fuel type Ram 3500 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 3500, Model: Ram 3500 2020Pages: 568

Page 9 of 568

7

PARKSENSE REAR PARK ASSIST —

IF EQUIPPED ...................................................... 296 ParkSense Sensors ...................................296

ParkSense Warning Display ......................296

ParkSense Display ..................................... 297Enabling And Disabling ParkSense ..........299

Service The ParkSense Rear Park

Assist System .............................................299 Cleaning The ParkSense System ..............299

ParkSense System Usage Precautions ....299

PARKSENSE FRONT AND REAR

PARK ASSIST ..................................................... 301

ParkSense Sensors ...................................301

ParkSense Warning Display ......................301

ParkSense Display ..................................... 301Enabling And Disabling Front And/Or

Rear ParkSense .........................................304 Service The ParkSense Front/Rear

Park Assist System ....................................305 Cleaning The ParkSense System ..............305

ParkSense System Usage Precautions ....305

LANESENSE — IF EQUIPPED ........................... 306

LaneSense Operation ................................306Turning LaneSense On Or Off ...................307LaneSense Warning Message ..................307

Changing LaneSense Status .....................309 PARKVIEW REAR BACK UP CAMERA..............309

AUX Camera — If Equipped ...................... 311

SURROUND VIEW CAMERA SYSTEM —

IF EQUIPPED ....................................................... 312

AUX Camera — If Equipped ...................... 318

ENGINE RUNAWAY — DIESEL ENGINE ............ 319

REFUELING THE VEHICLE — GAS ENGINE ...... 319

Loose Fuel Filler Cap Message ................ 320

REFUELING THE VEHICLE — DIESEL ENGINE ... 320

Diesel Exhaust Fluid .................................. 321

VEHICLE LOADING ............................................324

Gross Vehicle Weight Rating (GVWR) ...... 324

Payload ....................................................... 324Gross Axle Weight Rating (GAWR) ............ 324

Tire Size ...................................................... 324

Rim Size ..................................................... 324

Inflation Pressure ...................................... 324

Curb Weight................................................ 324

Loading ....................................................... 324

TRAILER TOWING ............................................... 325

Common Towing Definitions ..................... 325Trailer Hitch Type and Maximum

Trailer Weight ............................................. 329 Trailer Towing Weights (Maximum Trailer

Weight Ratings) ......................................... 330 Trailer And Tongue Weight ........................ 330

Towing Requirements ............................... 330Towing Tips ................................................ 335 SNOWPLOW ...................................................... 336

Before Plowing ........................................... 337

Snowplow Prep Package Model

Availability .................................................. 337 Over The Road Operation With

Snowplow Attached ................................... 338 Operating Tips............................................ 338General Maintenance................................ 338

RECREATIONAL TOWING (BEHIND

MOTORHOME, ETC.) ......................................... 339

Towing This Vehicle Behind Another

Vehicle ........................................................ 339 Recreational Towing — Two-Wheel Drive

Models........................................................ 339 Recreational Towing — Four-Wheel Drive

Models........................................................ 340

DRIVING TIPS ..................................................... 343

Driving On Slippery Surfaces ................... 343

Driving Through Water ............................. 343

Off-Road Driving Tips ................................. 344

IN CASE OF EMERGENCY

HAZARD WARNING FLASHERS ...................... 346

ASSIST AND SOS SYSTEM — IF EQUIPPED .... 346General Information .................................. 350

20_DJD2_OM_EN_USC_t.book Page 7

Page 11 of 568

9

Windshield Wiper Blades ..........................414

Exhaust System ........................................416

Cooling System .........................................417

Charge Air Cooler — Inter-Cooler ..............421

Brake System ............................................421

Automatic Transmission ............................422

Rear Axle And 4x4 Front Driving Axle

Fluid Level .................................................. 424 Transfer Case ............................................425

Noise Control System Required

Maintenance & Warranty .........................425

HOISTING ........................................................... 429

TIRES ................................................................... 429

Tire Safety Information .............................429Tires — General Information .....................435Tire Types ...................................................440

