technical specifications RAM CHASSIS CAB 2021 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2021Pages: 463, PDF Size: 21.5 MB

Page 3 of 463

TABLE OF CONTENTS

1

2

3

4

5

6

7

8

9

10

11

1 INTRODUCTION .............................................................................................................................. 9

2 GETTING TO KNOW YOUR VEHICLE ..................................................................................15

3 GETTING TO KNOW YOUR INSTRUMENT PANEL ....................................................... 80

4 STARTING AND OPERATING ................................................................................................ 118 5 MULTIMEDIA .............................................................................................................................. 220

6 SAFETY ........................................................................................................................................ 273 7 IN CASE OF EMERGENCY .................................................................................................... 334

8 SERVICING AND MAINTENANCE ...................................................................................... 353

9 TECHNICAL SPECIFICATIONS ............................................................................................. 431

10 CUSTOMER ASSISTANCE .....................................................................................................445 11 INDEX ............................................................................................................................................ 450

21_DPF_OM_EN_USC_t.book Page 1

Page 9 of 463

7

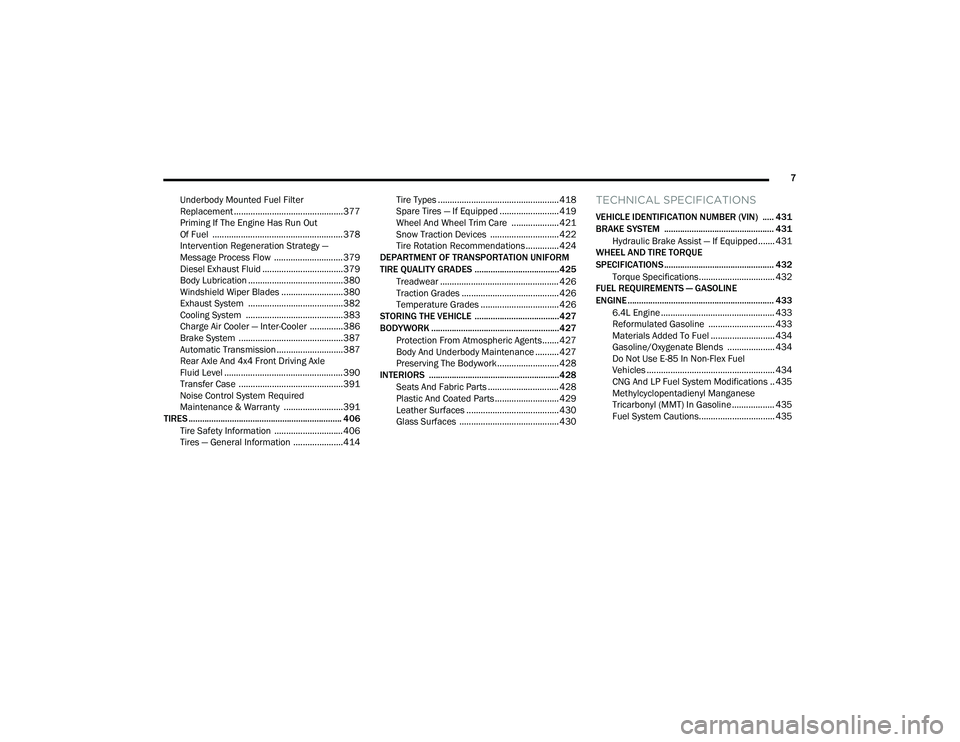

Underbody Mounted Fuel Filter

Replacement ..............................................377 Priming If The Engine Has Run Out

Of Fuel .......................................................378 Intervention Regeneration Strategy —

Message Process Flow .............................379 Diesel Exhaust Fluid ..................................379Body Lubrication ........................................380

Windshield Wiper Blades ..........................380

Exhaust System ........................................382

Cooling System .........................................383

Charge Air Cooler — Inter-Cooler ..............386

Brake System ............................................387

Automatic Transmission ............................387

Rear Axle And 4x4 Front Driving Axle

Fluid Level .................................................. 390 Transfer Case ............................................391

Noise Control System Required

Maintenance & Warranty .........................391

TIRES ................................................................... 406

Tire Safety Information .............................406Tires — General Information .....................414 Tire Types ................................................... 418

