sensor RENAULT KANGOO 1998 KC / 1.G Heating And Ventilation Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1998, Model line: KANGOO, Model: RENAULT KANGOO 1998 KC / 1.GPages: 73

Page 13 of 73

AIR CONDITIONING

General

62

A Passenger compartment

B Engine compartment

C Exterior air

D To air mixing unit

E Scuttle panel grille

F Exterior or recirculated air

1 Compressor with variable capacity

2 Condenser

3 Dehydration canister

4 Pressure sensor

5 High pressure valve

6 Pressure relief valve

7 Evaporator

8 Low pressure valve

9 Heating/ventilation fan

10 Cooling fan

11 Engine radiator

12 High pressure fluid

13 Low pressure vapour

14 High pressure vapour

Consumables:

- Compressor oil

SANDEN SP 10: 135 cm3 ± 15

- Coolant

R134a: 650 g ± 35

- Compressor

SANDEN SD 7V 16

62-2

Page 19 of 73

c11010.0

AIR CONDITIONING

Fault finding - Interpretation of XR25 bargraphs62

KANGOO

ALL TYPES

Enter G0** on the XR25.

Check that the system operates correctly.AFTER

REPAIR

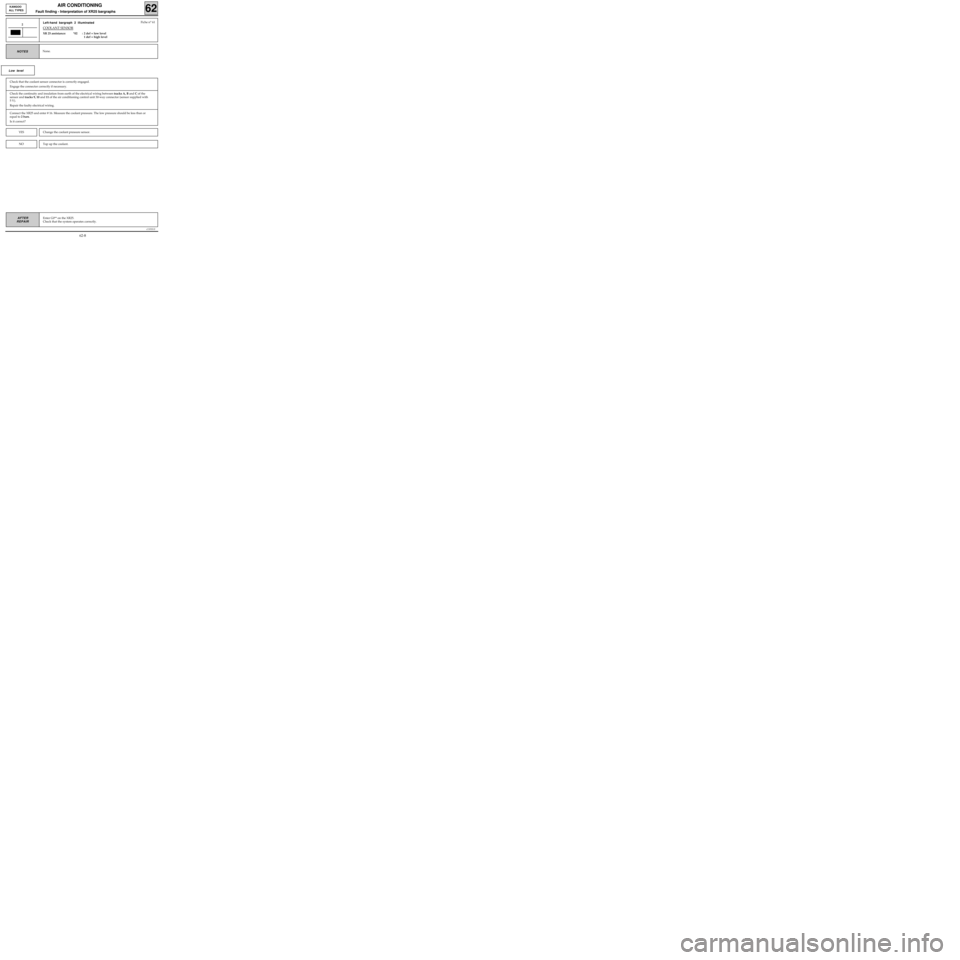

Left-hand bargraph 2 illuminated

COOLANT SENSOR

XR 25 assistance: *02 : 2 def = low level

1 def = high level

2

None.NOTES

Fiche n° 61

Low level

Check the continuity and insulation from earth of the electrical wiring between tracks A, B and C of the

sensor and tracks 9, 10 and 11 of the air conditioning control unit 30-way connector (sensor supplied with

5 V).

Repair the faulty electrical wiring.

