ECU RENAULT ALASKAN 2017 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2017, Model line: ALASKAN, Model: RENAULT ALASKAN 2017Pages: 340, PDF Size: 6.93 MB

Page 259 of 340

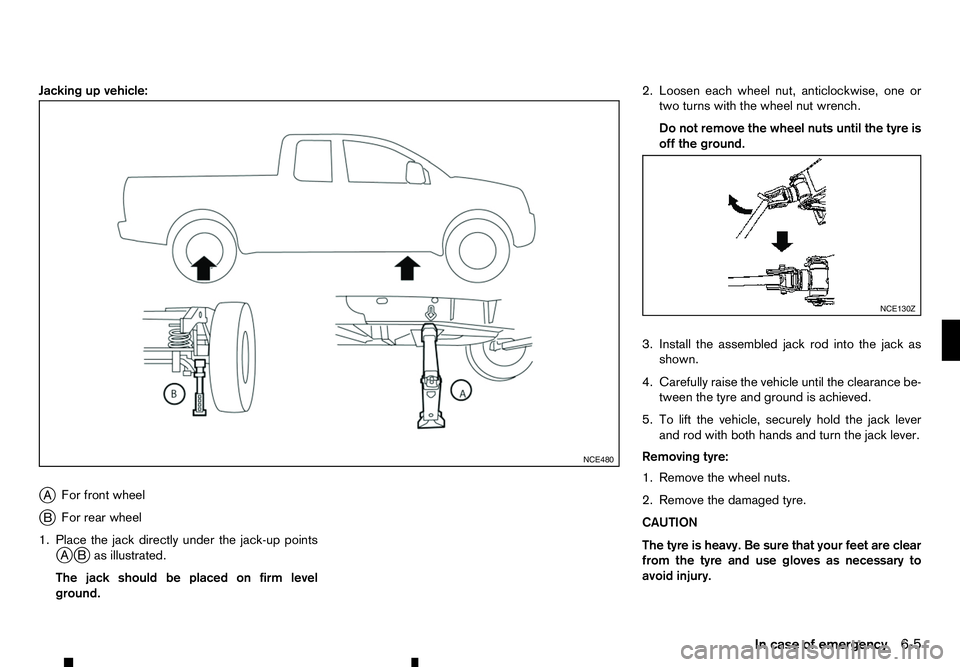

Jacking up vehicle:

j A For front wheel

j B For rear wheel

1. Place the jack directly under the jack-up points jA jBa sillustrated.

The jack should be placed on firm level

ground. 2. Loosen each wheel nut, anticlockwise, one or

two turns with the wheel nut wrench.

Do not remove the wheel nuts until the tyre is

off the ground.

3. Install the assembled jack rod into the jack as shown.

4. Carefully raise the vehicle until the clearance be- tween the tyre and ground is achieved.

5. To lift the vehicle, securely hold the jack lever and rod with both hands and turn the jack lever.

Removing tyre:

1. Remove the wheel nuts.

2. Remove the damaged tyre.

CAUTION

The tyre is heavy. Be sure that your feet are clear

from the tyre and use gloves as necessary to

avoid injury. NCE480 NCE130Z

In case of emergency

6-5

Page 260 of 340

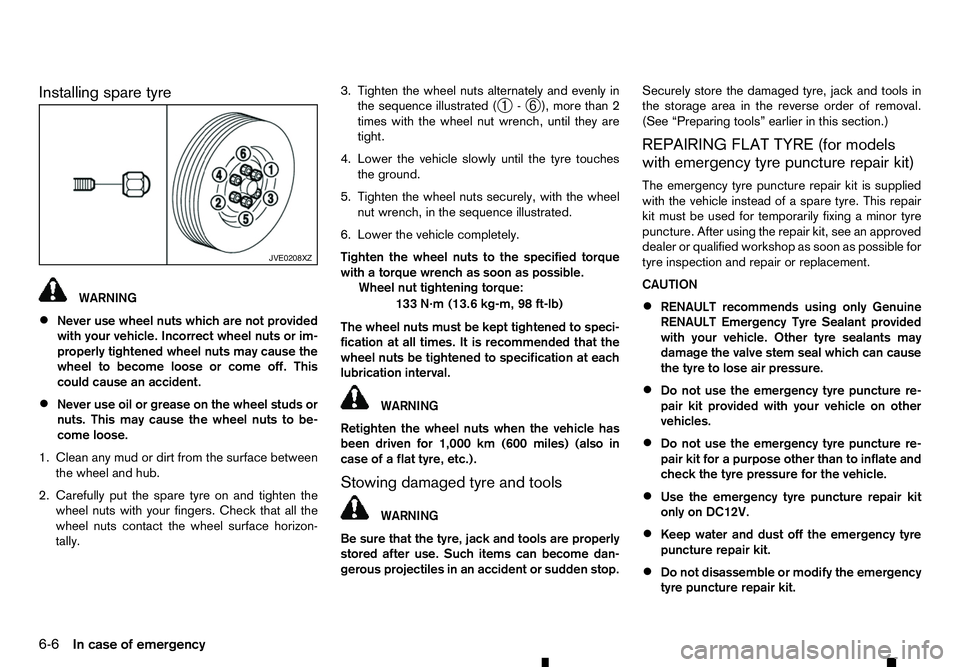

Installing spare tyre

WARNING

• Never use wheel nuts which are not provided

with your vehicle. Incorrect wheel nuts or im-

properly tightened wheel nuts may cause the

wheel to become loose or come off. This

could cause an accident.

• Never use oil or grease on the wheel studs or

nuts. This may cause the wheel nuts to be-

come loose.

1. Clean any mud or dirt from the surface between the wheel and hub.

2. Carefully put the spare tyre on and tighten the wheel nuts with your fingers. Check that all the

wheel nuts contact the wheel surface horizon-

tally. 3. Tighten the wheel nuts alternately and evenly in

the sequence illustrated ( ➀-

➅ ), more than 2

times with the wheel nut wrench, until they are

tight.

4. Lower the vehicle slowly until the tyre touches the ground.

5. Tighten the wheel nuts securely, with the wheel nut wrench, in the sequence illustrated.

6. Lower the vehicle completely.

Tighten the wheel nuts to the specified torque

with atorque wrench as soon as possible.

Wheel nut tightening torque:

133 N·m (13.6 kg-m, 98 ft-lb)

The wheel nuts must be kept tightened to speci-

fication at all times. It is recommended that the

wheel nuts be tightened to specification at each

lubrication interval. WARNING

Retighten the wheel nuts when the vehicle has

been driven for 1,000 km (600 miles) (also in

case of aflat tyre, etc.).

Stowing damaged tyre and tools WARNING

Be sure that the tyre, jack and tools are properly

stored after use. Such items can become dan-

gerous projectiles in an accident or sudden stop. Securely store the damaged tyre, jack and tools in

the storage area in the reverse order of removal.

(See “Preparing tools” earlier in this section.)

REPAIRING FLAT TYRE (for models

with emergency tyre puncture repair kit)

The emergency tyre puncture repair kit is supplied

with the vehicle instead of aspare tyre. This repair

kit must be used for temporarily fixing aminor tyre

puncture. After using the repair kit, see an approved

dealer or qualified workshop as soon as possible for

tyre inspection and repair or replacement.

CAUTION

• RENAULT recommends using only Genuine

RENAULT Emergency Tyre Sealant provided

with your vehicle. Other tyre sealants may

damage the valve stem seal which can cause

the tyre to lose air pressure.

• Do not use the emergency tyre puncture re-

pair kit provided with your vehicle on other

vehicles.

• Do not use the emergency tyre puncture re-

pair kit for

apurpose other than to inflate and

check the tyre pressure for the vehicle.

• Use the emergency tyre puncture repair kit

only on DC12V.

• Keep water and dust off the emergency tyre

puncture repair kit.

