instrument cluster Ram 4500 Chassis Cab 2018 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 142 of 298

The DEF injection system consists of the

following components:

• DEF tank

• DEF pump

• DEF injector

• Electronically-heated DEF lines

• DEF control module

• NOx sensors

• Temperature sensors

• SCR catalyst

• UQS Sensor

Refer to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

system messages and warnings.

NOTE:

• Your vehicle is equipped with a DEF injec-tion system. You may occasionally hear an

audible clicking noise. This is normal op-

eration.

• The DEF pump will run for a period of time after engine shutdown to purge the DEF

system. This is normal operation.Diesel Exhaust Fluid Storage

Diesel Exhaust Fluid (DEF) is considered a

very stable product with a long shelf life. If

DEF is kept in temperatures between 10° and

90°F (-12° and 32°C), it will last a minimum

of one year.

DEF is subject to freezing at the lowest tem-

peratures. For example, DEF may freeze at

temperatures at or below 12° F (-11° C). The

system has been designed to operate in this

environment.

NOTE:

When working with DEF, it is important to

know that:

• Any containers or parts that come into con-tact with DEF must be DEF compatible

(plastic or stainless steel). Copper, brass,

aluminum, iron or non-stainless steel

should be avoided as they are subject to

corrosion by DEF.

• If DEF is spilled, it should be wiped up completely.

Adding Diesel Exhaust Fluid

The DEF gauge (located on the instrument

cluster) will display the level of DEF remain-

ing in the tank. Refer to “Instrument Cluster”

and “Instrument Cluster Descriptions” in

“Getting To Know Your Instrument Panel” for

further information.

NOTE:

• Driving conditions (altitude, vehicle speed,load, etc.) will effect the amount of DEF

that is used in your vehicle.

• Another factor is that outside temperature can affect DEF consumption. In cold con-

ditions, 12° F (-11° C) and below, the DEF

gauge needle can stay on a fixed position

and may not move for extended periods of

time. This is a normal function of the sys-

tem.

• There is an electric heater inside the DEF tank that automatically works when neces-

sary. And if the DEF supply does freeze, the

truck will operate normally until it thaws.

STARTING AND OPERATING

140

Page 144 of 298

CAUTION!

• Never add anything other than DEF tothe tank – especially any form of hydro-

carbon such as diesel fuel, fuel system

additives, gasoline, or any other

petroleum-based product. Even a very

small amount of these, less than

100 parts per million or less than 1 oz.

per 78 gallons (295 liters) will contami-

nate the entire DEF system and will

require replacement. If owners use a

container, funnel or nozzle when refilling

the tank, it should either be new or one

that is has only been used for adding

DEF. Mopar provides an attachable

nozzle with its DEF for this purpose.

3. Stop filling the DEF tank immediately when any of the following happen: DEF

stops flowing from the fill bottle into the

DEF tank, DEF splashes out the filler

neck, or a DEF pump nozzle automatically

shuts off.

4. Reinstall cap onto DEF tank. Filling The Def Tank In Cold Climates

Since DEF will begin to freeze at 12°F

(-11°C), your vehicle is equipped with an

automatic DEF heating system. This allows

the DEF injection system to operate properly

at temperatures below 12°F (-11°C). If your

vehicle is not in operation for an extended

period of time with temperatures below 12°F

(-11°C), the DEF in the tank may freeze. If

the tank is overfilled and freezes, it could be

damaged. Therefore, do not overfill the DEF

tank.

Extra care should be taken when filling with

portable containers to avoid overfilling. Note

the level of the DEF gauge in your instrument

cluster. You may safely add a maximum of

2 gallons (7.5 Liters) of DEF from portable

containers when your DEF gauge is reading ½

full.

TRAILER TOWING

Trailer Towing Weights (Maximum

Trailer Weight Ratings)

NOTE:

For trailer towing information (maximum

trailer weight ratings) refer to the following

website addresses:

•

ramtrucks.com/en/towing_guide/

• ramtruck.ca (Canada)

• rambodybuilder.com

Towing Requirements

To promote proper break-in of your new ve-

hicle drivetrain components, the following

guidelines are recommended.

CAUTION!

• Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is

driven. The engine, axle or other parts

could be damaged.

