warning RAM PROMASTER 2022 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: PROMASTER, Model: RAM PROMASTER 2022Pages: 268, PDF Size: 13.26 MB

Page 191 of 268

IN CASE OF EMERGENCY189

(Continued)

SEALING A TIRE WITH TIRE SERVICE KIT

(A) Whenever You Stop To Use Tire

Service Kit:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning Flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to

the ground. This will allow the Tire Service Kit

Hoses (3) and (5) to reach the valve stem and

keep the Tire Service Kit flat on the ground.

This will provide the best positioning of the kit

when injecting the sealant into the deflated

tire and running the air pump. Move the

vehicle as necessary to place the valve stem in

this position before proceeding. 3. Place the transmission in PARK (P)

(auto transmission) or in Gear (manual

transmission) and place the ignition in the

OFF position.

4. Apply the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob (2) and turn to the Sealant Mode position.

2. Uncoil the Sealant Hose (3) and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose

(3) onto the valve stem.

5. Uncoil the Power Plug (7) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or

nails) from the tire.

If the tire has any damage from driving

with extremely low tire pressure.

If the tire has any damage from driving on

a flat tire.

If the wheel has any damage.

If you are unsure of the condition of the

tire or the wheel.

Keep Tire Service Kit away from open flames

or heat source.

A loose Tire Service Kit thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the Tire

Service Kit in the place provided. Failure to

follow these warnings can result in injuries

that are serious or fatal to you, your passen -

gers, and others around you.

Take care not to allow the contents of Tire

Service Kit to come in contact with hair, eyes,

or clothing. Tire Service Kit sealant is harmful

if inhaled, swallowed, or absorbed through the

skin. It causes skin, eye, and respiratory irrita -

tion. Flush immediately with plenty of water if

there is any contact with eyes or skin. Change

clothing as soon as possible, if there is any

contact with clothing.

WARNING!

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If swal -

lowed, rinse mouth immediately with plenty of

water and drink plenty of water. Do not induce

vomiting! Consult a physician immediately.

WARNING!

7

22_VF_OM_EN_USC_t.book Page 189

Page 193 of 268

IN CASE OF EMERGENCY191

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the

tire, drive the vehicle 5 miles (8 km) or 10 minutes to

ensure distribution of the Tire Service Kit Sealant within

the tire. Do not exceed 50 mph (80 km/h).

(E) After Driving:

Pull over to a safe location Ú page 189.

1. Push in the Mode Select Knob (2) and turn to the Air Mode position.

2. Uncoil the power plug and insert the plug into the vehicle's 12 Volt power outlet.

3. Uncoil the Air Pump Hose (5) (black in color) and screw the fitting at the end of hose onto

the valve stem.

4. Check the pressure in the tire by reading the Pressure Gauge (8). If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button (1) to turn on Tire

Service Kit and inflate the tire to the pressure

indicated on the tire and loading information

label on the driver-side door opening.

NOTE:If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and

unplug from 12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an

authorized dealer or tire service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been

repaired.

6. Replace the Sealant Bottle (4) and Sealant Hose (3) assembly at an authorized dealer as

soon as possible Ú page 191.

NOTE:When having the tire serviced, advise the autho -

rized dealer or service center that the tire has been

sealed using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (3) (clear in color).

2. Locate the red colored round Sealant Bottle release button at the lower right hand corner

of the kit.

3. Push and hold the Sealant Bottle release button, then pull out the bottle holding the

button.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (4) in the housing so that the Sealant Hose (3) aligns

with the hose slot in the front of the housing.

Push and hold the Sealant Bottle release

button, then push the bottle into the housing

by holding the button. An audible click will be

heard indicating the bottle is locked into place.

Release the button.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (3) and return the

hose to its storage area (located on top of the

housing).

7. Return the Tire Service Kit to its storage location in the vehicle.WARNING!

Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced

after using Tire Service Kit. Do not exceed 50 mph

(80 km/h) until the tire is repaired or replaced.

Failure to follow this warning can result in injuries

that are serious or fatal to you, your passengers, and

others around you.

7

22_VF_OM_EN_USC_t.book Page 191

Page 194 of 268

192IN CASE OF EMERGENCY

(Continued)

JUMP STARTING

If your vehicle has a discharged battery, it can be

jump started using a set of jumper cables and a

battery in another vehicle or by using a portable

battery booster pack. Jump starting can be

dangerous if done improperly, so please follow

the procedures in this section carefully.

NOTE:When using a portable battery booster pack, follow

the manufacturer’s operating instructions and

precautions.