• Do not disassemble or modify the emergency

tyre puncture repair kit. JVE0208XZ

6-6 In case of emergency

Page 262 of 340

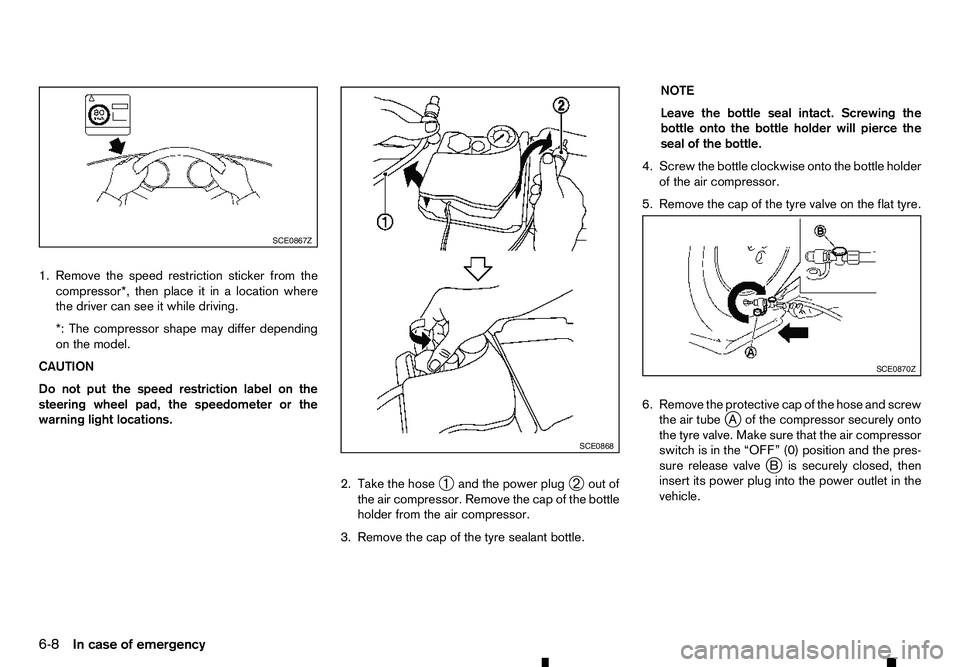

1. Remove the speed restriction sticker from the

compressor*, then place it in alocation where

the driver can see it while driving.

*: The compressor shape may differ depending

on the model.

CAUTION

Do not put the speed restriction label on the

steering wheel pad, the speedometer or the

warning light locations.

2. Take the hose➀and the power plug

➁out of

the air compressor. Remove the cap of the bottle holder from the air compressor.

3. Remove the cap of the tyre sealant bottle. NOTE

Leave the bottle seal intact. Screwing the

bottle onto the bottle holder will pierce the

seal of the bottle.

