flat tire Ram 4500 Chassis Cab 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 67 of 298

— Tire Pressure Monitoring System

(TPMS) Warning Light

The warning light switches on and a message

is displayed to indicate that the tire pressure

is lower than the recommended value and/or

that slow pressure loss is occurring. In these

cases, optimal tire duration and fuel con-

sumption may not be guaranteed.

Should one or more tires be in the condition

mentioned above, the display will show the

indications corresponding to each tire in

sequence.

CAUTION!

Do not continue driving with one or more

flat tires as handling may be compro-

mised. Stop the vehicle, avoiding sharp

braking and steering. If a tire puncture

occurs, repair immediately using the dedi-

cated tire repair kit and contact your au-

thorized dealer as soon as possible.

Each tire, including the spare (if provided),

should be checked monthly when cold and

inflated to the inflation pressure recom-

mended by the vehicle manufacturer on the vehicle placard or tire inflation pressure la-

bel. (If your vehicle has tires of a different

size than the size indicated on the vehicle

placard or tire inflation pressure label, you

should determine the proper tire inflation

pressure for those tires.)

As an added safety feature, your vehicle has

been equipped with a tire pressure monitor-

ing system (TPMS) that illuminates a low tire

pressure telltale when one or more of your

tires is significantly under-inflated. Accord-

ingly, when the low tire pressure telltale illu-

minates, you should stop and check your tires

as soon as possible, and inflate them to the

proper pressure. Driving on a significantly

under-inflated tire causes the tire to overheat

and can lead to tire failure. Under-inflation

also reduces fuel efficiency and tire tread

life, and may affect the vehicle’s handling

and stopping ability.

Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the

driver’s responsibility to maintain correct tire

pressure, even if under-inflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate when

the system is not operating properly. The

TPMS malfunction indicator is combined

with the low tire pressure telltale. When the

system detects a malfunction, the telltale will

flash for approximately one minute and then

remain continuously illuminated. This se-

quence will continue upon subsequent ve-

hicle start-ups as long as the malfunction

exists. When the malfunction indicator is

illuminated, the system may not be able to

detect or signal low tire pressure as intended.

TPMS malfunctions may occur for a variety of

reasons, including the installation of replace-

ment or alternate tires or wheels on the ve-

hicle that prevent the TPMS from functioning

properly. Always check the TPMS malfunc-

tion telltale after replacing one or more tires

or wheels on your vehicle to ensure that the

replacement or alternate tires and wheels

allow the TPMS to continue to function

properly.

65

Page 74 of 298

AUXILIARY DRIVING SYSTEMS

Tire Pressure Monitoring System

(TPMS)

The Tire Pressure Monitor System (TPMS)

will warn the driver of a low tire pressure

based on the vehicle recommended cold

placard pressure.

The tire pressure will vary with temperature

by about 1 psi (7 kPa) for every 12°F (6.5°C).

This means that when the outside tempera-

ture decreases, the tire pressure will de-

crease. Tire pressure should always be set

based on cold inflation tire pressure. This is

defined as the tire pressure after the vehicle

has not been driven for at least three hours, or

driven less than 1 mile (1.6 km) after a three

hour period. The cold tire inflation pressure

must not exceed the maximum inflation pres-

sure molded into the tire sidewall. Refer to

“Tires” in “Servicing And Maintenance” for

information on how to properly inflate the

vehicle’s tires. The tire pressure will also

increase as the vehicle is driven - this is

normal and there should be no adjustment for

this increased pressure.The TPMS will warn the driver of a low tire

pressure if the tire pressure falls below the

low-pressure warning limit for any reason,

including low temperature effects and natu-

ral pressure loss through the tire.

The TPMS will continue to warn the driver of

low tire pressure as long as the condition

exists, and will not turn off until the tire

pressure is at or above the recommended

cold placard pressure. Once the low tire pres-

sure warning (Tire Pressure Monitoring [TPM]

Telltale Light) illuminates, you must increase

the tire pressure to the recommended cold

placard pressure in order for the TPM Telltale

Light to turn off. The system will automati-

cally update and the TPM Telltale Light will

turn off once the system receives the updated

tire pressures. The vehicle may need to be

driven for up to 20 minutes above 15 mph

(24 km/h) in order for the TPMS to receive

this information.

