TPMS RENAULT ALASKAN 2017 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2017, Model line: ALASKAN, Model: RENAULT ALASKAN 2017Pages: 340, PDF Size: 6.93 MB

Page 213 of 340

•

Replacing tyres with those not originally speci-

fied by RENAULT could affect the proper op-

eration of the TPMS.

• RENAULT recommends using only the Emer-

gency Tyre Sealant provided with your vehicle.

Other tyre sealants may damage the valve

stem seal which can cause the tyre to lose air

pressure. Visit an approved dealer or quali-

fied workshop as soon as possible after using

tyre repair sealant (for models equipped with

the emergency tyre puncture repair kit).

CAUTION

• The TPMS may not function properly when the

wheels are equipped with tyre chains or the

wheels are buried in snow.

• Do not place metallised film or any metal parts

(antenna, etc.) on the windows. This may

cause poor reception of the signals from the

tyre pressure sensors, and the TPMS will not

function properly.

Some devices and transmitters may tempo-

rarily interfere with the operation of the TPMS

and cause the TPMS indicator light to illumi-

nate. Some examples are:

–F acilities or electric devices using similar

radio frequencies are near the vehicle.

–I fatransmitter set to similar frequencies is

being used in or near the vehicle. –I

fac omputer (or similar equipment) or a

DC/AC converter is being used in or near

the vehicle.

–I fdevices which transmit electrical noise

are connected to the vehicle’s 12V power

supply.

• When inflating the tyres and checking the tyre

pressure, never bend the valves.

• Special aluminium valves are fitted to mount

the TPMS sensors on the wheels. The TPMS

sensor is fixed at the wheels by

anut. The nut

needs to be correctly fitted at atorque setting

of 7.5 ±0.5 N•m. If the TPMS sensor is tight-

ened exceeding the limit, there is apossibility

the sensor grommet will be damaged. If the

sensor is tightened under the limit, there is a

possibility of causing an air leak.

• Use valve caps that comply with the factory-

fitted valve cap specifications.

• Do not use metal valve caps.

• Fit the valve caps properly. Without the valve

caps the valve and tyre pressure monitor sen-

sors could be damaged.

• Do not damage the valves and sensors when

storing the wheels or fitting different tyres.

• Replace the sensor grommet and washer dur-

ing

atyre change. Once they have been re-

moved, the sensor grommet and washer can-

not be reused and must be replaced. The

TPMS sensors can be used again. •

Use caution when using tyre inflation equip-

ment with

arigid air supply tube, as leverage

applied by the long nozzle can damage the

valve stem.