4. Screw the bottle clockwise onto the bottle holder of the air compressor.

5. Remove the cap of the tyre valve on the flat tyre.

6. Remove the protective cap of the hose and screw the air tube j

Ao fthe compressor securely onto

the tyre valve. Make sure that the air compressor

switch is in the “OFF” (0) position and the pres-

sure release valve j

Bi ssecurely closed, then

insert its power plug into the power outlet in the

vehicle. SCE0867Z

SCE0868 SCE0870Z

6-8 In case of emergency

Page 263 of 340

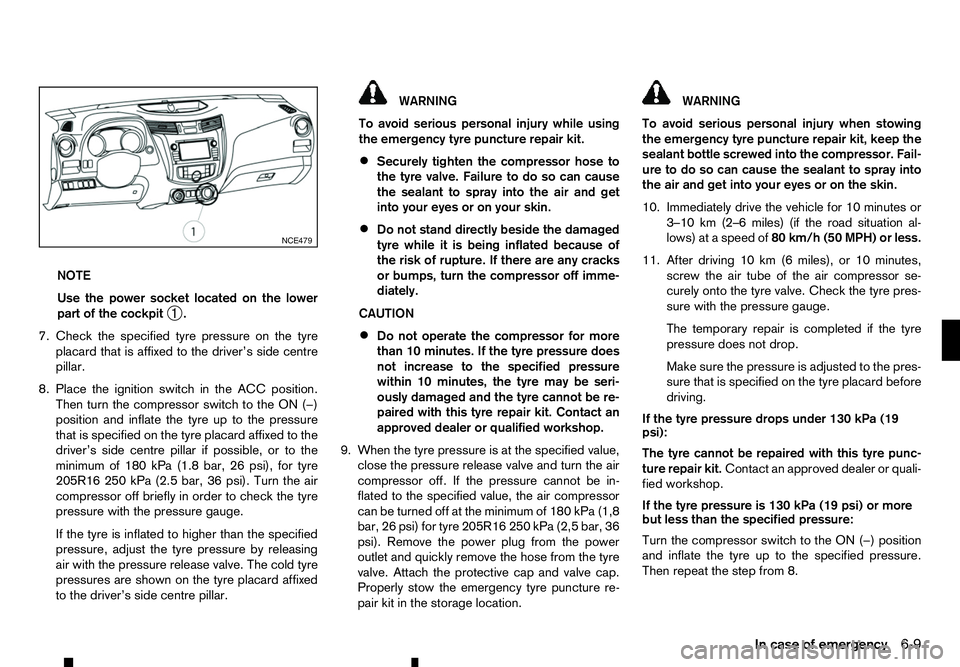

NOTE

Use the power socket located on the lower

part of the cockpit ➀.

7. Check the specified tyre pressure on the tyre placard that is affixed to the driver’s side centre

pillar.

8. Place the ignition switch in the ACC position. Then turn the compressor switch to the ON (−)

position and inflate the tyre up to the pressure

that is specified on the tyre placard affixed to the

driver’s side centre pillar if possible, or to the

minimum of 180 kPa (1.8 bar, 26 psi), for tyre

205R16 250 kPa (2.5 bar, 36 psi). Turn the air

compressor off briefly in order to check the tyre

pressure with the pressure gauge.

If the tyre is inflated to higher than the specified

pressure, adjust the tyre pressure by releasing

air with the pressure release valve. The cold tyre

pressures are shown on the tyre placard affixed

to the driver’s side centre pillar. WARNING

To avoid serious personal injury while using

the emergency tyre puncture repair kit.

• Securely tighten the compressor hose to

the tyre valve. Failure to do so can cause

the sealant to spray into the air and get

into your eyes or on your skin.

• Do not stand directly beside the damaged

tyre while it is being inflated because of

the risk of rupture. If there are any cracks

or bumps, turn the compressor off imme-

diately.

CAUTION

• Do not operate the compressor for more

than 10 minutes. If the tyre pressure does

not increase to the specified pressure

within 10 minutes, the tyre may be seri-

ously damaged and the tyre cannot be re-

paired with this tyre repair kit. Contact an

approved dealer or qualified workshop.

9. When the tyre pressure is at the specified value, close the pressure release valve and turn the air

compressor off. If the pressure cannot be in-

flated to the specified value, the air compressor

can be turned off at the minimum of 180 kPa (1,8

bar, 26 psi) for tyre 205R16 250 kPa (2,5 bar, 36

psi). Remove the power plug from the power

outlet and quickly remove the hose from the tyre

valve. Attach the protective cap and valve cap.

Properly stow the emergency tyre puncture re-

pair kit in the storage location. WARNING

To avoid serious personal injury when stowing

the emergency tyre puncture repair kit, keep the

sealant bottle screwed into the compressor. Fail-

ure to do so can cause the sealant to spray into

the air and get into your eyes or on the skin.

10. Immediately drive the vehicle for 10 minutes or

3–10 km (2–6 miles) (if the road situation al-lows) at aspeed of 80 km/h (50 MPH) or less.

11. After driving 10 km (6 miles), or 10 minutes, screw the air tube of the air compressor se-

curely onto the tyre valve. Check the tyre pres-

sure with the pressure gauge.

The temporary repair is completed if the tyre

pressure does not drop.

Make sure the pressure is adjusted to the pres-

sure that is specified on the tyre placard before

driving.

If the tyre pressure drops under 130 kPa (19

psi):

The tyre cannot be repaired with this tyre punc-

ture repair kit. Contact an approved dealer or quali-

fied workshop.

If the tyre pressure is 130 kPa (19 psi) or more

but less than the specified pressure:

Turn the compressor switch to the ON (−) position

and inflate the tyre up to the specified pressure.

Then repeat the step from 8. NCE479

In case of emergency

6-9

Page 268 of 340

2. Secure the steering wheel in

astraight ahead

position with rope or similar device.

3. Move the shift lever to the N(Neutral) position.

4. Release the parking brake.

5. Attach safety chains before towing.

Rear wheels on the ground:

RENAULT recommends that towing dollies be used

under the rear wheels when towing your vehicle or

the vehicle be placed on aflatbed tow truck as illus-

trated.

CAUTION

Never tow Automatic Transmission (AT) model

with the rear wheels on the ground. Doing so will

cause serious and expensive damage to the

transmission.