Spare Tires — If Equipped ......................... 419

Wheel And Wheel Trim Care .................... 421

Snow Traction Devices ............................. 422

Tire Rotation Recommendations .............. 424

DEPARTMENT OF TRANSPORTATION UNIFORM

TIRE QUALITY GRADES .....................................425

Treadwear .................................................. 426

Traction Grades ......................................... 426

Temperature Grades ................................. 426

STORING THE VEHICLE .....................................427

BODYWORK ........................................................ 427

Protection From Atmospheric Agents....... 427

Body And Underbody Maintenance .......... 427Preserving The Bodywork .......................... 428

INTERIORS ......................................................... 428

Seats And Fabric Parts .............................. 428

Plastic And Coated Parts ........................... 429

Leather Surfaces ....................................... 430Glass Surfaces .......................................... 430

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN) ..... 431

BRAKE SYSTEM ................................................ 431

Hydraulic Brake Assist — If Equipped....... 431

WHEEL AND TIRE TORQUE

SPECIFICATIONS ................................................ 432

Torque Specifications................................ 432

FUEL REQUIREMENTS — GASOLINE

ENGINE ................................................................ 433

6.4L Engine ................................................ 433

Reformulated Gasoline ............................ 433Materials Added To Fuel ........................... 434

Gasoline/Oxygenate Blends .................... 434Do Not Use E-85 In Non-Flex Fuel

Vehicles ...................................................... 434 CNG And LP Fuel System Modifications .. 435Methylcyclopentadienyl Manganese

Tricarbonyl (MMT) In Gasoline .................. 435 Fuel System Cautions................................ 435

21_DPF_OM_EN_USC_t.book Page 7

Page 12 of 463

10

SYMBOLS KEY

If you do not read this entire Owner’s Manual, you may miss important

information. Observe all Cautions and Warnings.

VAN CONVERSIONS/CAMPERS

The New Vehicle Limited Warranty does not apply to body modifications or

special equipment installed by van conversion/camper manufacturers/

body builders. US residents refer to the Warranty Information, Section

2.1.C. Canadian residents refer to the “What Is Not Covered” section of

the Warranty Information. Such equipment includes video monitors,

DVD/Blu-Ray™, heaters, stoves, refrigerators, etc. For warranty coverage

and service on these items, contact the applicable manufacturer.

Operating instructions for the special equipment installed by the

conversion/camper manufacturer should also be supplied with your

vehicle. For any additional instructions, please contact your conversion/

camper manufacturer.

To obtain dimensional and technical specifications for your vehicle,

refer to the Body Builder’s Guide at https://www.ramtrucks.com/

ram-commercial/body-builders-guide.html.

VEHICLE MODIFICATIONS/ALTERATIONS

WARNING!These statements are against operating

procedures that could result in a collision,

bodily injury and/or death.

CAUTION! These statements are against procedures that

could result in damage to your vehicle.

NOTE: A suggestion which will improve installation,

operation, and reliability. If not followed, may

result in damage.

TIP: General ideas/solutions/suggestions on easier

use of the product or functionality.

PAGE REFERENCE

ARROW

Follow this reference for additional information

on a particular feature.

FOOTNOTE Supplementary and relevant information

pertaining to the topic.

WARNING!

Any modifications or alterations to this vehicle could seriously affect its

roadworthiness and safety and may lead to a collision resulting in

serious injury or death.

21_DPF_OM_EN_USC_t.book Page 10

Page 433 of 463

431

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of

the instrument panel, visible through the

windshield.

Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for

example, repeated brake applications with

the engine off), the brakes will still function.

However, you will experience a substantial

increase in braking effort to stop the vehicle.

If either the front or rear hydraulic system loses

normal braking capability, the remaining system

will still function with some loss of overall braking

effectiveness. This will be evident by increased

pedal travel during application, greater pedal

force required to slow or stop, and activation of

the “Brake Warning Light” and/or the “ABS

Warning Light” during brake use.

HYDRAULIC BRAKE ASSIST — IF

E

QUIPPED

The brake system power assist is provided by a

hydro-boost unit which shares fluid with the

power steering system. You may experience

some clicking or hissing noises from the

hydro-boost system during hard braking

conditions.

