recommended oil RAM CHASSIS CAB 2022 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2022Pages: 428, PDF Size: 20.18 MB

Page 360 of 428

358SERVICING AND MAINTENANCE

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically Úpage 329.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked when performing under the hood service

or immediately if the Brake System Warning Light

indicates system failure.

If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the top

of the master cylinder area before removing cap.

With disc brakes the fluid level can be expected to

fall as the brake linings wear. However, an

unexpected drop in fluid level may be caused by a

leak and a system check should be conducted.

For further information Ú page 407.

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against

using any special additives in the transmission.

Automatic Transmission Fluid (ATF) is an

engineered product and its performance may be

impaired by supplemental additives. Therefore, do

not add any fluid additives to the transmission. The

only exception to this policy is the use of special

dyes for diagnosing fluid leaks in 6-speed

transmissions. Avoid using transmission sealers as

they may adversely affect seals.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer's recommended brake

fluid Úpage 407. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage your

transmission components. Such damage is not

covered by the New Vehicle Limited Warranty.

WARNING!

22_DPF_OM_EN_USC_t.book Page 358

Page 362 of 428

360SERVICING AND MAINTENANCE

NOTE:If it is necessary to check the transmission below

the operating temperature, the fluid level should

be between the two COLD (lower) holes on the

dipstick with the fluid at 68-86°F / 20-30°C. Only

use the COLD region of the dipstick as a rough

reference when setting the fluid level after a trans -

mission service or fluid change. Re-check the fluid

level, and adjust as required, once the trans -

mission reaches normal operating temperature.

Fluid And Filter Changes — 8-Speed

Transmission

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not required.

However, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Fluid And Filter Changes — 6-Speed

Transmission

For the proper maintenance intervals Úpage 329.

In addition, change the fluid and filters if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid

to ensure optimum transmission performance and

life. Use only the manufacturer’s specified

transmission fluid Ú page 407. It is important to

maintain the transmission fluid at the correct level

using the recommended fluid. No chemical flushes

should be used in any transmission; only the

approved lubricant should be used.

REAR AXLE AND 4X4 FRONT DRIVING

A

XLE FLUID LEVEL

For normal service, periodic fluid level checks are

not required. When the vehicle is serviced for other

reasons the exterior surfaces of the axle assembly

should be inspected. If gear oil leakage is

suspected inspect the fluid level. This inspection

should be made with the vehicle in a level position.

When checking the fluid level, the vehicle should

be in a level position. The fluid level at room

temperature should be as follows:

3500 Front Axle: ¼ inch ± ¼ inch (6.4 mm ±

6.4 mm) below the bottom of the fill hole.

3500 Rear Axle: ¼ inch ± ¼ inch (6.4 mm ±

6.4 mm) below the bottom of the fill hole.

4500/5500 Front Axle: ¼ inch +/- ¼ inch (6.4 mm

± 6.4 mm) below the bottom of the fill hole.

4500/5500 Rear Axle: 1/8 inch +/- 1/8 inch

(3.2 mm +/- 3.2 mm) below the bottom of the fill

hole.

CAUTION!

If the fluid temperature is below 50°F (10°C) it

may not register on the dipstick. Do not add fluid

until the temperature is elevated enough to

produce an accurate reading. Run the engine at

idle, in PARK, to warm the fluid.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder, and (for 6-speed

transmissions) will require more frequent fluid

and filter changes Ú page 407.