Manual Transmission (MT) model:

If you have to tow aMTvehicle with rear wheels on

the ground, perform the following procedures.

CAUTION

Observe the following restricted towing speeds

and distances.

• Speed: Below 50 km/h (30 MPH)

• Distance: Less than 65 km (40 miles)

1. Place the ignition switch in the “ON” position and turn all accessories off.

2. Move the shift lever to the N(Neutral) position.

3. Release the parking brake. 4. Attach safety chains whenever towing.

All four wheels on the ground:

RENAULT recommends that the vehicle be placed

on

aflatbed tow truck as illustrated.

CAUTION

Never tow Automatic Transmission (AT) model

with all four wheels on the ground. Doing so will

cause serious and expensive damage to the driv-

etrain.

Manual Transmission (MT) model:

If you have to tow aMTvehicle with all four wheels

on the ground, perform the following procedures.

CAUTION

• Never tow

aManual Transmission (MT) model

backward with all four wheels on the ground.

• Observe the following restricted towing

speeds and distances.

–S

peed: Below 50 km/h (30 MPH)

–D istance: Less than 65 km (40 miles)

1. Place the ignition switch in the “ON” position and turn all accessories off.

2. Move the shift lever to the N(Neutral) position.

3. Release the parking brake.

6-14 In case of emergency

Page 278 of 340

Some day-to-day and regular maintenance is essen-

tial to maintain your vehicle’s good mechanical con-

dition, as well as its emission and engine perfor-

mance.

It is the owner’s responsibility to make sure that the

specified maintenance, as well as general mainte-

nance, is performed.

As the vehicle owner, you are the only one who can

ensure that your vehicle receives the proper mainte-

nance care.

SCHEDULED MAINTENANCE

For your convenience, the required scheduled main-

tenance items are described and listed in aseparate

Warranty Information and Maintenance booklet. You

must refer to that booklet to ensure that necessary

maintenance is performed on your vehicle at regular

intervals.

GENERAL MAINTENANCE

General maintenance includes those items which should be checked during normal day-to-day opera-

tion of the vehicle. They are essential if your vehicle

is to continue to operate properly. It is your respon-

sibility to perform these procedures regularly as pre- scribed.

Performing general maintenance checks requires

minimal mechanical skill and only afew general au-

tomotive tools.

These checks or inspections can be done by your-

self, aqualified technician, or if you prefer, your

approved dealer or qualified workshop. WHERE TO GO FOR SERVICE

If maintenance service is required or your vehicle

appears to malfunction, have the systems checked

and tuned by an authorised approved dealer or

qualified workshop.

During normal day-to-day operation of the vehicle,

general maintenance should be performed regularly

as prescribed in this section. If you detect any un-

usual sounds, vibrations or smells, be sure to check

for the cause or have an approved dealer or quali-

fied workshop do it promptly. In addition, you should

notify an approved dealer or qualified workshop if

you think that repairs are required.

When performing any checks or maintenance work,

closely observe “Maintenance precautions” later in

this section.

EXPLANATION OF GENERAL

MAINTENANCE ITEMS

Additional information on the following items with

“*” is found later in this section.

Outside vehicle

The maintenance items listed here should be per-

formed from time to time, unless otherwise speci-

fied.

Doors and bonnet:

Check that all doors and the bonnet operate

smoothly as well as the tailgate. Also make sure that

all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the bon-

net from opening when the primary latch is released.

When driving in areas using road salt or other cor-

rosive materials, check lubrication frequently.

MAINTENANCE REQUIREMENTS

GENERAL MAINTENANCE

8-2 Maintenance and do-it-yourself

Page 279 of 340

Lights*:

Clean the headlights on

aregular basis. Make sure

that the headlights, stop lights, tail lights, turn signal

lights, and other lights are all operating properly and

installed securely. Also check the aim of the head-

lights.

Tyres*:

Check the pressure with agauge often and always

prior to long distance trips. Adjust the pressure in all

tyres, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear.

Tyre rotation*:

In the case of Two-Wheel Drive (2WD), and where

front and rear tyres are the same size: tyres should

be rotated every 10,000 km (6,000 miles). Tyres

marked with directional indicators can only be ro-

tated between front and rear. Make sure that the

directional indicators point in the direction of wheel

rotation after the tyre rotation is completed.

