RENAULT CLIO 1997 X57 / 1.G Petrol Engines Service Manual

Manufacturer: RENAULT, Model Year: 1997, Model line: CLIO, Model: RENAULT CLIO 1997 X57 / 1.GPages: 55, PDF Size: 4.15 MB

Page 41 of 55

ENGINE AND PERIPHERALS

En

gine repair10

PREPARATION OF THE GUDGEON PINS

Check that the gudgeon pins are able to slide

freely in the corresponding new pistons.

Use centring device

C13 and mounting tools

A13

or

A13-01 for the shouldered gudgeon pins.

Mount the gudgeon pin (E) on the mounting tool

(A), tighten the centring device (C)

until contact is

made, then slacken b

y a quarter turn.

76716R PREPARATION OF THE CONNECTING RODS

Visually check:

- the condition of the connecting rod (twisting -

straightness),

- the bearing surface between the shells and the

connecting rod bodies (if necessary, remove

any burrs with a grinding wheel to obtain a co

r-

rect bearing surface).

Use a

1500 W heating plate.

Put the little ends on the heating plate.

Ensure that the whole surface of the little end is in

contact with the plate.

Put a piece of self-pickling tin solder with a mel-

ting point of about

250

° onto each little end at (a)

to act as a temperature check.

Heat the little end until the piece of self-pickling

solder melts.

