lock Ram ProMaster 2019 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2019, Model line: ProMaster, Model: Ram ProMaster 2019Pages: 332, PDF Size: 3.66 MB

Page 183 of 332

Replacing Exterior Bulbs

Headlamps Low Beam And High beam

1. Remove one screw on the lower headlamp filler panel.

2. Remove two screws on the upper headlamp filler panel.

3. Remove one upper screw from the headlamp housing.

4. Remove two lower screws from the headlamp housing.

5. Pull Headlamp forward.

6. Remove appropriate plastic cap from the back of theheadlamp housing.

7. Push down on the upper portion of the socket.

8. Pull the socket outward from reflector.

9. Pull bulb outward from socket.

10. Install new bulb.

11. Push socket back into reflector until it locks back into place.

12. Install access cap.

13. Carefully reinstall headlamp in the same position on the vehicle, so as not to affect headlamp aiming. 14. Install one upper screw on the headlamp housing.

15. Install two lower screws on the headlamp housing.

16. Carefully reinstall one screw on the lower headlamp

filler panel.

17. Carefully reinstall two screws on the upper headlamp filler panel.

Front Turn Signal/Parking Lamps

1. Remove one screw on the lower headlamp filler panel.

2. Remove two screws on the upper headlamp filler panel.

3. Remove one upper screw from the headlamp housing.

4. Remove two lower screws from the headlamp housing.

5. Pull Headlamp forward.

6. Rotate the bulb counter clockwise and remove.

7. Install the bulb into socket, and rotate bulb/socketclockwise into lamp locking it in place.

8. Carefully reinstall headlamp in the same position on the vehicle, so as not to affect headlamp aiming.

9. Install the one upper screw on headlamp housing.

7

IN CASE OF EMERGENCY 181

Page 184 of 332

10. Install the two lower screws on headlamp housing.

11. Carefully reinstall one screw on the lower headlampfiller panel.

12. Carefully reinstall two screws the on upper headlamp filler panel.

Daytime Running Lamp (DRL)/Front Side Marker

Lamp

1. Remove one screw on the lower headlamp filler panel.

2. Remove two screws on the upper headlamp filler panel.

3. Remove one upper screw from the headlamp housing.

4. Remove two lower screws from the headlamp housing.

5. Pull Headlamp forward.

6.

Remove the DRL, side marker bulb by pulling straight out.

7. Replace lamp as required and lock in place.

8. Reinstall plastic cap.

9. Carefully reinstall headlamp in the same position on thevehicle, as not to affect headlamp aiming.

10. Install the one upper screw on the headlamp housing.

11. Install the two lower screws on the headlamp housing. 12. Carefully reinstall one screw on the lower headlamp

filler panel.

13. Carefully reinstall two screws on the upper headlamp filler panel.

Front Fog Lamps

1. Turn front wheels inboard to access cover in wheel liner.

2. Open the cover on the front of the wheel liner.

3. Remove connection and replace the bulb.

4. Connect the wire and rotate bulb/socket clockwise intolamp locking it in place.

5. Reinstall the plastic cap and close the cover on the wheel liner.

Front, Rear Roof Lamps

1. Remove two screw and remove the lamp assembly.

2. Remove the socket bulb by turning counterclockwise.

3. Remove bulb and replace as needed.

4. Reinstall the bulb socket and rotate clockwise to lock inplace.

5. Reinstall lamp.

182 IN CASE OF EMERGENCY

Page 185 of 332

Rear Tail, Stop, Backup, Turn Signal And Rear Side

Marker Lamps

1. Open rear doors.

2. Remove the two screws and remove the tail lamp.

3. Remove the tail/stop, turn signal, backup and rear sidemarker bulb/socket by rotating counter-clockwise.

4. Remove the bulb and replace as needed.

5. Reinstall bulb/socket and rotate clockwise to lock in place.

6. Reinstall lamp.

Replacing Interior Bulbs

Cargo Lamp

1. Using a suitable tool, remove either the lamp above the back door or the sliding door lamp as needed and

disconnect it.