STARTING AND OPERATING

142

Page 147 of 298

GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake

control power output to the trailer brakes in

0.5 increments. The GAIN setting can be

increased to a maximum of 10 or decreased

to a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer

brake control for the specific towing condi-

tion and should be changed as towing condi-

tions change. Changes to towing conditions

include trailer load, vehicle load, road condi-

tions and weather.

Adjusting GAIN

NOTE:

This should only be performed in a traffic free

environment at speeds of approximately 20–

25 mph (30–40 km/h).

1. Make sure the trailer brakes are in goodworking condition, functioning normally

and properly adjusted. See your trailer

dealer if necessary. 2. Hook up the trailer and make the electri-

cal connections according to the trailer

manufacturer's instructions.

3. When a trailer with electric/EOH brakes is plugged in, the trailer connected message

should appear in the instrument cluster

display (if the connection is not recog-

nized by the ITBM, braking functions will

not be available), the GAIN setting will

illuminate and the correct type of trailer

must be selected from the instrument

cluster display options.

4. Push the UP or DOWN button on the steering wheel until “TRAILER TOW” ap-

pears on the screen.

5. Push the RIGHT arrow on the steering wheel to enter “TRAILER TOW”.

6. Push the UP or DOWN buttons until the Trailer Brake Type appears on the screen. 7. Push the RIGHT arrow and then push the

UP or DOWN buttons until the proper

Trailer Brake Type appears on the screen.

8. In a traffic-free environment, tow the trailer on a dry, level surface at a speed of

20–25 mph (30–40 km/h) and squeeze

the manual brake control lever

completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting;

if the trailer wheels turn freely, increase

the GAIN setting.

Repeat steps 8 and 9 until the GAIN setting

is at a point just below trailer wheel lockup. If

towing a heavier trailer, trailer wheel lockup

may not be attainable even with the maxi-

mum GAIN setting of 10.