DI1038

12367R

10-39

Page 1 of 1 E_Series_41

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_41.htm

Page 42 of 55

ENGINE AND PERIPHERALS

En

gine repair10

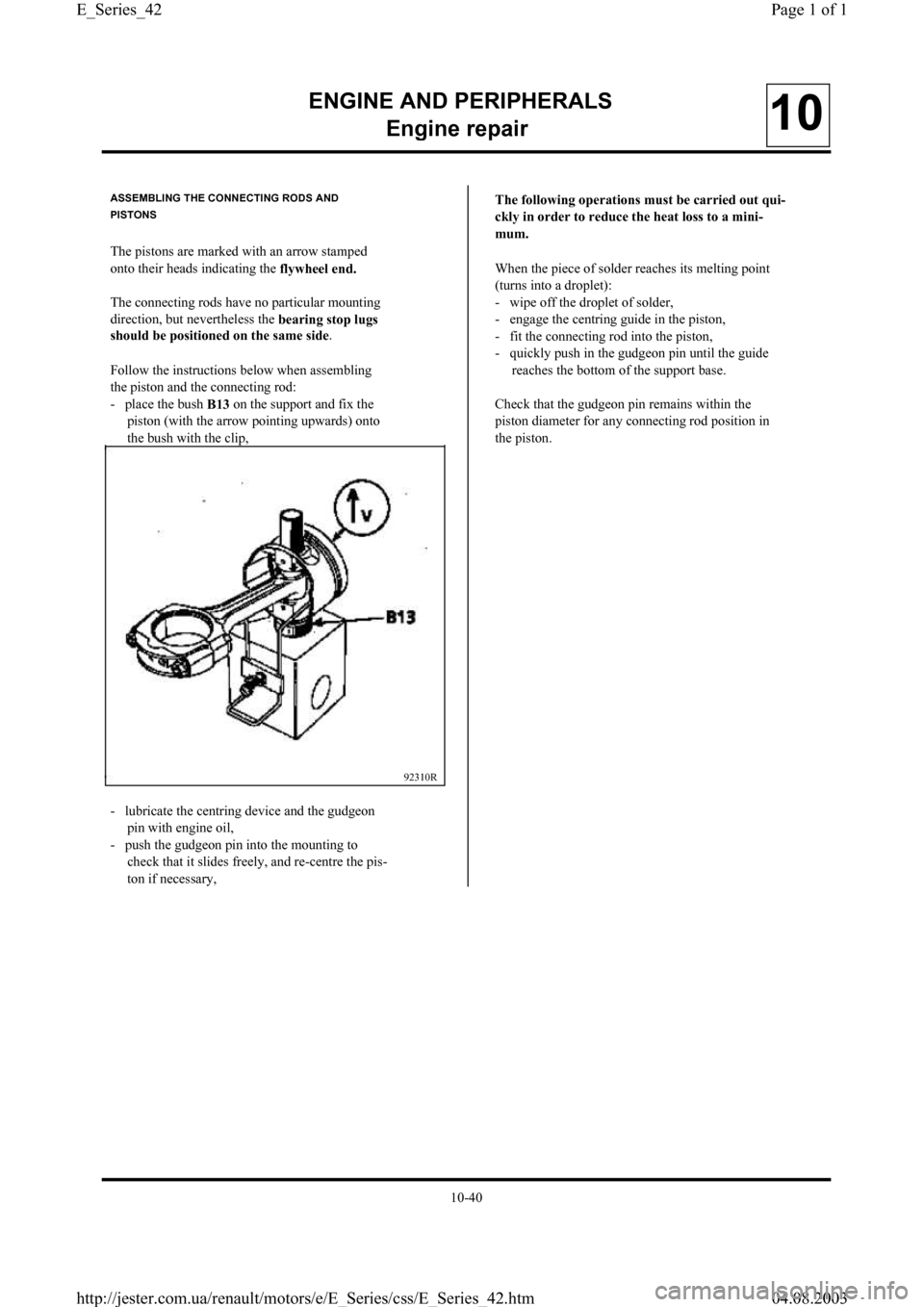

ASSEMBLING THE CONNECTING RODS AND

PISTONS

The pistons are marked with an arrow stamped

onto their heads indicating the

flywheel end.

The connecting rods have no particular mounting

direction, but nevertheless the

bearin

g stop lugs

should be

positioned on the same side.

Follow the instructions below when assembling

the piston and the connecting rod:

- place the bush

B13 on the support and fix the

piston (with the arrow pointing upwards) onto

the bush with the clip,

92310R

- lubricate the centring device and the gudgeon

pin with engine oil,

- push the gudgeon pin into the mounting to

check that it slides freely, and re-centre the pis-

ton if necessary,The followin

g operations must be carried out qui-

ckl

y in order to reduce the heat loss to a mini-

mum.

When the piece of solder reaches its melting poin

t

(turns into a droplet):

- wipe off the droplet of solder,

- engage the centring guide in the piston,

- fit the connecting rod into the piston,

- quickly push in the gudgeon pin until the guide

reaches the bottom of the support base.

Check that the gudgeon pin remains within the

piston diameter for any connecting rod position in

the piston.

