engine Ram 4500 Chassis Cab 2018 Repair Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 166 of 298

On 3500 models with dual rear wheels

(DRW), you must first remove the hub caps.

The jack handle driver has a hook at one end

that will fit in the pull off notch of the rear

hub caps. Position the hook and pull straight

out on the ratchet firmly. The hub cap should

pop off. The wheel skins can now be re-

moved. For the front hub cap, use the flat

blade on the end of the lug wrench to pull the

caps off. The wheel skin can now be removed.

CAUTION!

• Use a pulling motion to remove the hubcap. Do not use a twisting motion when

removing the hub cap, damage to the

hub cap; finish may occur.

• The rear hub caps on the dual rear wheel

has two pull off notches. Make sure that

the hook of the jack handle driver is

located squarely in the cap notch before

attempting to pull off.

You must use the flat end of the lug wrench to

pull off the wheel skins. Locate the hub cap

pull notches (2 notches on each cap). Insert the flat tip completely and using a back and

forth motion, loosen the wheel skin. Repeat

this procedure around the tire until the skin

pops off.

Replace the wheel skins first using a rubber

mallet. When replacing the hub caps, tilt the

cap retainer over the lug nut bolt circle and

strike the high side down with a rubber mal-

let. Be sure that the hub caps and wheel

skins are firmly seated around the wheel.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so

please follow the procedures in this section

carefully.

WARNING!

Do not attempt jump starting if the battery

is frozen. It could rupture or explode and

cause personal injury.

CAUTION!

Do not use a portable battery booster pack

or any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

NOTE:

When using a portable battery booster pack,

follow the manufacturer's operating instruc-

tions and precautions.

Preparations For Jump Start

The battery in your vehicle is located in the

front of the engine compartment, behind the

left headlight assembly.

IN CASE OF EMERGENCY

164

Page 168 of 298

NOTE:

Do not jump off fuses. Only jump directly off

positive post.

2. Connect the opposite end of the positive (+) jumper cable to the positive (+)post of

the booster battery.

3. Connect the negative (-)end of the jumper

cable to the negative (-)post of the

booster battery.

4. Connect the opposite end of the negative (-)jumper cable to a good engine ground

(exposed metal part of the discharged

vehicle’s engine) away from the battery

and the fuel injection system.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause

the battery to explode and could result in

personal injury. Only use the specific

ground point, do not use any other exposed

metal parts. 5. Start the engine in the vehicle that has

the booster battery, let the engine idle a

few minutes, and then start the engine in

the vehicle with the discharged battery.

CAUTION!

Do not connect jumper cable to any of the

fuses on the positive battery terminal. The

resulting electrical current will blow the

fuse.

6. Once the engine is started, remove the jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative (-)end of the

jumper cable from the engine ground of

the vehicle with the discharged battery.

2. Disconnect the opposite end of the nega- tive (-)jumper cable from the negative (-)

post of the booster battery.

3. Disconnect the positive (+)end of the

jumper cable from the positive (+)post of

the booster battery. 4. Disconnect the opposite end of the posi-

tive (+)jumper cable from the positive (+)

post of the vehicle with the discharged

battery.

If frequent jump starting is required to start

your vehicle you should have the battery and

charging system inspected at an authorized

dealer.

CAUTION!

Accessories plugged into the vehicle

power outlets draw power from the vehi-

cle’s battery, even when not in use (i.e.,

cellular devices, etc.). Eventually, if

plugged in long enough without engine

operation, the vehicle’s battery will dis-

charge sufficiently to degrade battery life

and/or prevent the engine from starting.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can

reduce the potential for overheating by taking

the appropriate action.

• On the highways — slow down.

IN CASE OF EMERGENCY

166

Page 169 of 298

• In city traffic — while stopped, place thetransmission in NEUTRAL, but do not in-

crease the engine idle speed while prevent-

ing vehicle motion with the brakes.

NOTE:

There are steps that you can take to slow

down an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off. The A/C system adds heat to the engine

cooling system and turning the A/C off can

help remove this heat.

• You can also turn the temperature control to maximum heat, the mode control to floor

and the blower control to high. This allows

the heater core to act as a supplement to

the radiator and aids in removing heat from

the engine cooling system.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never try to open a cooling system

WARNING!

pressure cap when the radiator or coolant

bottle is hot.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop

the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer

drops back into the normal range. If the

pointer remains on HOT (H), and you hear

continuous chimes, turn the engine off

immediately and call for service.

