is re-

quired.

Operation of the Brake Warning Light can be

checked by turning the ignition switch from

the OFF position to the ON/RUN position.

The light should illuminate for approximately

two seconds. The light should then turn off

unless the parking brake is applied or a brake

fault is detected. If the light does not illumi-

nate, have the light inspected by your autho-

rized dealer.

The light also will turn on when the parking

brake is applied with the ignition switch in

the ON/RUN position.

NOTE:

This light shows only that the parking brake is

applied. It does not show the degree of brake

application.— Vehicle Security Warning Light — If

Equipped

This light will flash at a fast rate for approxi-

mately 15 seconds when the vehicle security

alarm is arming, and then will flash slowly

until the vehicle is disarmed.

— Engine Coolant Temperature Warn-

ing Light

This light warns of an overheated engine

condition. If the engine coolant temperature

is too high, this indicator will illuminate and a

single chime will sound. If the temperature

reaches the upper limit, a continuous chime

will be sound for four minutes or until the

engine is able to cool: whichever comes first.

If the light turns on while driving, safely pull

over and stop the vehicle. If the A/C system is

on, turn it off. Also, shift the transmission

into NEUTRAL and idle the vehicle. If the

temperature reading does not return to nor-

mal, turn the engine off immediately and call

for service. Refer to “If Your Engine Over-

heats” in “In Case Of Emergency” for further

information.

— Battery Charge Warning Light

This light illuminates when the battery is not

charging properly. If it stays on while the

engine is running, there may be a malfunc-

tion with the charging system. Contact your

authorized dealer as soon as possible.

This indicates a possible problem with the

electrical system or a related component.

— Oil Pressure Warning Light

This light indicates low engine oil pressure. If

the light turns on while driving, stop the

vehicle and shut off the engine as soon as

possible. A chime will sound when this light

turns on.

Do not operate the vehicle until the cause is

corrected. This light does not indicate how

much oil is in the engine. The engine oil level

must be checked under the hood.

— Electronic Throttle Control (ETC)

Warning Light

This light informs you of a problem with the

Electronic Throttle Control (ETC) system. If a

problem is detected while the vehicle is run-

ning, the light will either stay on or flash

77

Page 83 of 372

CAUTION!

of the same size, type, and/or style. After-

market wheels can cause sensor damage.

Using aftermarket tire sealants may cause

the Tire Pressure Monitoring System

(TPMS) sensor to become inoperable. Af-

ter using an aftermarket tire sealant it is

recommended that you take your vehicle

to your authorized dealer to have your

sensor function checked.

— Low Fuel Indicator Light

When the fuel level reaches approximately

3.0 gal (11.0 L) this light will turn on, and

remain on until fuel is added.

— Anti-Lock Brake (ABS) Warning

Light

This light monitors the Anti-Lock Brake Sys-

tem (ABS). The light will turn on when the

ignition is placed in the ON/RUN or ACC/ON/

RUN position and may stay on for as long as

four seconds. If the ABS light remains on or turns on while

driving, then the Anti-Lock portion of the

brake system is not functioning and service is

required as soon as possible. However, the

conventional brake system will continue to

operate normally, assuming the Brake Warn-

ing Light is not also on.

If the ABS light does not turn on when the

ignition is placed in the ON/RUN or ACC/ON/

RUN position, have the brake system in-

spected by an authorized dealer.

— Low Coolant Level Warning Light

This telltale will turn on to indicate the ve-

hicle coolant level is low.

— Loose Fuel Filler Cap Warning Light

— If Equipped

This light will illuminate when the fuel filler

cap is loose. Properly close the filler cap to

disengage the light. If the light does not turn

off, please see your authorized dealer.

SERV4WD— Service 4WD Warning Light — If

Equipped

If the light stays on or comes on during driving,

it means that the 4WD system is not functioning

properly and that service is required. We recom-

mend you drive to the nearest service center and

have the vehicle serviced immediately.

— Transmission Temperature Warning

Light

This light indicates that the transmission

fluid temperature is running hot. This may

occur with severe usage, such as trailer tow-

ing. If this light turns on, safely pull over and

stop the vehicle. Then, shift the transmission

into PARK and run the engine at idle or

slightly higher until the light turns off.

WARNING!