10-40

Page 1 of 1 E_Series_42

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_42.htm

Page 43 of 55

ENGINE AND PERIPHERALS

En

gine repair10

92317S

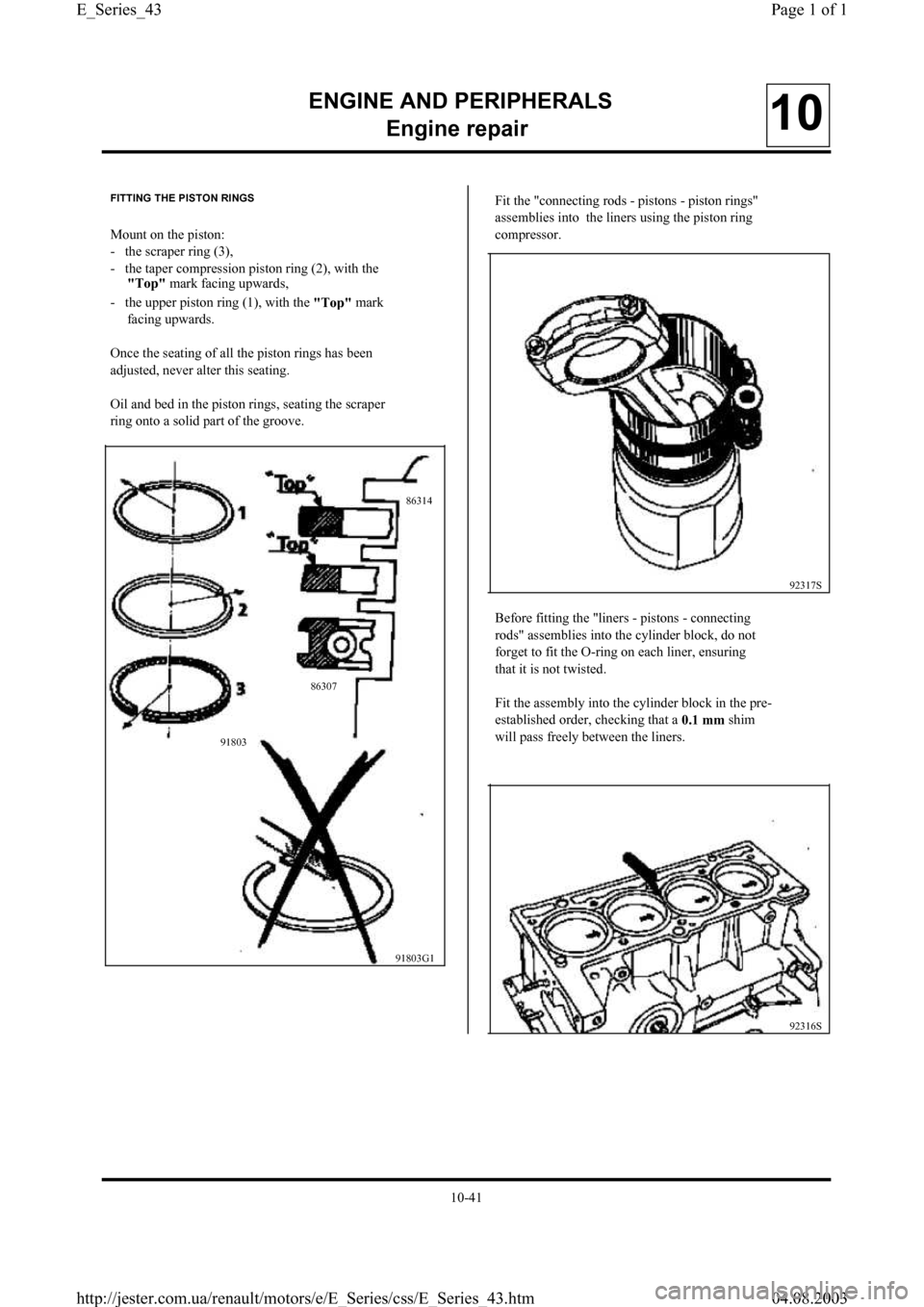

91803G1 FITTING THE PISTON RINGS

Mount on the piston:

- the scraper ring (3),

- the taper compression piston ring (2), with the

"To

p" mark facing upwards,

- the upper piston ring (1), with the

"To

p" mark

facing upwards.

Once the seating of all the piston rings has been

adjusted, never alter this seating.

Oil and bed in the piston rings, seating the scrape

r

ring onto a solid part of the groove.Fit the "connecting rods - pistons - piston rings"

assemblies into the liners using the piston ring

compressor.

Before fitting the "liners - pistons - connecting

rods" assemblies into the cylinder block, do no

t

forget to fit the O-ring on each liner, ensuring

that it is not twisted.

Fit the assembly into the cylinder block in the pre-

established order, checking that a

0.1 mm shim

will pass freely between the liners.

92316S 918038630786314

10-41

Page 1 of 1 E_Series_43

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_43.htm

Page 44 of 55

ENGINE AND PERIPHERALS

En

gine repair10

Immobilise the liners using tool

Mot. 588.

92062R

Shims of the following thicknesses (mm) are avai-

lable from the Parts Department:

2.80; 2.85; 2.90;

2.95.

