light Ram ProMaster City 2020 Manual PDF

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: ProMaster City, Model: Ram ProMaster City 2020Pages: 350, PDF Size: 13.27 MB

Page 229 of 350

226 IN CASE OF EMERGENCY

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels withwheel covers, install two wheel bolts on the wheel. Install

the wheel bolts with the threaded end of the bolt toward

the wheel. Lightly tighten the wheel bolts.

Tire And Wheel Cover Or Center Cap 3. Align the valve notch in the wheel cover with the valve

stem on the wheel. Install the cover by hand, snapping the

cover over the two wheel bolts. Do not use a hammer or

excessive force to install the cover.

4. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly tighten the

wheel bolts.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

1 — Valve Stem

2 — Valve Notch

3 — Wheel Bolt

4 — Wheel Cover

5 — Road Wheel

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not fully tighten the wheel bolts until the vehicle has

been lowered. Failure to follow this warning may result

in serious injury.

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 226

Page 234 of 350

IN CASE OF EMERGENCY 231

JUMP STARTING

If your vehicle has a discharged battery, it can be jump

started using a set of jumper cables and a battery in another

vehicle or by using a portable battery booster pack. Jump

starting can be dangerous if done improperly, so please

follow the procedures in this section carefully.

NOTE:

When using a portable battery booster pack, follow the

manufacturer’s operating instructions and precautions.

Preparations For Jump Starting

The battery in your vehicle is located in the front of the

engine compartment, behind the left headlight assembly.

NOTE:

The positive battery post is covered with a protective cap.

Lift up on the cap to gain access to the positive battery post.Positive Battery Post Location

WARNING!

Do not attempt jump starting if the battery is frozen. It

could rupture or explode and cause personal injury.

CAUTION!

Do not use a portable battery booster pack or any other

booster source with a system voltage greater than 12 Volts or

damage to the battery, starter motor, alternator or electrical

system may occur.

6

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 231

Page 244 of 350

241

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil change indicator

system. The oil change indicator system will remind you that it is

time to take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil change indi-

cator message will illuminate. This means that service is

required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, extended engine idle time,

extremely hot or cold ambient temperatures will influence

when the “Oil Change Required” message is displayed.

Severe Operating Conditions can cause the change oil

message to illuminate as early as 3,500 miles (5,600 km) since

last reset. Have your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

Your authorized dealer will reset the oil change indicator message

after completing the scheduled oil change. If a scheduled oil change

is performed by someone other than your authorized dealer, the

message can be reset by referring to the steps described under “Oil

Change Reset” in “Instrument Cluster Display” in “Getting To

Know Your Instrument Panel” for further information.

NOTE:

Under no circumstances should oil change intervals exceed

10,000 miles (16,000 km), 350 hours of engine run time or

12 months, whichever comes first. The 350 hours of engine run

or idle time is generally only a concern for fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) or 350 hours of engine

run time if the vehicle is operated in a dusty and off road environ -

ment or is operated predominantly at idle, or only very low engine

RPM. This type of vehicle use is considered Severe Duty.

Once A Month Or Before A Long Trip:

• Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual wear or damage. Rotate tires at the first sign of irregular wear, even if it

occurs before the oil indicator system turns on.

• Check the fluid levels of the coolant reservoir and brake master cylinder, fill as needed.

• Check function of all interior and exterior lights.

7

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 241

Page 263 of 350

260 SERVICING AND MAINTENANCE

(Continued)

Brake System

In order to ensure brake system performance, all brake

system components should be inspected periodically. Refer

to the “Maintenance Plan” in this section for the proper

maintenance intervals.

Brake Master Cylinder

The fluid in the master cylinder should be checked when

performing under hood services or immediately if the

“Brake Warning Light” is illuminated.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the fluid

level up to the requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be expected to fallas the brake pads wear. Brake fluid level should be checked

when pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.

Use only manufacturer's recommended brake fluid. Refer to

“Fluids And Lubricants” in “Technical Specifications” for

further information.

WARNING!

Riding the brakes can lead to brake failure and possibly

a collision. Driving with your foot resting or riding on

the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible brake

damage. You would not have your full braking capacity

in an emergency.

WARNING!

