torque Ram 3500 2020 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 3500, Model: Ram 3500 2020Pages: 568

Page 361 of 568

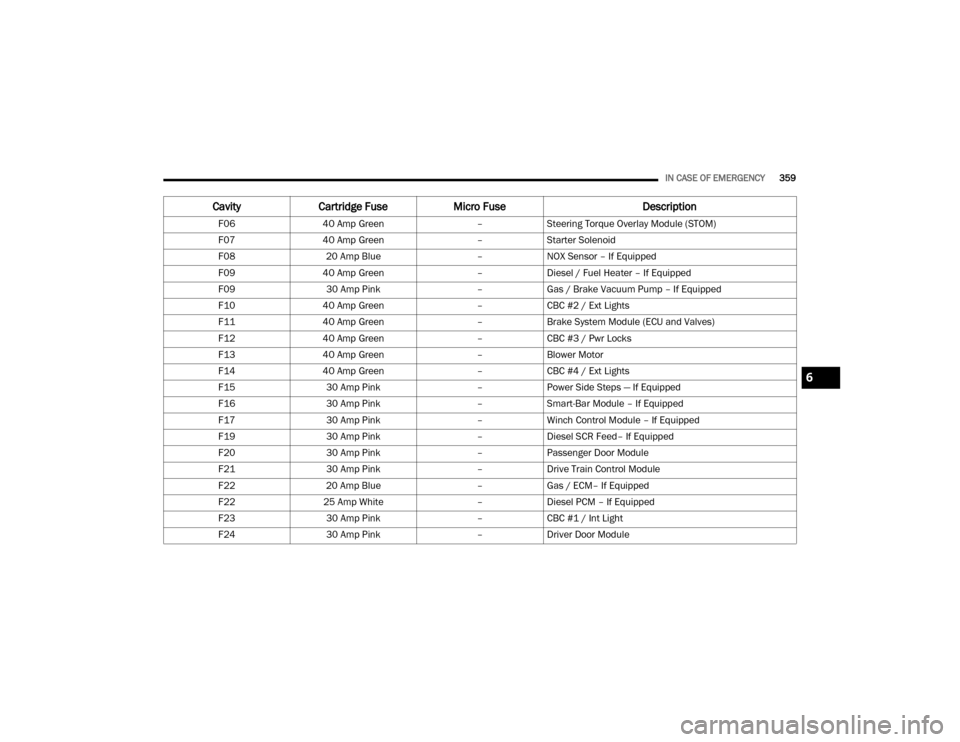

IN CASE OF EMERGENCY359

F0640 Amp Green –Steering Torque Overlay Module (STOM)

F07 40 Amp Green –Starter Solenoid

F08 20 Amp Blue –NOX Sensor – If Equipped

F09 40 Amp Green –Diesel / Fuel Heater – If Equipped

F09 30 Amp Pink –Gas / Brake Vacuum Pump – If Equipped

F10 40 Amp Green –CBC #2 / Ext Lights

F11 40 Amp Green –Brake System Module (ECU and Valves)

F12 40 Amp Green –CBC #3 / Pwr Locks

F13 40 Amp Green –Blower Motor

F14 40 Amp Green –CBC #4 / Ext Lights

F15 30 Amp Pink –Power Side Steps — If Equipped

F16 30 Amp Pink –Smart-Bar Module – If Equipped

F17 30 Amp Pink –Winch Control Module – If Equipped

F19 30 Amp Pink –Diesel SCR Feed– If Equipped

F20 30 Amp Pink –Passenger Door Module

F21 30 Amp Pink –Drive Train Control Module

F22 20 Amp Blue –Gas / ECM– If Equipped

F22 25 Amp White –Diesel PCM – If Equipped

F23 30 Amp Pink –CBC #1 / Int Light

F24 30 Amp Pink –Driver Door Module

Cavity Cartridge Fuse Micro Fuse Description

6

20_DJD2_OM_EN_USC_t.book Page 359

Page 374 of 568

372IN CASE OF EMERGENCY

6. Finish tightening the lug nuts. Push down on

the lug wrench while at the end of the

handle for increased leverage. Tighten the

lug nuts in a star pattern until each nut has

been tightened twice. For the correct lug nut

torque refer to “Wheel And Tire Torque

Specifications” in “Technical Specifi -

cations”. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or service

station.