Refit the connecting rod shells and tighten the

nuts to a torque value of

4.2 daN.m.

Check:

- the end float of the connecting rods,

- that the assembly is able to rotate properly. Fit the crankshaft and the end float shims.

Lubricate the crankpins and the main bearing

journals with engine oil.

Refit the crankshaft bearing shells.

Apply a thin layer of

RHODORSEAL 5661 on bea-

ring

N°

1 zone (K) and tighten the bolts to

2.5 daN.m , then angle tighten to

43°

± 6°.

Check the end floatof the crankshaft, which

should be between:

-

0.045 and 0.852 mmwith wear,

-

0.045 and 0.252 mmwithout wear.

92314S MOUNTING THE BEARING SHELLS

The connecting rod bearing shells are identical.

The crankshaft bearing shells are grooved on the

cylinder block side.

92315R

The upper shell of bearing

No. 5 is a special one

and is also grooved.

10-42

Page 1 of 1 E_Series_44

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_44.htm

Page 45 of 55

ENGINE AND PERIPHERALS

En

gine repair10

Fit:

- the oil pump, checking that the centring dowls

are present, and tighten to a torque value of

2.5 daN.m,

- the two sprockets and chain of the oil pump,

and tighten the three bolts mounting the

sprocket to the hub to

1 daN.m,

- the crankshaft end cover, sealing it with

Loctite

518.

The bead (H) should be

0.6 to 1 mm wide and

should be applied as shown in the diagram be-

low. - the crankshaft seal (bearing No.1), using tool

Mot. 1129-01; this tool is designed to ensure an

offset seal bearing surface. Lubricate the lip

and the outside of the seal.

92319R

92067R

-the crankshaft end seal, using tool

Mot. 1128-

01; lubricate the lip and the outside diamete

r

of the seal.

Turn over the s

pacer if the old seal has marked

the bearin

g surface.