145

Page 148 of 298

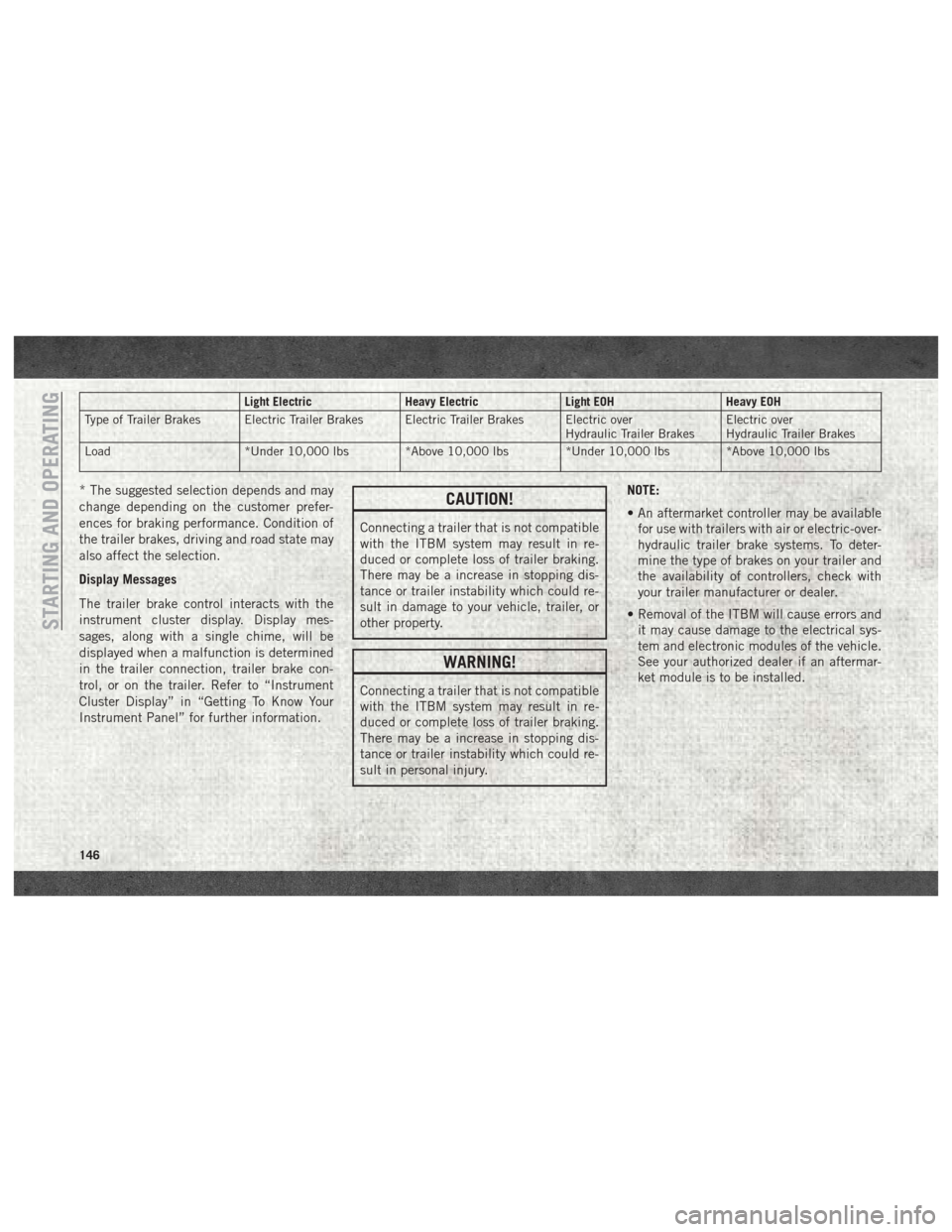

Light ElectricHeavy ElectricLight EOHHeavy EOH

Type of Trailer Brakes Electric Trailer Brakes Electric Trailer Brakes Electric over Hydraulic Trailer BrakesElectric over

Hydraulic Trailer Brakes

Load *Under 10,000 lbs *Above 10,000 lbs *Under 10,000 lbs *Above 10,000 lbs

* The suggested selection depends and may

change depending on the customer prefer-

ences for braking performance. Condition of

the trailer brakes, driving and road state may

also affect the selection.

Display Messages

The trailer brake control interacts with the

instrument cluster display. Display mes-

sages, along with a single chime, will be

displayed when a malfunction is determined

in the trailer connection, trailer brake con-

trol, or on the trailer. Refer to “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.CAUTION!

Connecting a trailer that is not compatible

with the ITBM system may result in re-

duced or complete loss of trailer braking.

There may be a increase in stopping dis-

tance or trailer instability which could re-

sult in damage to your vehicle, trailer, or

other property.

WARNING!

Connecting a trailer that is not compatible

with the ITBM system may result in re-

duced or complete loss of trailer braking.

There may be a increase in stopping dis-

tance or trailer instability which could re-

sult in personal injury. NOTE:

• An aftermarket controller may be available

for use with trailers with air or electric-over-

hydraulic trailer brake systems. To deter-

mine the type of brakes on your trailer and

the availability of controllers, check with

your trailer manufacturer or dealer.

• Removal of the ITBM will cause errors and it may cause damage to the electrical sys-

tem and electronic modules of the vehicle.

See your authorized dealer if an aftermar-

ket module is to be installed.