22_DPF_OM_EN_USC_t.book Page 360

Page 363 of 428

SERVICING AND MAINTENANCE361

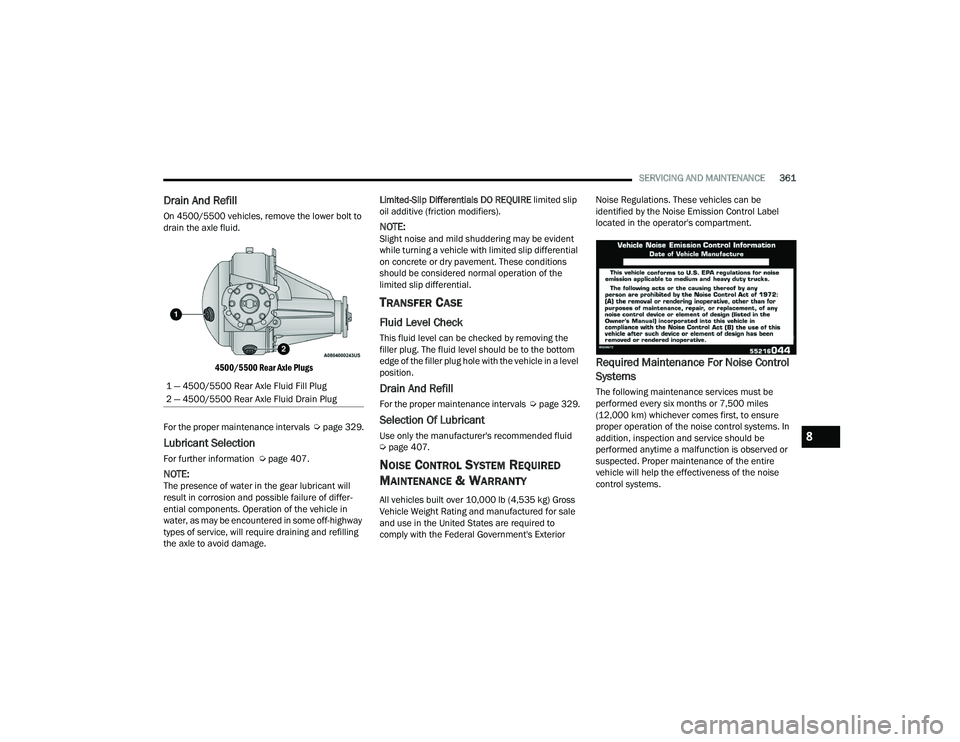

Drain And Refill

On 4500/5500 vehicles, remove the lower bolt to

drain the axle fluid.

4500/5500 Rear Axle Plugs

For the proper maintenance intervals Úpage 329.

Lubricant Selection

For further information Ú page 407.

NOTE:The presence of water in the gear lubricant will

result in corrosion and possible failure of differ -

ential components. Operation of the vehicle in

water, as may be encountered in some off-highway

types of service, will require draining and refilling

the axle to avoid damage. Limited-Slip Differentials DO REQUIRE

limited slip

oil additive (friction modifiers).

NOTE:Slight noise and mild shuddering may be evident

while turning a vehicle with limited slip differential

on concrete or dry pavement. These conditions

should be considered normal operation of the

limited slip differential.

TRANSFER CASE

Fluid Level Check

This fluid level can be checked by removing the

filler plug. The fluid level should be to the bottom

edge of the filler plug hole with the vehicle in a level

position.

Drain And Refill

For the proper maintenance intervals Úpage 329.

Selection Of Lubricant

Use only the manufacturer's recommended fluid

Úpage 407.

NOISE CONTROL SYSTEM REQUIRED

M

AINTENANCE & WARRANTY

All vehicles built over 10,000 lb (4,535 kg) Gross

Vehicle Weight Rating and manufactured for sale

and use in the United States are required to

comply with the Federal Government's Exterior Noise Regulations. These vehicles can be

identified by the Noise Emission Control Label

located in the operator's compartment.

Required Maintenance For Noise Control

Systems

The following maintenance services must be

performed every six months or 7,500 miles

(12,000 km) whichever comes first, to ensure

proper operation of the noise control systems. In

addition, inspection and service should be

performed anytime a malfunction is observed or

suspected. Proper maintenance of the entire

vehicle will help the effectiveness of the noise

control systems.