92318R

10-43

Page 1 of 1 E_Series_45

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_45.htm

Page 46 of 55

ENGINE AND PERIPHERALS

En

gine repair10

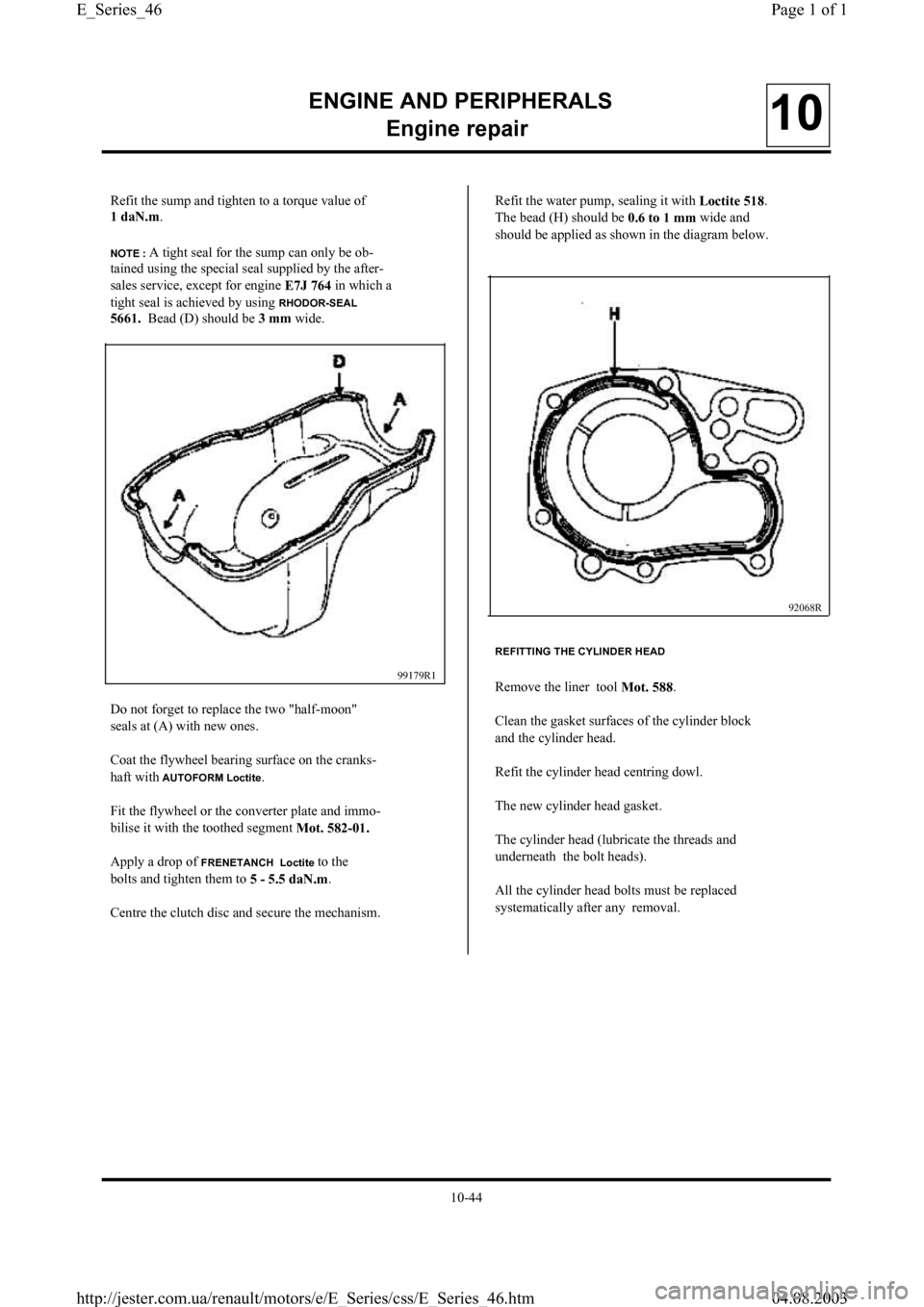

99179R1

Refit the sump and tighten to a torque value of

1 daN.m.

NOTE : A tight seal for the sump can only be ob-

tained using the special seal supplied by the afte

r-

sales service, except for engine

E7J 764 in which a

tight seal is achieved by using

RHODOR-SEAL

5661. Bead (D) should be

3 mm wide.

Do not forget to replace the two "half-moon"

seals at (A) with new ones.

Coat the flywheel bearing surface on the cranks-

haft with

AUTOFORM Loctite.

Fit the flywheel or the converter plate and immo-

bilise it with the toothed segment

Mot. 582-01.

Apply a drop of

FRENETANCH Loctite to the

bolts and tighten them to

5 - 5.5 daN.m.

Centre the clutch disc and secure the mechanism.

92068R

Refit the water pump, sealing it with

Loctite 518.

The bead (H) should be

0.6 to 1 mm wide and

should be applied as shown in the diagram below.

REFITTING THE CYLINDER HEAD

Remove the liner tool

Mot. 588.

Clean the gasket surfaces of the cylinder bloc

k

and the cylinder head.

Refit the cylinder head centring dowl.

The new cylinder head gasket.

The cylinder head (lubricate the threads and

underneath the bolt heads).

All the cylinder head bolts must be replaced

systematically after any removal.

10-44

Page 1 of 1 E_Series_46

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_46.htm

Page 47 of 55

ENGINE AND PERIPHERALS

En

gine repair10

Method of tightening the cylinder head

90775S

Preseating of the gasket:

Initial tightening to

2 daN, followed by angula

r

tightening to

97°

± 2° in the recommended or-

der:

- tighten bolts

1-2,

- tighten bolts

3-4-5-6,

- tighten bolts

7-8-9-10.

Seatin

g of the gasket:

Wait

3 minutes (settling time).