7. Install the wheel center cap and remove the wheel blocks. Do not install chrome or

aluminum wheel center caps on the spare

wheel. This may result in cap damage. 8. Lower the jack to its fully closed position.

Stow the replaced tire, jack, and tools as

previously described.

NOTE:

The bottle jack will not lower by turning the dial

(thumbwheel) by hand, it may be necessary to

use the jack driver in order to lower the jack.

9. Adjust the tire pressure when possible.

NOTE:

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated lug nuts.

TO STOW THE FLAT OR SPARE

NOTE:

Have the flat tire repaired or replaced immedi -

ately.

1. Turn the wheel so that the valve stem is facing the ground and toward the rear of

the vehicle for convenience in checking the

spare tire inflation. Slide the wheel retainer

through the center of the wheel.

Reinstalling The Retainer

2. Lift the spare tire with one hand to give clearance to tilt the retainer at the end of

the cable and position it properly across the

wheel opening.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

20_DJD2_OM_EN_USC_t.book Page 372

Page 424 of 568

422SERVICING AND MAINTENANCE

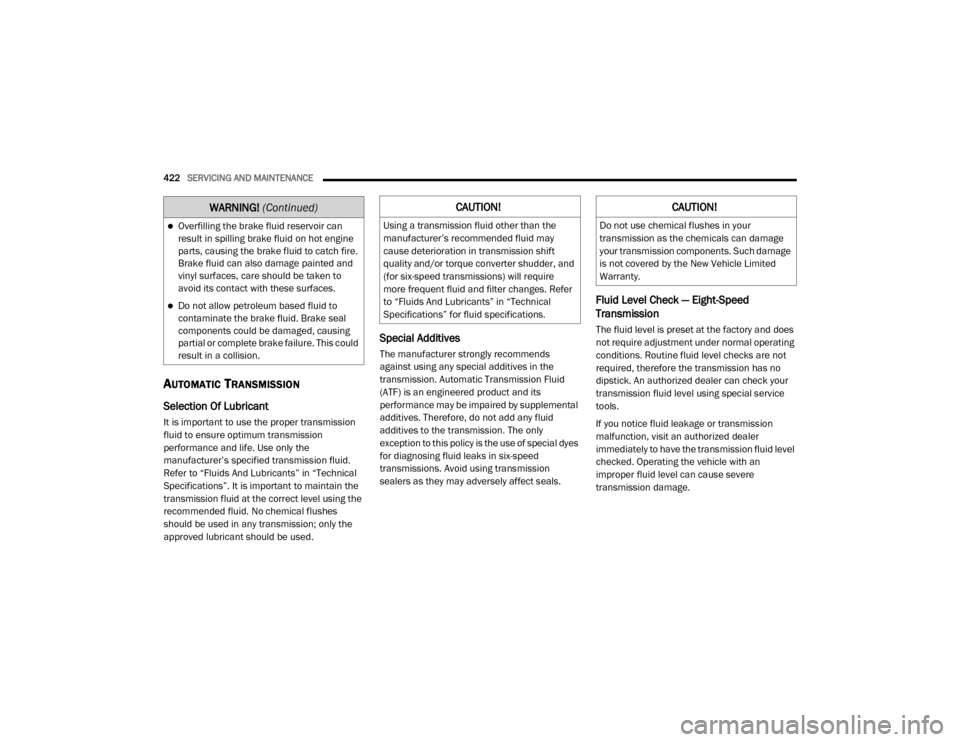

AUTOMATIC TRANSMISSION

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer’s specified transmission fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications”. It is important to maintain the

transmission fluid at the correct level using the

recommended fluid. No chemical flushes

should be used in any transmission; only the

approved lubricant should be used.