Starting and driving 5-11

Page 214 of 340

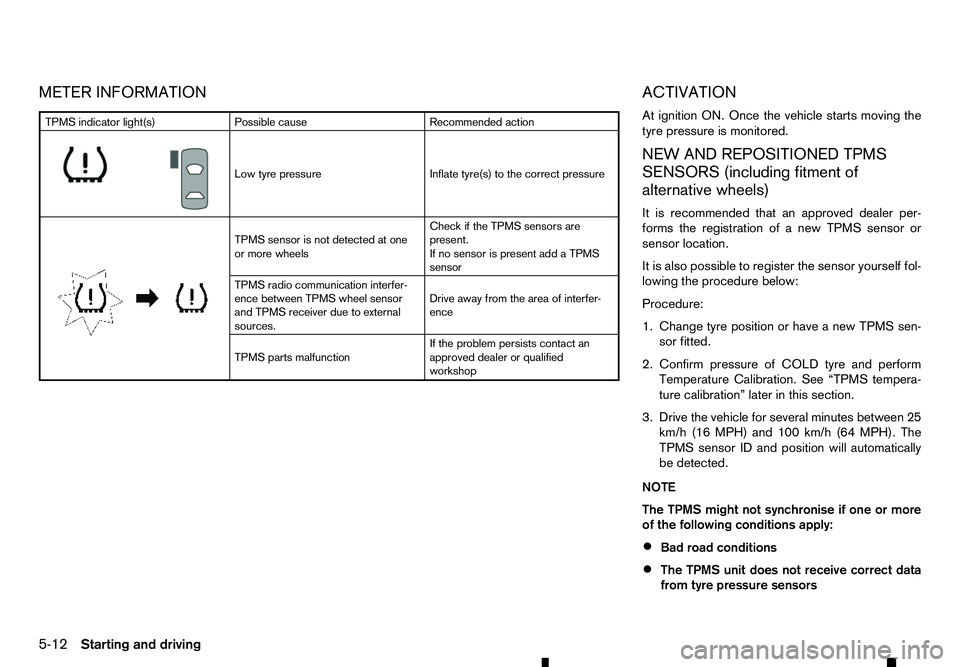

METER INFORMATION

ACTIVATION

At ignition ON. Once the vehicle starts moving the

tyre pressure is monitored.

NEW AND REPOSITIONED TPMSSENSORS (including fitment of

alternative wheels)

It is recommended that an approved dealer per-

forms the registration of anew TPMS sensor or

sensor location.

It is also possible to register the sensor yourself fol-

lowing the procedure below:

Procedure:

1. Change tyre position or have anew TPMS sen-

sor fitted.

2. Confirm pressure of COLD tyre and perform Temperature Calibration. See “TPMS tempera-

ture calibration” later in this section.

3. Drive the vehicle for several minutes between 25 km/h (16 MPH) and 100 km/h (64 MPH). The

TPMS sensor ID and position will automatically

be detected.

NOTE

The TPMS might not synchronise if one or more

of the following conditions apply:

• Bad road conditions

• The TPMS unit does not receive correct data

from tyre pressure sensors TPMS indicator light(s)

Possible cause Recommended action

m Low

tyre pressure

Inflate tyre(s) to the correct pressure

m TPMS

sensor is not detected at one

or more wheels Check if the TPMS sensors are

present.

If no sensor is present add aTPMS

sensor

TPMS radio communication interfer-

ence between TPMS wheel sensor

and TPMS receiver due to external

sources. Drive away from the area of interfer-

ence

TPMS parts malfunction If the problem persists contact an

approved dealer or qualified

workshop

5-12 Starting and driving

Page 215 of 340

•

Driving below 25 km/h (16 MPH)

• Driving above 100 km/h (64 MPH)