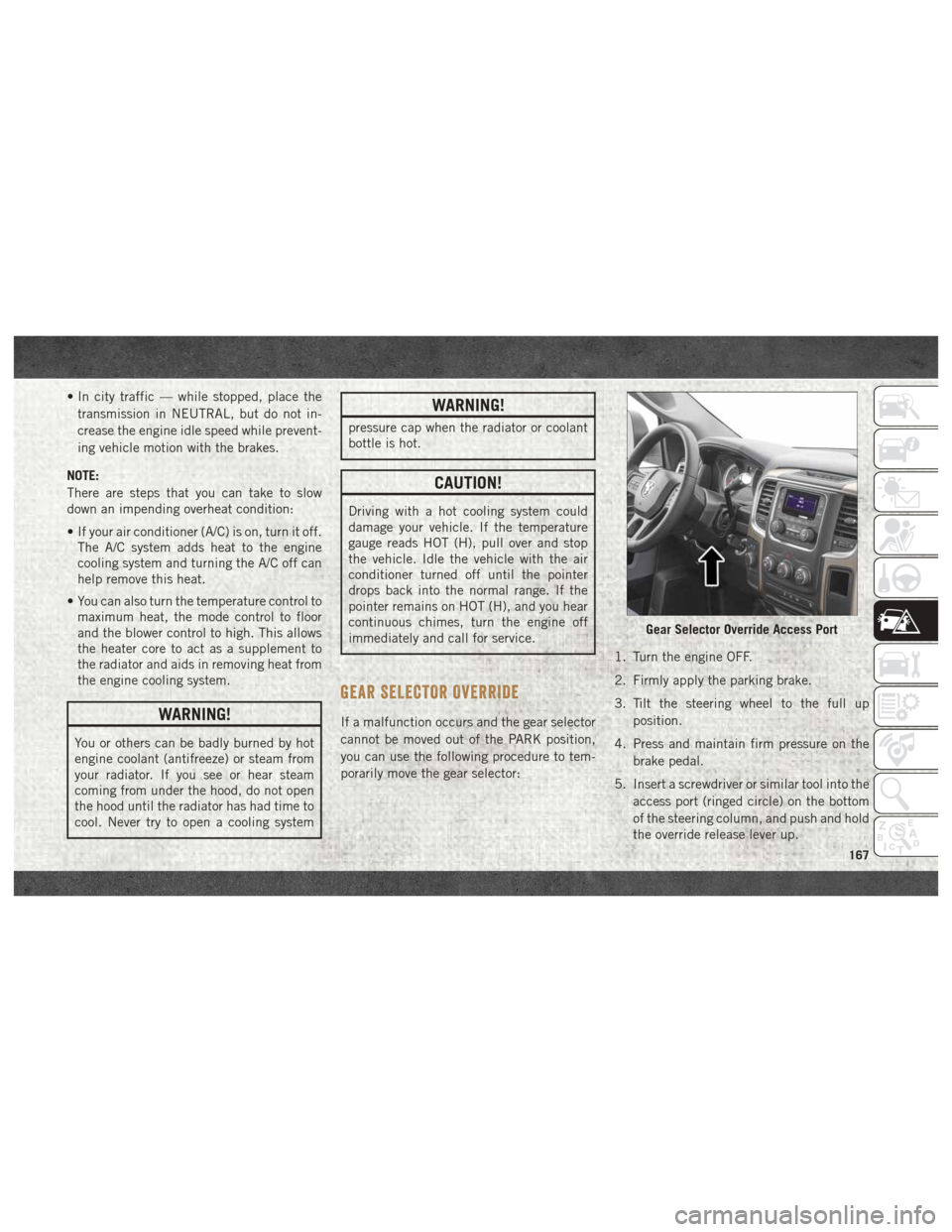

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector

cannot be moved out of the PARK position,

you can use the following procedure to tem-

porarily move the gear selector: 1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Tilt the steering wheel to the full up

position.

4. Press and maintain firm pressure on the brake pedal.

5. Insert a screwdriver or similar tool into the access port (ringed circle) on the bottom

of the steering column, and push and hold

the override release lever up.

Gear Selector Override Access Port

167

Page 170 of 298

6. Move the gear selector to the NEUTRALposition.

7. The vehicle may then be started in NEUTRAL.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand,

or snow, it can often be moved using a rock-

ing motion. Turn the steering wheel right and

left to clear the area around the front wheels.

