tow Ram ProMaster 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: ProMaster, Model: Ram ProMaster 2018Pages: 204, PDF Size: 4 MB

Page 98 of 204

RECREATIONAL TOWING (BEHIND MOTORHOME, ETC.)

Towing This Vehicle Behind Another Vehicle

Towing ConditionWheels OFF the Ground Gasoline Engine All Models Diesel Engine All Models

Flat Tow NONENOT ALLOWED

Trans InNEUTRAL

Dolly Tow Front

OKOK

Rear NOT ALLOWED

Trans InNEUTRAL

On Trailer ALLOKOK

NOTE:

When towing your vehicle, always follow applicable state and provincial laws. Contact state and provincial Highway Safety offices for additional

details.

NOTE:

For vehicles equipped with diesel engine and

electric park brake, see important informa-

tion under “Automated Manual Transmis-

sion”.STARTING AND OPERATING

96

Page 99 of 204

Recreational Towing — Gasoline

Engine All Models

Recreational towing is allowedONLYif the

front wheels are OFFthe ground. This may be

accomplished using a tow dolly or vehicle

trailer. If using a tow dolly, follow this proce-

dure:

1. Properly secure the dolly to the tow ve- hicle, following the dolly manufacturer's

instructions.

2. Drive the front wheels onto the tow dolly.

3. Firmly apply the parking brake. Place the transmission in PARK.

4. Properly secure the front wheels to the dolly, following the dolly manufacturer's

instructions.

5. Release the parking brake.

CAUTION!

• DO NOT flat tow this vehicle. Damage to the drivetrain will result. If this vehicle

requires towing, make sure the drive

wheels are OFF the ground.

• Towing this vehicle in violation of the

above requirements can cause severe

transmission damage. Damage from im-

proper towing is not covered under the

New Vehicle Limited Warranty.

Recreational Towing —

Diesel Engine All Models

NOTE:

Automated Manual transmission (diesel) ve-

hicles can also be flat towed (all four wheels

on the ground) with the transmission in NEU-

TRAL. Ensure the transmission is in neutral

(N) (by checking that the vehicle moves when

pushed) and tow in the same way as a normal

vehicle with a manual transmission.

97

Page 101 of 204

IN CASE OF EMERGENCY

BULB REPLACEMENT...........100

Replacement Bulbs............100

FUSES.................... .102

Underhood Fuses..............103

Interior Fuses ................106

Right Central Pillar Fuses .........107

JACKING AND TIRE CHANGING .....108

Jack Location................108

Spare Tire Removal .............109

Preparations For Jacking .........111

Jacking Instructions .............112

Wheel Covers ................115

JUMP STARTING ..............115

Preparations For Jump Start ........116

Jump Starting Procedure .........117

Battery Location ..............118

IF YOUR ENGINE OVERHEATS ......118

GEAR SELECTOR OVERRIDE

(GASOLINE ENGINE ONLY) ........119

FREEING A STUCK VEHICLE .......119

TOWING A DISABLED VEHICLE .....121

Automatic Transmission..........122

ENHANCED ACCIDENT RESPONSE

SYSTEM (EARS)...............122

EVENT DATA RECORDER (EDR) ......122

IN CASE OF EMERGENCY

99

Page 111 of 204

To open the jack kit container you must push

the containers release to separate the top and

bottom.Spare Tire Removal

1. Remove the spare tire before attemptingto jack up the vehicle. Attach the lug bolt

adapter to the winch extension and insert

it into the winch mechanism.

Container Release

Jacking Tools

1 — Jack

2 — Reversible Tool

3 — Tool Handle

4 — Winch Extension

5 — Tow Eye

6 — Wrench Handle

7 — Lug Bolt Adaptor

Jack Tools

1 — Wrench Handle

2 — Lug Bolt Adapter

3 — Winch Extension

109

Page 114 of 204

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Jacking Instructions

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface asfar from the edge of the roadway as

possible before raising the vehicle.