• High acceleration

• High deceleration

• In stop and go traffic or traffic waves

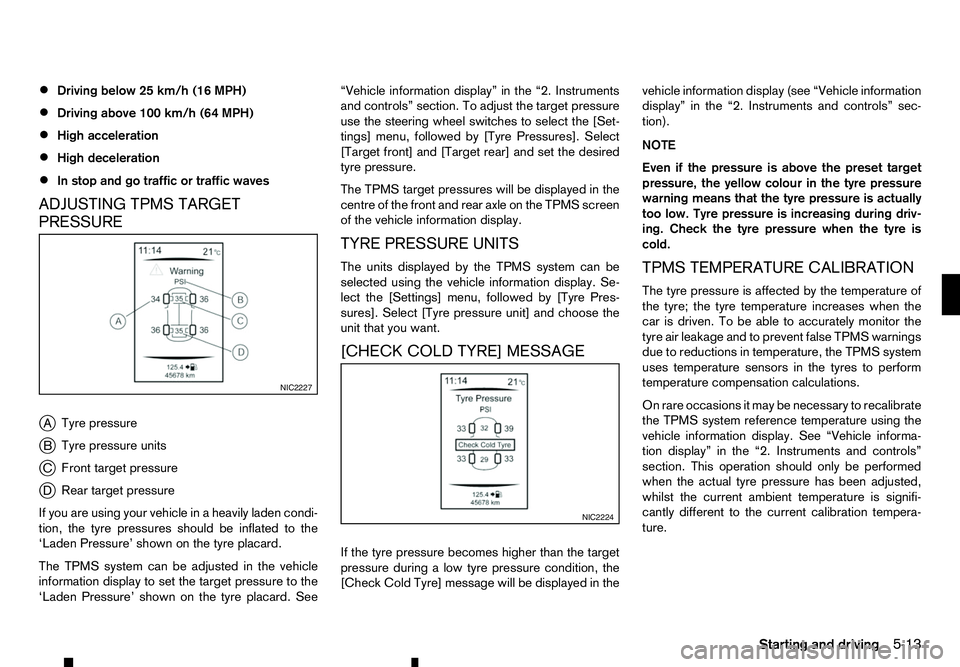

ADJUSTING TPMS TARGET

PRESSURE

j A Tyre pressure

j B Tyre pressure units

j C Front target pressure

j D Rear target pressure

If you are using your vehicle in aheavily laden condi-

tion, the tyre pressures should be inflated to the

‘Laden Pressure’ shown on the tyre placard.

The TPMS system can be adjusted in the vehicle

information display to set the target pressure to the

‘Laden Pressure’ shown on the tyre placard. See “Vehicle information display” in the “2. Instruments

and controls” section. To adjust the target pressure

use the steering wheel switches to select the [Set-

tings] menu, followed by [Tyre Pressures]. Select

[Target front] and [Target rear] and set the desired

tyre pressure.

The TPMS target pressures will be displayed in the centre of the front and rear axle on the TPMS screen

of the vehicle information display.

TYRE PRESSURE UNITS

The units displayed by the TPMS system can be

selected using the vehicle information display. Se-

lect the [Settings] menu, followed by [Tyre Pres-

sures]. Select [Tyre pressure unit] and choose the

unit that you want.

[CHECK COLD TYRE] MESSAGE

If the tyre pressure becomes higher than the target

pressure during alow tyre pressure condition, the

[Check Cold Tyre] message will be displayed in the vehicle information display (see “Vehicle information

display” in the “2. Instruments and controls” sec-

tion).

NOTE

Even if the pressure is above the preset target

pressure, the yellow colour in the tyre pressure

warning means that the tyre pressure is actually

too low. Tyre pressure is increasing during driv-

ing. Check the tyre pressure when the tyre is

cold.

TPMS TEMPERATURE CALIBRATION

The tyre pressure is affected by the temperature of

the tyre; the tyre temperature increases when the

car is driven. To be able to accurately monitor the

tyre air leakage and to prevent false TPMS warnings

due to reductions in temperature, the TPMS system

uses temperature sensors in the tyres to perform

temperature compensation calculations.

On rare occasions it may be necessary to recalibrate

the TPMS system reference temperature using the

vehicle information display. See “Vehicle informa-

tion display” in the “2. Instruments and controls”

section. This operation should only be performed

when the actual tyre pressure has been adjusted,

whilst the current ambient temperature is signifi-

cantly different to the current calibration tempera-

ture. NIC2227

NIC2224

Starting and driving

5-13

Page 216 of 340

![RENAULT ALASKAN 2017 User Guide To initiate TPMS temperature calibration use the

steering wheel switches to select the [Settings]

menu, followed by [Tyre Pressures]. Select [Cali-

brate] followed by [Start]. While the calibration pr RENAULT ALASKAN 2017 User Guide To initiate TPMS temperature calibration use the

steering wheel switches to select the [Settings]

menu, followed by [Tyre Pressures]. Select [Cali-

brate] followed by [Start]. While the calibration pr](/img/7/58394/w960_58394-215.png)

To initiate TPMS temperature calibration use the

steering wheel switches to select the [Settings]

menu, followed by [Tyre Pressures]. Select [Cali-

brate] followed by [Start]. While the calibration pro-

cess is active, the message: [Resetting tyre pres-

sure system] will be displayed in the vehicle informa-

tion display. WARNING

Never remove the key or turn the ignition switch

to the

ing wheel will lock. This will cause the driver to

lose control of the vehicle and could result in

serious vehicle damage or personal injury.