NOTE:

When filling warm tires, the tire pressure may

need to be increased up to an additional 4 psi

(30 kPa) above the recommended cold plac-

ard pressure in order to turn the Tire Pressure

Monitoring Telltale Light off.

For example, your vehicle may have a recom-

mended cold (parked for more than three

hours) placard pressure of 30 psi (207 kPa).

If the ambient temperature is 68°F (20°C)

and the measured tire pressure is 27 psi

(186 kPa), a temperature drop to 20°F (-7°C)

will decrease the tire pressure to approxi-

mately 23 psi (158 kPa). This tire pressure is

sufficiently low enough to turn on the TPM

Telltale Light. Driving the vehicle may cause

the tire pressure to rise to approximately

27 psi (186 kPa), but the TPM Telltale Light

will still be on. In this situation, the TPM

Telltale Light will turn off only after the tires

are inflated to the vehicle’s recommended

cold placard pressure value.

SAFETY

72

Page 75 of 298

CAUTION!

• The TPMS has been optimized for theoriginal equipment tires and wheels.

TPMS pressures and warning have been

established for the tire size equipped on

your vehicle. Undesirable system opera-

tion or sensor damage may result when

using replacement equipment that is not

of the same size, type, and/or style.

Aftermarket wheels can cause sensor

damage.

• Using aftermarket tire sealants may

cause the Tire Pressure Monitoring Sys-

tem (TPMS) sensor to become inoper-

able. After using an aftermarket tire

sealant it is recommended that you take

your vehicle to an authorized dealership

to have your sensor function checked.

• After inspecting or adjusting the tire

pressure always reinstall the valve stem

cap. This will prevent moisture and dirt

from entering the valve stem, which

could damage the TPMS sensor. NOTE:

• The TPMS is not intended to replace nor-

mal tire care and maintenance or to provide

warning of a tire failure or condition.

• The TPMS should not be used as a tire pressure gauge while adjusting your tire

pressure.

• Driving on a significantly under-inflated tire causes the tire to overheat and can lead to

tire failure. Under-inflation also reduces

fuel efficiency and tire tread life, and may

affect the vehicle’s handling and stopping

ability.

• The TPMS is not a substitute for proper tire maintenance, and it is the driver’s respon-

sibility to maintain correct tire pressure

using an accurate tire pressure gauge, even

if under-inflation has not reached the level

to trigger illumination of the TPM Telltale

Light.

• Seasonal temperature changes will affect tire pressure, and the TPMS will monitor

the actual tire pressure in the tire.

Premium System

The Tire Pressure Monitor System (TPMS)

uses wireless technology with wheel rim

mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire

pressure readings to the receiver module.

NOTE:

It is particularly important for you to check

the tire pressure in all of the tires on your

vehicle monthly and to maintain the proper

pressure.

The TPMS consists of the following compo-

nents:

• Receiver module

• Four tire pressure monitoring sensors

• Various tire pressure monitoring systemmessages, which display in the instrument

cluster

• Tire pressure monitoring telltale light

Tire Pressure Monitoring Low Pressure Warnings

73

Page 76 of 298

The “Tire Pressure Monitoring Telltale Light”

will illuminate in the instrument cluster and

a chime will sound when tire pressure is low

in one or more of the four active road tires. In

addition, the instrument cluster will display a

graphic showing the pressure values of each

tire with the low tire pressure values in a

different color. An "Inflate to XX" message

will also be displayed.

Should this occur, you should stop as soon as

possible and inflate the tires with a low pres-

sure condition (those in a different color inthe instrument cluster graphic) to the vehi-

cle’s recommended cold placard pressure in-

flation value as shown in the "Inflate to XX"

message. Once the system receives the up-

dated tire pressures, the system will auto-

matically update, the graphic display in the

instrument cluster will return to it’s original

color, and the “Tire Pressure Monitoring Tell-

tale Light” will turn off. The vehicle may need

to be driven for up to 20 minutes above

15 mph (24 km/h) in order for the TPMS to

receive this information.