1 — 4500/5500 Rear Axle Fluid Fill Plug

2 — 4500/5500 Rear Axle Fluid Drain Plug

8

22_DPF_OM_EN_USC_t.book Page 361

Page 388 of 428

386SERVICING AND MAINTENANCE

Keep dismounted tires in a cool, dry place with as

little exposure to light as possible. Protect tires

from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of

many characteristics. They should be inspected

regularly for wear and correct cold tire inflation

pressures. The manufacturer strongly

recommends that you use tires equivalent to the

originals in size, quality and performance when

replacement is needed Ú page 385. Refer to the

Tire and Loading Information placard or the

Vehicle Certification Label for the size designation

of your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

For more information relating to the Load Index

and Speed Symbol of a tire Ú page 376.

It is recommended to replace the two front tires or

two rear tires as a pair. Replacing just one tire can

seriously affect your vehicle’s handling. If you ever

replace a wheel, make sure that the wheel’s

specifications match those of the original wheels.

It is recommended you contact an authorized tire

dealer or original equipment dealer with any

questions you may have on tire specifications or

capability. Failure to use equivalent replacement

tires may adversely affect the safety, handling, and

ride of your vehicle.

TIRE TYPES

All Season Tires — If Equipped

All Season tires provide traction for all seasons

(Spring, Summer, Autumn, and Winter). Traction

levels may vary between different all season tires.

All season tires can be identified by the M+S, M&S,

M/S or MS designation on the tire sidewall. Use all

season tires only in sets of four; failure to do so

may adversely affect the safety and handling of

your vehicle.

Summer Or Three Season Tires —

If Equipped

Summer tires provide traction in both wet and dry

conditions, and are not intended to be driven in

snow or on ice. If your vehicle is equipped with

Summer tires, be aware these tires are not

designed for Winter or cold driving conditions.

Install Winter tires on your vehicle when ambient

temperatures are less than 40°F (5°C) or if roads

are covered with ice or snow. For more

information, contact an authorized dealer.

WARNING!

Do not use a tire, wheel size, load rating, or

speed rating other than that specified for your

vehicle. Some combinations of unapproved

tires and wheels may change suspension

dimensions and performance characteristics,

resulting in changes to steering, handling, and

braking of your vehicle. This can cause unpre -

dictable handling and stress to steering and

suspension components. You could lose

control and have a collision resulting in

serious injury or death. Use only the tire and

wheel sizes with load ratings approved for

your vehicle.

Never use a tire with a smaller load index or

capacity, other than what was originally

equipped on your vehicle. Using a tire with a

smaller load index could result in tire over -

loading and failure. You could lose control and

have a collision.

Failure to equip your vehicle with tires having

adequate speed capability can result in

sudden tire failure and loss of vehicle control.

CAUTION!

Replacing original tires with tires of a different

size may result in false speedometer and

odometer readings.

22_DPF_OM_EN_USC_t.book Page 386

Page 398 of 428

396SERVICING AND MAINTENANCE

Cleaning Plastic Instrument Cluster

Lenses

The lenses in front of the instruments in this

vehicle are molded in clear plastic. When cleaning

the lenses, care must be taken to avoid scratching

the plastic.

Clean with a wet soft cloth. A mild soap solution

may be used, but do not use high alcohol content

or abrasive cleaners. If soap is used, wipe clean

with a clean damp cloth. Dry with a soft cloth.

LEATHER SURFACES

Mopar® Total Clean is specifically recommended

for leather upholstery.

Your leather upholstery can be best preserved by

regular cleaning with a damp soft cloth. Small

particles of dirt can act as an abrasive and damage

the leather upholstery and should be removed

promptly with a damp cloth. Stubborn soils can be

removed easily with a soft cloth and Mopar® Total

Clean. Care should be taken to avoid soaking your

leather upholstery with any liquid. Please do not

use polishes, oils, cleaning fluids, solvents,

detergents, or ammonia-based cleaners to clean

your leather upholstery.

NOTE:If equipped with light colored leather, it tends to

show any foreign material, dirt, and fabric dye

transfer more so than darker colors. The leather is

designed for easy cleaning, and the manufacturer

recommends Mopar® Total Care leather cleaner

applied on a cloth to clean the leather seats as

needed.GLASS SURFACES

All glass surfaces should be cleaned on a regular

basis with Mopar® Glass Cleaner, or any

commercial household-type glass cleaner. Never

use an abrasive type cleaner. Use caution when

cleaning the inside rear window equipped with

electric defrosters or windows equipped with radio

antennas. Do not use scrapers or other sharp

instruments that may scratch the elements.