Connect the XR25 and enter # 16. Measure the coolant pressure. The low pressure should be less than or

equal to 2 bars.

Is it correct?

Change the coolant pressure sensor.YES

NOTop up the coolant.

Check that the coolant sensor connector is correctly engaged.

Engage the connector correctly if necessary.

62-8

Page 20 of 73

c11010.0

AIR CONDITIONING

Fault finding - Interpretation of XR25 bargraphs62

KANGOO

ALL TYPES

Enter G0** on the XR25.

Check that the system operates correctly.AFTER

REPAIR

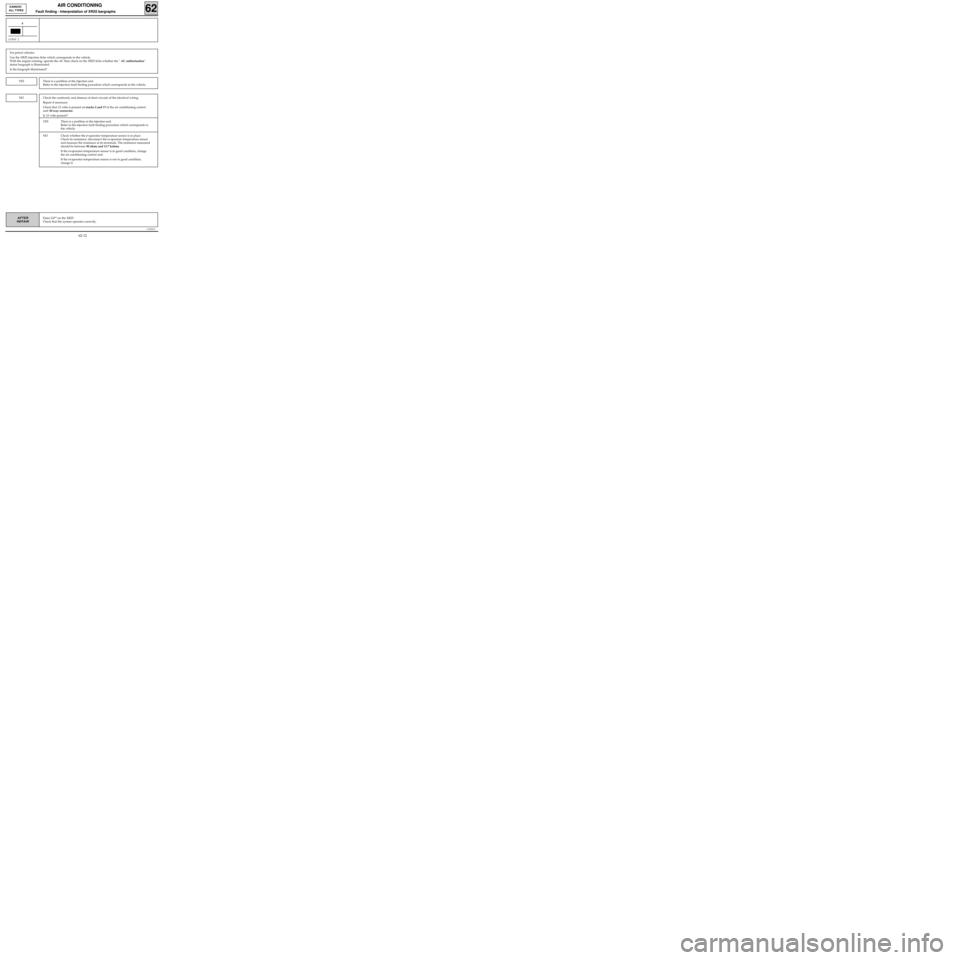

2

High level

Change the coolant pressure sensor.YES

NOTop up the coolant.

CONT

Check that the coolant sensor connector is correctly engaged.

Engage the connector correctly if necessary.

Check the condition of the electrical wiring between tracks A, B and C of the sensor and tracks 9, 10 and

11 of the air conditioning control unit 30-way connector (sensor supplied with 5 V).

Repair the faulty electrical wiring.