If you continue operating the vehicle when

the Transmission Temperature Warning

Light is illuminated you could cause the

fluid to boil over, come in contact with hot

engine or exhaust components and cause a

fire.

81

Page 136 of 372

SAFETY TIPS

Transporting Passengers

NEVER TRANSPORT PASSENGERS IN THE

CARGO AREA.

WARNING!

• Do not leave children or animals insideparked vehicles in hot weather. Interior

heat build-up may cause serious injury

or death.

• It is extremely dangerous to ride in a

cargo area, inside or outside of a vehicle.

In a collision, people riding in these

areas are more likely to be seriously

injured or killed.

• Do not allow people to ride in any area of

your vehicle that is not equipped with

seats and seat belts.

• Be sure everyone in your vehicle is in a

seat and using a seat belt properly.

Exhaust Gas

WARNING!

Exhaust gases can injure or kill. They con-

tain carbon monoxide (CO), which is col-

orless and odorless. Breathing it can make

you unconscious and can eventually poi-

son you. To avoid breathing (CO), follow

these safety tips:

• Do not run the engine in a closed garageor in confined areas any longer than

needed to move your vehicle in or out of

the area.

• If you are required to drive with the

trunk/liftgate/rear doors open, make

sure that all windows are closed and the

climate control BLOWER switch is set at

high speed. DO NOT use the recircula-

tion mode.

• If it is necessary to sit in a parked

vehicle with the engine running, adjust

your heating or cooling controls to force

outside air into the vehicle. Set the

blower at high speed. The best protection against carbon monoxide

entry into the vehicle body is a properly

maintained engine exhaust system.

Whenever a change is noticed in the sound of

the exhaust system, when exhaust fumes can

be detected inside the vehicle, or when the

underside or rear of the vehicle is damaged,

have a competent mechanic inspect the com-

plete exhaust system and adjacent body ar-

eas for broken, damaged, deteriorated, or

mispositioned parts. Open seams or loose

connections could permit exhaust fumes to

seep into the passenger compartment. In

addition, inspect the exhaust system each

time the vehicle is raised for lubrication or oil

change. Replace as required.

Safety Checks You Should Make

Inside The Vehicle

Seat Belts

Inspect the seat belt system periodically,

checking for cuts, frays, and loose parts.

Damaged parts must be replaced immedi-

ately. Do not disassemble or modify the sys-

tem.

SAFETY

134

Page 138 of 372

WARNING!

• ONLY use the driver’s side floor mat onthe driver’s side floor area. To check for

interference, with the vehicle properly

parked with the engine off, fully depress

the accelerator, the brake, and the

clutch pedal (if present) to check for

interference. If your floor mat interferes

with the operation of any pedal, or is not

secure to the floor, remove the floor mat

from the vehicle and place the floor mat

in your trunk.

• ONLY use the passenger’s side floor mat

on the passenger’s side floor area.

• ALWAYS make sure objects cannot fall or

slide into the driver’s side floor area

when the vehicle is moving. Objects can

become trapped under accelerator,

brake, or clutch pedals and could cause

a loss of vehicle control.

•

NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These ob-

jects could change the position of the

floor mat and may cause interference with

the accelerator, brake, or clutch pedals.

WARNING!

• If the vehicle carpet has been removed

and re-installed, always properly attach

carpet to the floor and check the floor

mat fasteners are secure to the vehicle

carpet. Fully depress each pedal to

check for interference with the accelera-

tor, brake, or clutch pedals then re-

install the floor mats.

• It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat

has been properly installed and is se-

cured to your vehicle using the floor mat

fasteners by lightly pulling mat.

Periodic Safety Checks You

Should Make Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones,

nails, glass, or other objects lodged in the

tread or sidewall. Inspect the tread for cuts and cracks. Inspect sidewalls for cuts,

cracks, and bulges. Check the wheel bolts for

tightness. Check the tires (including spare)

for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and lock-

ing.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid

leaks. Also, if gasoline fumes are detected or

if fuel, or brake fluid leaks are suspected. The

cause should be located and corrected imme-

diately.

SAFETY

136

Page 150 of 372

ignition from OFF or ACC to RUN, and will

illuminate the "Wait To Start" telltale. The

engine will not immediately crank, this is

normal operation.

2. The “Wait To Start" telltale will remain on for a period of time that varies depending

on the engine temperature.