Service TPMS Warning

If a system fault is detected, the “Tire Pres-

sure Monitoring Telltale Light” will flash on

and off for 75 seconds and then remain on

solid. The system fault will also sound a

chime. In addition, the instrument cluster

will display a "SERVICE TPM SYSTEM" mes-

sage for a minimum of five seconds and then

display dashes (- -) in place of the pressure

value to indicate which sensor is not being

received.

If the ignition switch is cycled, this sequence

will repeat, providing the system fault still

exists. If the system fault no longer exists, the

“Tire Pressure Monitoring Telltale Light” will

no longer flash, and the "SERVICE TPM SYS-

TEM" message will no longer display, and a

pressure value will display in place of the

dashes. A system fault can occur due to any

of the following:

“LOW TIRE PRESSURE” Message

Tire Pressure Monitor Display

SAFETY

74

Page 119 of 298

WARNING!

control. To prevent SERIOUS INJURY or

DEATH:

• ALWAYS securely attach

your floor

mat using the floor mat fasteners. DO

NOT install your floor mat upside down

or turn your floor mat over. Lightly pull to

confirm mat is secured using the floor

mat fasteners on a regular basis.

• ALWAYS REMOVE THE EXISTING

FLOOR MAT FROM THE VEHICLE

before installing any other floor mat.

NEVER install or stack an additional

floor mat on top of an existing floor mat.

• ONLY install floor mats designed to fit

your vehicle. NEVER install a floor mat

that cannot be properly attached and

secured to your vehicle. If a floor mat

needs to be replaced, only use a FCA

approved floor mat for the specific

make, model, and year of your vehicle.

• ONLY use the driver’s side floor mat on

the driver’s side floor area. To check for

interference, with the vehicle properly

parked with the engine off, fully depress

the accelerator, the brake, and the

WARNING!

clutch pedal (if present) to check for

interference. If your floor mat interferes

with the operation of any pedal, or is not

secure to the floor, remove the floor mat

from the vehicle and place the floor mat

in your trunk.

• ONLY use the passenger’s side floor mat

on the passenger’s side floor area.

• ALWAYS make sure objects cannot fall

or slide into the driver’s side floor area

when the vehicle is moving. Objects can

become trapped under accelerator,

brake, or clutch pedals and could cause

a loss of vehicle control.

• NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These ob-

jects could change the position of the

floor mat and may cause interference

with the accelerator, brake, or clutch

pedals.

• If the vehicle carpet has been removed

and re-installed, always properly attach

carpet to the floor and check the floor

mat fasteners are secure to the vehicle

carpet. Fully depress each pedal to

WARNING!

check for interference with the accelera-

tor, brake, or clutch pedals then re-

install the floor mats.

• It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat

has been properly installed and is se-

cured to your vehicle using the floor mat

fasteners by lightly pulling mat.

Periodic Safety Checks You

Should Make Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones,

nails, glass, or other objects lodged in the

tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts,

cracks, and bulges. Check the wheel bolts for

tightness. Check the tires (including spare)

for proper cold inflation pressure.