Connect the XR25 and enter # 16. Measure the coolant pressure. The high pressure should be less than or

equal to 28 bars.

Is it correct?

62-9

Page 23 of 73

c11010.0

AIR CONDITIONING

Fault finding - Interpretation of XR25 bargraphs62

KANGOO

ALL TYPES

Enter G0** on the XR25.

Check that the system operates correctly.AFTER

REPAIR

4

CONT 2

YES

NO

For petrol vehicles:

Use the XR25 injection fiche which corresponds to the vehicle.

With the engine running, operate the AC then check on the XR25 fiche whether the " AC authorisation"

status bargraph is illuminated.

Is the bargraph illuminated?

There is a problem at the injection end.

Refer to the injection fault finding procedure which corresponds to the vehicle.

Check the continuity and absence of short circuits of the electrical wiring.

Repair if necessary.

Check that 12 volts is present on tracks 2 and 17 of the air conditioning control

unit 30-way connector.

Is 12 volts present?

YES There is a problem at the injection end.

Refer to the injection fault finding procedure which corresponds to

the vehicle.

NO Check whether the evaporator temperature sensor is in place.

Check its resistance: disconnect the evaporator temperature sensor

and measure the resistance at its terminals. The resistance measured

should be between 90 ohms and 13.7 kohms.

If the evaporator temperature sensor is in good condition, change

the air conditioning control unit.

If the evaporator temperature sensor is not in good condition,

change it.

62-12

Page 46 of 73

yes

Check the connections between:

air 9 A fluid

conditioning pressure

computer 10 B sensor

Is the wiring in good condition?

c11010.0

AIR CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

AFTER

REPAIR

no

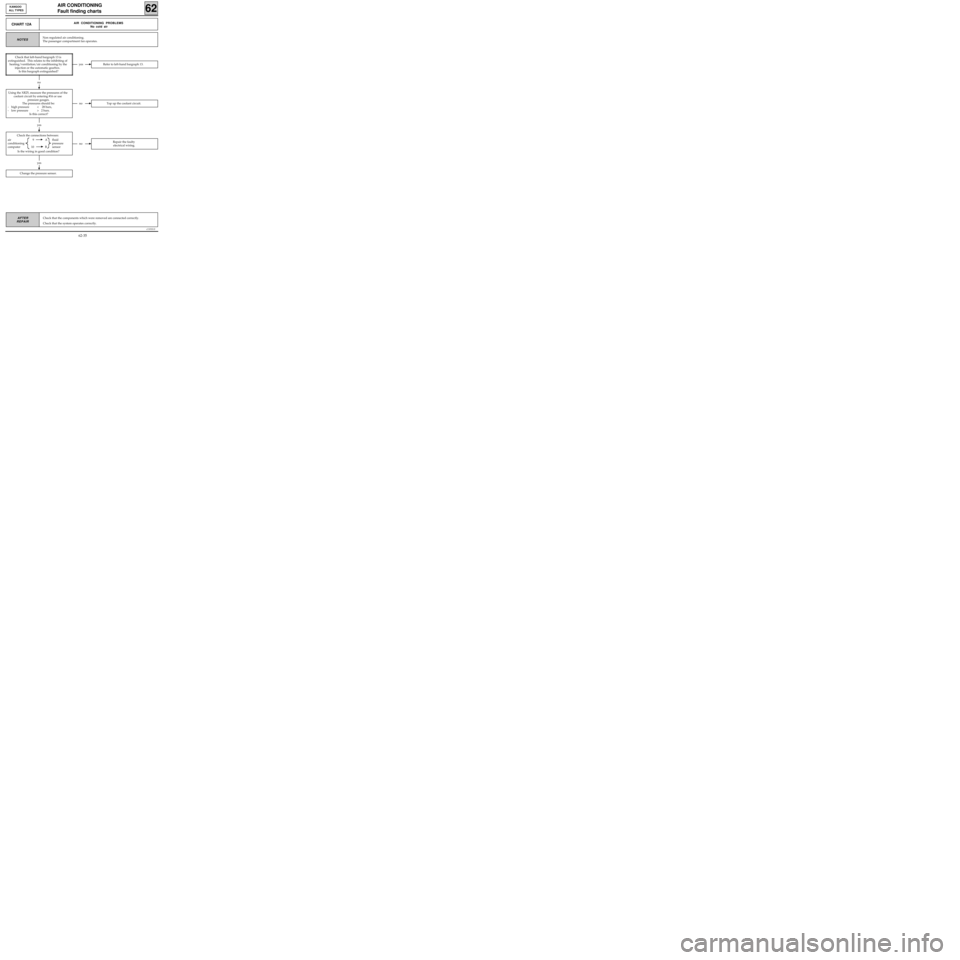

CHART 12AAIR CONDITIONING PROBLEMS

No cold air

NOTES

yesRefer to left-hand bargraph 13.

noTop up the coolant circuit.

yes

noRepair the faulty

electrical wiring.