PREPARATIONS FOR JUMP START

The vehicle’s jump starting remote posts are

located under the hood, in the engine

compartment on the driver's side.

The Remote positive (+) Post is covered with a

protective cap located on the side of the Front

Power Distribution Center.

The Remote negative (-) Post is located on the core

support closest to the front of the vehicle.

Jump Starting Locations

See the following steps to prepare for jump

starting:

1. Apply the parking brake, shift the automatic

transmission into PARK (P) and turn the

ignition to the OFF position.

2. Turn off the heater, radio, and all electrical accessories.

3. Pull upward and remove the protective cover over the remote positive (+) battery post.

4. If using another vehicle to jump start the battery, park the vehicle within the reach of the

jumper cables, apply the parking brake and

make sure the ignition is OFF.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

CAUTION!

Do not use a portable battery booster pack or

any other booster source with a system voltage

greater than 12 Volts or damage to the battery,

starter motor, alternator or electrical system may

occur.

Remote Positive (+) Post

Remote Negative (-) Post

WARNING!

Do not allow vehicles to touch each other as this

could establish a ground connection and

personal injury could result.

WARNING!

Take care to avoid the radiator cooling fan

whenever the hood is raised. It can start

anytime the ignition switch is ON. You can be

injured by moving fan blades.

22_VF_OM_EN_USC_t.book Page 192

Page 195 of 268

IN CASE OF EMERGENCY193

JUMP STARTING PROCEDURE

Connecting The Jumper Cables

1. Connect the positive

(+) end of the jumper

cable to the remote positive (+)

post of the

discharged vehicle.

NOTE:The remote positive (+) post is located in the

engine compartment on the driver's side under the

cover of the Front Power Distribution Center.

2. Connect the opposite end of the positive (+)

jumper cable to the positive (+) post of the

booster battery.

3. Connect the negative (-) end of the jumper

cable to the negative (-) post of the booster

battery.

4. Connect the opposite end of the negative (-)

jumper cable to the remote negative post or a

good engine ground of the discharged vehicle.

A “ground” is an exposed metallic/unpainted

part of the engine, frame or chassis, such as

an accessory bracket or large bolt. The ground

must be away from the battery and the fuel

injection system.

NOTE:The remote negative (-) post is located in the front

of the engine compartment on the driver's side. 5. Start the engine in the vehicle that has the

booster battery. Let the engine idle a few

minutes and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, follow the discon -

necting procedure below.

Disconnecting The Jumper Cables

1. Disconnect the negative

(-) end of the jumper

cable from the remote negative (-)

post of the

vehicle with the discharged battery.

2. Disconnect the opposite end of the negative (-)

jumper cable from the negative (-) post of the

booster battery.

3. Disconnect the positive (+) end of the jumper

cable from the positive (+) post of the booster

battery.

Remove any metal jewelry such as rings,

watch bands and bracelets that could make

an inadvertent electrical contact. You could be

seriously injured.

Batteries contain sulfuric acid that can burn

your skin or eyes and generate hydrogen gas

which is flammable and explosive. Keep open

flames or sparks away from the battery.

WARNING!

Failure to follow this jump starting procedure

could result in personal injury or property

damage due to battery explosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster

vehicle or the discharged vehicle.

WARNING!WARNING!

Do not connect the jumper cable to the negative

(-) post of the discharged battery. The resulting

electrical spark could cause the battery to

explode and could result in personal injury.

7

22_VF_OM_EN_USC_t.book Page 193

Page 197 of 268

IN CASE OF EMERGENCY195

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector

cannot be moved out of the PARK (P) position, you

can use the following procedure to temporarily

move the gear selector:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Using a small screwdriver or similar tool,

remove the shifter boot material of the gear

selector by pulling up to carefully separate the

gear selector bezel and boot assembly from

the console.

Shifter Boot And Bezel

4. Press and maintain firm pressure on the brake pedal. 5. Insert the screwdriver or similar tool into the

gear selector override release and push down

while depressing the shifter button at the

same time.

Gear Selector Override Release Lever

6. Move the gear selector to the NEUTRAL (N) position.

7. The vehicle may then be started in NEUTRAL.

8. Reinstall the shifter boot and bezel.

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator.

If you see or hear steam coming from under the

hood, do not open the hood until the radiator

has had time to cool. Never try to open a cooling

system pressure cap when the radiator or

coolant bottle is hot.

CAUTION!

Driving with a hot cooling system could damage

your vehicle. If the temperature gauge reads

HOT (H), pull over and stop the vehicle. Idle the

vehicle with the air conditioner turned off until

the pointer drops back into the normal range.

