engine RAM PROMASTER 2022 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2022, Model line: PROMASTER, Model: RAM PROMASTER 2022Pages: 268, PDF Size: 13.26 MB

Page 182 of 268

180IN CASE OF EMERGENCY

Automatic SOS — If Equipped

Automatic SOS is a hands-free safety service that

can immediately connect you with help in the event

that your vehicle’s airbags deploy. Please refer to

your provided radio supplement for complete

information.

ASSIST Call

The ASSIST Button is used to automatically

connect you to any one of the following support

centers:

Roadside Assistance – If you get a flat tire, or

need a tow, just push the ASSIST button and

you’ll be connected to someone who can help.

Roadside Assistance will know what vehicle

you’re driving and its location. Additional fees

may apply for roadside assistance.

SiriusXM Guardian™ Customer Care – In-vehicle

support for SiriusXM Guardian™.

Vehicle Customer Care – Total support for all

other vehicle issues.

Uconnect Customer Care - Total support for

Radio, Phone and NAV issues.

JACKING AND TIRE CHANGING PREPARATIONS FOR JACKING

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake firmly.

4. Place the transmission in PARK (P) or REVERSE (R) for manual transmission.

5. Turn the ignition OFF.

6. Block both front and rear of the wheel diagonally opposite of the jacking position.

For example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid the danger of

being hit when operating the jack or changing

the wheel.

Being under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on

you. You could be crushed. Never put any part

of your body under a vehicle that is on a jack.

If you need to get under a raised vehicle, take

it to a service center where it can be raised on

a lift.

Never start or run the engine while the vehicle

is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

22_VF_OM_EN_USC_t.book Page 180

Page 186 of 268

184IN CASE OF EMERGENCY

(Continued)

5. Pull the retainer through the center of the

wheel.

Retainer

JACKING INSTRUCTIONS

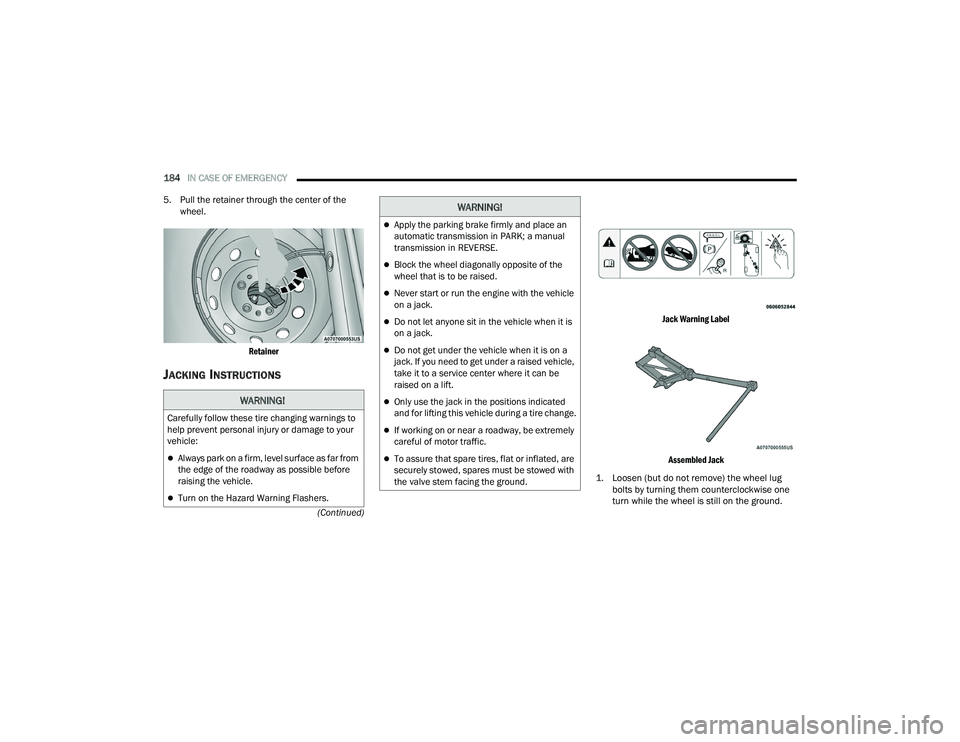

Jack Warning Label

Assembled Jack

1. Loosen (but do not remove) the wheel lug bolts by turning them counterclockwise one

turn while the wheel is still on the ground.

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and place an

automatic transmission in PARK; a manual

transmission in REVERSE.