Change the pressure sensor.

Non regulated air conditioning.

The passenger compartment fan operates.

Check that left-hand bargraph 13 is

extinguished. This relates to the inhibiting of

heating/ventilation/air conditioning by the

injection or the automatic gearbox.

Is this bargraph extinguished?

Using the XR25, measure the pressures of the

coolant circuit by entering #16 or use

pressure gauges.

The pressures should be:

- high pressure < 28 bars,

- low pressure > 2 bars.

Is this correct?

Check that the components which were removed are connected correctly.

Check that the system operates correctly.

62-35

Page 47 of 73

c11010.0

AIR CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

AFTER

REPAIR

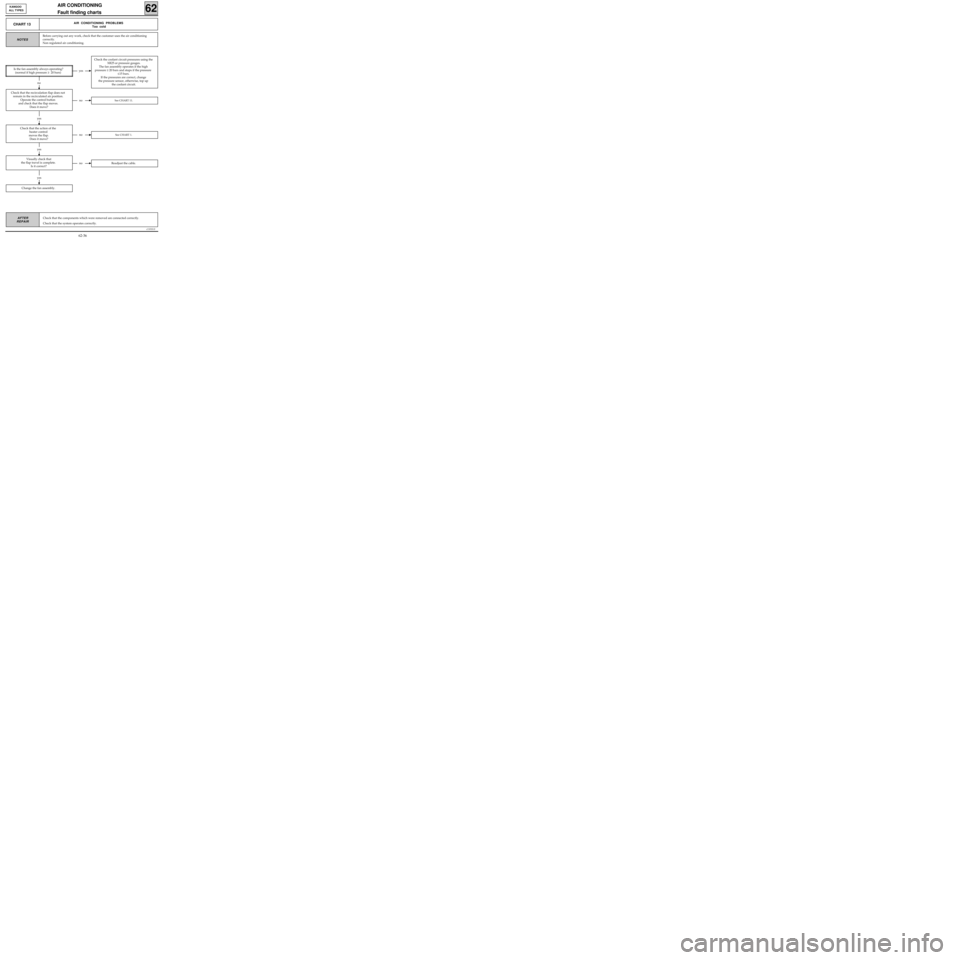

CHART 13AIR CONDITIONING PROBLEMS

Too cold

NOTES

yes

no

noSee CHART 11.

yes

noSee CHART 1.

yes

noReadjust the cable.

yes

Change the fan assembly.