Next, shift back and forth between DRIVE

and REVERSE (with automatic transmission)

or SECOND GEAR and REVERSE (with

manual transmission) while gently pressing

the accelerator. Use the least amount of ac-

celerator pedal pressure that will maintain

the rocking motion, without spinning the

wheels or racing the engine. NOTE:

Push the "ESC Off" switch, to place the Elec-

tronic Stability Control (ESC) system in "Par-

tial Off" mode, before rocking the vehicle.

Refer to “Electronic Brake Control System”

in “Safety” in the Owner’s Manual at

www.mopar.com/en-us/care/owners-manual.html

(U.S. Residents) or www.owners.mopar.ca

(Canadian Residents) for further information.

Once the vehicle has been freed, push the

"ESC Off" switch again to restore "ESC On"

mode.

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure,

of the axle and tires. A tire could explode

and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

CAUTION!

• Racing the engine or spinning the

wheels may lead to transmission over-

heating and failure. Allow the engine to

idle with the transmission in NEUTRAL

for at least one minute after every five

rocking-motion cycles. This will mini-

mize overheating and reduce the risk of

clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by shift-

ing between DRIVE/SECOND GEAR and

REVERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain

damage may result.

• Revving the engine or spinning the

wheels too fast may lead to transmission

overheating and failure. It can also dam-

age the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

IN CASE OF EMERGENCY

168

Page 175 of 298

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE................... .174

Maintenance Plan – Gasoline Engine . .175

Heavy Duty Use Of The Vehicle ......178

SCHEDULED MAINTENANCE —

6.7L CUMMINS DIESEL ENGINE.....178

Oil Change Indicator System — Cummins

Diesel.....................178

Perform Service Indicator — Cummins

Diesel .....................179

Maintenance Plan — Cummins Diesel

Engine .....................180

ENGINE COMPARTMENT .........184

6.4L Engine.................184

6.7L Diesel Engine — Six-Speed

AS69RC HD (3500/Chassis Cab

Models) ....................185

DEALER SERVICE —

6.7L DIESEL ENGINE ............186

Engine Air Cleaner Filter .........186

Draining Fuel/Water Separator Filter . .187

Engine Mounted Fuel Filter

Replacement .................188

Underbody Mounted Fuel Filter

Replacement .................189

Priming If The Engine Has Run Out

Of Fuel ....................190

HOISTING ................. .191

TIRES .................... .191

Tire Safety Information..........191

Tires — General Information .......199

Tire Types ...................203

Spare Tires — If Equipped .........204

Wheel And Wheel Trim Care .......206

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES . . . .207

Treadwear...................207

Traction Grades ...............207

Temperature Grades .............208

SERVICING AND MAINTENANCE

173

Page 176 of 298

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for scheduled

maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate.

This means that service is required for your

vehicle. Operating conditions such as fre-

quent short-trips, trailer tow, extremely hot or

cold ambient temperatures, and E85 fuel

usage will influence when the “Oil Change

Required” message is displayed. Severe Op-

erating Conditions can cause the change oil

message to illuminate as early as

3,500 miles (5,600 km) since last reset.

Have your vehicle serviced as soon as pos-

sible, within the next 500 miles (805 km).

Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change. If a scheduled oil

change is performed by someone other than

your authorized dealer, the message can bereset by referring to the steps described under

“Warning And Indicator Lights” or “Instru-

ment Cluster Display” in “Getting To Know

Your Instrument Panel” in your Owner’s

Manual at

www.mopar.com/en-us/care/

owner-manual.html (U.S. Residents) or

www.owners.mopar.ca (Canadian Residents)

for further information.

Gasoline Engines:

Under no circumstances should oil change

intervals exceed 8,000 miles (13,000 km),

twelve months or 350 hours of engine run

time, whichever comes first. The 350 hours

of engine run or idle time is generally only a

concern for fleet customers.