117

Page 155 of 298

IN CASE OF EMERGENCY

HAZARD WARNING FLASHERS.....154

BULB REPLACEMENT ...........154

Replacement Bulbs.............154

FUSES.................... .155

Power Distribution Center.........155

JACKING AND TIRE CHANGING .....160

4500/5500 Models.............160

Preparations For Jacking ..........160

Jacking Instructions 4500 And

5500 Series .................161 To Stow The Flat Or Spare —

If Equipped

.................163

Hub Caps/Wheel Covers —

If Equipped .................163

JUMP STARTING ..............164

Preparations For Jump Start ........164

Jump Starting Procedure ..........165

IF YOUR ENGINE OVERHEATS ......166

GEAR SELECTOR OVERRIDE .......167FREEING A STUCK VEHICLE

.......168

TOWING A DISABLED VEHICLE .....169

Two-Wheel Drive Models..........170

Four-Wheel Drive Models ..........170

Emergency Tow Hooks — If Equipped . .171

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS) ................... .171

EVENT DATA RECORDER (EDR) ......171

IN CASE OF EMERGENCY

153

Page 163 of 298

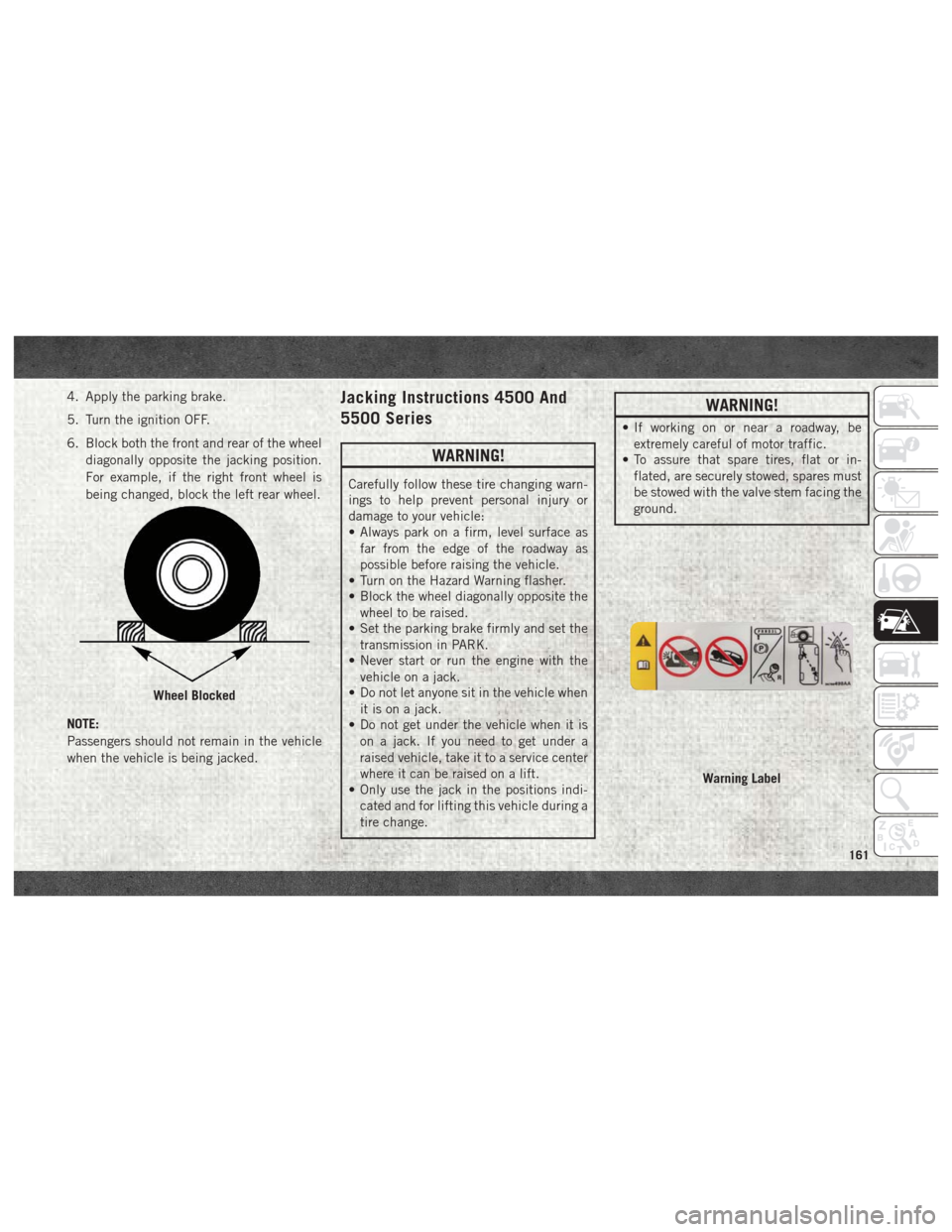

4. Apply the parking brake.

5. Turn the ignition OFF.

6. Block both the front and rear of the wheeldiagonally opposite the jacking position.

For example, if the right front wheel is

being changed, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.Jacking Instructions 4500 And

5500 Series

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the

wheel to be raised.