Special Additives

The manufacturer strongly recommends

against using any special additives in the

transmission. Automatic Transmission Fluid

(ATF) is an engineered product and its

performance may be impaired by supplemental

additives. Therefore, do not add any fluid

additives to the transmission. The only

exception to this policy is the use of special dyes

for diagnosing fluid leaks in six-speed

transmissions. Avoid using transmission

sealers as they may adversely affect seals.

Fluid Level Check — Eight-Speed

Transmission

The fluid level is preset at the factory and does

not require adjustment under normal operating

conditions. Routine fluid level checks are not

required, therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service

tools.

If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an

improper fluid level can cause severe

transmission damage.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder, and

(for six-speed transmissions) will require

more frequent fluid and filter changes. Refer

to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

20_DJD2_OM_EN_USC_t.book Page 422

Page 454 of 568

452

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA

VEHICLE IDENTIFICATION NUMBER

The Vehicle Identification Number (VIN) is found

on the left front corner of the instrument panel,

visible through the windshield.

Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for

example, repeated brake applications with the

engine off), the brakes will still function. However, you will experience a substantial

increase in braking effort to stop the vehicle.

If either the front or rear hydraulic system loses

normal braking capability, the remaining

system will still function with some loss of

overall braking effectiveness. This will be

evident by increased pedal travel during

application, greater pedal force required to slow

or stop, and activation of the “Brake Warning

Light” and/or the “ABS Warning Light” during

brake use.

HYDRAULIC BRAKE ASSIST — IF

E

QUIPPED

The brake system power assist is provided by a

hydro-boost unit which shares fluid with the

power steering system. You may experience

some clicking or hissing noises from the

hydro-boost system during hard braking

conditions.

NOTE:

Under cold temperatures, pedal effort will be

higher than normal until the power steering fluid

reaches operating temperature.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a high quality six

sided (hex) deep wall socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Lug Nut/

Bolt

Torque Lug Nut/

Bolt Type **Lug

Nut/Bolt

SizeLug Nut/

Bolt

Socket

Size

130

Ft-Lbs

(176 N·m) Cone

M14 x

1.5022 mm

140

Ft-Lbs

(190 N·m) Flanged

20_DJD2_OM_EN_USC_t.book Page 452

Page 455 of 568

TECHNICAL SPECIFICATIONS453

NOTE:

Dual wheels are flat mounted, center piloted.

The lug nuts are a two-piece assembly. When

the tires are being rotated or replaced, clean

these lug nuts and add two drops of oil at the

interface between the lug nut/bolt and the

washer. Do not oil wheel studs.

Two-Piece Lug Nut

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until

each nut/bolt has been tightened twice. Ensure

that the socket is fully engaged on the lug nut/

bolt (do not insert it halfway).

After 25 miles (40 km), check the lug nut/bolt torque to be sure that all the lug nuts/bolts are

properly seated against the wheel.

Four And Five Lug Nuts/Bolts Torque Pattern

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully

until the vehicle has been lowered. Failure to

follow this warning may result in personal

injury.

8

20_DJD2_OM_EN_USC_t.book Page 453

Page 472 of 568

470MULTIMEDIA

Units

After pressing Units on the touchscreen, the following settings will be available:

Voice

After pressing the Voice button on the touchscreen, the following settings will be available:

Setting Name Selectable Options

UnitsUSMetric Custom

Speed MPH km/h

Distance mi km

Fuel Consumption MPG (UG)MPG (UK)L/100 km km/L

Pressure psikPa bar

Power — If Equipped HP (US)HP (UK) Kw

Temperature °C °F

Torque — If Equipped lb-ft Nm

Setting Name Selectable Options

Voice Response LengthBrief Long

Show Command List AlwaysWith Help Never

20_DJD2_OM_EN_USC_t.book Page 470

Page 489 of 568

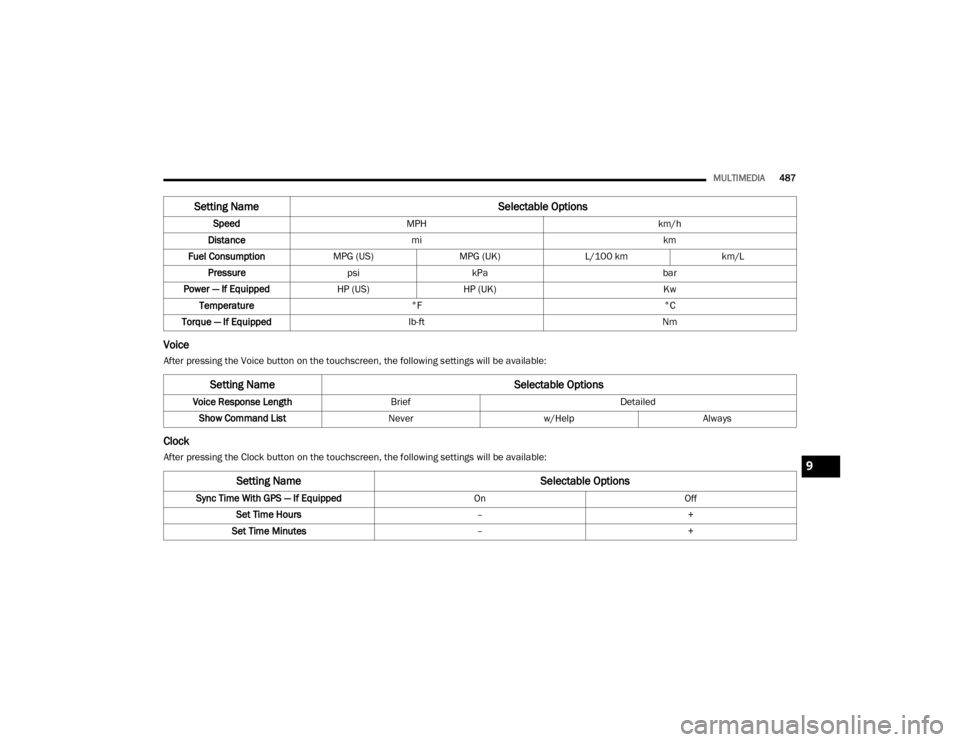

MULTIMEDIA487

Voice

After pressing the Voice button on the touchscreen, the following settings will be available:

Clock

After pressing the Clock button on the touchscreen, the following settings will be available:Speed

