tire size Ram 4500 Chassis Cab 2018 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 529, PDF Size: 5.89 MB

Page 415 of 529

WARNING!

Compact and Collapsible spares are for temporary

emergency use only. With these spares, do not drive

more than 50 mph (80 km/h). Temporary use spares

have limited tread life. When the tread is worn to the

tread wear indicators, the temporary use spare tire

needs to be replaced. Be sure to follow the warnings,

which apply to your spare. Failure to do so could result

in spare tire failure and loss of vehicle control.

Full Size Spare — If Equipped

The full size spare is for temporary emergency use only.

This tire may look like the originally equipped tire on the

front or rear axle of your vehicle, but it is not. This spare

tire may have limited tread life. When the tread is worn to

the tread wear indicators, the temporary use full size spare

tire needs to be replaced. Since it is not the same as your

original equipment tire, replace (or repair) the original

equipment tire and reinstall on the vehicle at the first

opportunity.

Limited Use Spare — If Equipped

The limited use spare tire is for temporary emergency use

only. This tire is identified by a label located on the limiteduse spare wheel. This label contains the driving limitations

for this spare. This tire may look like the original equipped

tire on the front or rear axle of your vehicle, but it is not.

Installation of this limited use spare tire affects vehicle

handling. Since it is not the same as your original equip-

ment tire, replace (or repair) the original equipment tire

and reinstall on the vehicle at the first opportunity.

WARNING!

Limited use spares are for emergency use only. Instal-

lation of this limited use spare tire affects vehicle

handling. With this tire, do not drive more than the

speed listed on the limited use spare wheel. Keep

inflated to the cold tire inflation pressures listed on

your Tire and Loading Information Placard located on

the driver ’s side B-Pillar or the rear edge of the driver ’s

side door. Replace (or repair) the original equipment

tire at the first opportunity and reinstall it on your

vehicle. Failure to do so could result in loss of vehicle

control.

Wheel And Wheel Trim Care

All wheels and wheel trim, especially aluminum and

chrome plated wheels, should be cleaned regularly using

mild (neutral Ph) soap and water to maintain their luster

8

SERVICING AND MAINTENANCE 413

Page 417 of 529

Dark Vapor Chrome, Black Satin Chrome, or Low Gloss

Clear Coat Wheels

CAUTION!

If your vehicle is equipped with these specialty

wheels, DO NOT USE wheel cleaners, abrasives, or

polishing compounds. They will permanently damage

this finish and such damage is not covered by the New

Vehicle Limited Warranty. HAND WASH ONLY US-

ING MILD SOAP AND WATER WITH A SOFT

CLOTH. Used on a regular basis; this is all that is

required to maintain this finish.