• Set the parking brake firmly and set the

transmission in PARK.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

Wheel Blocked

Warning Label

161

Page 164 of 298

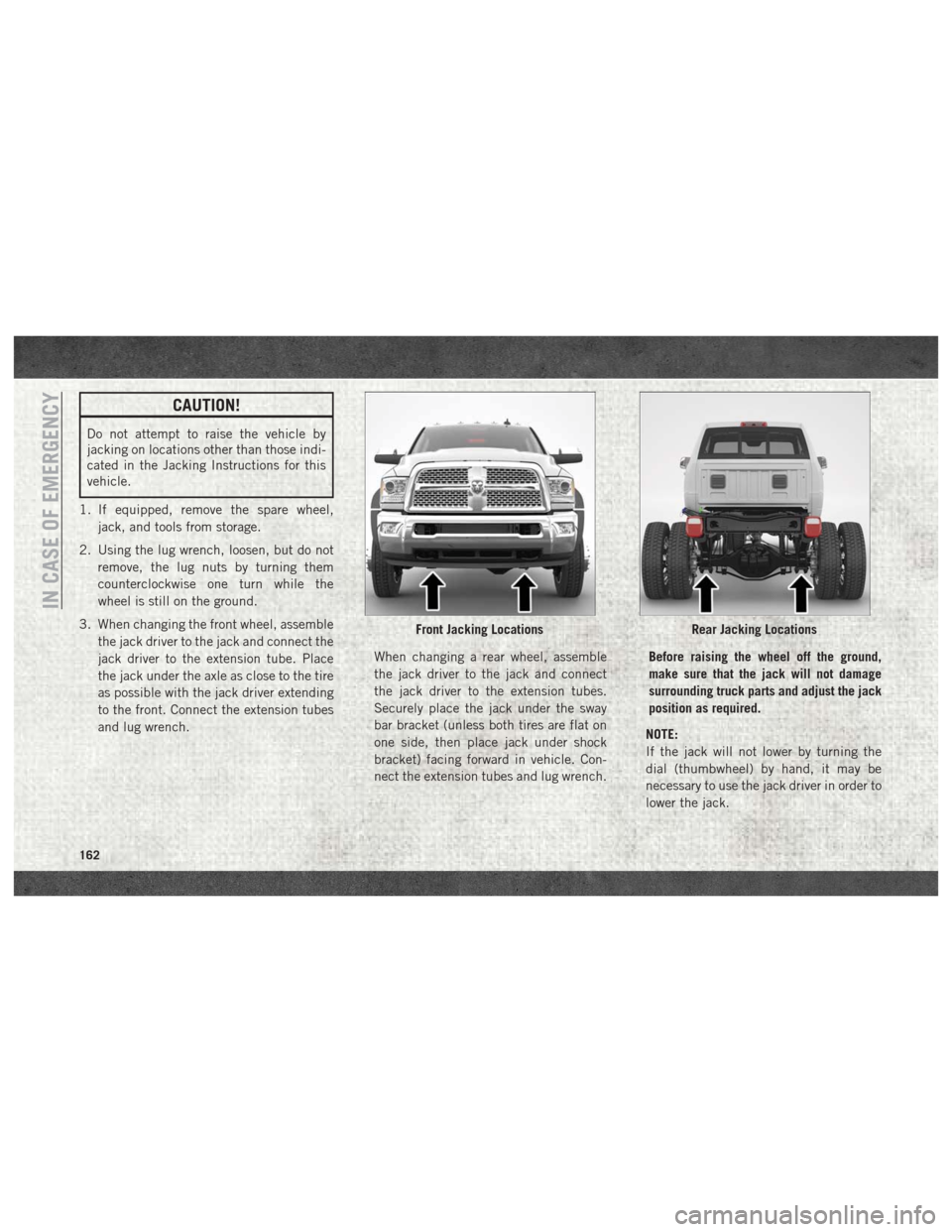

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

1. If equipped, remove the spare wheel, jack, and tools from storage.

2. Using the lug wrench, loosen, but do not remove, the lug nuts by turning them

counterclockwise one turn while the

wheel is still on the ground.