• Use only manufacturer's recommended brake fluid. Refer to “Fluids And Lubricants” in “Technical Speci -

fications” for further information. Using the wrong

type of brake fluid can severely damage your brake

system and/or impair its performance. The proper type

of brake fluid for your vehicle is also identified on the

original factory installed hydraulic master cylinder

reservoir.

• To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been in

a tightly closed container. Keep the master cylinder

reservoir cap secured at all times. Brake fluid in a open

container absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil unexpect -

edly during hard or prolonged braking, resulting in

sudden brake failure. This could result in a collision.

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 260

Page 267 of 350

264 SERVICING AND MAINTENANCE

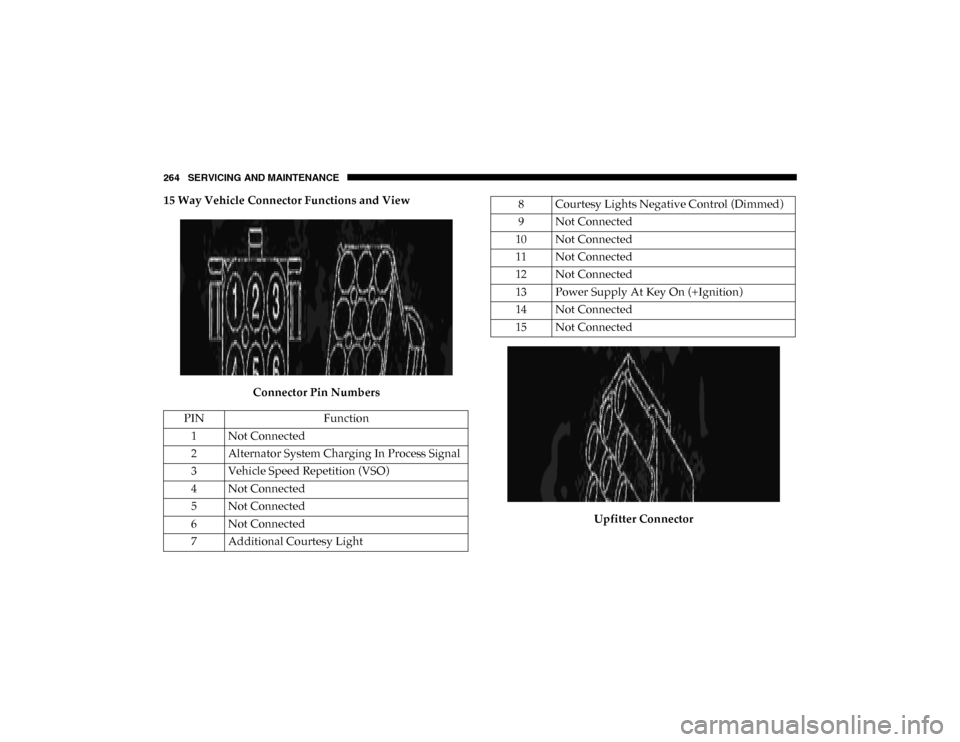

15 Way Vehicle Connector Functions and ViewConnector Pin Numbers Upfitter Connector

PIN

Function

1 Not Connected

2 Alternator System Charging In Process Signal

3 Vehicle Speed Repetition (VSO) 4 Not Connected

5 Not Connected

6 Not Connected

7 Additional Courtesy Light8 Courtesy Lights Negative Control (Dimmed)

9 Not Connected

10 Not Connected

11 Not Connected

12 Not Connected

13 Power Supply At Key On (+Ignition) 14 Not Connected

15 Not Connected

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 264

Page 270 of 350

SERVICING AND MAINTENANCE 267

NOTE:

• P (Passenger) — Metric tire sizing is based on US designstandards. P-Metric tires have the letter “P” molded into

the sidewall preceding the size designation. Example:

P215/65R15 95H.

• European — Metric tire sizing is based on European design standards. Tires designed to this standard have the

tire size molded into the sidewall beginning with the

section width. The letter "P" is absent from this tire size

designation. Example: 215/65R15 96H.

• LT (Light Truck) — Metric tire sizing is based on US design standards. The size designation for LT-Metric tires is the

same as for P-Metric tires except for the letters “LT” that

are molded into the sidewall preceding the size designa -

tion. Example: LT235/85R16. • Temporary spare tires are designed for temporary emer

-

gency use only. Temporary high pressure compact spare

tires have the letter “T” or “S” molded into the sidewall

preceding the size designation. Example: T145/80D18

103M.