Block the wheel diagonally opposite of the

wheel that is to be raised.

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with

the valve stem facing the ground.

WARNING!

22_VF_OM_EN_USC_t.book Page 184

Page 192 of 268

190IN CASE OF EMERGENCY

(C) Injecting Tire Service Kit Sealant Into

The Deflated Tire:

Always start the engine before turning ON the

Tire Service Kit.

NOTE:Manual transmission vehicles must have the

parking brake engaged and the gear selector in

NEUTRAL.

After pushing the Power Button (1), the sealant

(white fluid) will flow from the Sealant Bottle (4)

through the Sealant Hose (3) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within

0 – 10 seconds through the Sealant Hose (3):

1. Push the Power Button (1) to turn Off the Tire

Service Kit. Disconnect the Sealant Hose (3)

from the valve stem. Make sure the valve

stem is free of debris. Reconnect the Sealant

Hose (3) to the valve stem. Check that the

Mode Select Knob (2) is in the Sealant Mode

position and not Air Mode. Push the Power

Button (1) to turn On the Tire Service Kit.

2. Connect the Power Plug (7) to a different 12 Volt power outlet in your vehicle or another

vehicle, if available. Make sure the engine is

running before turning ON the Tire Service Kit. 3. The Sealant Bottle (4) may be empty due to

previous use. Call for assistance.

NOTE:If the Mode Select Knob (2) is on Air Mode and the

pump is operating, air will dispense from the Air

Pump Hose (5) only, not the Sealant Hose (3).

If the sealant (white fluid) does flow through the

Sealant Hose (3):

1. Continue to operate the pump until sealant is no longer flowing through the hose (typically takes

30 - 70 seconds). As the sealant flows through the

Sealant Hose (3), the Pressure Gauge (8) can read

as high as 70 psi (4.8 Bar). The Pressure Gauge (8)

will decrease quickly from approximately 70 psi

(4.8 Bar) to the actual tire pressure when the

Sealant Bottle (4) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (4) is

empty. Continue to operate the pump and

inflate the tire to the pressure indicated on the

tire pressure label on the driver-side latch

pillar (recommended pressure). Check the tire

pressure by looking at the Pressure Gauge (8).

If the tire does not inflate to at least 26 psi

(1.8 Bar) pressure within 15 minutes:

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

NOTE:If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

If the tire inflates to the recommended pressure or

is at least 26 psi (1.8 Bar) pressure within

15 minutes:

1. Push the Power Button (1) to turn off the Tire Service Kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle (4) and place the sticker on

the instrument panel.

3. Immediately disconnect the Sealant Hose (3) from the valve stem, reinstall the cap on the

fitting at the end of the hose, and place the Tire

Service Kit in the vehicle storage location.

CAUTION!

The metal end fitting from Power Plug (8) may get

hot after use, so it should be handled carefully.

Failure to reinstall the cap on the fitting at the end

of the Sealant Hose (6) can result in sealant

contacting your skin, clothing, and the vehicle’s

interior. It can also result in sealant contacting

internal Tire Service Kit components which may

cause permanent damage to the kit.

22_VF_OM_EN_USC_t.book Page 190

Page 194 of 268

192IN CASE OF EMERGENCY

(Continued)

JUMP STARTING

If your vehicle has a discharged battery, it can be

jump started using a set of jumper cables and a

battery in another vehicle or by using a portable

battery booster pack. Jump starting can be

dangerous if done improperly, so please follow

the procedures in this section carefully.

NOTE:When using a portable battery booster pack, follow

the manufacturer’s operating instructions and

precautions.

PREPARATIONS FOR JUMP START

The vehicle’s jump starting remote posts are

located under the hood, in the engine

compartment on the driver's side.

The Remote positive (+) Post is covered with a

protective cap located on the side of the Front

Power Distribution Center.

The Remote negative (-) Post is located on the core

support closest to the front of the vehicle.

Jump Starting Locations

See the following steps to prepare for jump

starting:

1. Apply the parking brake, shift the automatic

transmission into PARK (P) and turn the

ignition to the OFF position.

2. Turn off the heater, radio, and all electrical accessories.

3. Pull upward and remove the protective cover over the remote positive (+) battery post.

4. If using another vehicle to jump start the battery, park the vehicle within the reach of the

jumper cables, apply the parking brake and

make sure the ignition is OFF.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

CAUTION!

Do not use a portable battery booster pack or

any other booster source with a system voltage

greater than 12 Volts or damage to the battery,

starter motor, alternator or electrical system may

occur.