3. When changing the front wheel, assemble the jack driver to the jack and connect the

jack driver to the extension tube. Place

the jack under the axle as close to the tire

as possible with the jack driver extending

to the front. Connect the extension tubes

and lug wrench. When changing a rear wheel, assemble

the jack driver to the jack and connect

the jack driver to the extension tubes.

Securely place the jack under the sway

bar bracket (unless both tires are flat on

one side, then place jack under shock

bracket) facing forward in vehicle. Con-

nect the extension tubes and lug wrench.Before raising the wheel off the ground,

make sure that the jack will not damage

surrounding truck parts and adjust the jack

position as required.

NOTE:

If the jack will not lower by turning the

dial (thumbwheel) by hand, it may be

necessary to use the jack driver in order to

lower the jack.

Front Jacking LocationsRear Jacking Locations

IN CASE OF EMERGENCY

162

Page 165 of 298

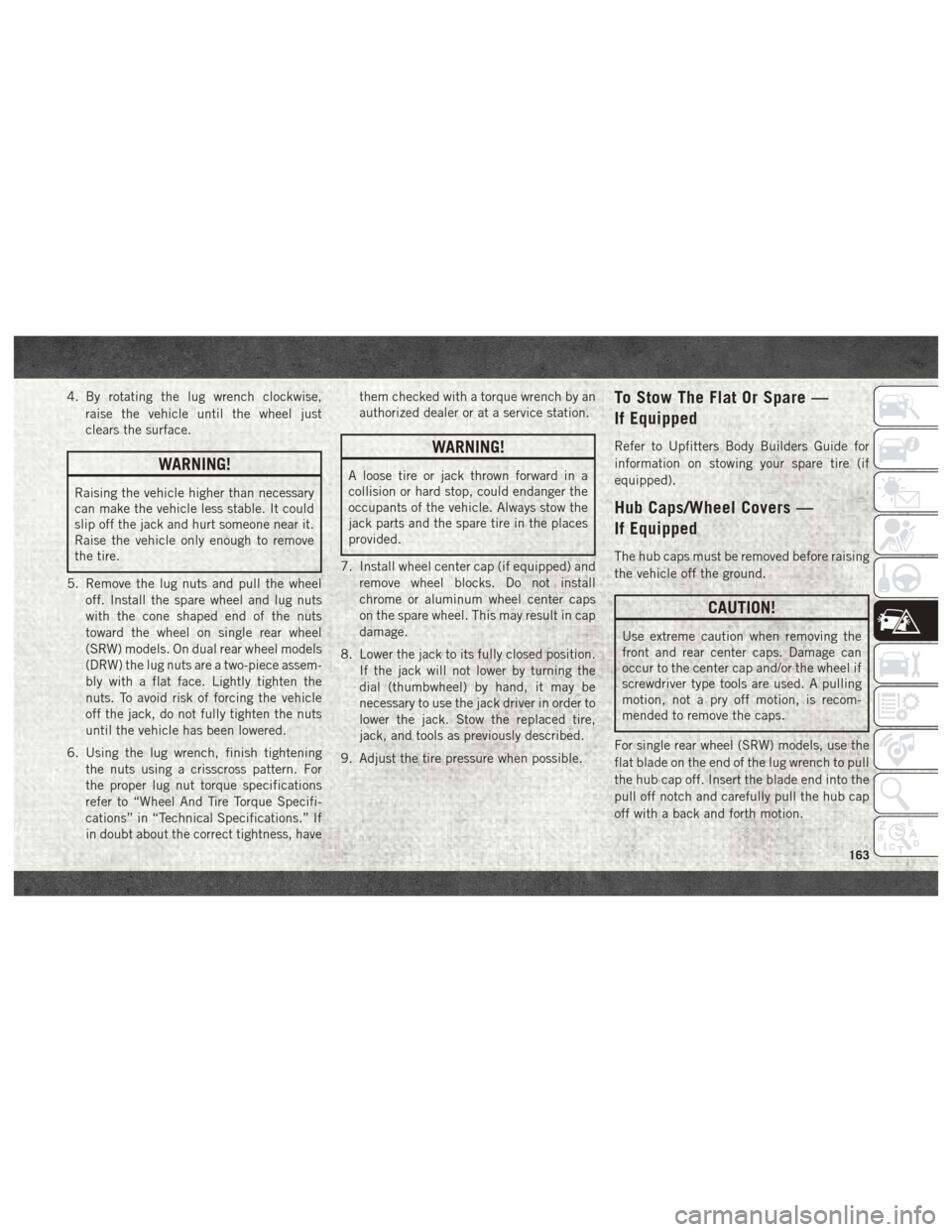

4. By rotating the lug wrench clockwise,raise the vehicle until the wheel just

clears the surface.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

5. Remove the lug nuts and pull the wheel off. Install the spare wheel and lug nuts

with the cone shaped end of the nuts

toward the wheel on single rear wheel

(SRW) models. On dual rear wheel models

(DRW) the lug nuts are a two-piece assem-

bly with a flat face. Lightly tighten the

nuts. To avoid risk of forcing the vehicle

off the jack, do not fully tighten the nuts

until the vehicle has been lowered.

6. Using the lug wrench, finish tightening the nuts using a crisscross pattern. For

the proper lug nut torque specifications

refer to “Wheel And Tire Torque Specifi-

cations” in “Technical Specifications.” If

in doubt about the correct tightness, have them checked with a torque wrench by an

authorized dealer or at a service station.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided.

7. Install wheel center cap (if equipped) and remove wheel blocks. Do not install

chrome or aluminum wheel center caps

on the spare wheel. This may result in cap

damage.

8. Lower the jack to its fully closed position. If the jack will not lower by turning the

dial (thumbwheel) by hand, it may be

necessary to use the jack driver in order to

lower the jack. Stow the replaced tire,

jack, and tools as previously described.

9. Adjust the tire pressure when possible.

To Stow The Flat Or Spare —

If Equipped

Refer to Upfitters Body Builders Guide for

information on stowing your spare tire (if