If the pointer remains on HOT (H), and you hear

continuous chimes, turn the engine off

immediately and call for service.

7

22_VF_OM_EN_USC_t.book Page 195

Page 198 of 268

196IN CASE OF EMERGENCY

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Shift back

and forth between DRIVE (D) and REVERSE (R),

while gently pressing the accelerator. Use the least

amount of accelerator pedal pressure that will

maintain the rocking motion, without spinning the

wheels or racing the engine.

NOTE:Push the ESC OFF button, to place the Electronic

Stability Control System (ESC) in “Partial OFF”

mode, before rocking the vehicle Ú page 138.

Once the vehicle has been freed, push the ESC OFF

button again to restore “ESC ON” mode.

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial towing service.

CAUTION!

Racing the engine or spinning the wheels may lead

to transmission overheating and failure. Allow the

engine to idle with the transmission in NEUTRAL for

at least one minute after every five rocking-motion

cycles. This will minimize overheating and reduce the

risk of transmission failure during prolonged efforts

to free a stuck vehicle.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may cause

damage, or even failure, of the axle and tires. A tire

could explode and injure someone. Do not spin your

vehicle's wheels faster than 30 mph (48 km/h) or for

longer than 30 seconds continuously without

stopping when you are stuck and do not let anyone

near a spinning wheel, no matter what the speed.

CAUTION!

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin the

wheels faster than 15 mph (24 km/h), or

drivetrain damage may result.

Spinning the wheels too fast may lead to

transmission overheating and failure. It can

also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

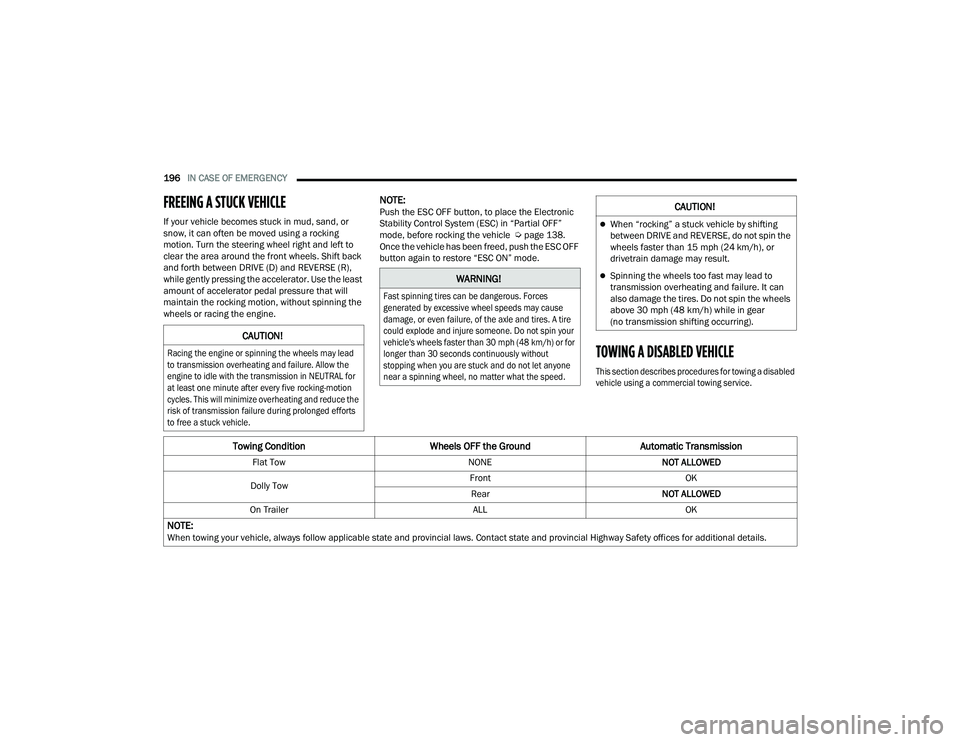

Towing Condition Wheels OFF the Ground Automatic Transmission

Flat Tow NONENOT ALLOWED

Dolly Tow Front

OK

Rear NOT ALLOWED

On Trailer ALLOK

NOTE:When towing your vehicle, always follow applicable state and provincial laws. Contact state and provincial Highway Safety offices for additional details.

22_VF_OM_EN_USC_t.book Page 196

Page 203 of 268

SERVICING AND MAINTENANCE201

Flush and replace the engine coolant at 10 years or 150,000 miles (240,000 km)

whichever comes first. X

X

Inspect and replace the PCV valve if necessary. X

1. The brake fluid change interval is time based only, mileage intervals do not apply.

2. The spark plug change interval is mileage based only, yearly intervals do not apply.

WARNING!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have

any doubt about your ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and affect vehicle handling and performance. This could cause an accident.