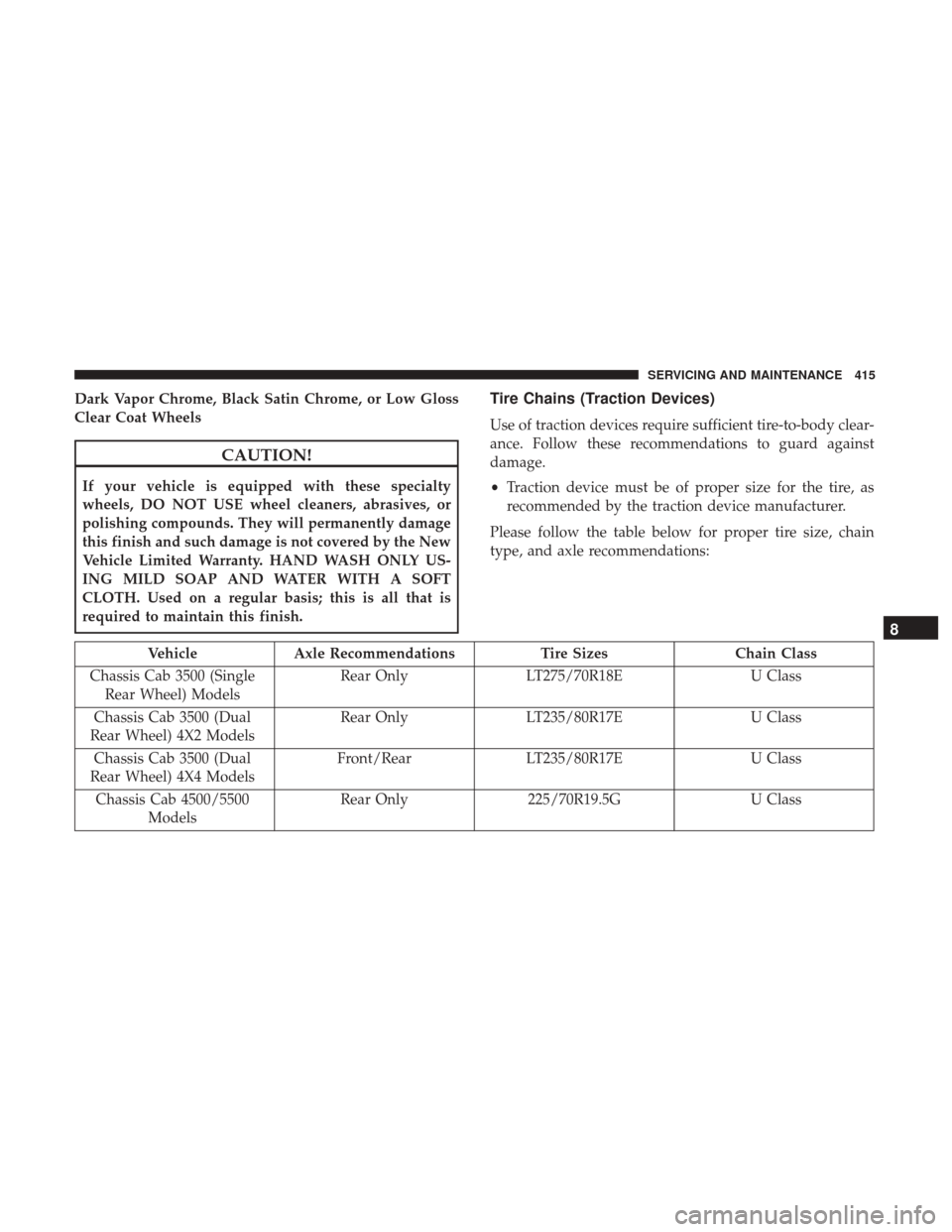

Tire Chains (Traction Devices)

Use of traction devices require sufficient tire-to-body clear-

ance. Follow these recommendations to guard against

damage.

•Traction device must be of proper size for the tire, as

recommended by the traction device manufacturer.

Please follow the table below for proper tire size, chain

type, and axle recommendations:

Vehicle Axle Recommendations Tire SizesChain Class

Chassis Cab 3500 (Single Rear Wheel) Models Rear Only

LT275/70R18E U Class

Chassis Cab 3500 (Dual

Rear Wheel) 4X2 Models Rear Only

LT235/80R17E U Class

Chassis Cab 3500 (Dual

Rear Wheel) 4X4 Models Front/Rear

LT235/80R17E U Class

Chassis Cab 4500/5500 Models Rear Only

225/70R19.5G U Class

8

SERVICING AND MAINTENANCE 415

Page 418 of 529

WARNING!

Using tires of different size and type (M+S, Snow)

between front and rear axles can cause unpredictable

handling. You could lose control and have a collision.

CAUTION!

To avoid damage to your vehicle or tires, observe the

following precautions:

•Because of restricted traction device clearance be-

tween tires and other suspension components, it is

important that only traction devices in good condi-

tion are used. Broken devices can cause serious

damage. Stop the vehicle immediately if noise occurs

that could indicate device breakage. Remove the

damaged parts of the device before further use.

• Install device as tightly as possible and then re-

tighten after driving about ½ mile (0.8 km).

• Do not exceed 30 mph (48 km/h).

• Drive cautiously and avoid severe turns and large

bumps, especially with a loaded vehicle.

• Do not drive for a prolonged period on dry pave-

ment.

(Continued)

CAUTION! (Continued)

•Observe the traction device manufacturer ’s instruc-

tions on the method of installation, operating speed,

and conditions for use. Always use the suggested

operating speed of the device manufacturer ’s if it is

less than 30 mph (48 km/h).

• Do not use traction devices on a compact spare tire.

Tire Rotation Recommendations

Tires on the front and rear axles of vehicles operate at

different loads and perform different steering, driving, and

braking functions. For these reasons, they wear at unequal

rates.

These effects can be reduced by timely rotation of tires. The

benefits of rotation are especially worthwhile with aggres-

sive tread designs such as those on On/Off Road type tires.

Rotation will increase tread life, help to maintain mud,

snow, and wet traction levels, and contribute to a smooth,

quiet ride.

Refer to the “Maintenance Plan” for the proper mainte-

nance intervals. More frequent rotation is permissible if

desired. The reasons for any rapid or unusual wear should

be corrected prior to rotation being performed.