3. While the "Wait to Start" telltale is on, the instrument cluster will additionally dis-

play a gauge or bar whose initial length

represents the full "Wait to Start" time

period. Its length will decrease until it

disappears when the "Wait to Start" time

has elapsed.

CAUTION!

If the “Water in Fuel Indicator Light” re-

mains on, DO NOT START engine before

you drain the water from the fuel filters to

avoid engine damage. Refer to “Draining

Fuel/Water Separator Filter” in “Dealer

Service” under “Servicing And Mainte-

nance” for further information. 4. After the engine “Wait To Start” telltale

goes off, the engine will automatically

crank.

CAUTION!

Do not crank engine for more than 15 sec-

onds at a time or starter motor damage

may result. Turn the ignition switch to the

OFF position and wait at least two minutes

for the starter to cool before repeating start

procedure.

5. After engine start-up, check to see that there is oil pressure.

6. Allow the engine to idle about three min- utes until the manifold heaters have com-

pleted the post-heat cycle.

7. Release the parking brake and drive.

NOTE:

• Engine idle speed will automatically in- crease to 1,000 RPM and engage the Vari-

able Geometry Turbocharger at low coolant

temperatures to improve engine warm-up. • The engine may not automatically crank

after the engine "Wait To Start" telltale goes

off if a door or the hood is ajar.

• If the engine stalls, or if the ignition switch is left ON for more than two minutes after

the “Wait To Start Light” goes out, reset the

grid heaters by turning the ignition switch

to the OFF position for at least five seconds

and then back ON. Repeat steps 1 through

7 of “Keyless Enter-N-Go Starting Proce-

dure – Engine Manifold Air Temperature

Below 66° F (19° C).”

Extreme Cold Weather

The Cummins diesel engine is equipped with

several features designed to assist cold

weather starting and operation:

• The engine block heater is a resistance

heater installed in the water jacket of the

engine just above and behind the oil filter.