Ti

ghtening:

- Slacken bolts

1-2.

Retighten bolts

1-2 to

2 daN.m, then angle

tighten to

97

° ±

2°.

- Slacken bolts

3-4-5-6.

Retighten bolts

3-4-5-6 to

2 daN.m, then angle

tighten to

97

° ±

2°.

- Slacken bolts

7-8-9-10.

Retighten bolts

7-8-9-10 to

2 daN.m, then angle

tighten to

97

° ±

2°.

There is no cylinder head retightening operation.Refit the rocker shaft, positioning the mark (1) on

the timing side and the bolts (A) at (B).

92063R

NOTE :

There are two sizes of bolts (A) :

M8×

100

and M8×

125.

Refit:

- the rocker shaft mounting bolts (2), tightening

them to a torque of

2.3 daN.m and not forge

t-

ting to lubricate the threads and underneath

the bolt heads with engine oil,

- the cylinder head cover without tightening i

t

in order to facilitate the setting of the timing,

- the crankshaft sprocket.

10-45

Page 1 of 1 E_Series_47

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_47.htm

Page 48 of 55

ENGINE AND PERIPHERALS

En

gine repair10

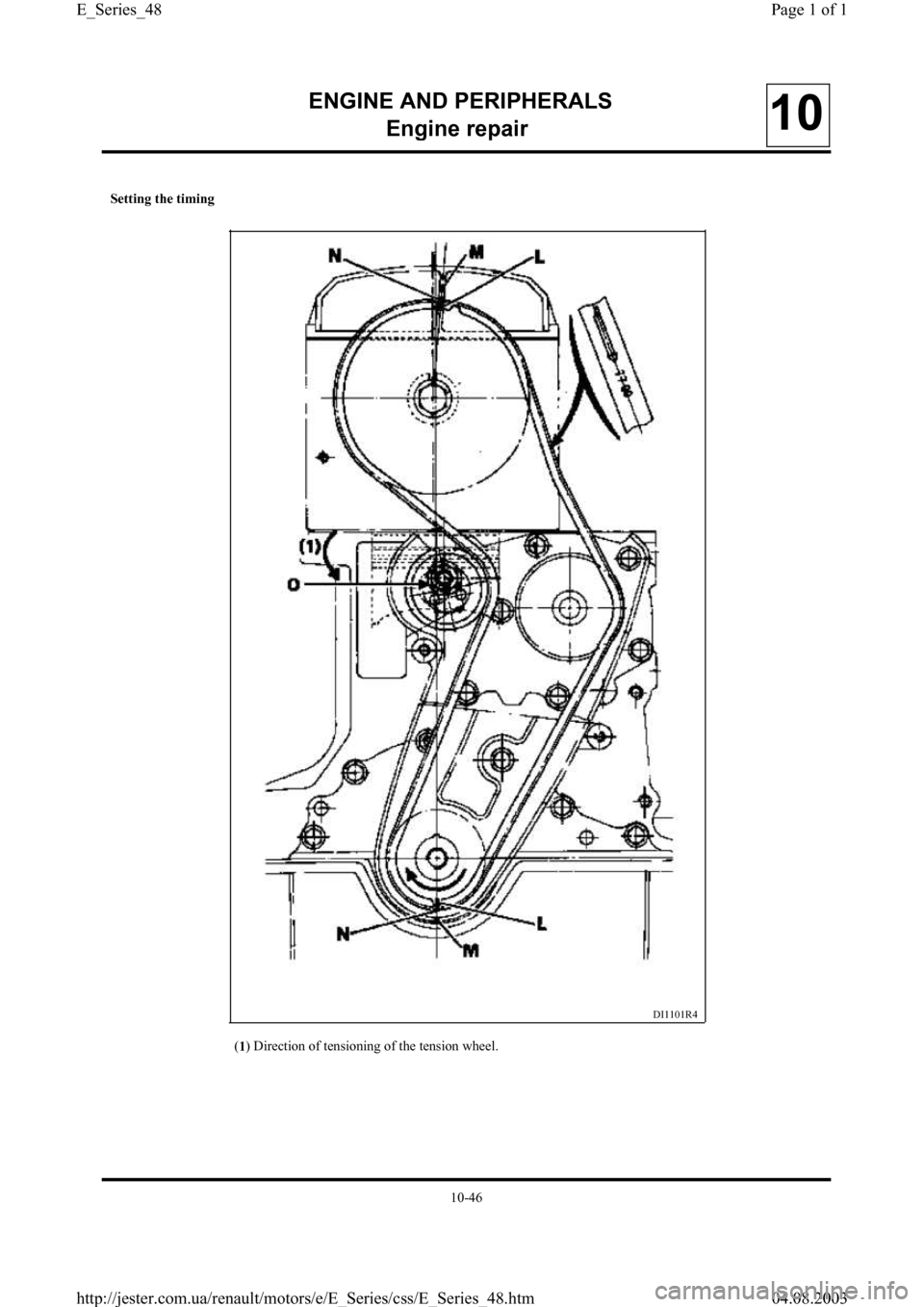

Setting the timing

DI1101R4

(

1) Direction of tensioning of the tension wheel.

10-46

Page 1 of 1 E_Series_48

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_48.htm

Page 49 of 55

ENGINE AND PERIPHERALS

En

gine repair10

There is an arrow painted on the back of the belt

showing the direction of rotation and two marks

for the setting.

Line up the marks (N) on the belt with those on

the sprockets (L) and the housings (M).

Respect the direction of mounting of the belt and

begin to position it on the crankshaft sprocket.

Fit the sensor of

Mot. 1273.

98708R

Turn the knurled wheel of the sensor until it re-

leases (three "clicks").

Tension the belt using tool

Mot. 1135-01 until

the display of the

Mot. 1273 shows the re-

commended fitting value

.

Belt tension (in SEEM units)

Fitting value: 30 U.S.

Lock the tension wheel, carry out a check and ad-

just the value.

Rotate the crankshaft at least

three turns.

Check that the tension value is within the fitting

tension tolerance (

±10 %), and if not readjust it.

NOTE : Never refit a belt which has been remo-

ved.

Tighten nut (O) of the tension wheel to 5 daN.m.

It is essential to tighten the tension wheel nut to

a tor

que value of 5 daN.m to prevent any risk of

working loose which might damage the engine.