Mileage or time passed (whichever comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

8

22_VF_OM_EN_USC_t.book Page 201

Page 205 of 268

SERVICING AND MAINTENANCE203

(Continued)

CHECKING OIL LEVEL

To ensure proper engine lubrication, the engine oil

must be maintained at the correct level. Check the

oil level at regular intervals, such as every fuel

stop. The best time to check the engine oil level is

about five minutes after a fully warmed up engine

is shut off.

Checking the oil while the vehicle is on level ground

will improve the accuracy of the oil level readings.

There are four possible dipstick types:

Crosshatched zone.

Crosshatched zone marked SAFE.

Crosshatched zone marked with MIN at the low

end of the range and MAX at the high end of the

range.

Crosshatched zone marked with dimples at the

MIN and the MAX ends of the range.

NOTE:Always maintain the oil level within the crosshatch

markings on the dipstick. Adding 1 quart (1 liter) of oil when the reading is at

the low end of the dipstick range will raise the oil

level to the high end of the range marking.

ADDING WASHER FLUID

The fluid reservoir is located in the engine

compartment and should be checked at regular

intervals. Fill the reservoir with windshield washer

solvent (not radiator antifreeze) and operate the

system for a few seconds to flush out any residual

water.

The washer fluid reservoir will hold a full gallon of

fluid when the Low Washer Fluid Light illuminates.

WARNING!

Never smoke while working in the engine

compartment: gas and inflammable vapors

may be present, with the risk of fire.

Be very careful when working in the engine

compartment when the engine is hot: you may

get burned. Do not get too close to the radiator

cooling fan: the electric fan may start; danger

of injury. Scarves, ties and other loose clothing

might be pulled by moving parts.

CAUTION!

Be careful not to confuse the various types of

fluids while topping up: they are not compatible

with each other! Topping up with an unsuitable

fluid could severely damage your car.

The oil level must never exceed the MAX mark.

Always top up using engine oil of the same

specifications as that already in the engine.

If the engine oil is being topped up, wait for the

engine to cool down before loosening the filler

cap, particularly for vehicles with aluminum

caps (if equipped). WARNING: risk of burns!

Overfilling or underfilling the crankcase

will cause aeration or loss of oil pressure.

This could damage your engine.

CAUTION!

CAUTION!

Overfilling or underfilling the crankcase will

cause aeration or loss of oil pressure. This could

damage your engine.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling or

working around the washer solution.

8

22_VF_OM_EN_USC_t.book Page 203

Page 206 of 268

204SERVICING AND MAINTENANCE

(Continued)

After the engine has warmed, operate the

defroster for a few minutes to reduce the

possibility of smearing or freezing the fluid on the

cold windshield. Mopar® All Weather Windshield

Washer Solution or equivalent, used with water as

directed on the container, aids cleaning action,

reduces the freezing point to avoid line clogging,

and is not harmful to paint or trim.

MAINTENANCE-FREE BATTERY

Your vehicle is equipped with a maintenance-free

battery. You will never have to add water, and

periodic maintenance is not required.

PRESSURE WASHING

Cleaning the engine compartment with a high

pressure washer is not recommended.

VEHICLE MAINTENANCE

An authorized dealer has the qualified service

personnel, special tools, and equipment to

perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:Intentional tampering with emissions control

systems may void your warranty and could result in

civil penalties being assessed against you.

WARNING!

Battery fluid is a corrosive acid solution and

can burn or even blind you. Do not allow

battery fluid to contact your eyes, skin, or

clothing. Do not lean over a battery when

attaching clamps. If acid splashes in eyes or

on skin, flush the area immediately with large

amounts of water Ú

page 192.

Battery gas is flammable and explosive. Keep

flame or sparks away from the battery. Do not use

a booster battery or any other booster source with

an output greater than 12 Volts. Do not allow

cable clamps to touch each other.

Battery posts, terminals, and related accesso -

ries contain lead and lead compounds. Wash

hands after handling.

CAUTION!

It is essential when replacing the cables on

the battery that the positive cable is attached

to the positive post and the negative cable is

attached to the negative post. Battery posts

are marked positive (+) and negative (-) and

are identified on the battery case. Cable

clamps should be tight on the terminal posts

and free of corrosion.

If a “fast charger” is used while the battery is

in the vehicle, disconnect both vehicle battery

cables before connecting the charger to the

battery. Do not use a “fast charger” to provide

starting voltage.