Remote Positive (+) Post

Remote Negative (-) Post

WARNING!

Do not allow vehicles to touch each other as this

could establish a ground connection and

personal injury could result.

WARNING!

Take care to avoid the radiator cooling fan

whenever the hood is raised. It can start

anytime the ignition switch is ON. You can be

injured by moving fan blades.

22_VF_OM_EN_USC_t.book Page 192

Page 195 of 268

IN CASE OF EMERGENCY193

JUMP STARTING PROCEDURE

Connecting The Jumper Cables

1. Connect the positive

(+) end of the jumper

cable to the remote positive (+)

post of the

discharged vehicle.

NOTE:The remote positive (+) post is located in the

engine compartment on the driver's side under the

cover of the Front Power Distribution Center.

2. Connect the opposite end of the positive (+)

jumper cable to the positive (+) post of the

booster battery.

3. Connect the negative (-) end of the jumper

cable to the negative (-) post of the booster

battery.

4. Connect the opposite end of the negative (-)

jumper cable to the remote negative post or a

good engine ground of the discharged vehicle.

A “ground” is an exposed metallic/unpainted

part of the engine, frame or chassis, such as

an accessory bracket or large bolt. The ground

must be away from the battery and the fuel

injection system.

NOTE:The remote negative (-) post is located in the front

of the engine compartment on the driver's side. 5. Start the engine in the vehicle that has the

booster battery. Let the engine idle a few

minutes and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, follow the discon -

necting procedure below.

Disconnecting The Jumper Cables

1. Disconnect the negative

(-) end of the jumper

cable from the remote negative (-)

post of the

vehicle with the discharged battery.

2. Disconnect the opposite end of the negative (-)

jumper cable from the negative (-) post of the

booster battery.

3. Disconnect the positive (+) end of the jumper

cable from the positive (+) post of the booster

battery.

Remove any metal jewelry such as rings,

watch bands and bracelets that could make

an inadvertent electrical contact. You could be

seriously injured.

Batteries contain sulfuric acid that can burn

your skin or eyes and generate hydrogen gas

which is flammable and explosive. Keep open

flames or sparks away from the battery.

WARNING!

Failure to follow this jump starting procedure

could result in personal injury or property

damage due to battery explosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster

vehicle or the discharged vehicle.

WARNING!WARNING!

Do not connect the jumper cable to the negative

(-) post of the discharged battery. The resulting

electrical spark could cause the battery to

explode and could result in personal injury.

7

22_VF_OM_EN_USC_t.book Page 193

Page 196 of 268

194IN CASE OF EMERGENCY

4. Disconnect the opposite end of the positive (+)

jumper cable from the remote positive (+) post

of the discharged vehicle, and reinstall the

protective cap.

5. Close the cover of the Front Power Distribution Center.

If frequent jump starting is required to start your

vehicle you should have the battery and charging

system inspected at an authorized dealer.