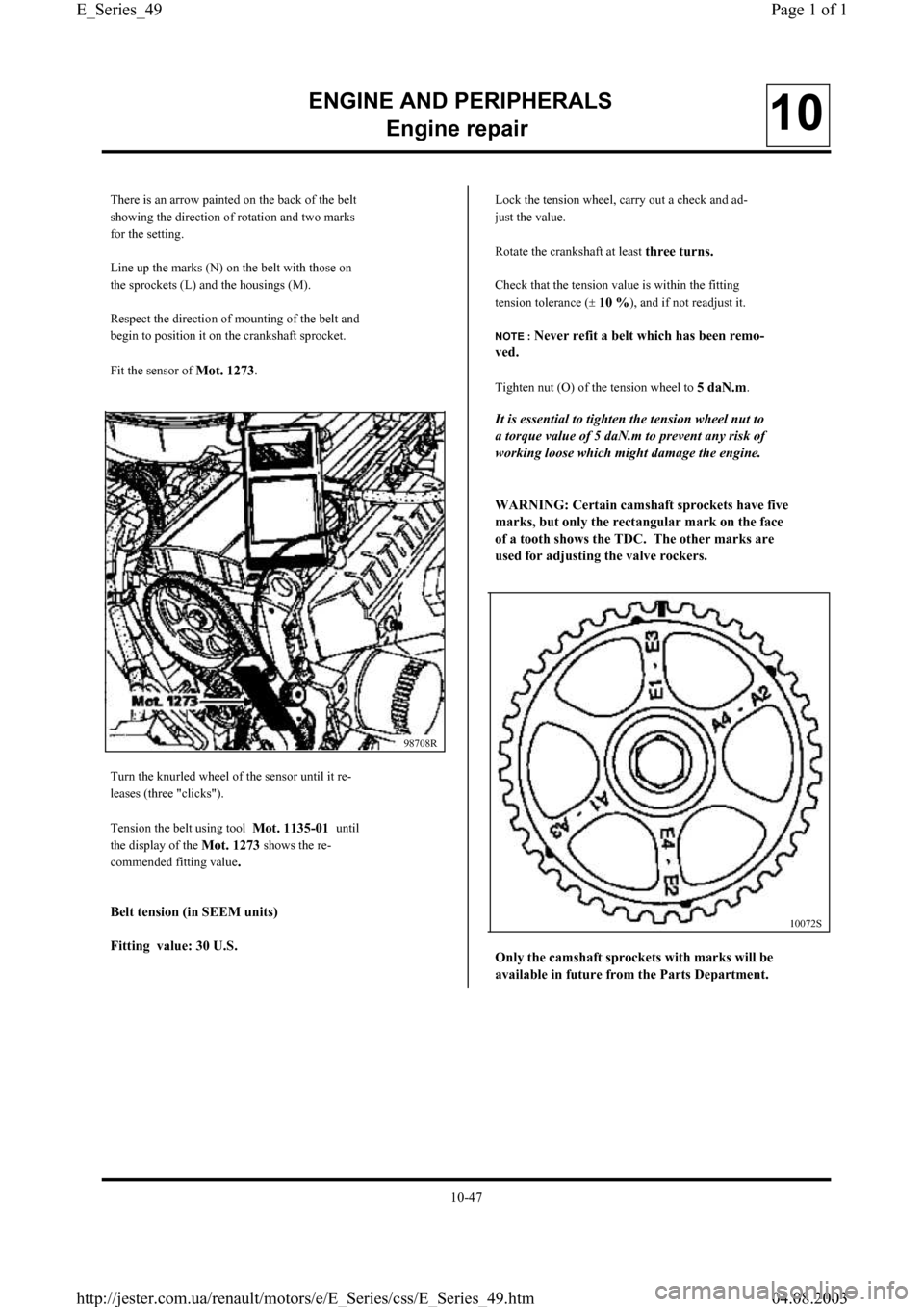

WARNING: Certain camshaft s

prockets have five

marks, but onl

y the rectangular mark on the face

of a tooth shows the TDC. The other marks are

used for ad

justing the valve rockers.

10072S

Only the camshaft sprockets with marks will be

available in future from the Parts De

partment.

10-47

Page 1 of 1 E_Series_49

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_49.htm

Page 50 of 55

ENGINE AND PERIPHERALS

En

gine repair10

SETTING THE VALVE ROCKER CLEARANCES

Setting values (cold) (in mm):

- inle

t0.10

- exhaus

t0.25

Engine fitted with a CAMSHAFT SPROCKET WITH

NO MARKS

"Tilt" method

Set the valves of the

cylinder concerned to the

end-of-exhaust / start-

of- inlet positionSet the clearance of the

valve rockers of the

cylinder concerned

1

3

4

24

2

1

3Full

y open exhaust valve method

Leave the exhaust valve of cylinder

n

° 1 fully open

and set the clearance of the inlet valve of cylinde

r

n°3and the clearance of the exhaust valve of

cylinder

n

°4.

Proceed similarly for the other cylinders,

following the order shown in the table.

Inlet valve to be se

tExhaust valve to be setExhaust valve to be left fully open

78373R

10-48

Page 1 of 1 E_Series_50

04.08.2003 http://jester.com.ua/renault/motors/e/E_Series/css/E_Series_50.htm