Spare Tires — If Equipped .........................441

Wheel And Wheel Trim Care ....................442

Tire Chains And Traction Devices ............443

Tire Rotation Recommendations .............444 DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES .................. 446

Treadwear .................................................. 446

Traction Grades ......................................... 446

Temperature Grades ................................. 446

STORING THE VEHICLE .....................................447

BODYWORK ........................................................ 447

Protection From Atmospheric Agents....... 447

Body And Underbody Maintenance .......... 447Preserving The Bodywork .......................... 448

INTERIORS ......................................................... 450

Seats And Fabric Parts .............................. 450

Plastic And Coated Parts ........................... 450

Leather Parts ............................................. 451

Glass Surfaces .......................................... 451

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA .......................................452Vehicle Identification Number ................. 452

BRAKE SYSTEM ................................................. 452

Hydraulic Brake Assist — If Equipped ....... 452

WHEEL AND TIRE TORQUE SPECIFICATIONS ... 452

Torque Specifications ............................... 452 FUEL REQUIREMENTS — GAS ENGINE ............ 454

6.4L Engine ................................................ 454

Reformulated Gasoline ............................ 454Materials Added To Fuel ........................... 454

Gasoline/Oxygenate Blends ..................... 454

Do Not Use E-85 In Non-Flex Fuel

Vehicles ...................................................... 455 CNG And LP Fuel System Modifications .. 455MMT In Gasoline........................................ 455

Fuel System Cautions................................ 455

Carbon Monoxide Warnings ..................... 456

FUEL REQUIREMENTS – DIESEL ENGINE ....... 456

Fuel Specifications ................................... 457

Biodiesel Fuel Requirements.................... 457

FLUID CAPACITIES — GAS ENGINE ................. 459

FLUID CAPACITIES — DIESEL ENGINE............. 460

FLUIDS AND LUBRICANTS — GAS ENGINE..... 461 Engine ....................................................... 461

Chassis ...................................................... 463

FLUIDS AND LUBRICANTS — DIESEL ENGINE ...464

Engine ....................................................... 464

Chassis ....................................................... 466

20_DJD2_OM_EN_USC_t.book Page 9

Page 119 of 568

GETTING TO KNOW YOUR INSTRUMENT PANEL117

System Off

ACC Proximity Warning

ACC Unavailable Warning

For further information, refer to “Adaptive

Cruise Control (ACC) — If Equipped” in “Starting

And Operating.”

LaneSense — If Equipped

The instrument cluster display displays the

current LaneSense system settings. The

information displayed depends on LaneSense

system status and the conditions that need to

be met. For further information, refer to

“LaneSense — If Equipped” in “Starting And

Operating.”

Fuel Economy

Push and release the up or down arrow button

until the Fuel Economy menu item is highlighted

in the instrument cluster display. Push and Hold

the right arrow button to reset Average Fuel

Economy.

Current Fuel Economy Gauge

Average Fuel Economy Value

Range To Empty

Trip A/Trip B

Push and release the up or down arrow button

until the Trip menu item is highlighted in the

instrument cluster display. Push and release

the right arrow button to enter the submenus of

Trip A and Trip B. The Trip A or Trip B information

will display the following:

Distance

Average Fuel Economy

Elapsed Time

Push and hold right arrow button to reset all

information.

Trailer Tow — If Equipped

Push and release the up or down arrow button

until the Trailer Tow menu item is highlighted in

the instrument cluster display. Push and

release the right arrow button and the next

screen will display the following trailer trip

information:

Trip Distance (trailer specific): Push and hold

the right arrow button to reset the distance.

Trailer Brake

Output

Type

Gain

Trailer Tire Pressure — If Equipped

Audio

Push and release the up or down arrow button

until the Audio Menu icon/title is highlighted in

the instrument cluster display. This menu will

display the audio source information, including

the Song name, Artist name, and audio source

with an accompanying graphic.

Phone Call Status

When a call is incoming, a Phone Call Status

pop-up will display on the screen. The pop-up

will remain until the phone is answered or

ignored.