It requires a 110–115 Volt AC electrical

outlet with a grounded, three-wire exten-

sion cord.STARTING AND OPERATING

148

Page 155 of 372

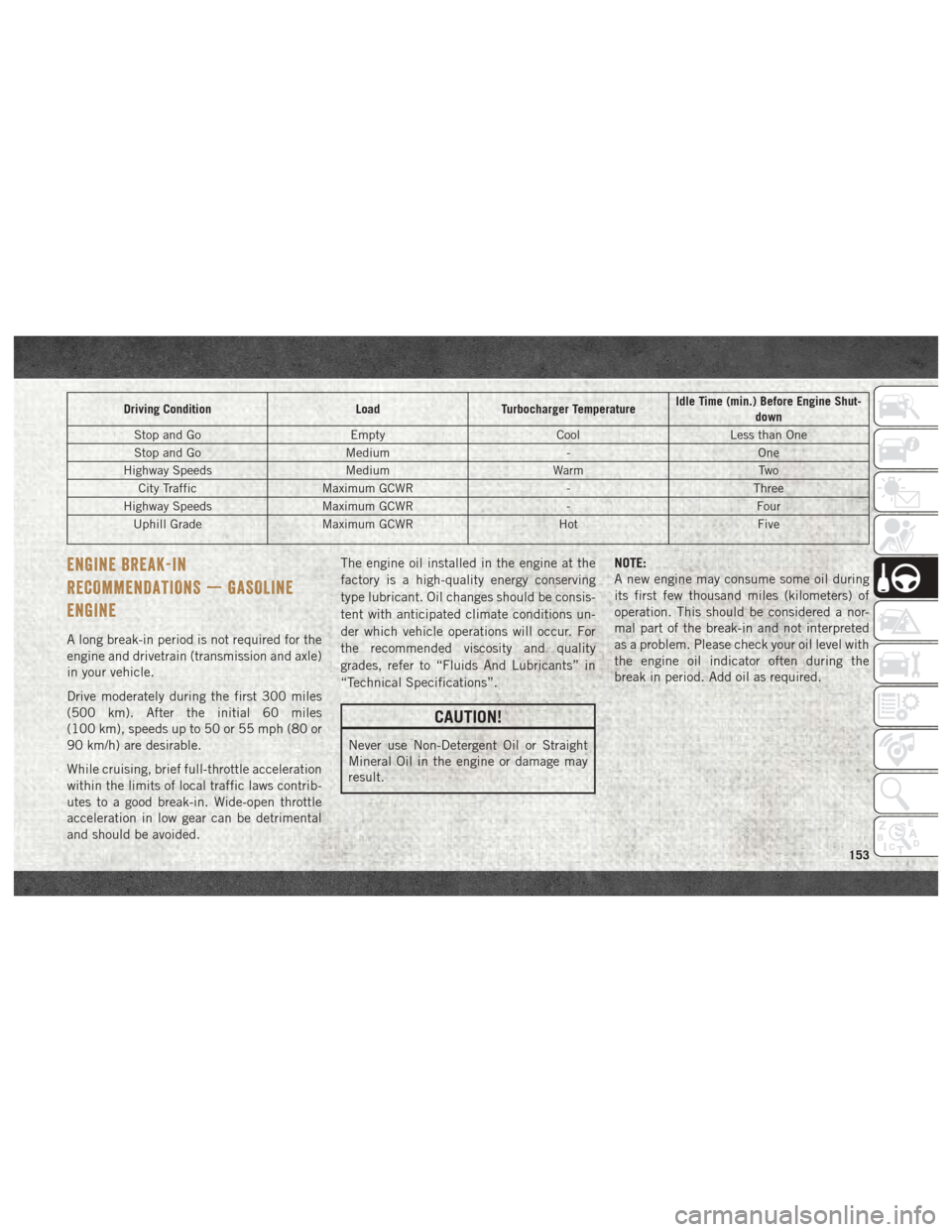

Driving ConditionLoadTurbocharger Temperature Idle Time (min.) Before Engine Shut-

down

Stop and Go EmptyCoolLess than One

Stop and Go Medium -One

Highway Speeds MediumWarmTwo

City Traffic Maximum GCWR -Three

Highway Speeds Maximum GCWR -Four

Uphill Grade Maximum GCWR HotFive

ENGINE BREAK-IN

RECOMMENDATIONS — GASOLINE

ENGINE

A long break-in period is not required for the

engine and drivetrain (transmission and axle)

in your vehicle.

Drive moderately during the first 300 miles

(500 km). After the initial 60 miles

(100 km), speeds up to 50 or 55 mph (80 or

90 km/h) are desirable.

While cruising, brief full-throttle acceleration

within the limits of local traffic laws contrib-

utes to a good break-in. Wide-open throttle

acceleration in low gear can be detrimental

and should be avoided. The engine oil installed in the engine at the

factory is a high-quality energy conserving

type lubricant. Oil changes should be consis-

tent with anticipated climate conditions un-

der which vehicle operations will occur. For

the recommended viscosity and quality

grades, refer to “Fluids And Lubricants” in

“Technical Specifications”.

CAUTION!

Never use Non-Detergent Oil or Straight

Mineral Oil in the engine or damage may

result.

NOTE:

A new engine may consume some oil during

its first few thousand miles (kilometers) of

operation. This should be considered a nor-

mal part of the break-in and not interpreted

as a problem. Please check your oil level with

the engine oil indicator often during the

break in period. Add oil as required.

153

Page 156 of 372

ENGINE BREAK-IN

RECOMMENDATIONS — 3.0L DIESEL

The diesel engine does not require a break-in

period due to its construction. Normal opera-

tion is allowed, providing the following rec-

ommendations are followed:

• Warm up the engine before placing it underload.

• Do not operate the engine at idle for pro- longed periods.

• Use the appropriate transmission gear to prevent engine lugging.

• Observe vehicle oil pressure and tempera- ture indicators.

• Check the coolant and oil levels frequently.

• Vary throttle position at highway speeds when carrying or towing significant weight.

NOTE:

Light duty operation such as light trailer

towing or no load operation will extend the

time before the engine is at full efficiency.

Reduced fuel economy and power may be

seen at this time. The engine oil installed in the engine at the

factory is a high-quality energy conserving

type lubricant. Oil changes should be consis-

tent with anticipated climate conditions un-

der which vehicle operations will occur. The

recommended viscosity and quality grades

are shown under “Fluids And Lubricants” in

"Technical Specifications” in this manual.

NON-DETERGENT OR STRAIGHT MINERAL

OILS MUST NEVER BE USED.