STARTING AND OPERATING

146

Page 159 of 298

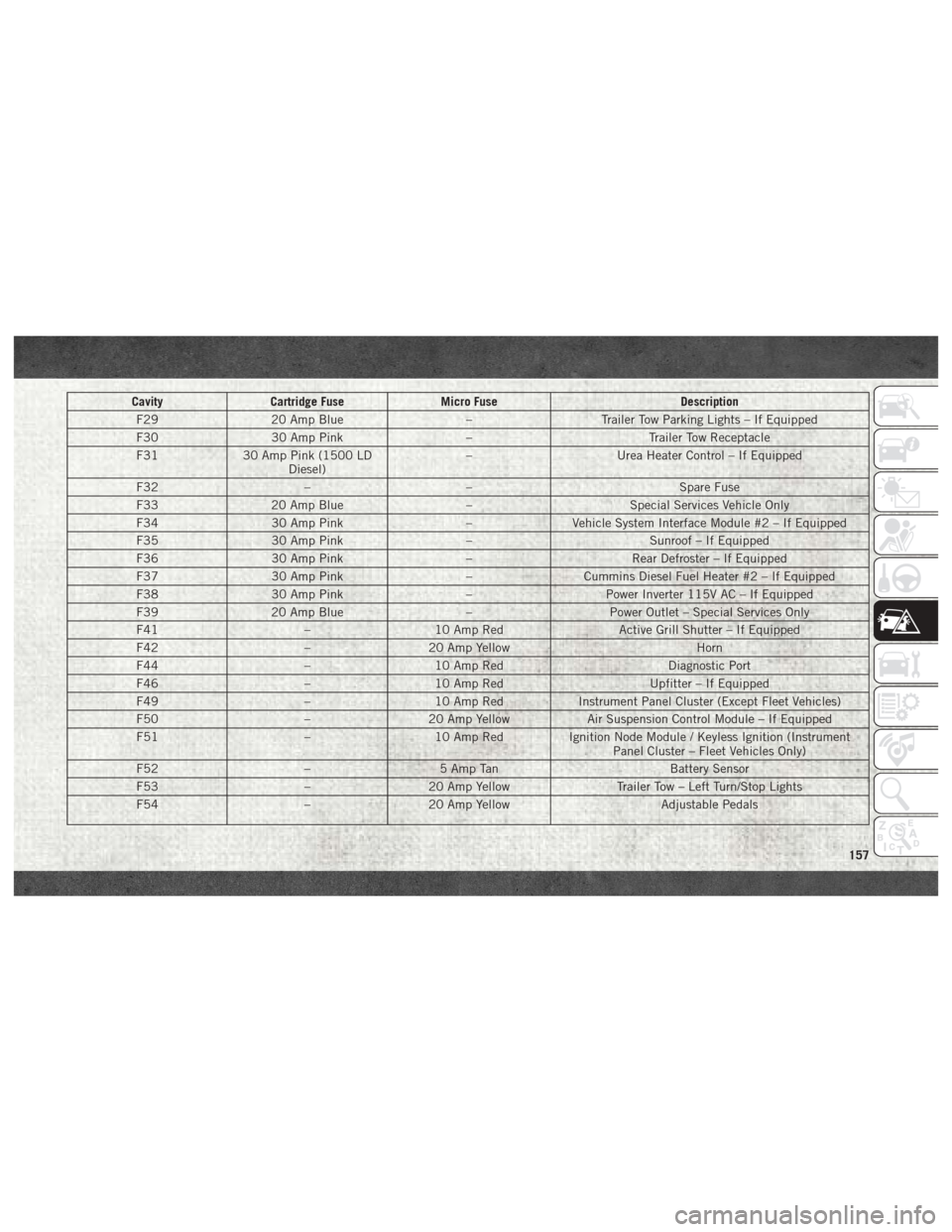

CavityCartridge Fuse Micro Fuse Description

F29 20 Amp Blue –Trailer Tow Parking Lights – If Equipped

F30 30 Amp Pink –Trailer Tow Receptacle

F31 30 Amp Pink (1500 LD

Diesel) –

Urea Heater Control – If Equipped

F32 –– Spare Fuse

F33 20 Amp Blue –Special Services Vehicle Only

F34 30 Amp Pink –Vehicle System Interface Module #2 – If Equipped

F35 30 Amp Pink –Sunroof – If Equipped

F36 30 Amp Pink –Rear Defroster – If Equipped

F37 30 Amp Pink –Cummins Diesel Fuel Heater #2 – If Equipped

F38 30 Amp Pink –Power Inverter 115V AC – If Equipped

F39 20 Amp Blue –Power Outlet – Special Services Only

F41 –10 Amp Red Active Grill Shutter – If Equipped

F42 –20 Amp Yellow Horn

F44 –10 Amp Red Diagnostic Port

F46 –10 Amp Red Upfitter – If Equipped

F49 –10 Amp Red Instrument Panel Cluster (Except Fleet Vehicles)

F50 –20 Amp Yellow Air Suspension Control Module – If Equipped

F51 –10 Amp Red Ignition Node Module / Keyless Ignition (Instrument

Panel Cluster – Fleet Vehicles Only)