416 SERVICING AND MAINTENANCE

Page 429 of 529

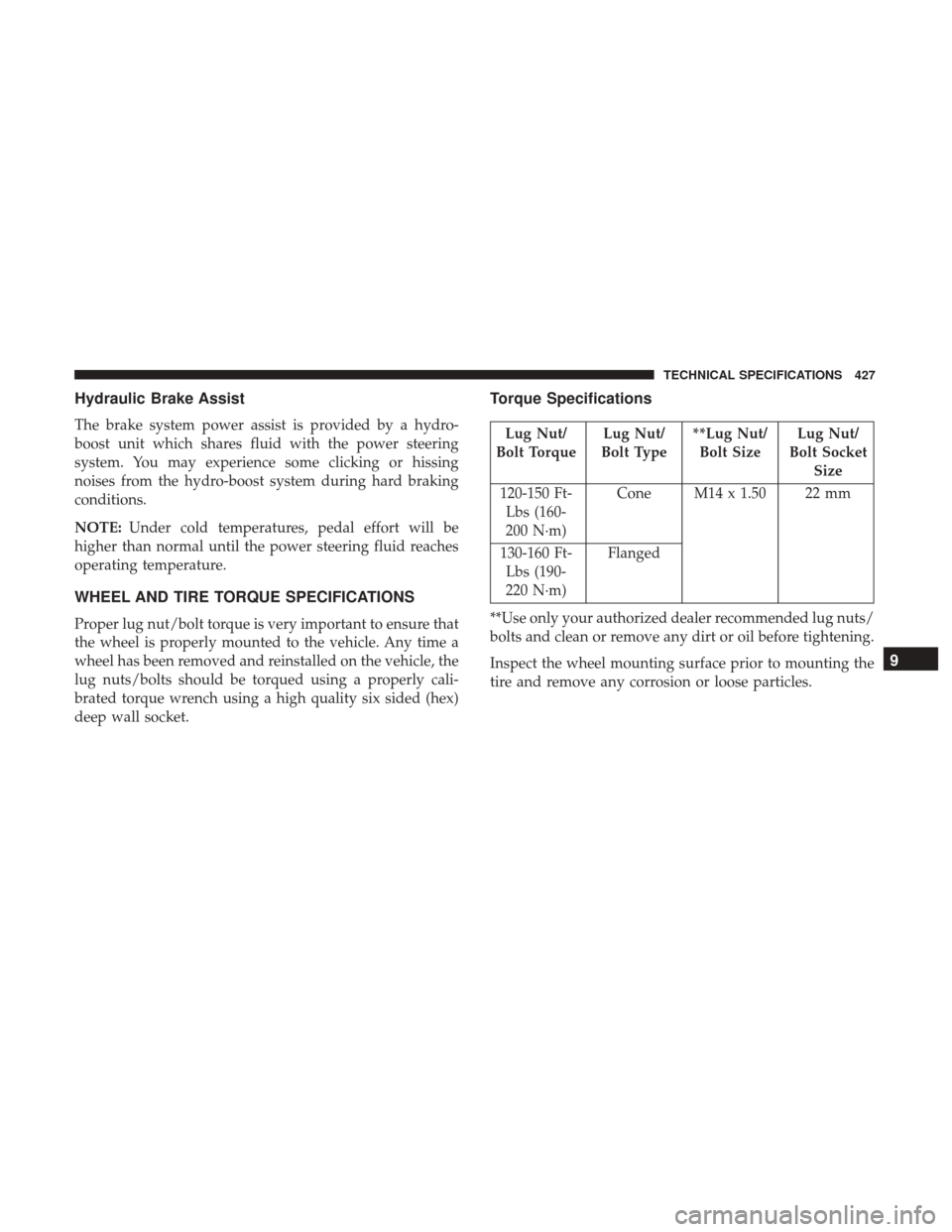

Hydraulic Brake Assist

The brake system power assist is provided by a hydro-

boost unit which shares fluid with the power steering

system. You may experience some clicking or hissing

noises from the hydro-boost system during hard braking

conditions.

NOTE:Under cold temperatures, pedal effort will be

higher than normal until the power steering fluid reaches

operating temperature.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a properly cali-

brated torque wrench using a high quality six sided (hex)

deep wall socket.

Torque Specifications

Lug Nut/

Bolt Torque Lug Nut/

Bolt Type **Lug Nut/

Bolt Size Lug Nut/

Bolt Socket Size

120-150 Ft- Lbs (160-

200 N·m) Cone M14 x 1.50 22 mm

130-160 Ft- Lbs (190-

220 N·m) Flanged

**Use only your authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

9

TECHNICAL SPECIFICATIONS 427

Page 526 of 529

Load Capacity...................... .400, 401

Pressure Monitor System (TPMS) .............176

Pressure Warning Light ....................155

Quality Grading ........................ .418

Radial ............................... .406

Replacement ........................... .409

Rotation .............................. .416

Safety ............................ .394, 404

Sizes ................................ .396

Snow Tires .............................411

Spare Tire ...........................411,413

Spinning .............................. .407

Trailer Towing .......................... .301

Tread Wear Indicators .....................408

Wheel Nut Torque ....................343, 427

Tire Safety Information ...................... .394

Tongue Weight/Trailer Weight .................299

To Open Hood ........................... .101

Torque Converter Clutch .....................256

Towing ............................. .292, 352

Disabled Vehicle ........................ .352

Guide ................................ .299

Recreational ............................311

Weight ............................... .299

Towing Vehicle Behind A Motorhome ............311Traction

................................ .316

Traction Control .......................... .168

Trailer Sway Control (TSC) ....................173

Trailer Towing ............................ .292

Cooling System Tips ..................... .308

Hitches ............................... .298

Minimum Requirements ....................300

Mirrors ................................67

Tips ................................. .307

Trailer And Tongue Weight ..................299

Wiring ............................... .306

T

railer Towing Guide ....................... .299

Trailer Weight ............................ .299

Transfer Case ............................ .393

Electronically Shifted ..................... .260

Fluid ................................ .437

Transmission Automatic ......................... .248, 389

Fluid ................................ .437

Maintenance ........................... .389

Shifting .............................. .246

Transporting Pets ......................... .233

Tread Wear Indicators ...................... .408

Turn Signals ....................... .75, 158, 326

524 INDEX