ENGINE BREAK-IN

RECOMMENDATIONS — 6.7L DIESEL

The Cummins turbocharged diesel engine

does not require a break-in period due to its

construction. Normal operation is allowed,

providing the following recommendations are

followed:

• Warm up the engine before placing it under

load.

• Do not operate the engine at idle for pro- longed periods.

• Use the appropriate transmission gear to prevent engine lugging. • Observe vehicle oil pressure and tempera-

ture indicators.

• Check the coolant and oil levels frequently.

• Vary throttle position at highway speeds when carrying or towing significant weight.

NOTE:

Light duty operation such as light trailer

towing or no load operation will extend the

time before the engine is at full efficiency.

Reduced fuel economy and power may be

seen at this time.

For additional vehicle break-in requirements,

refer to “Trailer Towing” in “Starting And

Operating” of the Owner’s Manual.

Because of the construction of the Cummins

turbocharged diesel engine, engine run-in is

enhanced by loaded operating conditions

which allow the engine parts to achieve final

finish and fit during the first 6,000 miles

(10 000 km).STARTING AND OPERATING

154

Page 215 of 372

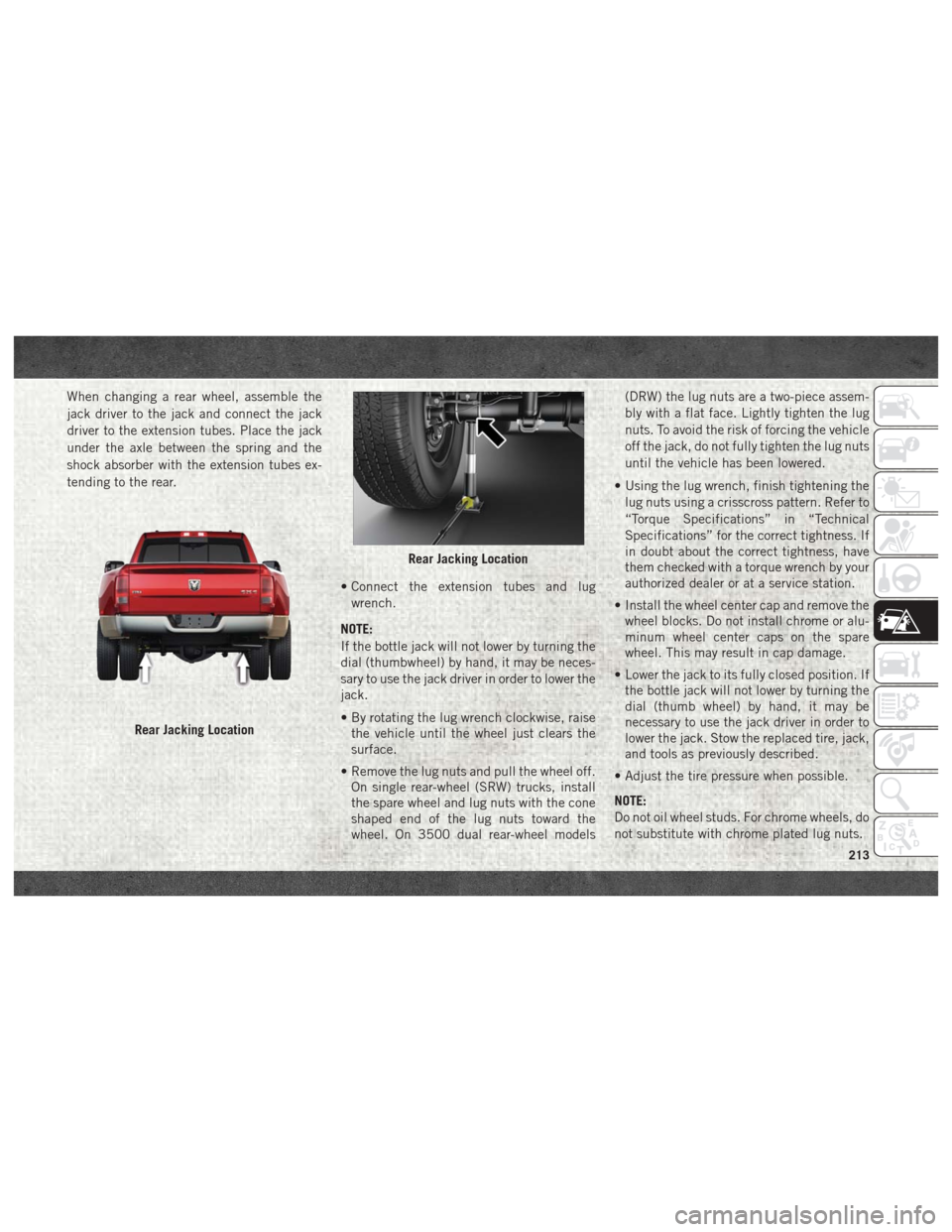

When changing a rear wheel, assemble the

jack driver to the jack and connect the jack

driver to the extension tubes. Place the jack

under the axle between the spring and the

shock absorber with the extension tubes ex-

tending to the rear.• Connect the extension tubes and lugwrench.

NOTE:

If the bottle jack will not lower by turning the

dial (thumbwheel) by hand, it may be neces-

sary to use the jack driver in order to lower the

jack.

• By rotating the lug wrench clockwise, raise the vehicle until the wheel just clears the

surface.

• Remove the lug nuts and pull the wheel off. On single rear-wheel (SRW) trucks, install

the spare wheel and lug nuts with the cone

shaped end of the lug nuts toward the

wheel. On 3500 dual rear-wheel models (DRW) the lug nuts are a two-piece assem-

bly with a flat face. Lightly tighten the lug

nuts. To avoid the risk of forcing the vehicle

off the jack, do not fully tighten the lug nuts

until the vehicle has been lowered.

• Using the lug wrench, finish tightening the lug nuts using a crisscross pattern. Refer to

“Torque Specifications” in “Technical

Specifications” for the correct tightness. If

in doubt about the correct tightness, have

them checked with a torque wrench by your