• High flotation tire sizing is based on US design standards and it begins with the tire diameter molded into the side -

wall. Example: 31x10.5 R15 LT.

7

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 267

Page 271 of 350

268 SERVICING AND MAINTENANCE

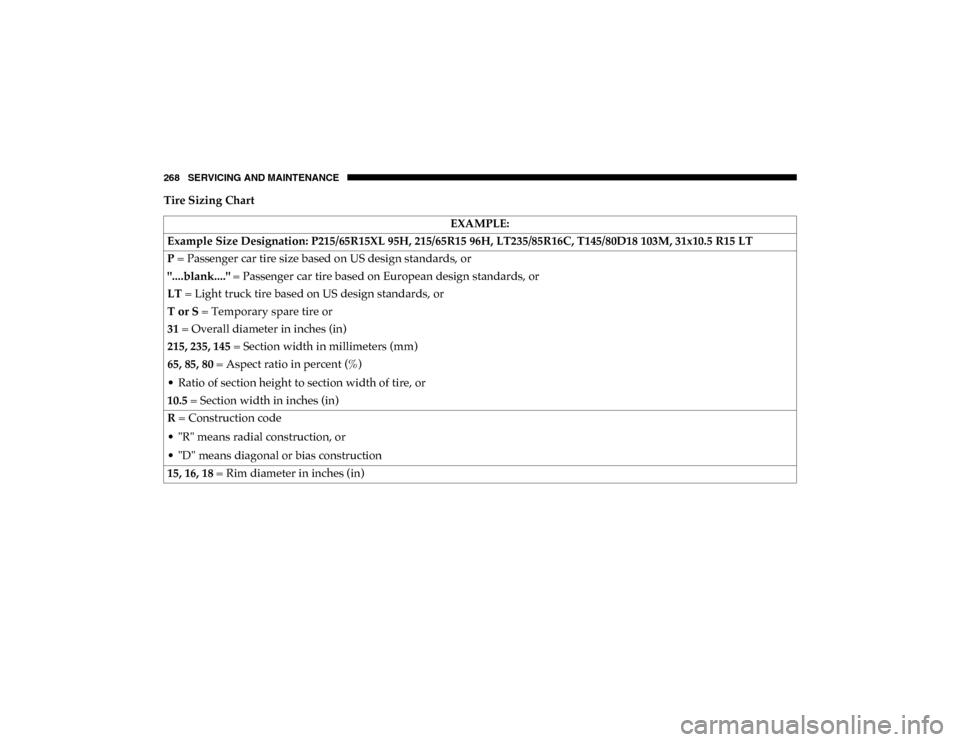

Tire Sizing Chart EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

• Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

• "R" means radial construction, or

• "D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 268

Page 272 of 350

SERVICING AND MAINTENANCE 269

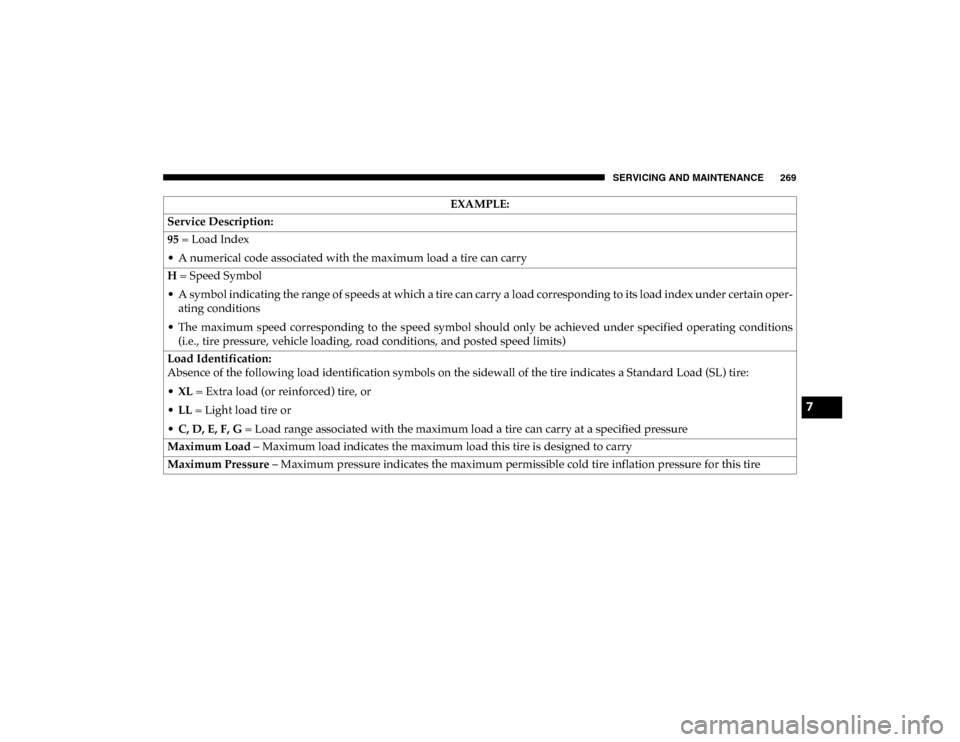

Service Description:

95 = Load Index

• A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

• A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain oper -

ating conditions

• The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

• XL = Extra load (or reinforced) tire, or

• LL = Light load tire or

• C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire EXAMPLE:

7

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 269

Page 283 of 350

280 SERVICING AND MAINTENANCE

Tread Wear Indicators

Tread wear indicators are in the original equipment tires to

help you in determining when your tires should be replaced.

These indicators are molded into the bottom of the tread

grooves. They will appear as bands when the tread depth

becomes a 1/16 of an inch (1.6 mm). When the tread is worn

to the tread wear indicators, the tire should be replaced.

Refer to “Replacement Tires” in this section for further infor-

mation.

Life Of Tire

The service life of a tire is dependent upon varying factors

including, but not limited to:

• Driving style.

• Tire pressure - Improper cold tire inflation pressures can cause uneven wear patterns to develop across the tire

tread. These abnormal wear patterns will reduce tread life,

resulting in the need for earlier tire replacement.

• Distance driven.

• Performance tires, tires with a speed rating of V or higher, and Summer tires typically have a reduced tread life. Rota -

tion of these tires per the vehicle scheduled maintenance is

highly recommended. NOTE:

Wheel Valve Stem must be replaced as well when installing

new tires due to wear and tear in existing tires.

Keep dismounted tires in a cool, dry place with as little expo

-