When cleaning the rear view mirror, spray cleaner

on the towel or cloth that you are using. Do not

spray cleaner directly on the mirror.

CAUTION!

Do not use Alcohol and Alcohol-based and/or

Ketone based cleaning products to clean leather

upholstery, as damage to the upholstery may

result.

22_DPF_OM_EN_USC_t.book Page 396

Page 399 of 428

397

TECHNICAL SPECIFICATIONS

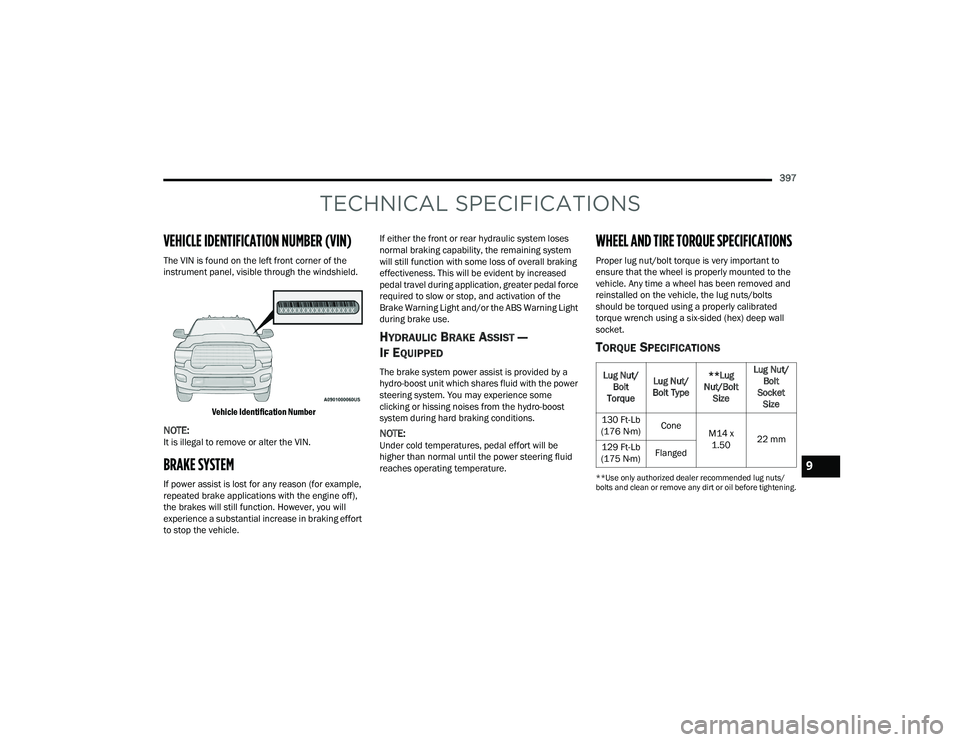

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the

instrument panel, visible through the windshield.

Vehicle Identification Number

NOTE:It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for example,

repeated brake applications with the engine off),

the brakes will still function. However, you will

experience a substantial increase in braking effort

to stop the vehicle. If either the front or rear hydraulic system loses

normal braking capability, the remaining system

will still function with some loss of overall braking

effectiveness. This will be evident by increased

pedal travel during application, greater pedal force

required to slow or stop, and activation of the

Brake Warning Light and/or the ABS Warning Light

during brake use.

HYDRAULIC BRAKE ASSIST —

I

F EQUIPPED

The brake system power assist is provided by a

hydro-boost unit which shares fluid with the power

steering system. You may experience some

clicking or hissing noises from the hydro-boost

system during hard braking conditions.