In the case of the Four-Wheel Drive and All Wheel

Drive (4WD/AWD), and where front and rear tyres

are the same size: tyres should be rotated every

5,000 km (3,000 miles). Tyres marked with direc-

tional indicators can only be rotated between front

and rear. Make sure that the directional indicators

point in the direction of wheel rotation after the tyre

rotation is completed.

In the case that front tyres are different size from

rear tyres: tyres cannot be rotated.

The timing for tyre rotation may vary according to

your driving habits and the road surface conditions. Tyre Pressure Monitoring System (TPMS)

transmitter components (where fitted):

Replace the TPMS transmitter grommet seal, valve

core and cap when the tyres are replaced due to

wear or age.

Wheel alignment and balance:

If the vehicle should pull to either side while driving

on astraight and level road, or if you detect uneven

or abnormal tyre wear, there may be aneed for

wheel alignment. If the steering wheel or seat vi-

brates at normal highway speeds, wheel balancing

may be needed.

Windscreen:

Clean the windscreen on aregular basis. Check the

windscreen at least every six months for cracks or

other damage. Repair as necessary.

Wiper blades*:

Check for cracks or wear if not functioning cor-

rectly. Replace as necessary.

Inside vehicle

The maintenance items listed here should be

checked on aregular basis, such as when perform-

ing periodic maintenance, cleaning the vehicle, etc.

Accelerator pedal:

Check the pedal for smooth operation and make

sure that the pedal does not catch or require uneven

effort. Keep the floor mats away from the pedal. Brake pedal*:

Check the pedal for smooth operation and make

sure that it is the proper distance from the floor mat

when depressed fully. Check the brake booster

function. Be sure to keep the floor mats away from

the pedal.

Parking brake*:

Check the parking brake operation regularly. Check

that the lever (where fitted) or the pedal (where fit-

ted) has the proper travel. Also make sure that the

vehicle is held securely on

afairly steep hill when

only the parking brake is applied.

Seat belts:

Check that all parts of the seat belt system (for

example, buckles, anchors, adjusters and retrac-

tors) operate properly and smoothly, and are in-

stalled securely. Check the belt webbing for cuts,

fraying, wear or damage.

Steering wheel:

Check for changes in the steering condition, such

as excessive play, hard steering or strange noises.

Warning lights and chimes:

Make sure that all warning lights and chimes are

operating properly.

Windscreen defogger:

Check that the air comes out of the defogger outlets

properly and in good quantity when operating the

heater or air conditioner.

Maintenance and do-it-yourself 8-3

Page 280 of 340

Windscreen wiper and washer*:

Check that the wipers and washer operate properly

and that the wipers do not streak.

Under bonnet and vehicle

The maintenance items listed here should be

checked periodically (for example, each time you

check the engine oil or refuel).

Battery (except for maintenance free batter-

ies)*:

Check the fluid level in each cell. It should be be-

tween the

operated in high temperatures or under severe con-

ditions require frequent checks of the battery fluid

level.

Brake (and clutch) fluid level(s)*:

For Manual Transmission (MT) model: make sure

that the brake and clutch fluid levels are between

the

Except for Manual Transmission (MT) model: make

sure that the brake fluid level is between the

and

Engine coolant level*:

Check the coolant level when the engine is cold.

Make sure that the coolant level is between the

Engine drive belt(s)*:

Make sure that drive belt(s) is/are not frayed, worn,

cracked or oily. Engine oil level*:

Check the level after parking the vehicle (on

alevel

ground) and turning off the engine.

Fluid leaks:

Check under the vehicle for fuel, oil, water or other

fluid leaks after the vehicle has been parked for a

while. Water dripping from the air conditioner after

use is normal. If you should notice any leaks or if fuel

fumes are evident, check for cause and have it cor-

rected immediately.

Power steering fluid level and lines*:

Check the level when the fluid is cold, with the en-

gine off. Check the lines for proper attachment,

leaks, cracks, etc.

Windscreen washer fluid*:

Check that there is adequate fluid in the reservoir.