Before carrying out any work, check that the customer uses the air conditioning

correctly.

Non regulated air conditioning.

Is the fan assembly always operating?

(normal if high pressure ≥ 20 bars)

Check that the recirculation flap does not

remain in the recirculated air position.

Operate the control button

and check that the flap moves.

Does it move?

Check that the action of the

heater control

moves the flap.

Does it move?

Visually check that

the flap travel is complete.

Is it correct?

Check the coolant circuit pressures using the

XR25 or pressure gauges.

The fan assembly operates if the high

pressure ≥ 20 bars and stops if the pressure

≤15 bars.

If the pressures are correct, change

the pressure sensor, otherwise, top up

the coolant circuit.

Check that the components which were removed are connected correctly.

Check that the system operates correctly.

62-36

Page 49 of 73

yes

c11010.0

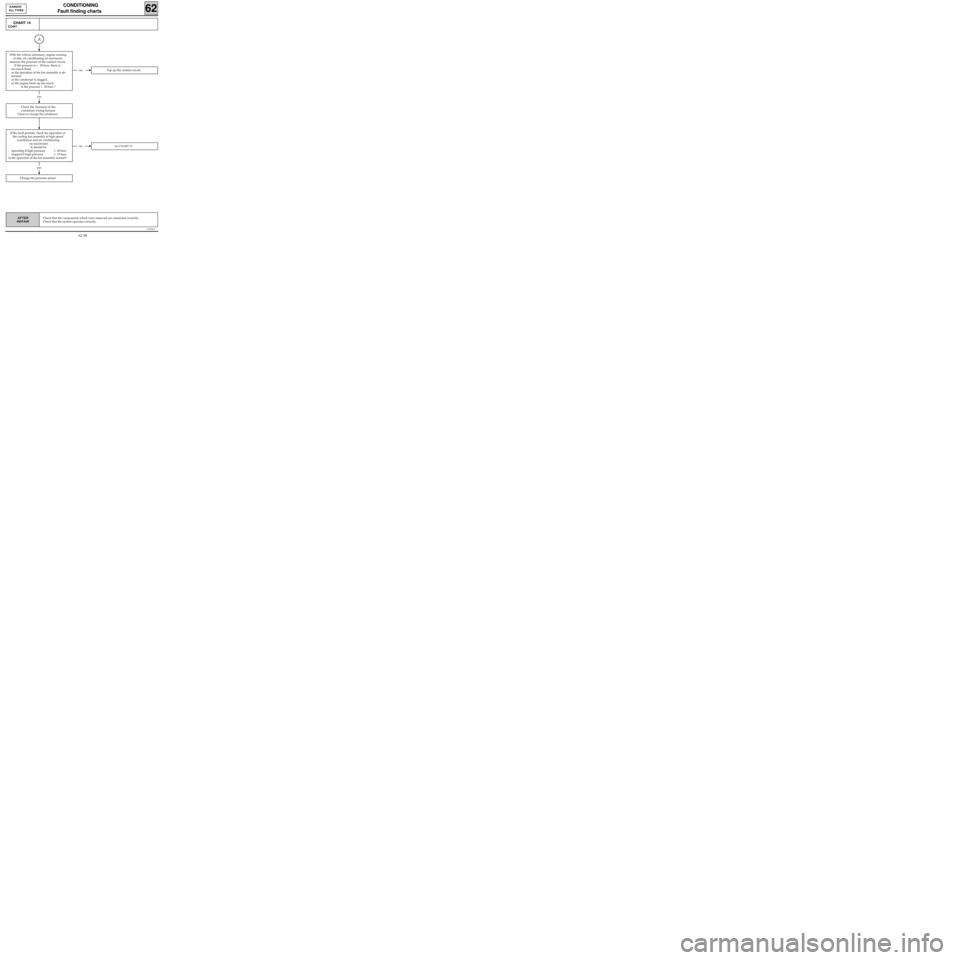

CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

AFTER

REPAIR

CHART 14

CONT

noTop up the coolant circuit.

yes

noSee CHART 15.

Change the pressure sensor.

Check the cleanness of the

condenser wiring harness.

Clean or change the condenser.

If the fault persists, check the operation of

the cooling fan assembly at high speed

(ventilation and air conditioning

on maximum).