WARNING!

• Turn on the Hazard Warning flashers.

• Block the wheel diagonally opposite thewheel to be raised.

• Set the parking brake firmly and set an

automatic transmission in PARK; a

manual transmission in REVERSE.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

• If working on or near a roadway, be

extremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

Wheel Blocked

Jack Warning Label

IN CASE OF EMERGENCY

112

Page 117 of 204

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.NOTE:

Do not install the wheel cover on the spare

tire.

7. Lower the vehicle by turning the jack screw to the left.

8. Refer to “Wheel And Tire Torque Specifi- cations” in “Technical Specifications” for

proper wheel lug bolt torque.

9. Lower the jack to its fully-closed position.

10. Stow the damaged wheel/spare tire with the cable and wheel spacer before driv-

ing the vehicle.

11. Install the winch extension and rotate the

wrench handle clockwise until the winch

mechanism operator hears “3 clicks” from

the device to indicate the wheel is properly

stowed under the vehicle. 12. Stow the jack, jack handle and winch

handle tools back in the storage

compartment.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

13. Check the spare tire pressure as soon as possible. Correct the tire pressure, as

required.

For vehicles with aluminum wheels:

The center cap must be pushed out from the

rear to install the retainer and stow the tire.

Wheel Covers

CAUTION!

Use a back-and-forth motion to remove the

hub cap. Do not use a twisting motion when

removing the hub cap, damage to the hub

cap finish may occur.

The wheel covers on the vehicle are held in

place by the wheel lug bolts and can be

removed after the wheel lug bolts are taken

off.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so

please follow the procedures in this section

carefully.

NOTE:

When using a portable battery booster pack,

follow the manufacturer’s operating instruc-

tions and precautions.