Rear Cargo Lamp Bulb Access

7

IN CASE OF EMERGENCY 183

Page 194 of 332

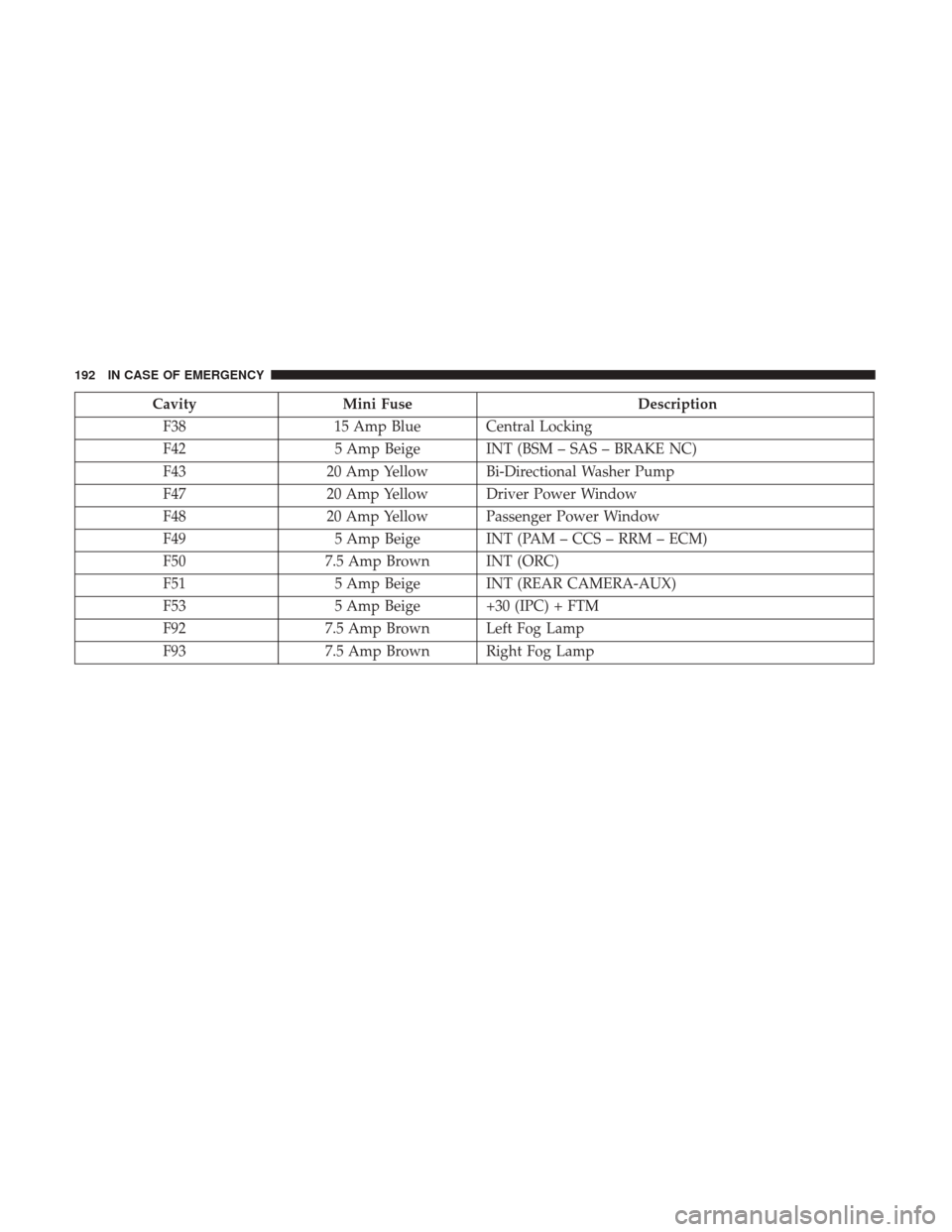

CavityMini Fuse Description

F38 15 Amp Blue Central Locking

F42 5 Amp Beige INT (BSM – SAS – BRAKE NC)

F43 20 Amp Yellow Bi-Directional Washer Pump

F47 20 Amp Yellow Driver Power Window

F48 20 Amp Yellow Passenger Power Window

F49 5 Amp Beige INT (PAM – CCS – RRM – ECM)

F50 7.5 Amp Brown INT (ORC)

F51 5 Amp Beige INT (REAR CAMERA-AUX)

F53 5 Amp Beige +30 (IPC) + FTM

F92 7.5 Amp Brown Left Fog Lamp

F93 7.5 Amp Brown Right Fog Lamp

192 IN CASE OF EMERGENCY

Page 196 of 332

JACKING AND TIRE CHANGING

WARNING!

•Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

• Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service center

where it can be raised on a lift.

• Never start or run the engine while the vehicle is on

a jack.

• The jack is designed to be used as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should be

jacked on a firm level surface only. Avoid ice or

slippery areas.