NOTE:

Under cold temperatures, pedal effort will be

higher than normal until the power steering fluid

reaches operating temperature.

9

21_DPF_OM_EN_USC_t.book Page 431

Page 434 of 463

432TECHNICAL SPECIFICATIONS

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening. Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

NOTE:

Dual wheels are flat mounted, center piloted.

The lug nuts are a two-piece assembly. When

the tires are being rotated or replaced, clean

these lug nuts and add two drops of oil at the

interface between the hex and the washer.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it half way).

Oil Interface Location

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

Wheel Mounting Surface

Retighten the wheel nuts in the same sequence

to the torques listed in the table. Go through the

sequence a second time to verify that specific

torque has been achieved. Retighten to

specifications after 25 miles (40 km) and check

the lug nut/bolt torque to be sure that all the lug

nuts/bolts are properly tightened.

Lug Nut/Bolt

Torque

Lug

Nut/Bolt

Type**Lug

Nut/Bolt

Size Lug Nut/

Bolt

Socket

Size

120-150

Ft-Lbs

(160-200 N·m) Cone

M14 x

1.50 22 mm

130-160

Ft-Lbs

(190-220 N·m) Flanged

21_DPF_OM_EN_USC_t.book Page 432

Page 435 of 463

TECHNICAL SPECIFICATIONS433

8/10 Lug Nuts/Bolts Torque Patterns

It is recommended that wheel stud nuts be kept

torqued to specifications at all times. Torque

wheel stud nuts to specifications at each

lubrication interval.

All wheel nuts should be tightened occasionally

to eliminate the possibility of wheel studs being

sheared or the bolt holes in the wheels becoming

elongated. This is especially important during the

first few hundred miles/kilometers of operation

to allow the wheel nuts to become properly set.

All wheel nuts should first be firmly seated

against the wheel. The wheel nuts should then be

tightened to recommended torque. Tighten the wheel nuts to final torque in increments.

Progress around the bolt circle, tightening the

wheel nut opposite to the wheel nut just

previously tightened until final torque is

achieved.

FUEL REQUIREMENTS — GASOLINE ENGINE

While operating on gasoline with the required

octane number, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see a dealer immediately. Use

of gasoline with a lower than recommended

octane number can cause engine failure and

may void or not be covered by the New Vehicle

Limited Warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand of

gasoline before considering service for the vehicle.

6.4L ENGINE

Do not use E-85 flex fuel or ethanol blends

greater than 15% in this engine.

This engine is designed to meet all

emissions regulations and provide

satisfactory fuel economy and

performance when using high quality

unleaded gasoline having a posted octane number

of 87 as specified by the (R+M)/2 method.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as

“reformulated gasoline”. Reformulated

gasoline contains oxygenates and are

specifically blended to reduce vehicle

emissions and improve air quality.

The use of reformulated gasoline is

recommended. Properly blended reformulated

gasoline will provide improved performance

and durability of engine and fuel system

components.

1 — 10 Bolt Pattern

2 — 8 Bolt Pattern

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully until

the vehicle has been lowered. Failure to follow

this warning may result in personal injury.

9

21_DPF_OM_EN_USC_t.book Page 433

Page 436 of 463

434TECHNICAL SPECIFICATIONS

MATERIALS ADDED TO FUEL

Besides using unleaded gasoline with the

proper octane rating, gasolines that contain

detergents, corrosion and stability additives are

recommended. Using gasolines that have these

additives will help improve fuel economy,

reduce emissions, and maintain vehicle

performance.

Designated TOP TIER Detergent

Gasoline contains a higher level

of detergents to further aide in

minimizing engine and fuel system

deposits. When available, the usage of TOP

TIER Detergent Gasoline is recommended. Visit

www.toptiergas.com for a list of TOP TIER

Detergent Gasoline Retailers.

Indiscriminate use of fuel system cleaning

agents should be avoided. Many of these

materials intended for gum and varnish

removal may contain active solvents or similar

ingredients. These can harm fuel system gasket

and diaphragm materials.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline

with oxygenates such as ethanol.

Problems that result from using gasoline

containing more than 15% ethanol (E-15) or

gasoline containing methanol are not the

responsibility of the manufacturer and may void

or not be covered under New Vehicle Limited

Warranty.