It should be:

- operating if high pressure≥ 20 bars

- stopped if high pressure≤ 15 bars

Is the operation of the fan assembly normal?

Check that the components which were removed are connected correctly.

Check that the system operates correctly.

A

With the vehicle stationary, engine running

at idle, air conditioning on maximum,

measure the pressure of the coolant circuit.

If the pressure is > 28 bars, there is :

- too much fluid,

- or the operation of the fan assembly is ab-

normal,

- or the condenser is clogged,

- or the engine heats up too much.

Is the pressure < 28 bars ?

62-38

Page 50 of 73

yes

Check the electrical wiring:

air 9 1 pressure

conditioning 10 4 sensor

computer 11 3 connector

and between the connector and the sensor.

Is the wiring in good condition?

c11010.0

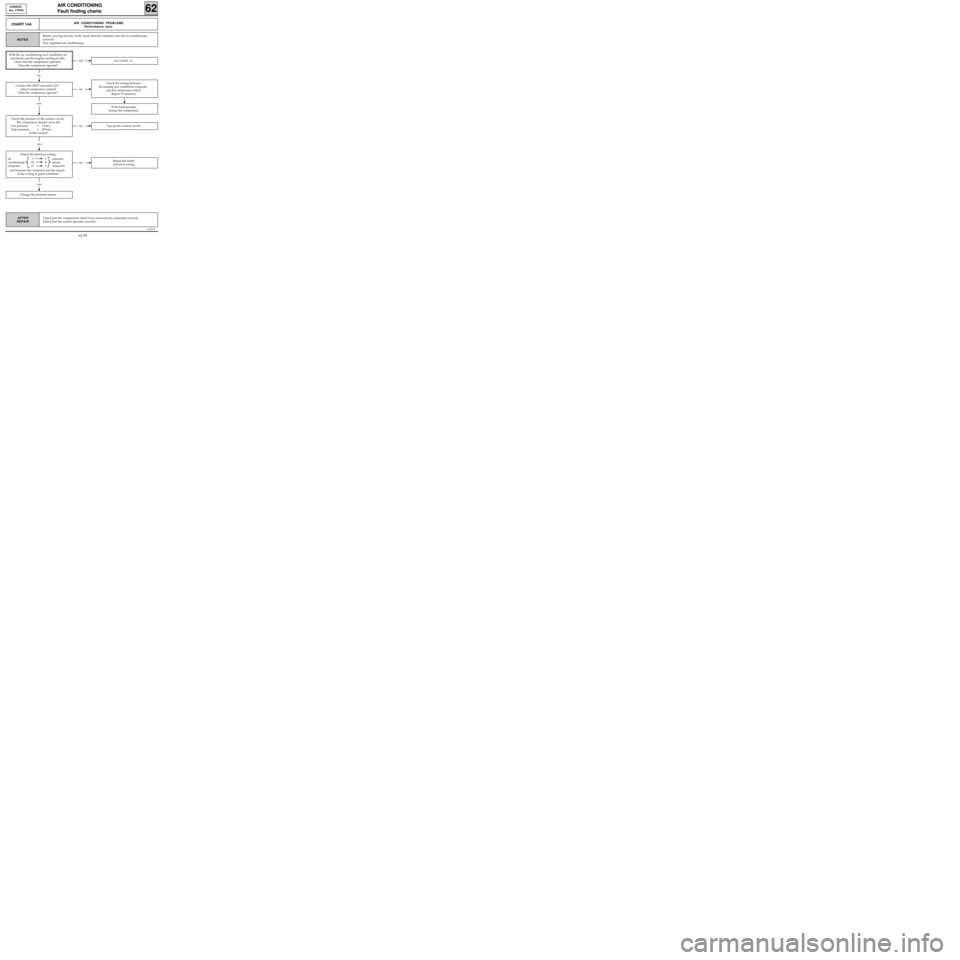

AIR CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

AFTER

REPAIR

CHART 14AAIR CONDITIONING PROBLEMS

Performance poor

NOTES

yesSee CHART 14.

no

no

If the fault persists,

change the compressor.

yes

noRepair the faulty

electrical wiring.

yes

noTop up the coolant circuit.

Change the pressure sensor.

Before carrying out any work, check that the customer uses the air conditioning

correctly.

Non regulated air conditioning.

With the air conditioning and ventilation on

maximum and the engine running at idle,

check that the compressor operates.