MANUAL TRANSMISSION (MT)

The switch includes an anti-theft steering lock de-

vice.

The ignition key can only be removed when theswitch is in the

(0).

There is an “OFF” position ➀in between

and

cylinder.

To lock the steering wheel, remove the key. To

unlock the steering wheel, insert the key and turn

it gently while rotating the steering wheel slightly

right and left. KEY POSITIONS

LOCK (Normal parking position) (0):

The ignition key can only be removed at this posi-

tion.

OFF (1):

The engine can be turned off without locking the

steering wheel.

ACC (Accessories) (2):

This position activates electrical accessories such

as the radio when the engine is not running.

ON (Normal operating position) (3):

This position turns on the ignition system and elec-

trical accessories.

START (4):

This position starts the engine. As soon as the en-

gine has started, release the key immediately. It will

automatically return to the

STEERING LOCK

Locking the steering wheel

1) Place the ignition switch in the

tion.

2) Remove the key from the ignition switch.

3) Turn the steering wheel 1/6 of aturn clockwise

from the straight up position. SSD0392Z

IGNITION SWITCH (models without

Remote Control Key system)

5-14 Starting and driving

Page 264 of 340

If the pressure drops again,

the tyre cannot be

repaired with this tyre puncture repair kit. Con-

tact an approved dealer or qualified workshop.

When the tyre pressure is the specified

pressure:

The temporary repair is completed.

See an approved dealer or qualified workshop for

the repair/replacement as soon as possible.

After repairing tyre

See an approved dealer or qualified workshop for

tyre repair or replacement and for anew tyre seal-

ant bottle and hose, as soon as possible.

CAUTION

• Before driving, ensure tyre is adjusted to rec-

ommended inflation pressure as indicated on

vehicle placard. Monitor tyre pressure until

sealed tyre is replaced.

• Do not drive the vehicle at speeds faster than

50 MPH (80 km/h), and the damaged tyre

must be replaced as quickly as possible

(within

amaximum driving distance of 200 km

(120 miles)). You must not continue to drive if

heavy vibrations, unsteady steering behaviour

or noises should occur while driving.

• Immediately after using Emergency Tyre Seal-

ant to repair

aminor tyre puncture, take your

vehicle to an approved dealer or qualified

workshop to inspect, and repair or replace

the tyre. The Emergency Tyre Sealant cannot

permanently seal apunctured tyre. Continu- ing operation of the vehicle without

aperma-

nent tyre repair can lead to acrash.

• If you used Emergency Tyre Sealant to repair

am

inor tyre puncture, your approved dealer

or qualified workshop will also need to re-

place the TPMS sensor in addition to repair-

ing or replacing the tyre.

• RENAULT recommends using only RENAULT

Genuine Emergency Tyre Sealant provided

with your vehicle. Other tyre sealants may

damage the valve stem seal which can cause

the tyre to lose air pressure. WARNING

• Incorrect jump starting can lead to

abattery

explosion. The battery explosion may result in

severe injury or death. It may also result in

damage to the vehicle. Be sure to follow the

instructions in this section.

• Explosive hydrogen gas is always present in

the vicinity of the battery. Keep all sparks and

flames away from the battery.

• Always wear suitable eye protection and re-

move rings, bracelets, and any other jewellery

whenever working on or near

abattery.

• Never lean over the battery while jump start-

ing.

• Never allow battery fluid to come into contact

with eyes, skin, clothes or the vehicle’s

painted surfaces. Battery fluid is

acorrosive

sulphuric acid which can cause severe burns.

If the fluid comes into contact with anything,

immediately flush the contacted area with

plenty of water.

• Keep the battery out of the reach of children.

• The booster battery must be rated at 12 volts.

Use of an incorrectly rated battery will dam-

age your vehicle.

• Never attempt to jump start

afrozen battery.

It could explode and cause serious injury.