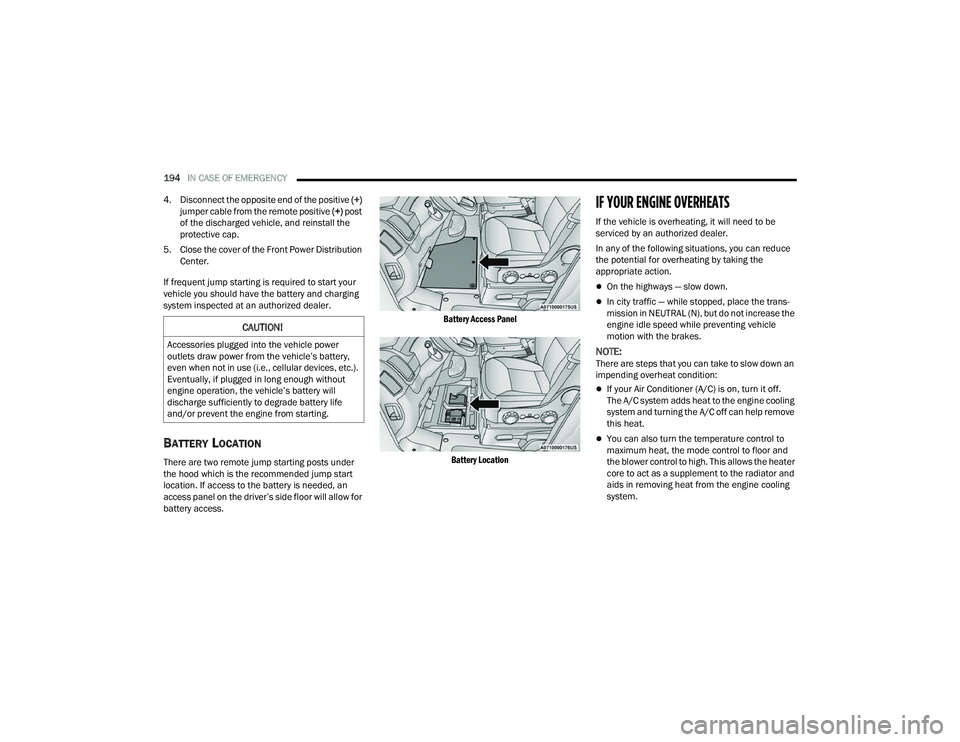

BATTERY LOCATION

There are two remote jump starting posts under

the hood which is the recommended jump start

location. If access to the battery is needed, an

access panel on the driver’s side floor will allow for

battery access.

Battery Access Panel

Battery Location

IF YOUR ENGINE OVERHEATS

If the vehicle is overheating, it will need to be

serviced by an authorized dealer.

In any of the following situations, you can reduce

the potential for overheating by taking the

appropriate action.

On the highways — slow down.

In city traffic — while stopped, place the trans -

mission in NEUTRAL (N), but do not increase the

engine idle speed while preventing vehicle

motion with the brakes.

NOTE:There are steps that you can take to slow down an

impending overheat condition:

If your Air Conditioner (A/C) is on, turn it off.

The A/C system adds heat to the engine cooling

system and turning the A/C off can help remove

this heat.

You can also turn the temperature control to

maximum heat, the mode control to floor and

the blower control to high. This allows the heater

core to act as a supplement to the radiator and

aids in removing heat from the engine cooling

system.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

22_VF_OM_EN_USC_t.book Page 194

Page 197 of 268

IN CASE OF EMERGENCY195

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector

cannot be moved out of the PARK (P) position, you

can use the following procedure to temporarily

move the gear selector:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Using a small screwdriver or similar tool,

remove the shifter boot material of the gear

selector by pulling up to carefully separate the

gear selector bezel and boot assembly from

the console.

Shifter Boot And Bezel

4. Press and maintain firm pressure on the brake pedal. 5. Insert the screwdriver or similar tool into the

gear selector override release and push down

while depressing the shifter button at the

same time.

Gear Selector Override Release Lever

6. Move the gear selector to the NEUTRAL (N) position.

7. The vehicle may then be started in NEUTRAL.

8. Reinstall the shifter boot and bezel.

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator.

If you see or hear steam coming from under the

hood, do not open the hood until the radiator

has had time to cool. Never try to open a cooling

system pressure cap when the radiator or

coolant bottle is hot.

CAUTION!

Driving with a hot cooling system could damage

your vehicle. If the temperature gauge reads

HOT (H), pull over and stop the vehicle. Idle the

vehicle with the air conditioner turned off until

the pointer drops back into the normal range.

If the pointer remains on HOT (H), and you hear

continuous chimes, turn the engine off

immediately and call for service.

7

22_VF_OM_EN_USC_t.book Page 195

Page 198 of 268

196IN CASE OF EMERGENCY

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Shift back

and forth between DRIVE (D) and REVERSE (R),

while gently pressing the accelerator. Use the least

amount of accelerator pedal pressure that will

maintain the rocking motion, without spinning the

wheels or racing the engine.

NOTE:Push the ESC OFF button, to place the Electronic

Stability Control System (ESC) in “Partial OFF”

mode, before rocking the vehicle Ú page 138.

Once the vehicle has been freed, push the ESC OFF

button again to restore “ESC ON” mode.