Severe Duty:

Change Engine Oil at 4,000 miles

(6,500 km) or 350 hours of engine run time

if the vehicle is operated in a dusty and off

road environment or is operated predomi-

nately at idle or very low engine RPM’s. This

type of vehicle use is considered Severe Duty. Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look

for unusual wear or damage

• Check the fluid levels of the coolant reser- voir, brake master cylinder, power steering

and automatic transmission, and fill as

needed

• Check function of all interior and exterior lights

SERVICING AND MAINTENANCE

174

Page 177 of 298

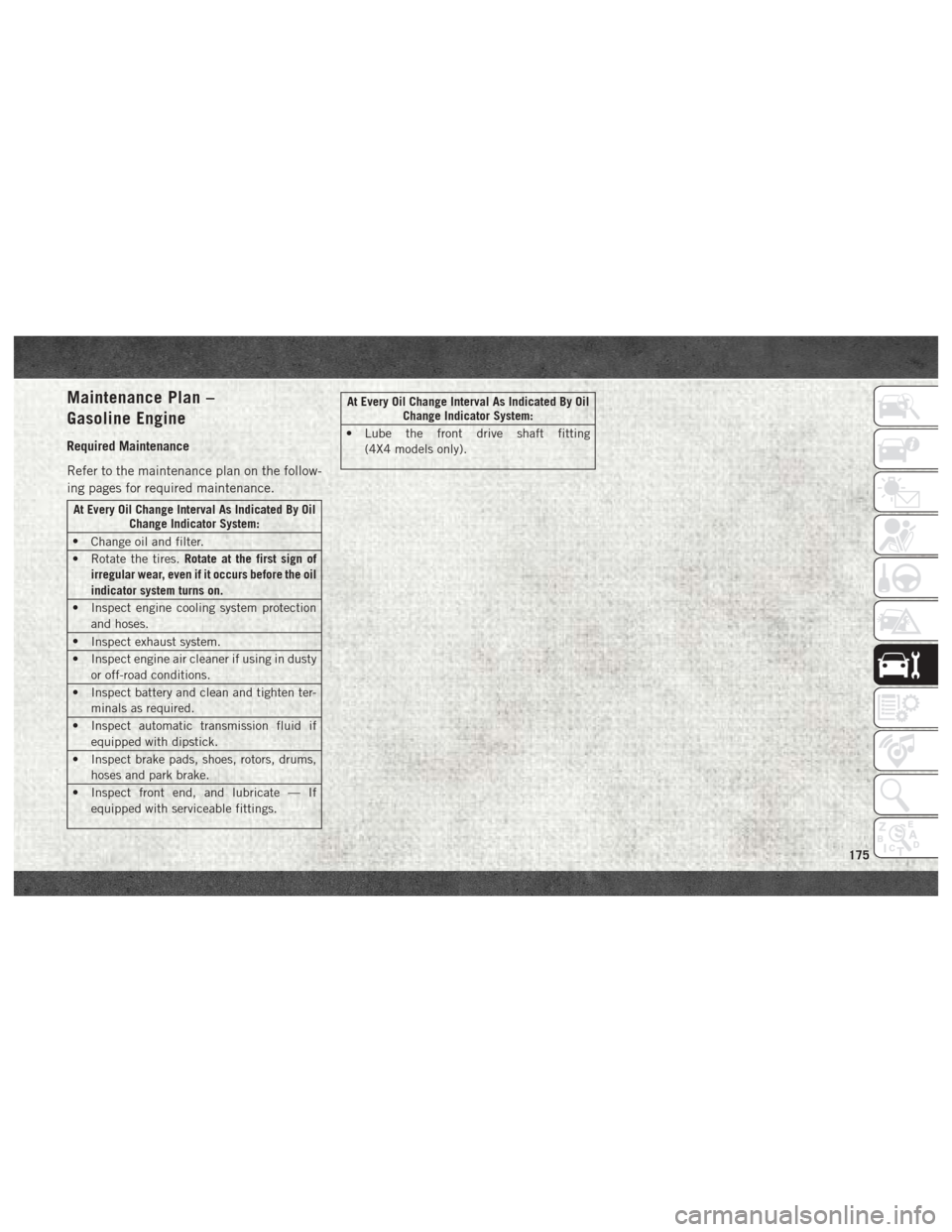

Maintenance Plan –

Gasoline Engine

Required Maintenance

Refer to the maintenance plan on the follow-

ing pages for required maintenance.

At Every Oil Change Interval As Indicated By OilChange Indicator System:

• Change oil and filter.

• Rotate the tires. Rotate at the first sign of

irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect engine cooling system protection and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or off-road conditions.

• Inspect battery and clean and tighten ter- minals as required.

• Inspect automatic transmission fluid if equipped with dipstick.

• Inspect brake pads, shoes, rotors, drums, hoses and park brake.

• Inspect front end, and lubricate — If equipped with serviceable fittings.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

• Lube the front drive shaft fitting (4X4 models only).