115

Page 123 of 204

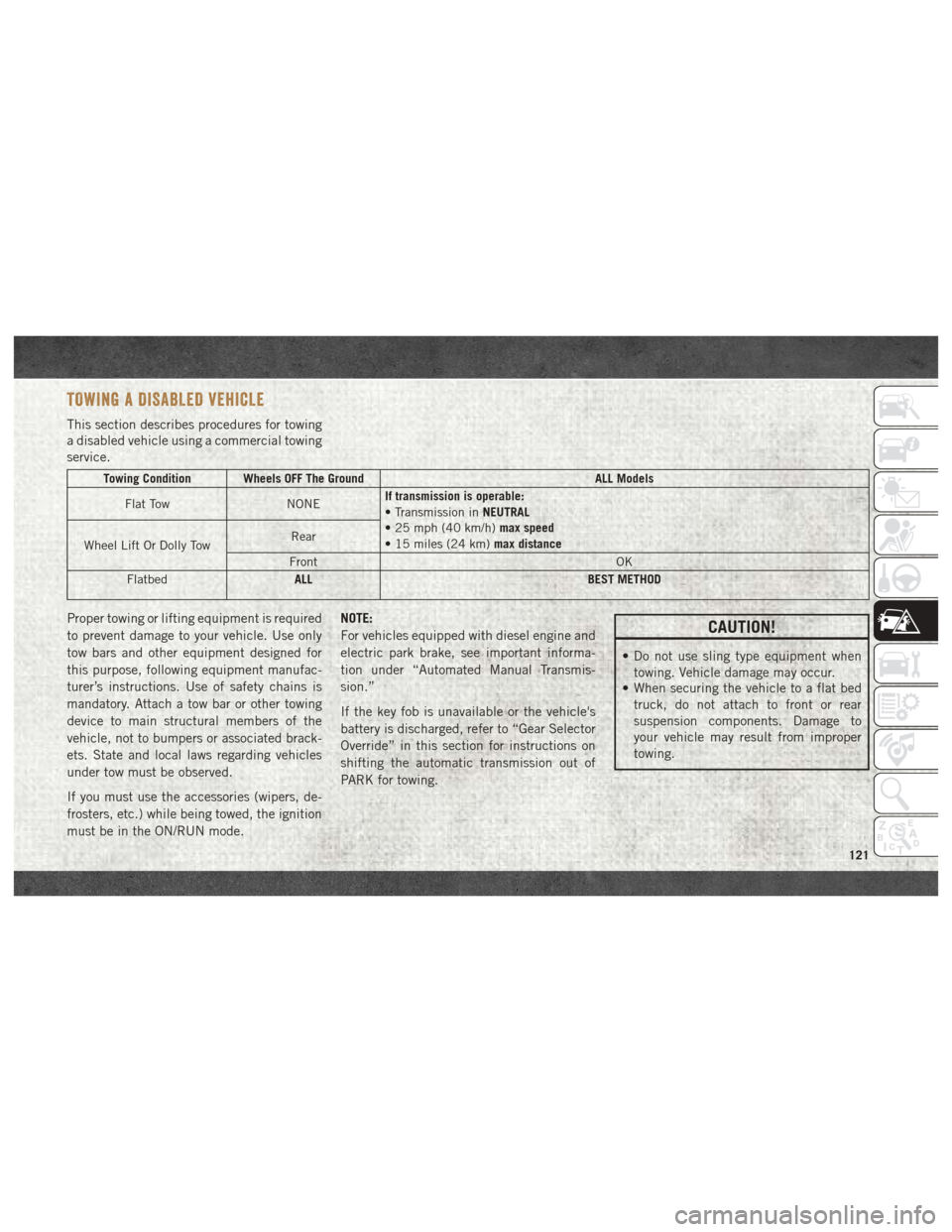

TOWING A DISABLED VEHICLE

This section describes procedures for towing

a disabled vehicle using a commercial towing

service.

Towing Condition Wheels OFF The GroundALL Models

Flat Tow NONEIf transmission is operable:

• Transmission in

NEUTRAL

• 25 mph (40 km/h) max speed

• 15 miles (24 km) max distance

Wheel Lift Or Dolly Tow Rear

Front OK

Flatbed ALL

BEST METHOD

Proper towing or lifting equipment is required

to prevent damage to your vehicle. Use only

tow bars and other equipment designed for

this purpose, following equipment manufac-

turer’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towing

device to main structural members of the

vehicle, not to bumpers or associated brack-

ets. State and local laws regarding vehicles

under tow must be observed.

If you must use the accessories (wipers, de-

frosters, etc.) while being towed, the ignition

must be in the ON/RUN mode.NOTE:

For vehicles equipped with diesel engine and

electric park brake, see important informa-

tion under “Automated Manual Transmis-

sion.”

If the key fob is unavailable or the vehicle's

battery is discharged, refer to “Gear Selector

Override” in this section for instructions on

shifting the automatic transmission out of

PARK for towing.CAUTION!

• Do not use sling type equipment when

towing. Vehicle damage may occur.

• When securing the vehicle to a flat bed

truck, do not attach to front or rear

suspension components. Damage to

your vehicle may result from improper

towing.

121

Page 124 of 204

Automatic Transmission

The manufacturer recommends towing your

vehicle with all four wheelsOFFthe ground

using a flatbed.

If flatbed equipment is not available, and the

transmission is operable, this vehicle may be

towed (with front wheels on the ground) un-

der the following conditions:

• The transmission must be in NEUTRAL.

• The towing speed must not exceed 25 mph (40 km/h).

• The towing distance must not exceed 15 miles (24 km).

If the transmission is not operable, or the

vehicle must be towed faster than 25 mph

(40 km/h) or farther than 15 miles (24 km),

tow with the front wheels OFFthe ground

(using a flatbed truck, or wheel lift equip-

ment with the front wheels raised).

CAUTION!

• Towing faster than 25 mph (40 km/h) or farther than 15 miles (24 km) with front

wheels on the ground can cause severe

transmission damage. Damage from im-

proper towing is not covered under the

New Vehicle Limited Warranty.