Jack Location

The jack and jack tools are stored under the front passenger

seat.

To release the jack kit for it’s storage location, turn the lock

knob 1/4 turn counter clockwise to the unlock position.

Jack Kit Location

194 IN CASE OF EMERGENCY

Page 197 of 332

CAUTION!

Do not force lock knob over limit. Damage to lock

knob may occur.To open the jack kit container, you must push the contain-

er ’s release to separate the top and bottom.

Lock Knob

1 — Unlock Position

2 — Lock Position

Container Release

7

IN CASE OF EMERGENCY 195

Page 199 of 332

The winch mechanism is located under the rear of the

vehicle to the right of the spare tire.

2. Rotate the wheel wrench handle counterclockwise untilthe spare tire is on the ground with enough cable slack

to allow you to pull it out from under the vehicle.

Winch Location

Winch Extension

7

IN CASE OF EMERGENCY 197

Page 202 of 332

Preparations For Jacking

1. Park the vehicle on a firm, level surface. Avoid ice orslippery areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off the

road to avoid being hit when operating the jack or

changing the wheel.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake firmly.

4. Place the transmission in PARK (REVERSE for manual transmission) .

5. Turn the ignition OFF. 6. Block both the front and rear of the wheel diagonally

opposite the jacking position. For example, if the right

front wheel is being changed, block the left rear wheel.

NOTE:Passengers should not remain in the

vehicle when the vehicle is being jacked.

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

•

Always park on a firm, level surface as far from the edge

of the roadway as possible before raising the vehicle.

• Turn on the Hazard Warning flashers.

• Block the wheel diagonally opposite the wheel to be

raised.

• Apply the parking brake firmly and place an auto-

matic transmission in PARK; a manual transmission

in REVERSE.

(Continued)

200 IN CASE OF EMERGENCY

Page 207 of 332

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

NOTE: Do not install the wheel cover on the spare tire.

7. Lower the vehicle by turning the jack screw to the left.

8. Refer to “Wheel And Tire Torque Specifications” in “Technical Specifications” for proper wheel lug bolt

torque.

9. Lower the jack to its fully-closed position.

10. Stow the damaged wheel/spare tire with the cable and wheel spacer before driving the vehicle.

11. Install the winch extension and rotate the wrench

handle clockwise until the winch mechanism opera-

tor hears “3 clicks” from the device to indicate the

wheel is properly stowed under the vehicle.

12. Stow the jack, jack handle and winch handle tools back in the storage compartment.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

13. Check the spare tire pressure as soon as possible. Correct the tire pressure, as required.

For vehicles with aluminum wheels:

The center cap must be pushed out from the rear to install

the retainer and stow the tire.

Wheel Covers

CAUTION!

Use a back-and-forth motion to remove the hub cap.

Do not use a twisting motion when removing the hub

cap, damage to the hub cap finish may occur.

The wheel covers on the vehicle are held in place by the

wheel lug bolts and can be removed after the wheel lug

bolts are taken off.

7

IN CASE OF EMERGENCY 205

Page 215 of 332

5. Remove the Speed Limit sticker from the instrumentpanel after the tire has been repaired.

6. Replace the Sealant Bottle (4) and Sealant Hose (3) assembly at an authorized dealer as soon as possible.

Refer to “(F) Sealant Bottle And Hose Replacement”.

NOTE: When having the tire serviced, advise the autho-

rized dealer or service center that the tire has been sealed

using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (3) (clear in color).

2. Locate the red colored round Sealant Bottle release button at the lower right hand corner of the kit.

3. Push and hold the Sealant Bottle release button, then pull out the bottle holding the button.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (4) in the housing so that the Sealant Hose (3) aligns with the hose slot in the front

of the housing. Push and hold the Sealant Bottle release

button, then push the bottle into the housing by holding the button. An audible click will be heard indicating the

bottle is locked into place. Release the button.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (3) and return the hose to its storage

area (located on top of the housing).

7. Return the Tire Service Kit to its storage location in the vehicle.

JUMP STARTING

If your vehicle has a discharged battery, it can be jump

started using a set of jumper cables and a battery in another

vehicle or by using a portable battery booster pack. Jump

starting can be dangerous if done improperly, so please

follow the procedures in this section carefully.

NOTE: When using a portable battery booster pack, follow

the manufacturer ’s operating instructions and precautions.

WARNING!

Do not attempt jump starting if the battery is frozen. It

could rupture or explode and cause personal injury.

7

IN CASE OF EMERGENCY 213