F52 –5 Amp Tan Battery Sensor

F53 –20 Amp Yellow Trailer Tow – Left Turn/Stop Lights

F54 –20 Amp Yellow Adjustable Pedals

157

Page 161 of 298

CavityCartridge Fuse Micro Fuse Description

F78 –10 Amp Red Engine Control Module / Electric Power Steering

F79 –15 Amp Blue Clearance Lights

F80 –10 Amp Red Universal Garage Door Opener / Compass

F81 –20 Amp Yellow Trailer Tow Right Turn / Stop Lights

F82 –10 Amp Red Steering Column Control Module / Cruise Control

F84 –15 Amp Blue Switch Bank / Instrument Cluster

F85 –10 Amp Red Airbag Module

F86 –10 Amp Red Airbag Module

F87 –10 Amp Red Air Suspension – If Equipped / Trailer Tow / Steering Col-

umn Control Module

F88 –15 Amp Blue Instrument Panel Cluster

F90/F91 –20 Amp Yellow Power Outlet (Rear Seats) Customer Selectable

F93 –20 Amp Yellow Cigar Lighter

F94 –10 Amp Red Shifter / Transfer Case Module

F95 –10 Amp Red Rear Camera / Park Assist

F96 –10 Amp Red Rear Seat Heater Switch

F97 –25 Amp Clear Rear Heated Seats & Heated Steering Wheel – If

Equipped

F98 –25 Amp Clear Front Heated Seats – If Equipped

F99 –10 Amp Red Climate Control

F100 –10 Amp Red Upfitters – If Equipped

F101 –15 Amp Blue Electrochromatic Mirror / Smart High Beams – If

Equipped

F104 –20 Amp Yellow Power Outlets (Instrument Panel / Center Console)

159

Page 176 of 298

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for scheduled

maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate.

This means that service is required for your

vehicle. Operating conditions such as fre-

quent short-trips, trailer tow, extremely hot or

cold ambient temperatures, and E85 fuel

usage will influence when the “Oil Change

Required” message is displayed. Severe Op-

erating Conditions can cause the change oil

message to illuminate as early as

3,500 miles (5,600 km) since last reset.

Have your vehicle serviced as soon as pos-

sible, within the next 500 miles (805 km).

Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change. If a scheduled oil

change is performed by someone other than

your authorized dealer, the message can bereset by referring to the steps described under

“Warning And Indicator Lights” or “Instru-

ment Cluster Display” in “Getting To Know

Your Instrument Panel” in your Owner’s

Manual at

www.mopar.com/en-us/care/

owner-manual.html (U.S. Residents) or

www.owners.mopar.ca (Canadian Residents)

for further information.

Gasoline Engines:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

twelve months or 350 hours of engine run

time, whichever comes first. The 350 hours

of engine run or idle time is generally only a

concern for fleet customers.

Severe Duty:

Change Engine Oil at 4,000 miles

(6,500 km) or 350 hours of engine run time

if the vehicle is operated in a dusty and off

road environment or is operated predomi-

nately at idle or very low engine RPM’s. This

type of vehicle use is considered Severe Duty. Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look

for unusual wear or damage

• Check the fluid levels of the coolant reser- voir, brake master cylinder, power steering

and automatic transmission, and fill as

needed

• Check function of all interior and exterior lights

SERVICING AND MAINTENANCE

174

Page 180 of 298

Heavy Duty Use Of The Vehicle

Change engine oil at 4,000 miles (6,500 km)

or 350 hours of engine run time if the vehicle

is operated in a dusty and off road environ-

ment or is operated predominately at idle or

only very low engine RPM’s. This type of

vehicle use is considered Severe Duty.

SCHEDULED MAINTENANCE — 6.7L

CUMMINS DIESEL ENGINE

CAUTION!

Failure to perform the required mainte-

nance items may result in damage to the

vehicle.

At Each Stop For Fuel

Check the engine oil level at least 30 minutes

after a fully warmed engine is shut off.

Checking the oil level while the vehicle is on

level ground will improve the accuracy of the

oil level reading. Add oil only when the level

is at or below the ADD or MIN mark. Once A Month

• Inspect the batteries, and clean and

tighten the terminals as required.

• Check the fluid levels of the coolant reser- voir, brake master cylinder, and automatic

transmission (if equipped), and add as

needed.

At Each Oil Change

• Change the engine oil filter.

• Inspect the exhaust system.

• Inspect engine air filter.

• Check the coolant level, hoses, and clamps.

• Inspect front end, and lubricate — If equipped with serviceable fittings.

• Lube the front drive shaft fitting (4X4 mod- els only).

Inspection and service should also be per-

formed anytime a malfunction is observed or

suspected. Retain all receipts.