JUMP STARTING

6-10 In case of emergency

Page 279 of 340

Lights*:

Clean the headlights on

aregular basis. Make sure

that the headlights, stop lights, tail lights, turn signal

lights, and other lights are all operating properly and

installed securely. Also check the aim of the head-

lights.

Tyres*:

Check the pressure with agauge often and always

prior to long distance trips. Adjust the pressure in all

tyres, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear.

Tyre rotation*:

In the case of Two-Wheel Drive (2WD), and where

front and rear tyres are the same size: tyres should

be rotated every 10,000 km (6,000 miles). Tyres

marked with directional indicators can only be ro-

tated between front and rear. Make sure that the

directional indicators point in the direction of wheel

rotation after the tyre rotation is completed.

In the case of the Four-Wheel Drive and All Wheel

Drive (4WD/AWD), and where front and rear tyres

are the same size: tyres should be rotated every

5,000 km (3,000 miles). Tyres marked with direc-

tional indicators can only be rotated between front

and rear. Make sure that the directional indicators

point in the direction of wheel rotation after the tyre

rotation is completed.

In the case that front tyres are different size from

rear tyres: tyres cannot be rotated.

The timing for tyre rotation may vary according to

your driving habits and the road surface conditions. Tyre Pressure Monitoring System (TPMS)

transmitter components (where fitted):

Replace the TPMS transmitter grommet seal, valve

core and cap when the tyres are replaced due to

wear or age.

Wheel alignment and balance:

If the vehicle should pull to either side while driving

on astraight and level road, or if you detect uneven

or abnormal tyre wear, there may be aneed for

wheel alignment. If the steering wheel or seat vi-

brates at normal highway speeds, wheel balancing

may be needed.

Windscreen:

Clean the windscreen on aregular basis. Check the

windscreen at least every six months for cracks or

other damage. Repair as necessary.

Wiper blades*:

Check for cracks or wear if not functioning cor-

rectly. Replace as necessary.

Inside vehicle

The maintenance items listed here should be

checked on aregular basis, such as when perform-

ing periodic maintenance, cleaning the vehicle, etc.

Accelerator pedal:

Check the pedal for smooth operation and make

sure that the pedal does not catch or require uneven

effort. Keep the floor mats away from the pedal. Brake pedal*:

Check the pedal for smooth operation and make

sure that it is the proper distance from the floor mat

when depressed fully. Check the brake booster

function. Be sure to keep the floor mats away from

the pedal.

Parking brake*:

Check the parking brake operation regularly. Check

that the lever (where fitted) or the pedal (where fit-

ted) has the proper travel. Also make sure that the

vehicle is held securely on

afairly steep hill when

only the parking brake is applied.

Seat belts:

Check that all parts of the seat belt system (for

example, buckles, anchors, adjusters and retrac-

tors) operate properly and smoothly, and are in-

stalled securely. Check the belt webbing for cuts,

fraying, wear or damage.

Steering wheel:

Check for changes in the steering condition, such

as excessive play, hard steering or strange noises.

Warning lights and chimes:

Make sure that all warning lights and chimes are

operating properly.

Windscreen defogger:

Check that the air comes out of the defogger outlets

properly and in good quantity when operating the

heater or air conditioner.