175

Page 178 of 298

Mileage or time passed (whichever comesfirst)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X

Inspect front suspension, tie rod ends, and

replace if necessary. XXX X X X X

Inspect the front and rear axle surfaces. If

gear oil leakage is suspected, check the

fluid level. If using your vehicle for police,

taxi, fleet, off-road or frequent trailer tow-

ing, change axle fluid. XXX X X X X

Inspect the brake linings, parking brake

function. XXX X X X X

Additional Maintenance

Replace engine air filter. X X X X X

Replace spark plugs. ** X

Flush and replace the engine coolant at

10 years or 150,000 miles (240,000 km)

whichever comes first. XX

Change the automatic transmission fluid

(AS66RC Transmission Only). XX X

Change the automatic transmission fluid

and sump filter (AS66RC Transmission

Only). XX

SERVICING AND MAINTENANCE

176

Page 180 of 298

Heavy Duty Use Of The Vehicle

Change engine oil at 4,000 miles (6,500 km)

or 350 hours of engine run time if the vehicle

is operated in a dusty and off road environ-

ment or is operated predominately at idle or

only very low engine RPM’s. This type of

vehicle use is considered Severe Duty.

SCHEDULED MAINTENANCE — 6.7L

CUMMINS DIESEL ENGINE

CAUTION!

Failure to perform the required mainte-

nance items may result in damage to the

vehicle.

At Each Stop For Fuel

Check the engine oil level at least 30 minutes

after a fully warmed engine is shut off.

Checking the oil level while the vehicle is on

level ground will improve the accuracy of the

oil level reading. Add oil only when the level

is at or below the ADD or MIN mark. Once A Month

• Inspect the batteries, and clean and

tighten the terminals as required.

• Check the fluid levels of the coolant reser- voir, brake master cylinder, and automatic

transmission (if equipped), and add as

needed.

At Each Oil Change

• Change the engine oil filter.

• Inspect the exhaust system.

• Inspect engine air filter.

• Check the coolant level, hoses, and clamps.

• Inspect front end, and lubricate — If equipped with serviceable fittings.

• Lube the front drive shaft fitting (4X4 mod- els only).

Inspection and service should also be per-

formed anytime a malfunction is observed or

suspected. Retain all receipts.

Oil Change Indicator System —

Cummins Diesel

Your vehicle is equipped with an engine oil

change indicator system. This system will

alert you when it is time to change your

engine oil by displaying the words “Oil

Change Due” in your instrument cluster dis-

play. The oil change reminder will remind the

owner to change the engine oil every

15,000 miles or 500 hours, whichever

comes first, except for the Chassis Cab mod-

els and Pickup models configured with op-

tional B20 capability that are using B20 bio-

diesel, which are 12,500 miles or 400 hours,

whichever comes first. Failure to change the

engine oil per the maintenance schedule can

result in internal engine damage.

Replace the engine oil and oil filter every

15,000 miles (24,000 km) or six months, or

sooner if prompted by the oil change indicator

system. Under no circumstances should oil

change intervals exceed 15,000 miles

(24,000 km) or six months, whichever comes

first.

SERVICING AND MAINTENANCE

178

Page 181 of 298

NOTE:

• Under no circumstances should oil changeintervals exceed 15,000 miles

(24,000 km) or six months or 500 Hours,

whichever comes first.

• Replace the engine oil and oil filter every 12,500 miles (20 000 km) when running

B20 fuel (Chassis Cab Only).

If Chassis Cab models and Pickup models

configured with optional B20 capability are

operated with greater than 5% levels of bio-

diesel, the oil change interval must not ex-

ceed 12,500 miles (20 000 km) under any

circumstances. See the Fuel Requirements

section for more information regarding opera-

tion of Chassis Cab models and Pickup mod-

els configured for use with biodiesel blend

(B6-B20) fuel meeting ASTM specification

D-7467.Perform Service Indicator —

Cummins Diesel

Your vehicle will require emissions mainte-

nance at a set interval. To help remind you

when this maintenance is due, the instru-

ment cluster will display “Perform Service”.

When the “Perform Service” message is dis-

played on the instrument cluster it is neces-

sary to have the emissions maintenance per-

formed. Emissions maintenance may include

replacing the Closed Crankcase Ventilation

(CCV) filter element. The procedure for clear-

ing and resetting the “Perform Service” indi-

cator message is located in the appropriate

Service Information.

179