Oil Change Indicator System —

Cummins Diesel

Your vehicle is equipped with an engine oil

change indicator system. This system will

alert you when it is time to change your

engine oil by displaying the words “Oil

Change Due” in your instrument cluster dis-

play. The oil change reminder will remind the

owner to change the engine oil every

15,000 miles or 500 hours, whichever

comes first, except for the Chassis Cab mod-

els and Pickup models configured with op-

tional B20 capability that are using B20 bio-

diesel, which are 12,500 miles or 400 hours,

whichever comes first. Failure to change the

engine oil per the maintenance schedule can

result in internal engine damage.

Replace the engine oil and oil filter every

15,000 miles (24,000 km) or six months, or

sooner if prompted by the oil change indicator

system. Under no circumstances should oil

change intervals exceed 15,000 miles

(24,000 km) or six months, whichever comes

first.

SERVICING AND MAINTENANCE

178

Page 181 of 298

NOTE:

• Under no circumstances should oil changeintervals exceed 15,000 miles

(24,000 km) or six months or 500 Hours,

whichever comes first.

• Replace the engine oil and oil filter every 12,500 miles (20 000 km) when running

B20 fuel (Chassis Cab Only).

If Chassis Cab models and Pickup models

configured with optional B20 capability are

operated with greater than 5% levels of bio-

diesel, the oil change interval must not ex-

ceed 12,500 miles (20 000 km) under any

circumstances. See the Fuel Requirements

section for more information regarding opera-

tion of Chassis Cab models and Pickup mod-

els configured for use with biodiesel blend

(B6-B20) fuel meeting ASTM specification

D-7467.Perform Service Indicator —

Cummins Diesel

Your vehicle will require emissions mainte-

nance at a set interval. To help remind you

when this maintenance is due, the instru-

ment cluster will display “Perform Service”.

When the “Perform Service” message is dis-

played on the instrument cluster it is neces-

sary to have the emissions maintenance per-

formed. Emissions maintenance may include

replacing the Closed Crankcase Ventilation

(CCV) filter element. The procedure for clear-

ing and resetting the “Perform Service” indi-

cator message is located in the appropriate

Service Information.

179

Page 188 of 298

DEALER SERVICE — 6.7L DIESEL

ENGINE

Your authorized dealer has the qualified ser-

vice personnel, special tools, and equipment

to perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals be-

fore attempting any procedure yourself.

NOTE:

Intentional tampering with emissions control

systems may void your warranty and could

result in civil penalties being assessed

against you.

WARNING!

You can be badly injured working on or

around a motor vehicle. Only do service

work for which you have the knowledge

and the proper equipment. If you have any

doubt about your ability to perform a ser-

vice job, take your vehicle to a competent

mechanic.

Engine Air Cleaner Filter

CAUTION!

All air entering the engine intake must be

filtered. The abrasive particles in unfil-

tered air will cause rapid wear to engine

components.

WARNING!

The air induction system (air cleaner,

hoses, etc.) provides a measure of protec-

tion. Do not remove the air induction sys-

tem (air cleaner, hoses, etc.) unless such

removal is necessary for repair or mainte-

nance. Make sure that no one is near the

engine compartment before starting the

vehicle with the air induction system (air

cleaner, hoses, etc.) removed. Failure to

do so can result in serious personal injury.

The condition of the air cleaner filter is moni-

tored by the Engine Control Module. The

“SERVICE AIR FILTER” message will display

in the instrument cluster when service is required. Refer to “Instrument Cluster Dis-

play” in “Getting To Know Your Instrument

Panel” for further information.

The “SERVICE AIR FILTER” message could

be displayed periodically. This is because

engine air flow requirements change based

on driving conditions. As the filter becomes

more restrictive and air flow requirements

increase the “SERVICE AIR FILTER” mes-

sage will be displayed. The message may not

be displayed in subsequent drive cycles if the

same conditions are not met. The air filter

element should be replaced within 250 miles

(402 km) from the first time this message is

displayed to ensure proper engine operation

during all driving conditions.

CAUTION!

Driving with a restricted air filter can

cause engine damage. Driving in dusty

environments for extended periods will

lead to rapid air filter plugging. Action

should be taken as soon as the “SERVICE

AIR FILTER” message is displayed.

SERVICING AND MAINTENANCE

186