Maintenance and do-it-yourself 8-3

Page 331 of 340

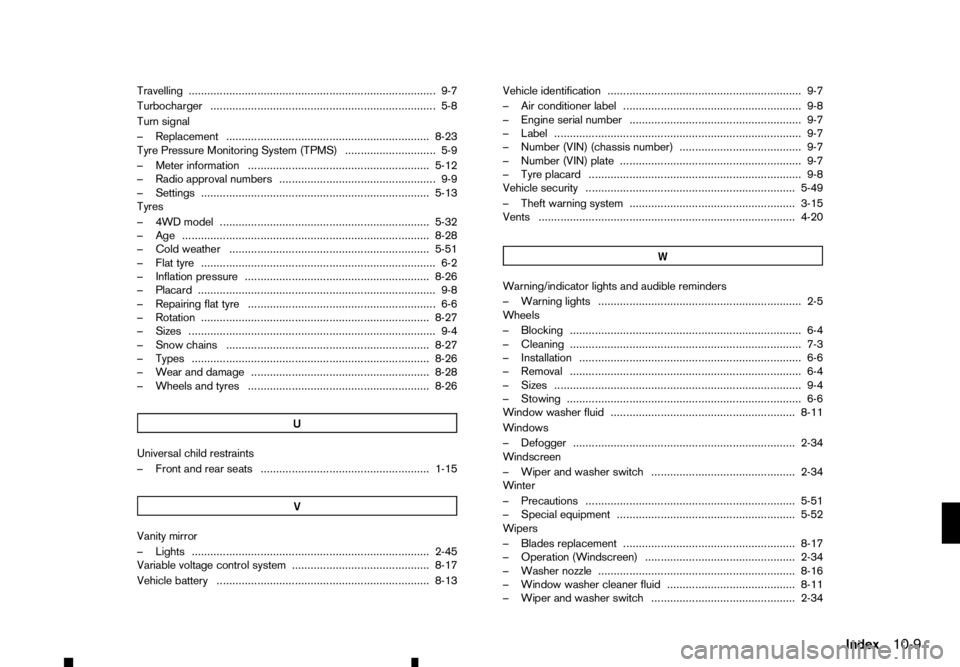

Travelling ........................................................................V

....... 9-7

Turbocharger ........................................................................V

5-8

Turn signal

–R eplacement ................................................................. 8-23

Tyre Pressure Monitoring System (TPMS) ............................. 5-9

–M eter information .......................................................... 5-12

–R adio approval numbers .................................................. 9-9

–S ettings ........................................................................V

. 5-13

Tyres

–4 WD model ................................................................... 5-32

–A ge ........................................................................V

....... 8-28

–C old weather ................................................................ 5-51

–F lat tyre ........................................................................V

... 6-2

–I nflation pressure ........................................................... 8-26

–P lacard ........................................................................V

.... 9-8

–R epairing flat tyre ............................................................ 6-6

–R otation ........................................................................V

. 8-27

–S izes ........................................................................V

....... 9-4

–S now chains ................................................................. 8-27

–T ypes ........................................................................V

.... 8-26

–W ear and damage ......................................................... 8-28

–W heels and tyres .......................................................... 8-26

U Universal child restraints

–F ront and rear seats ...................................................... 1-15

V Vanity mirror

–L ights ........................................................................V

.... 2-45

Variable voltage control system ............................................ 8-17

Vehicle battery .................................................................... 8-13 Vehicle identification .............................................................. 9-7

–A

ir conditioner label ......................................................... 9-8

–E ngine serial number ....................................................... 9-7

–L abel ........................................................................V

....... 9-7

–N umber (VIN) (chassis number) ....................................... 9-7

–N umber (VIN) plate .......................................................... 9-7

–T yre placard .................................................................... 9-8

Vehicle security ................................................................... 5-49

–T heft warning system ..................................................... 3-15

Vents ........................................................................V

.......... 4-20

W Warning/indicator lights and audible reminders

–W arning lights ................................................................. 2-5

Wheels

–B locking ........................................................................V

.. 6-4

–C leaning ........................................................................V

.. 7-3

–I nstallation ....................................................................... 6-6

–R emoval ........................................................................V

.. 6-4

–S izes ........................................................................V

....... 9-4

–S towing ........................................................................V

... 6-6

Window washer fluid ........................................................... 8-11

Windows

–D efogger ....................................................................... 2-34

Windscreen

–W iper and washer switch .............................................. 2-34

Winter

–P recautions ................................................................... 5-51

–S pecial equipment ......................................................... 5-52

Wipers

–B lades replacement ....................................................... 8-17

–O peration (Windscreen) ................................................ 2-34

–W asher nozzle ............................................................... 8-16

–W indow washer cleaner fluid ......................................... 8-11

–W iper and washer switch .............................................. 2-34

Index10-9