DO NOT USE E-85 IN NON-FLEX FUEL

V

EHICLES

Non-Flex Fuel Vehicles (FFV) are compatible

with gasoline containing up to 15% ethanol

(E-15). Use of gasoline with higher ethanol

content may void the New Vehicle Limited

Warranty.

If a Non-FFV vehicle is inadvertently fueled with

E-85 fuel, the engine will have some or all of

these symptoms:

Operate in a lean mode.

OBD II Malfunction Indicator Light on.

Poor engine performance.

Poor cold start and cold drivability.

Increased risk for fuel system component

corrosion.

CAUTION!

DO NOT use E-85, gasoline containing

methanol, or gasoline containing more than

15% ethanol (E-15). Use of these blends may

result in starting and drivability problems,

damage critical fuel system components,

cause emissions to exceed the applicable

standard, and/or cause the Malfunction

Indicator Light to illuminate. Please observe

pump labels as they should clearly

communicate if a fuel contains greater than

15% ethanol (E-15).

21_DPF_OM_EN_USC_t.book Page 434

Page 437 of 463

TECHNICAL SPECIFICATIONS435

(Continued)

CNG AND LP FUEL SYSTEM

M

ODIFICATIONS

Modifications that allow the engine to run on

Compressed Natural Gas (CNG) or Liquid

Propane (LP) may result in damage to the engine,

emissions, and fuel system components.

Problems that result from running CNG or LP are

not the responsibility of the manufacturer and

may void or not be covered under the New

Vehicle Limited Warranty.

METHYLCYCLOPENTADIENYL

M

ANGANESE TRICARBONYL (MMT) IN

G

ASOLINE

MMT is a manganese-containing metallic

additive that is blended into some gasoline to

increase octane. Gasoline blended with MMT

provides no performance advantage beyond

gasoline of the same octane number without

MMT. Gasoline blended with MMT reduces

spark plug life and reduces emissions system

performance in some vehicles. The manufacturer

recommends that gasoline without MMT be used in your vehicle. The MMT content of gasoline may

not be indicated on the gasoline pump; therefore,

you should ask your gasoline retailer whether the

gasoline contains MMT. MMT is prohibited in

Federal and California reformulated gasoline.

FUEL SYSTEM CAUTIONS

NOTE:

Intentional tampering with the emissions

control system can result in civil penalties being

assessed against you.

CAUTION!

Follow these guidelines to maintain your

vehicle’s performance:

The use of leaded gasoline is prohibited by

Federal law. Using leaded gasoline can

impair engine performance and damage

the emissions control system.

An out-of-tune engine or certain fuel or igni

-

tion malfunctions can cause the catalytic

converter to overheat. If you notice a

pungent burning odor or some light smoke,

your engine may be out of tune or malfunc -

tioning and may require immediate service.

Contact an authorized dealer for service

assistance.

The use of fuel additives, which are now

being sold as octane enhancers, is not

recommended. Most of these products

contain high concentrations of methanol.

Fuel system damage or vehicle perfor -

mance problems resulting from the use of

such fuels or additives is not the responsi -

bility of the manufacturer and may void or

not be covered under the New Vehicle

Limited Warranty.

CAUTION! (Continued)

9

21_DPF_OM_EN_USC_t.book Page 435

Page 438 of 463

436TECHNICAL SPECIFICATIONS

FUEL REQUIREMENTS – DIESEL ENGINE

Use good quality diesel fuel from a reputable

supplier in your vehicle. Federal law requires

that you must fuel this vehicle with Ultra Low

Sulfur Highway Diesel fuel (15 ppm Sulfur

maximum) and prohibits the use of Low Sulfur

Highway Diesel fuel (500 ppm Sulfur maximum)

to avoid damage to the emissions control

system.

For most year-round service, Number 2 diesel

fuel meeting ASTM (formerly known as the

American Society for Testing and Materials)

specification D-975 Grade S15 will provide

good performance. If the vehicle is exposed

to extreme cold (below 20°F or -7°C), or is

required to operate at colder-than-normal

conditions for prolonged periods, use climatized

Number 2 diesel fuel or dilute the Number 2

diesel fuel with 50% Number 1 diesel fuel. This

will provide better protection from fuel gelling or

wax-plugging of the fuel filters.