• Towing this vehicle in violation of the

above requirements can cause severe

transmission damage. Damage from im-

proper towing is not covered under the

New Vehicle Limited Warranty.

ENHANCED ACCIDENT RESPONSE

SYSTEM (EARS)

This vehicle is equipped with an Enhanced

Accident Response System. Please refer to “Occupant Restraint Sys-

tems” in “Safety” for further information on

the Enhanced Accident Response System

(EARS) function.

EVENT DATA RECORDER (EDR)

This vehicle is equipped with an Event Data

Recorder (EDR). The main purpose of an EDR

is to record data that will assist in under-

standing how a vehicle’s systems performed

under certain crash or near crash-like situa-

tions, such as an air bag deployment or hit-

ting a road obstacle.

Please refer to “Occupant Restraint Sys-

tems” in “Safety” for further information on

the Event Data Recorder (EDR).

IN CASE OF EMERGENCY

122

Page 126 of 204

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for scheduled

maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate in

the instrument cluster. This means that ser-

vice is required for your vehicle. Operating

conditions such as frequent short-trips,

trailer tow, and extremely hot or cold ambient

temperatures will influence when the “Oil

Change Required” message is displayed. Se-

vere Operating Conditions can cause the

change oil message to illuminate as early as

3,500 miles (5,600 km) since last reset.

Have your vehicle serviced as soon as pos-

sible, within the next 500 miles (805 km).

Your authorized dealer will reset the oil change

indicator message after completing the sched-

uled oil change. If a scheduled oil change is

performed by someone other than your autho-

rized dealer, the message can be reset byreferring to the steps described under “Instru-

ment Cluster Display” in “Getting To Know

Your Instrument Panel” in your Owner’s

Manual on

www.ramtrucks.com/en/owners/

manuals for further information.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

twelve months or 350 hours of engine run

time, whichever comes first. The 350 hours

of engine run or idle time is generally only a

concern for fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles

(6,500 km) or 350 hours of engine run time

if the vehicle is operated in a dusty and off

road environment or is operated predomi-

nately at idle or only very low engine RPM’s.

This type of vehicle use is considered Severe

Duty. Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look

for unusual wear or damage

• Check the fluid levels of the coolant reser- voir, brake master cylinder, and power