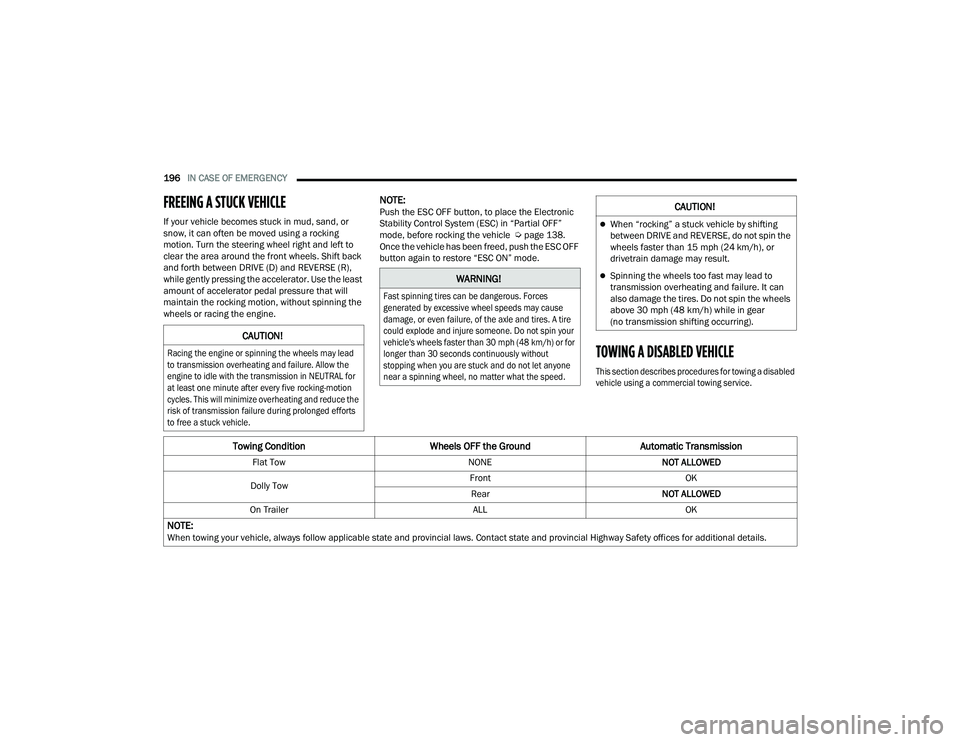

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial towing service.

CAUTION!

Racing the engine or spinning the wheels may lead

to transmission overheating and failure. Allow the

engine to idle with the transmission in NEUTRAL for

at least one minute after every five rocking-motion

cycles. This will minimize overheating and reduce the

risk of transmission failure during prolonged efforts

to free a stuck vehicle.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may cause

damage, or even failure, of the axle and tires. A tire

could explode and injure someone. Do not spin your

vehicle's wheels faster than 30 mph (48 km/h) or for

longer than 30 seconds continuously without

stopping when you are stuck and do not let anyone

near a spinning wheel, no matter what the speed.

CAUTION!

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin the

wheels faster than 15 mph (24 km/h), or

drivetrain damage may result.

Spinning the wheels too fast may lead to

transmission overheating and failure. It can

also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

Towing Condition Wheels OFF the Ground Automatic Transmission

Flat Tow NONENOT ALLOWED

Dolly Tow Front

OK

Rear NOT ALLOWED

On Trailer ALLOK

NOTE:When towing your vehicle, always follow applicable state and provincial laws. Contact state and provincial Highway Safety offices for additional details.

22_VF_OM_EN_USC_t.book Page 196

Page 200 of 268

198

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate in the

instrument cluster. This means that service is

required for your vehicle. Operating conditions such

as frequent short-trips, trailer tow, and extremely hot

or cold ambient temperatures will influence when

the “Oil Change Required” message is displayed.

Have the vehicle serviced as soon as possible, within

the next 500 miles (805 km).

An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, the

message can be reset by referring to the steps

described under Instrument Cluster Display

Ú

page 56.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for fleet

customers. Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check the tire pressures and look for unusual

wear or damage. Rotate at the first sign of irreg

-

ular wear, even if it occurs before the oil indi -

cator system turns on

Check the fluid levels of the coolant reservoir,

and brake master cylinder and fill as needed

Check function of all interior and exterior lights

22_VF_OM_EN_USC_t.book Page 198

Page 201 of 268

SERVICING AND MAINTENANCE199

MAINTENANCE PLAN

Refer to the maintenance plan for the required maintenance intervals. More frequent maintenance may be needed in severe conditions, such as dusty areas

and very short trip driving. In some extreme conditions, additional maintenance not specified in the maintenance schedule may be required.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter.

Rotate the tires at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect battery and clean and tighten terminals as required.

Inspect the CV/Universal joints.

Inspect brake pads, shoes, rotors, drums, hoses and parking brake.

Inspect engine cooling system protection and hoses.

Inspect exhaust system.

Inspect engine air cleaner filter if using in dusty or off-road conditions.

Inspect and replace the Evaporative System Fresh Air Filter as necessary, replacement may be more frequent if vehicle is operated in extreme dusty conditions.

8

22_VF_OM_EN_USC_t.book Page 199