equipped).

Hub Caps/Wheel Covers —

If Equipped

The hub caps must be removed before raising

the vehicle off the ground.

CAUTION!

Use extreme caution when removing the

front and rear center caps. Damage can

occur to the center cap and/or the wheel if

screwdriver type tools are used. A pulling

motion, not a pry off motion, is recom-

mended to remove the caps.

For single rear wheel (SRW) models, use the

flat blade on the end of the lug wrench to pull

the hub cap off. Insert the blade end into the

pull off notch and carefully pull the hub cap

off with a back and forth motion.

163

Page 166 of 298

On 3500 models with dual rear wheels

(DRW), you must first remove the hub caps.

The jack handle driver has a hook at one end

that will fit in the pull off notch of the rear

hub caps. Position the hook and pull straight

out on the ratchet firmly. The hub cap should

pop off. The wheel skins can now be re-

moved. For the front hub cap, use the flat

blade on the end of the lug wrench to pull the

caps off. The wheel skin can now be removed.

CAUTION!

• Use a pulling motion to remove the hubcap. Do not use a twisting motion when

removing the hub cap, damage to the

hub cap; finish may occur.

• The rear hub caps on the dual rear wheel

has two pull off notches. Make sure that

the hook of the jack handle driver is

located squarely in the cap notch before

attempting to pull off.

You must use the flat end of the lug wrench to

pull off the wheel skins. Locate the hub cap

pull notches (2 notches on each cap). Insert the flat tip completely and using a back and

forth motion, loosen the wheel skin. Repeat

this procedure around the tire until the skin

pops off.

Replace the wheel skins first using a rubber

mallet. When replacing the hub caps, tilt the

cap retainer over the lug nut bolt circle and

strike the high side down with a rubber mal-

let. Be sure that the hub caps and wheel

skins are firmly seated around the wheel.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so

please follow the procedures in this section

carefully.

WARNING!

Do not attempt jump starting if the battery

is frozen. It could rupture or explode and

cause personal injury.

CAUTION!

Do not use a portable battery booster pack

or any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

NOTE:

When using a portable battery booster pack,

follow the manufacturer's operating instruc-

tions and precautions.

Preparations For Jump Start

The battery in your vehicle is located in the

front of the engine compartment, behind the

left headlight assembly.

IN CASE OF EMERGENCY

164