authorized dealer or at a service station.

• Install the wheel center cap and remove the wheel blocks. Do not install chrome or alu-

minum wheel center caps on the spare

wheel. This may result in cap damage.

• Lower the jack to its fully closed position. If the bottle jack will not lower by turning the

dial (thumb wheel) by hand, it may be

necessary to use the jack driver in order to

lower the jack. Stow the replaced tire, jack,

and tools as previously described.

• Adjust the tire pressure when possible.

NOTE:

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated lug nuts.

Rear Jacking Location

Rear Jacking Location

213

Page 232 of 372

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for scheduled

maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate.

This means that service is required for your

vehicle. Operating conditions such as fre-

quent short-trips, trailer tow, extremely hot or

cold ambient temperatures, and E85 fuel

usage will influence when the “Oil Change

Required” message is displayed. Severe Op-

erating Conditions can cause the change oil

message to illuminate as early as

3,500 miles (5,600 km) since last reset.

Have your vehicle serviced as soon as pos-

sible, within the next 500 miles (805 km).Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change. If a scheduled oil

change is performed by someone other than

your authorized dealer, the message can be

reset by referring to the steps described un-

der “Instrument Cluster Display” in “Getting

To Know Your Instrument Panel”.

1500 Models Only

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

twelve months or 350 hours of engine run

time, whichever comes first. The 350 hours

of engine run or idle time is generally only a

concern for fleet customers.

2500 – 3500 Models Only

NOTE:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

twelve months or 350 hours of engine run

time, whichever comes first. The 350 hours

of engine run or idle time is generally only a

concern for fleet customers. Severe Duty All Models

NOTE:

Change Engine Oil at 4,000 miles

(6,500 km) or 350 hours of engine run time

if the vehicle is operated in a dusty and off

road environment or is operated predomi-

nantly at idle, or only very low engine RPM’s.

This type of vehicle use is considered Severe

Duty.

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

• Check the fluid levels of the coolant reser- voir, brake master cylinder, power steering