MPH km/h

Distance mi km

Fuel Consumption MPG (US)MPG (UK)L/100 km km/L

Pressure psikPa bar

Power — If Equipped HP (US)HP (UK) Kw

Temperature °F °C

Torque — If Equipped lb-ft Nm

Setting Name Selectable Options

Setting NameSelectable Options

Voice Response LengthBrief Detailed

Show Command List Neverw/Help Always

Setting Name Selectable Options

Sync Time With GPS — If Equipped OnOff

Set Time Hours –+

Set Time Minutes –+

9

20_DJD2_OM_EN_USC_t.book Page 487

Page 510 of 568

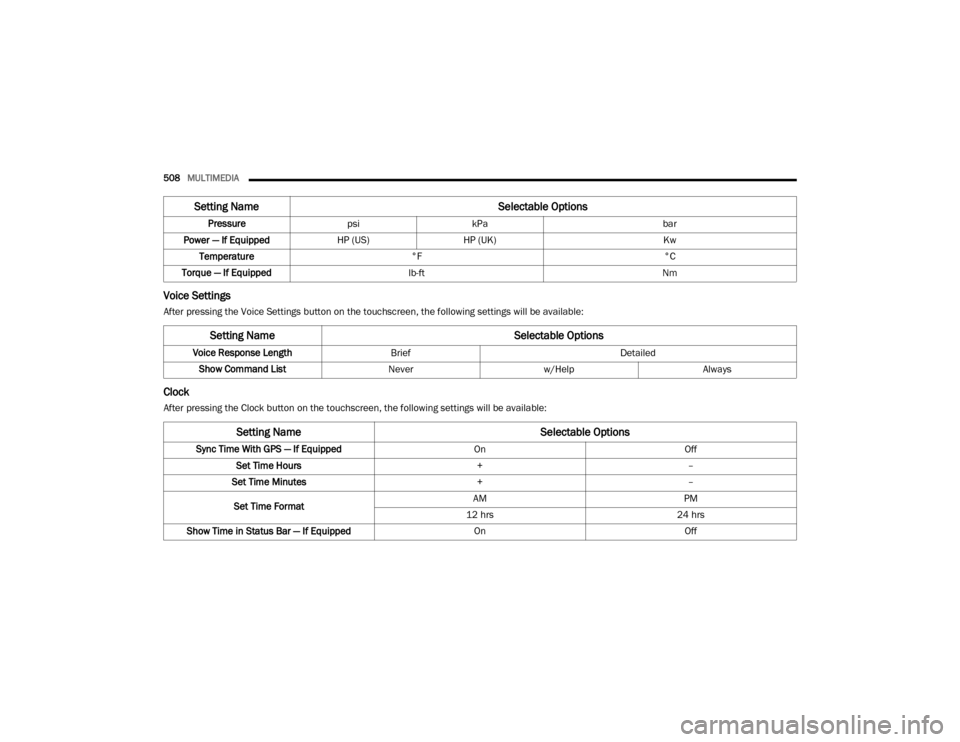

508MULTIMEDIA

Voice Settings

After pressing the Voice Settings button on the touchscreen, the following settings will be available:

Clock

After pressing the Clock button on the touchscreen, the following settings will be available:Pressure

psikPa bar

Power — If Equipped HP (US)HP (UK) Kw

Temperature °F °C

Torque — If Equipped lb-ft Nm

Setting Name Selectable Options

Setting NameSelectable Options

Voice Response LengthBrief Detailed

Show Command List Neverw/Help Always

Setting Name Selectable Options

Sync Time With GPS — If Equipped OnOff

Set Time Hours +–

Set Time Minutes +–

Set Time Format AM

PM

12 hrs 24 hrs

Show Time in Status Bar — If Equipped OnOff

20_DJD2_OM_EN_USC_t.book Page 508

Page 562 of 568

560 Inflation Pressure

...................................... 436Life Of Tires............................................... 439Load Capacity.................................. 433, 434

Pressure Monitoring System (TPMS)... 136, 163

Quality Grading.......................................... 446Radial........................................................ 437Replacement............................................. 439Rotation.................................................... 444Safety.............................................. 429, 435Sizes.......................................................... 430Snow Tires................................................. 440Spare Tires...................................... 441, 442Spinning.................................................... 438Trailer Towing............................................ 331Tread Wear Indicators............................... 438Wheel Nut Torque..................................... 452To Open Hood.................................................. 74Tongue Weight/Trailer Weight....................... 330Tonneau Cover.................................... 100, 448Tonneau Cover Cleaning................................ 448Torque Converter Clutch................................ 245

Towing................................................. 325, 381Disabled Vehicle....................................... 381Guide........................................................ 330Recreational............................................. 339Weight...................................................... 330Towing Behind A Motorhome........................ 339Traction......................................................... 343Traction Control............................................ 153Trailer Sway Control (TSC)............................. 153Trailer Towing............................................... 325Cooling System Tips................................. 336Hitches..................................................... 329Minimum Requirements........................... 330Mirrors......................................................... 46Tips........................................................... 335Trailer And Tongue Weight........................ 330Wiring....................................................... 334Trailer Towing Guide..................................... 330Trailer Weight................................................ 330Transfer Case............................................... 425Electronically Shifted....................... 246, 250Fluid................................................ 463, 466

Transmission................................................. 235Automatic............................... 235, 239, 422Fluid................................................. 463, 466Maintenance............................................ 422Shifting..................................................... 233Transporting Pets.......................................... 209Tread Wear Indicators................................... 438Turn Signals......................... 51, 141, 353, 355

U

UconnectUconnect Settings

.......................... 476, 478,494, 497, 514, 516Uconnect PhoneCall Continuation...................................... 537Uconnect SettingsCustomer Programmable Features... 28, 476, 478, 494, 497, 514, 516Passive Entry Programming............... 28, 476, 494, 514Uconnect Voice Command............................ 541Uniform Tire Quality Grades.......................... 446

20_DJD2_OM_EN_USC_t.book Page 560