NOTE:

The call status will temporarily replace the

previous media source information displayed

on the screen. When the pop-up is no longer

displayed, the display will return to the last used

screen.

3

20_DJD2_OM_EN_USC_t.book Page 117

Page 218 of 568

216STARTING AND OPERATING

If the driver shifts into PARK while moving, the

vehicle may AutoPark.

AutoPark will engage ONLY when vehicle speed

is 1.2 mph (1.9 km/h) or less.

The message “ Vehicle Speed is Too High to

Shift to P ” will be displayed in the instrument

cluster if vehicle speed is above 1.2 mph

(1.9 km/h).

4WD LOW — If Equipped

AutoPark will be disabled when operating the

vehicle in 4WD LOW.

The message “ AutoPark Disabled ” will be

displayed in the instrument cluster. Additional customer warnings will be given

when all of these conditions are met:

Vehicle is not in PARK

Driver’s door is ajar

Vehicle is in 4WD LOW range

The message “ AutoPark Not Engaged ” will be

displayed in the instrument cluster. A warning

chime will continue until you shift the vehicle

into PARK or the driver’s door is closed.

ALWAYS DO A VISUAL CHECK

that your vehicle

is in PARK by looking for the “P” in the

Instrument Cluster Display and near the shifter.

As an added precaution, always apply the

parking brake when exiting the vehicle.

If Engine Fails To Start

If the engine fails to start after you have

followed the “Normal Starting” procedure, it

may be flooded. Push the accelerator pedal all

the way to the floor and hold it there while the

engine is cranking. This should clear any excess

fuel in case the engine is flooded. The starter motor will engage automatically, run

for 10 seconds, and then disengage. Once this

occurs, release the accelerator pedal and the

brake pedal, wait 10 to 15 seconds, then repeat

the “Normal Starting” procedure.

WARNING!

If vehicle speed is above 1.2 mph (1.9 km/h),

the transmission will default to NEUTRAL until

the vehicle speed drops below 1.2 mph

(1.9 km/h). A vehicle left in the NEUTRAL

position can roll. As an added precaution,

always apply the parking brake when exiting

the vehicle.

WARNING!

Never pour fuel or other flammable liquid

into the throttle body air inlet opening in an

attempt to start the vehicle. This could result

in flash fire causing serious personal injury.

Do not attempt to push or tow your vehicle to

get it started. Vehicles equipped with an

automatic transmission cannot be started

this way. Unburned fuel could enter the cata

-

lytic converter and once the engine has

started, ignite and damage the converter

and vehicle.

If the vehicle has a discharged battery,

booster cables may be used to obtain a

start from a booster battery or the battery in

another vehicle. This type of start can be

dangerous if done improperly. Refer to

“Jump Starting Procedure” in “In Case Of

Emergency” for further information.

20_DJD2_OM_EN_USC_t.book Page 216

Page 321 of 568

STARTING AND OPERATING319

(Continued)

ENGINE RUNAWAY — DIESEL ENGINE

Diesel engine runaway is a rare condition

affecting diesel engines, where the engine

consumes its own lubrication oil and runs at

higher and higher RPM until it overspeeds to a

point where it destroys itself due to either

mechanical failure or engine seizure through

lack of lubrication.