MAINTENANCE PRECAUTIONS

When performing any inspection or maintenance

work on your vehicle, always take care to prevent

serious accidental injury to yourself or damage to

the vehicle. The following are general precautions

which should be closely observed. WARNING

• Park the vehicle on

alevel surface, apply the

parking brake securely and block the wheels

to prevent the vehicle from moving. Move the

shift lever to the P(Park) position (AT model)

or the shift lever to the N(Neutral) position

(MT model). •

Be sure the ignition switch is in the LOCK

position when performing any parts replace-

ment or repairs.

• Do not work under the bonnet while the en-

gine is hot. Always turn off the engine and

wait until it cools down.

• If you must work with the engine running,

keep your hands, clothing, hair and tools away

from moving fans, belts and any other moving

parts.

• It is advisable to secure or remove any loose

clothing and any jewellery, such as rings,

watches, etc. before working on your vehicle.

• If you must run the engine in an enclosed

space such as

agarage, be sure there is

proper ventilation for exhaust gasses to es-

cape.

• DO NOT GET UNDER

AVEHICLE THAT IS

SUPPORTED BY AJACK.

• Keep smoking materials, flame and sparks

away from fuel and the battery.

• Never connect or disconnect either the bat-

tery or any transistorised component connec-

tor while the ignition switch is in the ON posi-

tion.

8-4 Maintenance and do-it-yourself

Page 282 of 340

The radiator is fitted with

apressure cap. To prevent

engine damage, use only aGenuine RENAULT ra-

diator cap or its equivalent when replacement is

required.

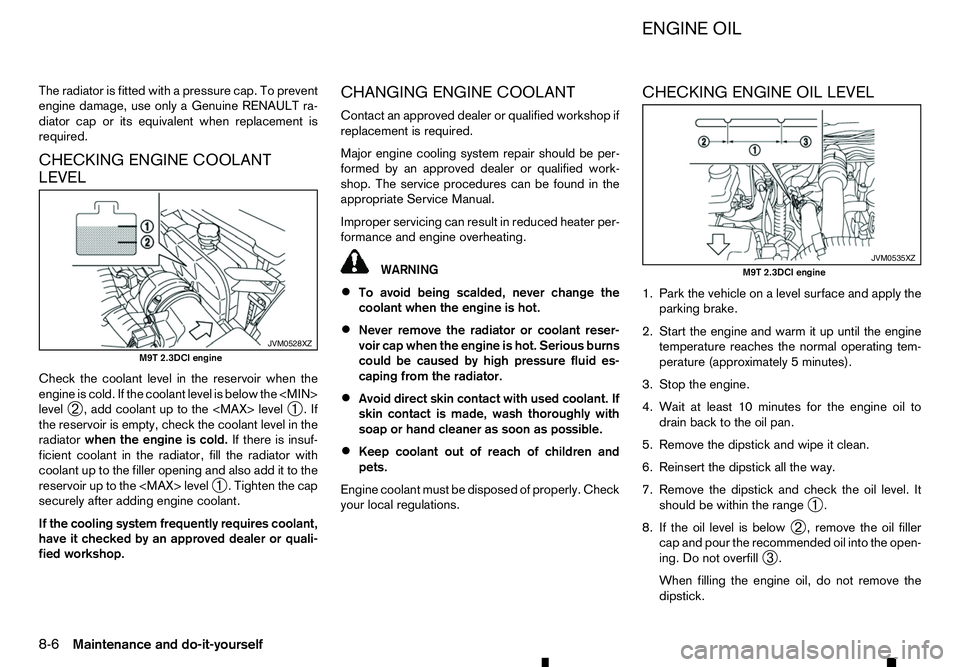

CHECKING ENGINE COOLANT

LEVEL

Check the coolant level in the reservoir when the

engine is cold. If the coolant level is below the

level ➁,a

dd coolant up to the

➀.If

the reservoir is empty, check the coolant level in the

radiator when the engine is cold. If there is insuf-

ficient coolant in the radiator, fill the radiator with

coolant up to the filler opening and also add it to the

reservoir up to the

ighten the cap

securely after adding engine coolant.

If the cooling system frequently requires coolant,

have it checked by an approved dealer or quali-

fied workshop. CHANGING ENGINE COOLANT

Contact an approved dealer or qualified workshop if

replacement is required.

Major engine cooling system repair should be per-

formed by an approved dealer or qualified work-

shop. The service procedures can be found in the

appropriate Service Manual.