Does the compressor operate?

Connect the XR25 and enter G21*

(direct compressor control).

Does the compressor operate?

Check the pressure of the coolant circuit.

The compressor should cut in for:

- low pressure≥ 2 bars,

- high pressure≤ 28 bars.

Is this correct?

Check the wiring between

the heating and ventilation computer

and the compressor clutch.

Repair if necessary.

Check that the components which were removed are connected correctly.

Check that the system operates correctly.

62-39

Page 51 of 73

Check the electrical wiring between:

air 9 1 pressure

conditioning 10 4 sensor

computer 11 5 connector

and between the connector and the sensor.

Is the electrical wiring in good condition?

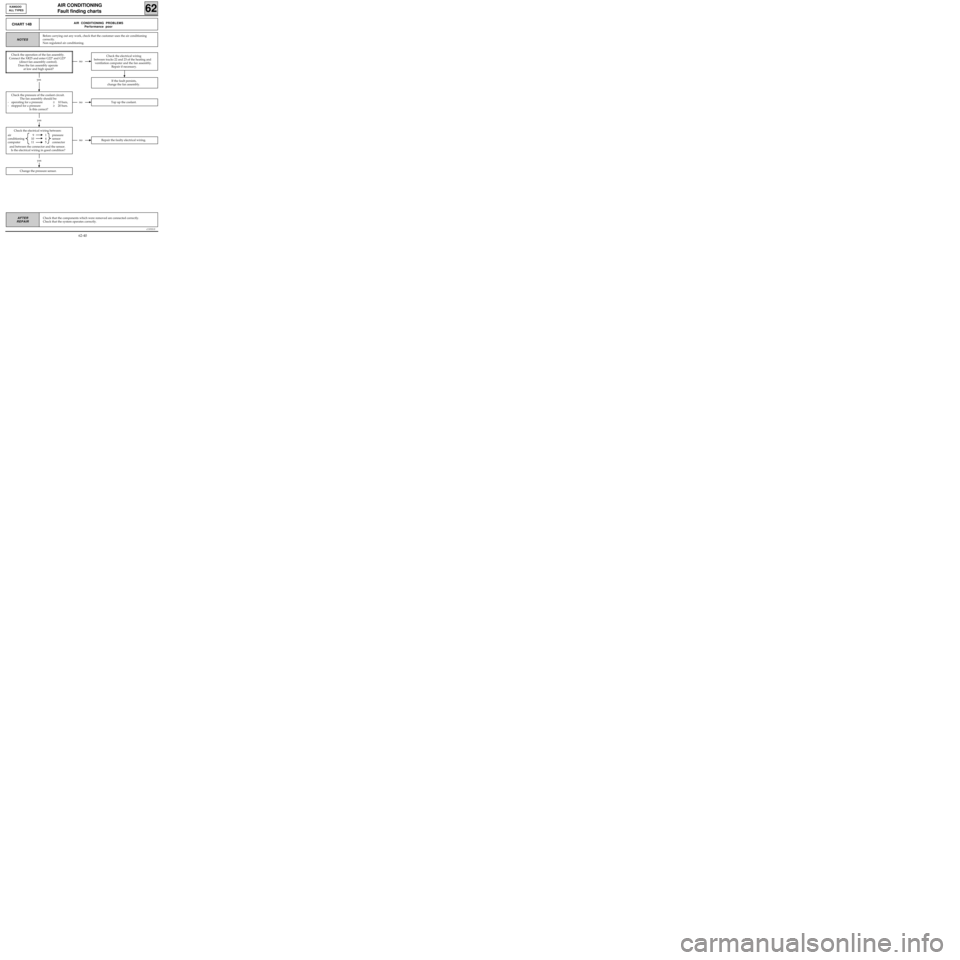

c11010.0

AIR CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

AFTER

REPAIR

yes

CHART 14BAIR CONDITIONING PROBLEMS

Performance poor

NOTES

no

yes

noRepair the faulty electrical wiring.

yes

noTop up the coolant.

Change the pressure sensor.

Before carrying out any work, check that the customer uses the air conditioning

correctly.

Non regulated air conditioning.

Check the operation of the fan assembly.

Connect the XR25 and enter G22* and G23*

(direct fan assembly control).

Does the fan assembly operate

at low and high speed?

Check the pressure of the coolant circuit.