sure to light as possible. Protect tires from contact with oil,

grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of many

characteristics. They should be inspected regularly for wear

and correct cold tire inflation pressures. The manufacturer

strongly recommends that you use tires equivalent to the

originals in size, quality and performance when replacement

is needed. Refer to the paragraph on “Tread Wear Indica -

tors” in this section. Refer to the Tire and Loading Informa -WARNING!

Tires and the spare tire should be replaced after six

years, regardless of the remaining tread. Failure to follow

this warning can result in sudden tire failure. You could

lose control and have a collision resulting in serious

injury or death.

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 280

Page 293 of 350

290 SERVICING AND MAINTENANCE

BODYWORK

Protection From Atmospheric Agents

Vehicle body care requirements vary according to

geographic locations and usage. Chemicals that make roads

passable in snow and ice and those that are sprayed on trees

and road surfaces during other seasons are highly corrosive

to the metal in your vehicle. Outside parking, which exposes

your vehicle to airborne contaminants, road surfaces on

which the vehicle is operated, extreme hot or cold weather

and other extreme conditions will have an adverse effect on

paint, metal trim, and underbody protection.

The following maintenance recommendations will enable

you to obtain maximum benefit from the corrosion resistance

built into your vehicle.

What Causes Corrosion?

Corrosion is the result of deterioration or removal of paint

and protective coatings from your vehicle.

The most common causes are:

• Road salt, dirt and moisture accumulation

• Stone and gravel impact• Insects, tree sap and tar

• Salt in the air near seacoast localities

• Atmospheric fallout/industrial pollutants

Body And Underbody Maintenance

Cleaning Headlights

Your vehicle is equipped with plastic headlights and fog

lights that are lighter and less susceptible to stone breakage

than glass headlights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution followed

by rinsing.

Do not use abrasive cleaning components, solvents, steel

wool or other aggressive material to clean the lenses.

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 290