(2500/3500 Models Only) and automatic

transmission (six-speed only) and fill as

needed

• Check function of all interior and exterior lights

SERVICING AND MAINTENANCE

230

Page 234 of 372

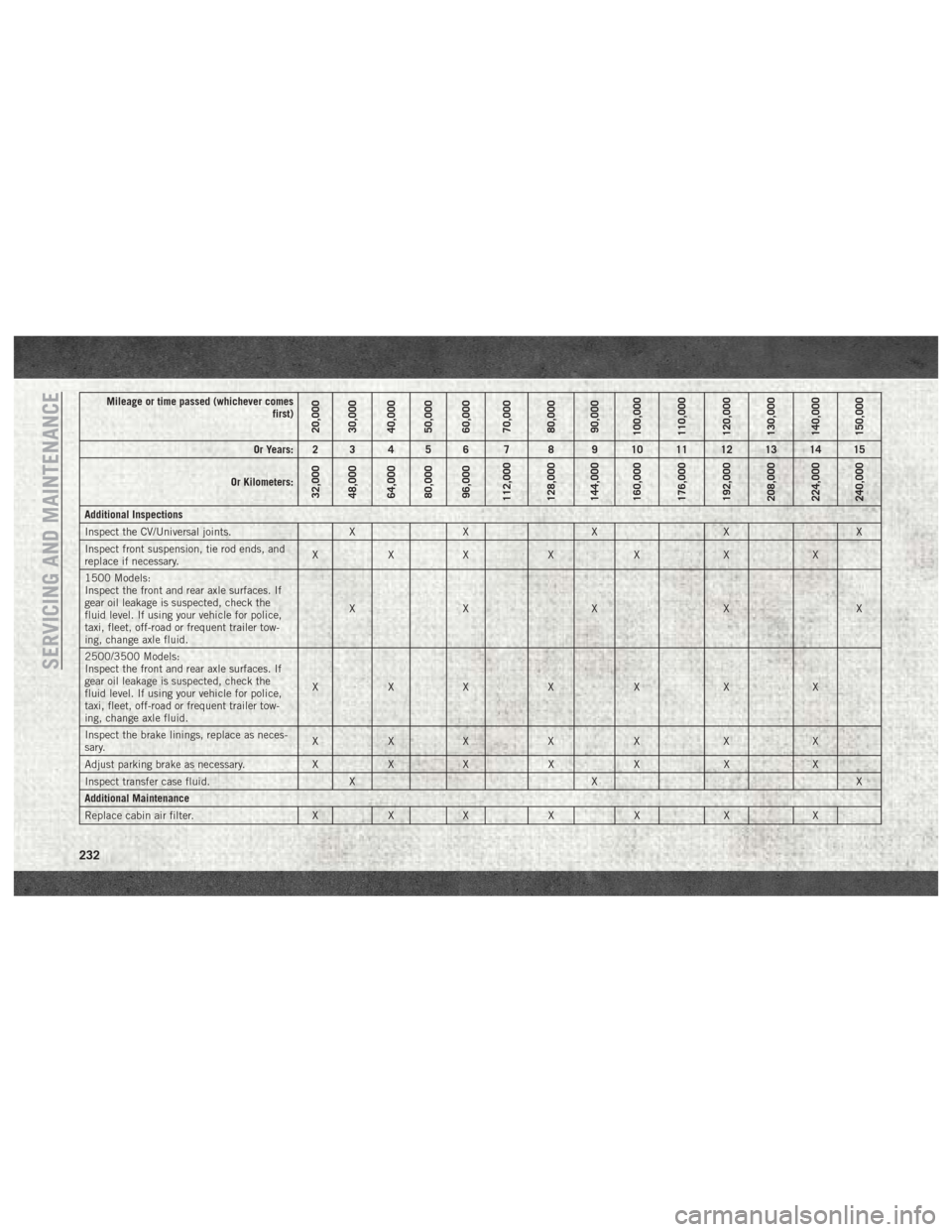

Mileage or time passed (whichever comesfirst)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X

Inspect front suspension, tie rod ends, and

replace if necessary. XXX X X X X

1500 Models:

Inspect the front and rear axle surfaces. If

gear oil leakage is suspected, check the

fluid level. If using your vehicle for police,

taxi, fleet, off-road or frequent trailer tow-

ing, change axle fluid. XX X X X

2500/3500 Models:

Inspect the front and rear axle surfaces. If

gear oil leakage is suspected, check the

fluid level. If using your vehicle for police,

taxi, fleet, off-road or frequent trailer tow-

ing, change axle fluid. XXX X X X X

Inspect the brake linings, replace as neces-

sary. XXX X X X X

Adjust parking brake as necessary. XXX X X XX

Inspect transfer case fluid. XX X

Additional Maintenance

Replace cabin air filter. XXX X X XX

SERVICING AND MAINTENANCE

232