WARNING!

CAUTION!

Precautions have been taken to safeguard all

parts and connections however, the pressures

generated by these machines is such that

complete protection against water ingress

cannot be guaranteed.

22_VF_OM_EN_USC_t.book Page 204

Page 207 of 268

SERVICING AND MAINTENANCE205

ENGINE OIL

Engine Oil Selection

Use only the manufacturer's recommended fluids

Úpage 251.

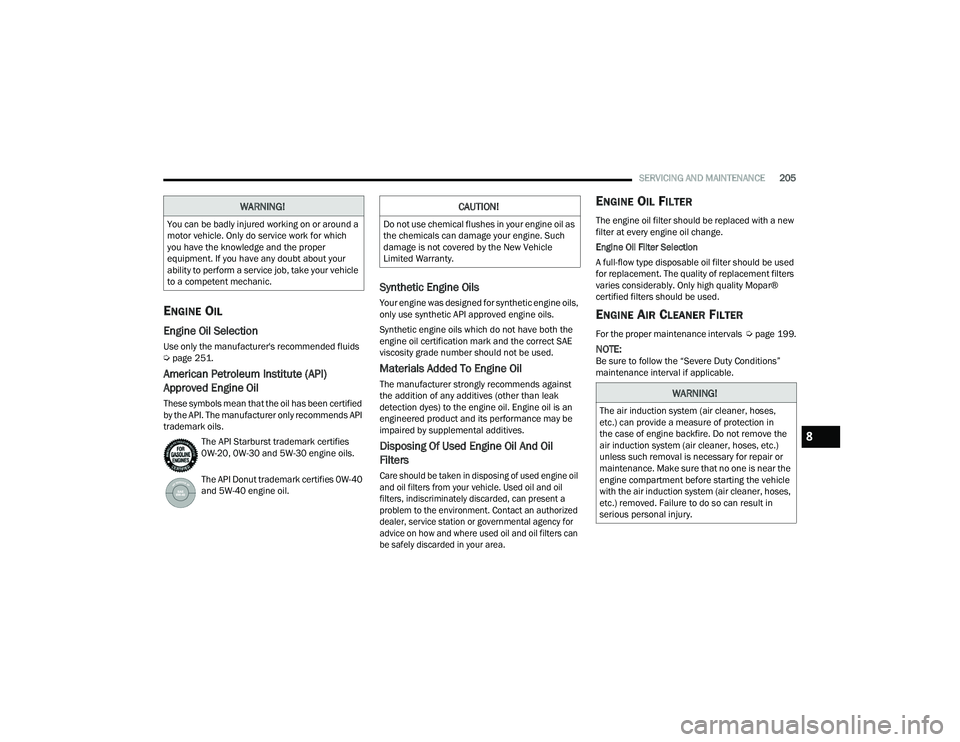

American Petroleum Institute (API)

Approved Engine Oil

These symbols mean that the oil has been certified

by the API. The manufacturer only recommends API

trademark oils.

The API Starburst trademark certifies

0W-20, 0W-30 and 5W-30 engine oils.

The API Donut trademark certifies 0W-40

and 5W-40 engine oil.

Synthetic Engine Oils

Your engine was designed for synthetic engine oils,

only use synthetic API approved engine oils.

Synthetic engine oils which do not have both the

engine oil certification mark and the correct SAE

viscosity grade number should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against

the addition of any additives (other than leak

detection dyes) to the engine oil. Engine oil is an

engineered product and its performance may be

impaired by supplemental additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine oil

and oil filters from your vehicle. Used oil and oil

filters, indiscriminately discarded, can present a

problem to the environment. Contact an authorized

dealer, service station or governmental agency for

advice on how and where used oil and oil filters can

be safely discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new

filter at every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used

for replacement. The quality of replacement filters

varies considerably. Only high quality Mopar®

certified filters should be used.

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 199.

NOTE:Be sure to follow the “Severe Duty Conditions”

maintenance interval if applicable.

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which

you have the knowledge and the proper

equipment. If you have any doubt about your

ability to perform a service job, take your vehicle

to a competent mechanic.

CAUTION!

Do not use chemical flushes in your engine oil as

the chemicals can damage your engine. Such

damage is not covered by the New Vehicle

Limited Warranty.

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in

the case of engine backfire. Do not remove the

air induction system (air cleaner, hoses, etc.)

unless such removal is necessary for repair or

maintenance. Make sure that no one is near the

engine compartment before starting the vehicle

with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in

serious personal injury.

8

22_VF_OM_EN_USC_t.book Page 205