NOTE:Under cold temperatures, pedal effort will be

higher than normal until the power steering fluid

reaches operating temperature.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Lug Nut/

Bolt

Torque Lug Nut/

Bolt Type **Lug

Nut/Bolt Size Lug Nut/

Bolt

Socket Size

130 Ft-Lb

(176 N·m) Cone

M14 x

1.50 22 mm

129 Ft-Lb

(175 N·m) Flanged

9

22_DPF_OM_EN_USC_t.book Page 397

Page 400 of 428

398TECHNICAL SPECIFICATIONS

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

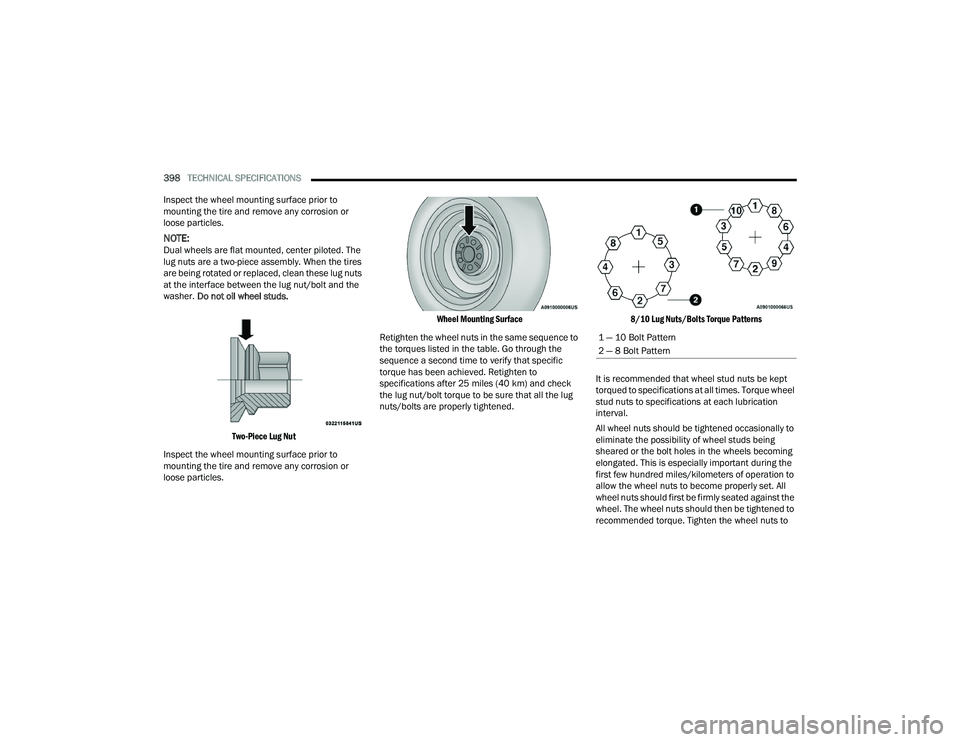

NOTE:Dual wheels are flat mounted, center piloted. The

lug nuts are a two-piece assembly. When the tires

are being rotated or replaced, clean these lug nuts

at the interface between the lug nut/bolt and the

washer. Do not oil wheel studs.

Two-Piece Lug Nut

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Retighten the wheel nuts in the same sequence to

the torques listed in the table. Go through the

sequence a second time to verify that specific

torque has been achieved. Retighten to

specifications after 25 miles (40 km) and check

the lug nut/bolt torque to be sure that all the lug

nuts/bolts are properly tightened.

8/10 Lug Nuts/Bolts Torque Patterns

It is recommended that wheel stud nuts be kept

torqued to specifications at all times. Torque wheel

stud nuts to specifications at each lubrication

interval.

All wheel nuts should be tightened occasionally to

eliminate the possibility of wheel studs being

sheared or the bolt holes in the wheels becoming

elongated. This is especially important during the

first few hundred miles/kilometers of operation to

allow the wheel nuts to become properly set. All

wheel nuts should first be firmly seated against the

wheel. The wheel nuts should then be tightened to

recommended torque. Tighten the wheel nuts to

1 — 10 Bolt Pattern

2 — 8 Bolt Pattern

22_DPF_OM_EN_USC_t.book Page 398