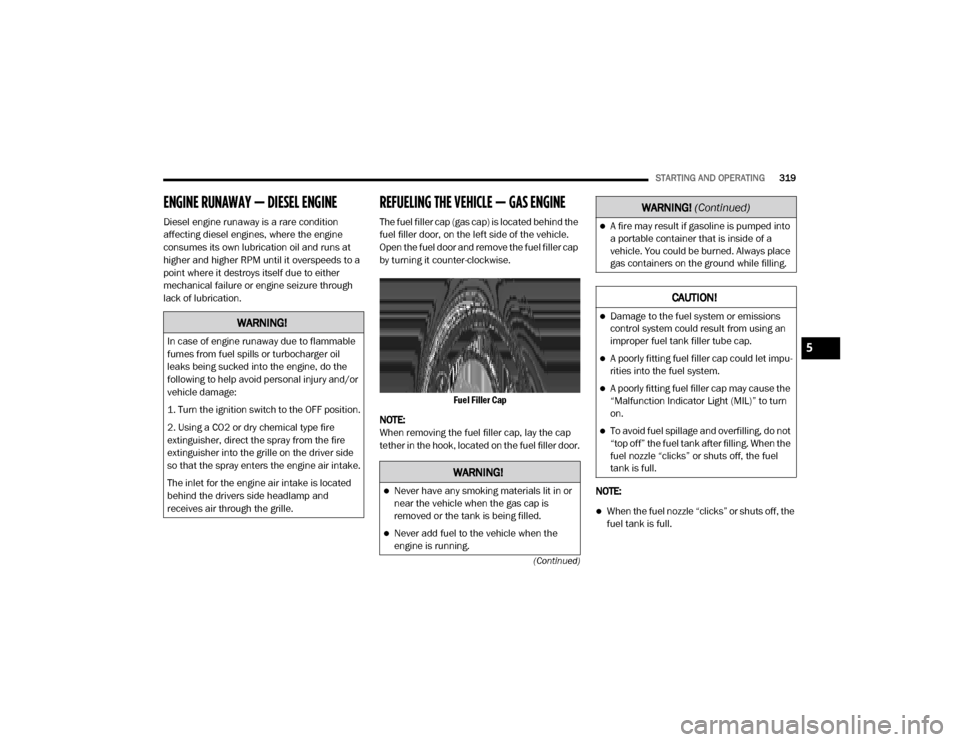

REFUELING THE VEHICLE — GAS ENGINE

The fuel filler cap (gas cap) is located behind the

fuel filler door, on the left side of the vehicle.

Open the fuel door and remove the fuel filler cap

by turning it counter-clockwise.

Fuel Filler Cap

NOTE:

When removing the fuel filler cap, lay the cap

tether in the hook, located on the fuel filler door.

NOTE:

When the fuel nozzle “clicks” or shuts off, the

fuel tank is full.

WARNING!

In case of engine runaway due to flammable

fumes from fuel spills or turbocharger oil

leaks being sucked into the engine, do the

following to help avoid personal injury and/or

vehicle damage:

1. Turn the ignition switch to the OFF position.

2. Using a CO2 or dry chemical type fire

extinguisher, direct the spray from the fire

extinguisher into the grille on the driver side

so that the spray enters the engine air intake.

The inlet for the engine air intake is located

behind the drivers side headlamp and

receives air through the grille.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the gas cap is

removed or the tank is being filled.

Never add fuel to the vehicle when the

engine is running.

A fire may result if gasoline is pumped into

a portable container that is inside of a

vehicle. You could be burned. Always place

gas containers on the ground while filling.

CAUTION!

Damage to the fuel system or emissions

control system could result from using an

improper fuel tank filler tube cap.

A poorly fitting fuel filler cap could let impu-

rities into the fuel system.

A poorly fitting fuel filler cap may cause the

“Malfunction Indicator Light (MIL)” to turn

on.

To avoid fuel spillage and overfilling, do not

“top off” the fuel tank after filling. When the

fuel nozzle “clicks” or shuts off, the fuel

tank is full.

WARNING! (Continued)

5

20_DJD2_OM_EN_USC_t.book Page 319

Page 324 of 568

322STARTING AND OPERATING

Temperature sensors

SCR catalyst

UQS Sensor

Refer to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

system messages and warnings.

NOTE:

Your vehicle is equipped with a DEF injection

system. You may occasionally hear an audible

clicking noise. This is normal operation.

The DEF pump will run for a period of time

after engine shutdown to purge the DEF

system. This is normal operation.

Diesel Exhaust Fluid Storage

Diesel Exhaust Fluid (DEF) is considered a very

stable product with a long shelf life. If DEF is

kept in temperatures between 10°F and 90°F

(-12°C and 32°C), it will last a minimum of one

year.