steering and fill as needed

• Check function of all interior and exterior lights

SERVICING AND MAINTENANCE

124

Page 130 of 204

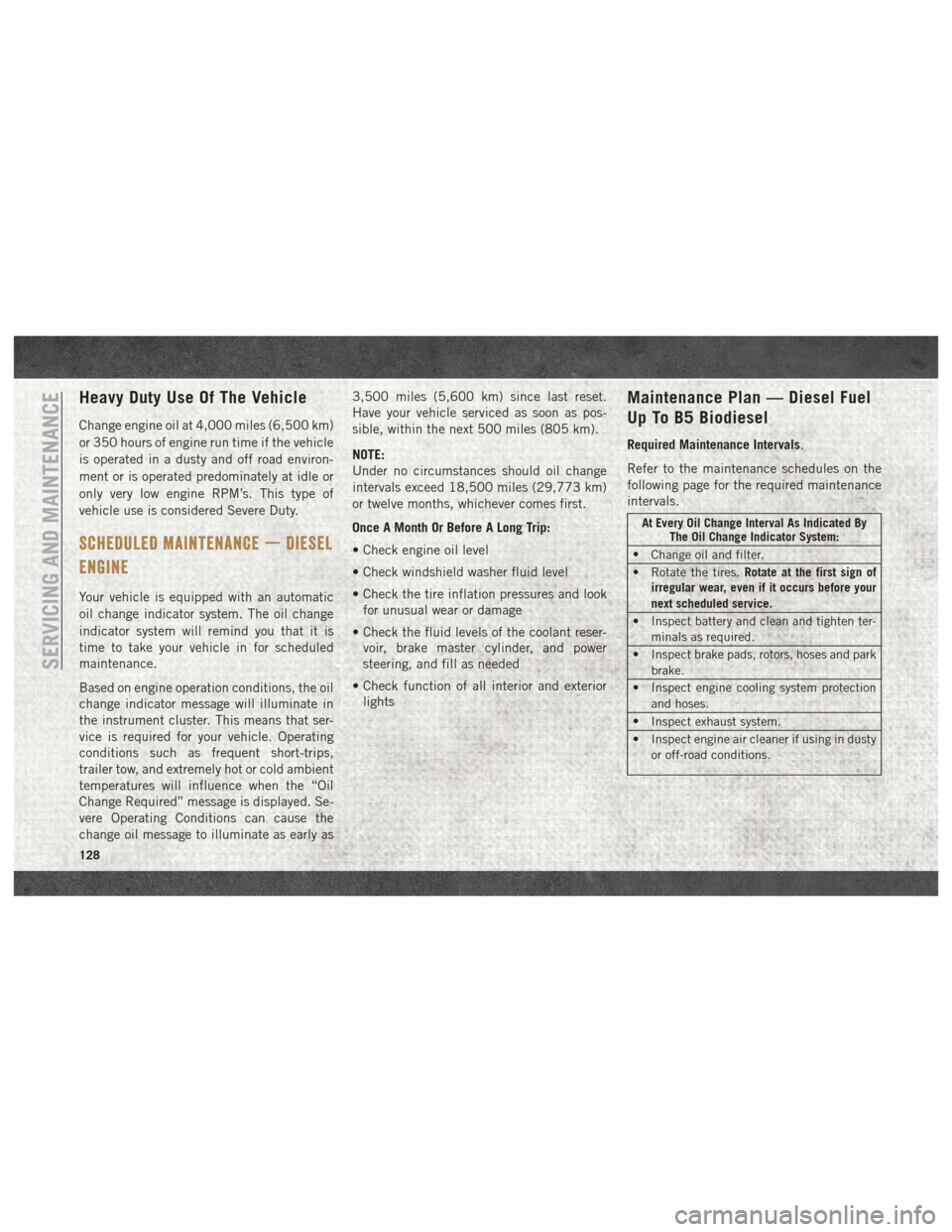

Heavy Duty Use Of The Vehicle

Change engine oil at 4,000 miles (6,500 km)

or 350 hours of engine run time if the vehicle

is operated in a dusty and off road environ-

ment or is operated predominately at idle or

only very low engine RPM’s. This type of

vehicle use is considered Severe Duty.

SCHEDULED MAINTENANCE — DIESEL

ENGINE

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for scheduled

maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate in

the instrument cluster. This means that ser-

vice is required for your vehicle. Operating

conditions such as frequent short-trips,

trailer tow, and extremely hot or cold ambient

temperatures will influence when the “Oil

Change Required” message is displayed. Se-

vere Operating Conditions can cause the

change oil message to illuminate as early as3,500 miles (5,600 km) since last reset.

Have your vehicle serviced as soon as pos-

sible, within the next 500 miles (805 km).

NOTE:

Under no circumstances should oil change

intervals exceed 18,500 miles (29,773 km)

or twelve months, whichever comes first.

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look

for unusual wear or damage

• Check the fluid levels of the coolant reser- voir, brake master cylinder, and power

steering, and fill as needed

• Check function of all interior and exterior lights

Maintenance Plan — Diesel Fuel

Up To B5 Biodiesel

Required Maintenance Intervals.

Refer to the maintenance schedules on the

following page for the required maintenance

intervals.

At Every Oil Change Interval As Indicated By The Oil Change Indicator System:

• Change oil and filter.

• Rotate the tires. Rotate at the first sign of

irregular wear, even if it occurs before your

next scheduled service.

• Inspect battery and clean and tighten ter- minals as required.

• Inspect brake pads, rotors, hoses and park brake.

• Inspect engine cooling system protection and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or off-road conditions.

SERVICING AND MAINTENANCE

128