The fan assembly should be:

- operating for a pressure≥ 10 bars,

- stopped for a pressure≥ 20 bars.

Is this correct?

Check the electrical wiring

between tracks 22 and 23 of the heating and

ventilation computer and the fan assembly.

Repair if necessary.

If the fault persists,

change the fan assembly.

Check that the components which were removed are connected correctly.

Check that the system operates correctly.

62-40

Page 53 of 73

yes

Check the electrical wiring between:

heating and 9 1 inter-

ventilation 10 4 mediate

computer 11 3 connector

and between:

inter- 1 A pressure

mediate 4 C sensor

connector 3 B

Is the wiring in good condition?

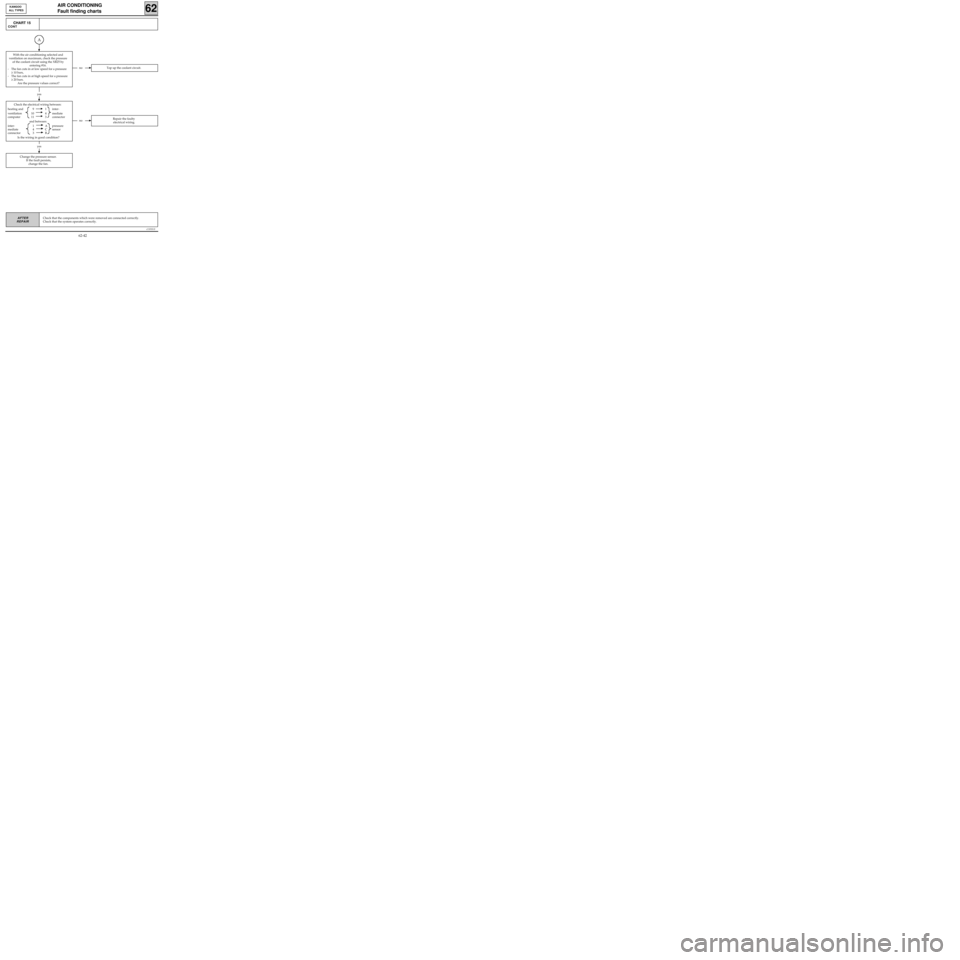

c11010.0

AIR CONDITIONING

Fault finding charts

62

KANGOO

ALL TYPES

AFTER

REPAIR

CHART 15

CONT

A

noTop up the coolant circuit.

yes

noRepair the faulty

electrical wiring.

With the air conditioning selected and

ventilation on maximum, check the pressure

of the coolant circuit using the XR25 by

entering #16.

- The fan cuts in at low speed for a pressure

≥ 10 bars,

- The fan cuts in at high speed for a pressure

≥ 20 bars.

Are the pressure values correct?

Change the pressure sensor.

If the fault persists,

change the fan.

Check that the components which were removed are connected correctly.

Check that the system operates correctly.

62-42