DEF is subject to freezing at the lowest

temperatures. For example, DEF may freeze at

temperatures at or below 12°F (-11°C). The

system has been designed to operate in this

environment. NOTE:

When working with DEF, it is important to know

that:

Any containers or parts that come into

contact with DEF must be DEF compatible

(plastic or stainless steel). Copper, brass,

aluminum, iron or non-stainless steel should

be avoided as they are subject to corrosion

by DEF.

If DEF is spilled, it should be wiped up

completely.

Adding Diesel Exhaust Fluid

The DEF gauge (located on the instrument

cluster) will display the level of DEF remaining in

the tank. Refer to “Instrument Cluster” and

“Instrument Cluster Descriptions” in “Getting To

Know Your Instrument Panel” for further

information.

NOTE:

Driving conditions (altitude, vehicle speed,

load, etc.) will affect the amount of DEF that

is used in your vehicle.

Another factor is that outside temperature

can affect DEF consumption. In cold condi

-

tions, 12°F (-11°C) and below, the DEF gauge needle can stay on a fixed position and

may not move for extended periods of time.

This is a normal function of the system.

There is an electric heater inside the DEF

tank that automatically works when neces

-

sary. And if the DEF supply does freeze, the

truck will operate normally until it thaws.

DEF Fill Procedure

NOTE:

Refer to “Fluids And Lubricants” in “Technical

Specifications” for the correct fluid type.

1. Remove cap from DEF tank (located on driver’s side of the vehicle or in fuel door).

Fill Locations

1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Diesel Fuel Fill Location

20_DJD2_OM_EN_USC_t.book Page 322

Page 387 of 568

385

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GAS ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will

influence when the “Oil Change Required”

message is displayed. Severe Operating

Conditions can cause the change oil message to

illuminate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles

(805 km).

An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change.If a scheduled oil change is performed by

someone other than an authorized dealer, the

message can be reset by referring to the steps

described under “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel”.

NOTE:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

NOTE:

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominantly at idle, or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:Check engine oil level

Check windshield washer fluid level

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, power steering and

automatic transmission (six-speed only) and

fill as needed

Check function of all interior and exterior

lights7

20_DJD2_OM_EN_USC_t.book Page 385

Page 391 of 568

SERVICING AND MAINTENANCE389

HEAVY DUTY USE OF THE VEHICLE

Change engine oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominately at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

SCHEDULED SERVICING— DIESEL ENGINE

Required Maintenance Intervals

Refer to the maintenance plan on the following

pages for the required maintenance intervals.

More frequent maintenance may be needed in

severe conditions, such as dusty areas and very

short trip driving. In some extreme conditions,

additional maintenance not specified in the

maintenance schedule may be required.

At Each Stop For Fuel

Check the engine oil level at least 30 minutes

after a fully warmed engine is shut off. Checking

the oil level while the vehicle is on level ground

will improve the accuracy of the oil level

reading. Add oil only when the level is at or

below the ADD or MIN mark. Once A Month

Inspect the batteries, and clean and tighten

the terminals as required.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and automatic trans-

mission, and add as needed.

At Each Oil Change

Change the engine oil filter.

Inspect the exhaust system.

Inspect engine air filter. Replace the engine

air filter cleaner, if necessary.

Inspect the CV/Universal joints.

Check the coolant level, hoses, and clamps.

Inspect front end, and lubricate — If equipped

with serviceable fittings.

Inspect and replace the Evaporative System

Fresh Air Filter as necessary, replacement

may be more frequent if vehicle is operated

in extreme dusty conditions.

WARNING!

You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge and

the right equipment. If you have any doubt

about your ability to perform a service job,

take your vehicle to a competent mechanic.

Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an acci -

dent.

CAUTION!

Failure to perform the required maintenance

items may result in damage to the vehicle.