Diesel fuel is seldom completely free of water.

To prevent fuel system trouble, drain the

accumulated water from the fuel/water

separator using the fuel/water separator drain

provided on both fuel filters. If you buy good

quality fuel and follow the cold weather advice

above, fuel conditioners should not be required

in your vehicle. If available in your area, a high

cetane “premium” diesel fuel may offer improved

cold-starting and warm-up performance.

FUEL SPECIFICATIONS

The Cummins® Turbo Diesel engine has been

developed to take advantage of the high energy

content and generally lower cost Number 2

Ultra Low Sulfur diesel fuel or Number 2 Ultra

Low Sulfur climatized diesel fuels. Experience

has shown that it also operates on Number 1

Ultra Low Sulfur diesel fuels or other fuels

within specification.

NOTE:

If you accidentally fill the fuel tank with gaso

-

line on your diesel vehicle, Do not start the

vehicle. If you restart your vehicle you risk

damaging the engine and fuel system. Please

call an authorized dealer for service.

A maximum blend of 5% biodiesel meeting

ASTM specification D-975 may be used with

your Cummins diesel engine. (Chassis Cab

models not configured with B20 capability).

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under

certain conditions and hazardous or

explosive when mixed with diesel fuel.

CAUTION!

If the “Water in Fuel Indicator Light” remains

on, DO NOT START engine before you drain

the water from the fuel filter(s) to avoid

engine damage Ú page 375.

21_DPF_OM_EN_USC_t.book Page 436

Page 439 of 463

TECHNICAL SPECIFICATIONS437

In addition, commercially available fuel addi -

tives are not necessary for the proper opera -

tion of your Cummins diesel engine. However,

if seasonably adjusted fuel is not available and

you are operating below 20°F (-6°C), Mopar

Premium Diesel Fuel Treatment (or equivalent)

may be beneficial to avoid fuel gelling.

Number 1 Ultra Low Sulfur diesel fuel should

only be used where extended arctic condi -

tions (0°F or -18°C) exist.

BIODIESEL FUEL REQUIREMENTS

Chassis Cab Models

A maximum blend of 5% biodiesel meeting

ASTM specification D975 may be used with

your Cummins diesel engine. If operation with

biodiesel blends greater than 5% but not

greater than 20% (B6-B20) is desired, the truck

must first be reconfigured by an authorized

Ram dealer and the provisions in the following

section must be adhered to.

Pickup Models And Chassis Cab Models

Ordered With B20 Option

Your vehicle has been validated and approved

for the use of biodiesel in blends up to 20%

(B20) provided that you comply with the

requirements outlined below. It is important

that you understand and comply with these

requirements. Failure to comply with Oil Change

requirements for vehicles operating on

biodiesel blends up to B20 will result in

premature engine wear. Such wear is not

covered by the New Vehicle Limited Warranty.

Biodiesel is a fuel produced from renewable

resources typically derived from animal fat,

rapeseed oil (Rapeseed Methyl Ester (RME)

base), or soybean oil (Soy Methyl Ester (SME or

SOME) base). Biodiesel fuel has inherent

limitations which require that you understand

and adhere to the following requirements if you

use blends of biodiesel greater then 5% but not

greater than 20% (B6-B20). There are no

unique restrictions for the use of B5. Use of

blends greater than 20% is not approved. Use of

blends greater than 20% can result in engine

damage. Such damage is not covered by the

New Vehicle Limited Warranty.

Fuel Quality — Must Comply With ASTM

Standards

The quality of biodiesel fuel may vary widely.

Only fuel produced by a BQ9000 supplier to the

following specifications may be blended to

meet biodiesel blend (B6–B20) fuel meeting

ASTM specification D-7467:

Petrodiesel fuel meeting ASTM specification

D-975 and biodiesel fuel (B100) meeting

ASTM specification D-6751.

Fuel Oxidation Stability — Must Use Fuel

Within Six Months Of Manufacture

Biodiesel fuel has poor oxidation stability which

can result in long term storage problems. Fuel

produced to approved ASTM standards, if

stored properly, provides for protection against

fuel oxidation for up to six months.

9

21_DPF_OM_EN_USC_t.book Page 437