Improper servicing can result in reduced heater per-

formance and engine overheating.

WARNING

• To avoid being scalded, never change the

coolant when the engine is hot.

• Never remove the radiator or coolant reser-

voir cap when the engine is hot. Serious burns

could be caused by high pressure fluid es-

caping from the radiator.

• Avoid direct skin contact with used coolant. If

skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

• Keep coolant out of reach of children and

pets.

Engine coolant must be disposed of properly. Check

your local regulations. CHECKING ENGINE OIL LEVEL

1. Park the vehicle on

alevel surface and apply the

parking brake.

2. Start the engine and warm it up until the engine temperature reaches the normal operating tem-

perature (approximately 5minutes).

3. Stop the engine.

4. Wait at least 10 minutes for the engine oil to drain back to the oil pan.

5. Remove the dipstick and wipe it clean. 6. Reinsert the dipstick all the way.

7. Remove the dipstick and check the oil level. It should be within the range ➀.

8. If the oil level is below ➁,r

emove the oil filler

cap and pour the recommended oil into the open-

ing. Do not overfill ➂.

When filling the engine oil, do not remove the

dipstick. JVM0528XZ

M9T 2.3DCI engine JVM0535XZ

M9T 2.3DCI engine

ENGINE OIL

8-6 Maintenance and do-it-yourself

Page 283 of 340

9. Recheck the oil level with the dipstick.

CAUTION

• The oil level should be checked regularly. Op-

erating your vehicle with an insufficient

amount of oil can damage the engine, and

such damage is not covered by the warranty.

• It is normal to add some oil between oil main-

tenance intervals or during the running-in pe-

riod, depending on the severity of operating

conditions.

CHANGING ENGINE OIL AND OIL

FILTER

Contact an approved dealer or qualified workshop

when the engine oil and oil filter require replace-

ment.

PROTECT ENVIRONMENT

It is illegal to pollute drains, watercourses and soil.

Use authorised waste collection facilities, including

civil amenity sites and garages providing facilities

for disposal of used oil and used oil filters. If in

doubt, contact your local authority for advice on dis-

posal.

The regulations concerning the pollution of the

environment will vary from country to country. REFILLING THE AdBlue® TANK

When the [Refill AdBlue] warning appears in the

vehicle information display, refill the AdBlue® tank

before the tank is empty (see “AdBlue® Selective

Catalytic Reduction (SCR) system (where fitted for

diesel engine model)” in the “5. Starting and driving”

section for the AdBlue® warning display.) Refill the

AdBlue® tank according to the procedures shown

in this section.

CAUTION

•

Use only AdBlue®. Using other fluids will

damage the AdBlue® Selective Catalytic Re-

duction (SCR) system.

• Be careful not to spill AdBlue®. If the AdBlue®

is spilled on the vehicle body, wipe it away

with

awet cloth immediately to avoid paint

damage.

• AdBlue® residues crystallize after

aperiod of

time and contaminate the paint surfaces. If

the spilled AdBlue® has crystallized, use a

sponge and cold water to clean it.

• Be careful not to inhale any ammonia vapours

that may be released. Fill the AdBlue® tank in

well-ventilated areas.

The AdBlue® tank is located underneath the ve-

hicle. (see “AdBlue® filler lid and cap” in the “3. Pre-

driving checks and adjustments” section for the

AdBlue® filler lid location.)

1. Apply the parking brake. 2. Automatic Transmission (AT) model: Move the

shift lever to the P(Park) position.

Manual Transmission (MT) model: Move the shift

lever to the N(Neutral) position.

3. Place the ignition switch in the OFFposition.

4. Open the AdBlue® filler lid.

5. Remove the AdBlue® tank cap by turning it anticlockwise.

6. Refill the AdBlue® tank.

7. Securely install the AdBlue® tank cap.

8. Close the AdBlue® filler lid.

9. Place the ignition switch in the ONposition and

wait for approximately 1minute until the [Refill

AdBlue] warning turns off.

NOTE

In the case that the [ENG can’t start Refill

AdBlue] warning was displayed, check that

the warning turned off, place the ignition

switch in the OFF position once and then startthe engine.

AdBlue® TANK (where fitted for

diesel engine model)

Maintenance and do-it-yourself8-7