7

20_DJD2_OM_EN_USC_t.book Page 389

Page 423 of 568

SERVICING AND MAINTENANCE421

(Continued)

CHARGE AIR COOLER — INTER-COOLER

The charge air cooler is positioned below the

radiator and the air conditioner condenser. Air

enters the engine through the air cleaner and

passes through the turbocharger, where it is

pressurized. This pressurized air rapidly

reaches high temperature. The air is then

directed through a hose to the charge air cooler

and through another hose to the intake

manifold of the engine. The air entering the

engine has been cooled by about 50° to 100°F

(10° to 38°C). This cooling process enables

more efficient burning of fuel resulting in fewer

emissions.

To guarantee optimum performance of the

system, keep the surfaces of the charge air

cooler, condenser and radiator clean and free

of debris. Periodically check the hoses leading

to and from the charge air cooler for cracks or

loose clamps resulting in loss of pressure and

reduced engine performance.

BRAKE SYSTEM

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the “Maintenance Plan” in this section for the

proper maintenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood

service or immediately if the brake system

warning lamp indicates system failure.

If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the

top of the master cylinder area before removing

cap.

With disc brakes the fluid level can be expected

to fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by

a leak and a system check should be

conducted.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further infor-

mation. Using the wrong type of brake fluid

can severely damage your brake system

and/or impair its performance. The proper

type of brake fluid for your vehicle is also

identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or fluid

that has been in a tightly closed container.

Keep the master cylinder reservoir cap

secured at all times. Brake fluid in a open

container absorbs moisture from the air

resulting in a lower boiling point. This may

cause it to boil unexpectedly during hard or

prolonged braking, resulting in sudden brake

failure. This could result in a collision.

7

20_DJD2_OM_EN_USC_t.book Page 421

Page 438 of 568

436SERVICING AND MAINTENANCE

Both underinflation and overinflation affect the

stability of the vehicle and can produce a feeling

of sluggish response or over responsiveness in

the steering.

NOTE:

Unequal tire pressures from side to side may

cause erratic and unpredictable steering

response.

Unequal tire pressure from side to side may

cause the vehicle to drift left or right. Fuel Economy

Underinflated tires will increase tire rolling

resistance resulting in higher fuel consumption.

Tread Wear

Improper cold tire inflation pressures can cause

abnormal wear patterns and reduced tread life,

resulting in the need for earlier tire

replacement.

Ride Comfort And Vehicle Stability

Proper tire inflation contributes to a

comfortable ride. Overinflation produces a

jarring and uncomfortable ride.

Tire Inflation Pressures

The proper cold tire inflation pressure is listed

on the driver's side B-Pillar or rear edge of the

driver's side door.

At least once a month:

Check and adjust tire pressure with a good

quality pocket-type pressure gauge. Do not

make a visual judgement when determining

proper inflation. Tires may look properly

inflated even when they are under-inflated.

Inspect tires for signs of tire wear or visible

damage.

Inflation pressures specified on the placard are

always “cold tire inflation pressure”. Cold tire

inflation pressure is defined as the tire pressure

after the vehicle has not been driven for at least

three hours, or driven less than 1 mile (1.6 km)

after sitting for a minimum of three hours. The

cold tire inflation pressure must not exceed the

maximum inflation pressure molded into the

tire sidewall.

Check tire pressures more often if subject to a

wide range of outdoor temperatures, as tire

pressures vary with temperature changes.

Tire pressures change by approximately 1 psi

(7 kPa) per 12°F (7°C) of air temperature

change. Keep this in mind when checking tire

pressure inside a garage, especially in the

Winter.

Example: If garage temperature = 68°F (20°C)

and the outside temperature = 32°F (0°C) then

Overinflated or underinflated tires can

affect vehicle handling and can fail

suddenly, resulting in loss of vehicle

control.

Unequal tire pressures can cause steering

problems. You could lose control of your

vehicle.

Unequal tire pressures from one side of the

vehicle to the other can cause the vehicle

to drift to the right or left.

Always drive with each tire inflated to the

recommended cold tire inflation pressure.

WARNING!

(Continued)CAUTION!

After inspecting or adjusting the tire pressure,

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the valve

stem.

20_DJD2_OM_EN_USC_t.book Page 436